Double supporting rollers-type double circular molds granulator

A support roller and granulator technology, which is applied in the direction of mold extrusion granulation, etc., can solve the problems of difficulty in controlling the feeding amount and feeding uniformity, limited feeding space, and low bearing capacity, and achieves convenient disassembly and replacement Fast, simple and stable material receiving process, and the effect of improving granulation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

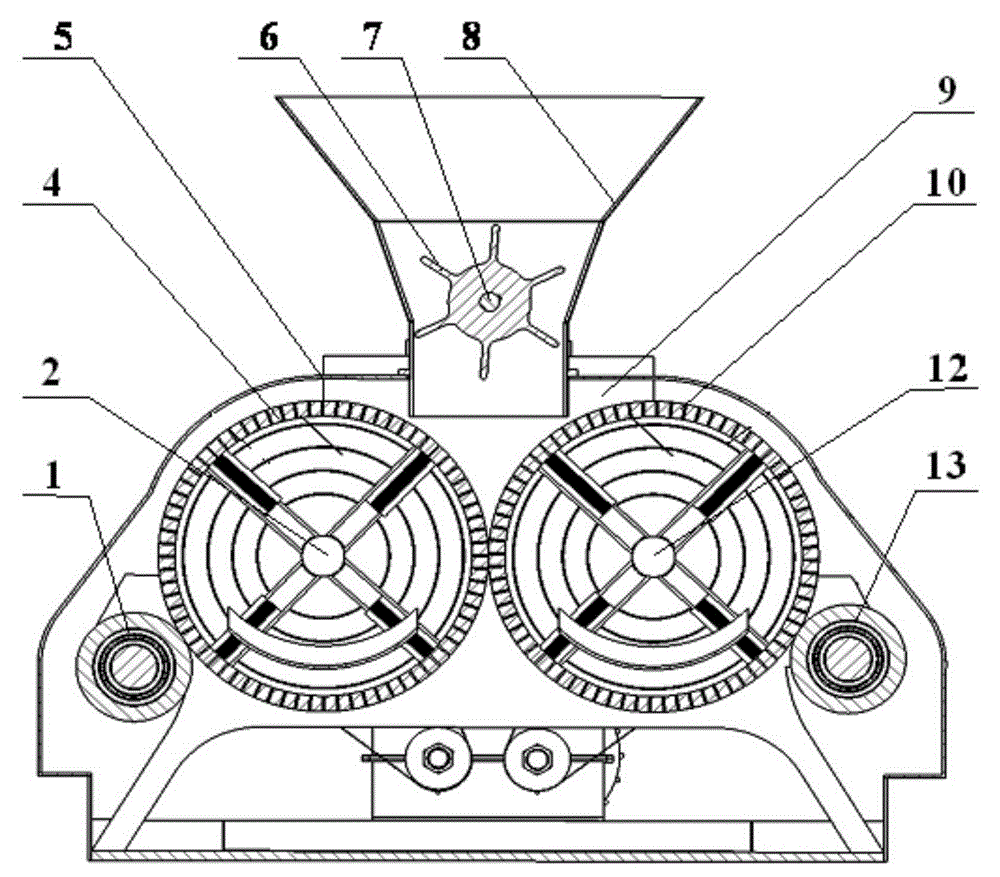

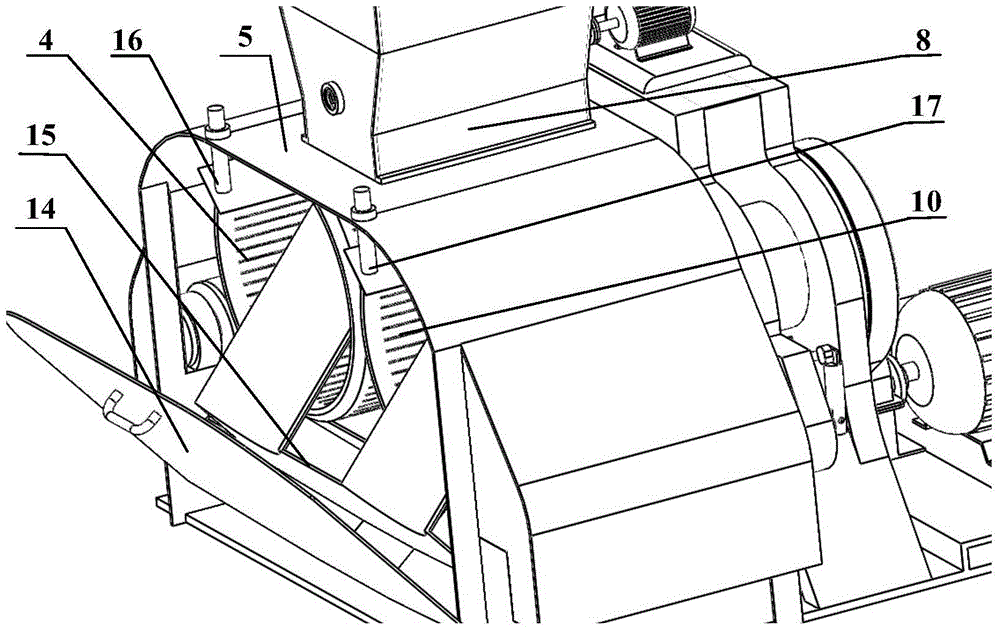

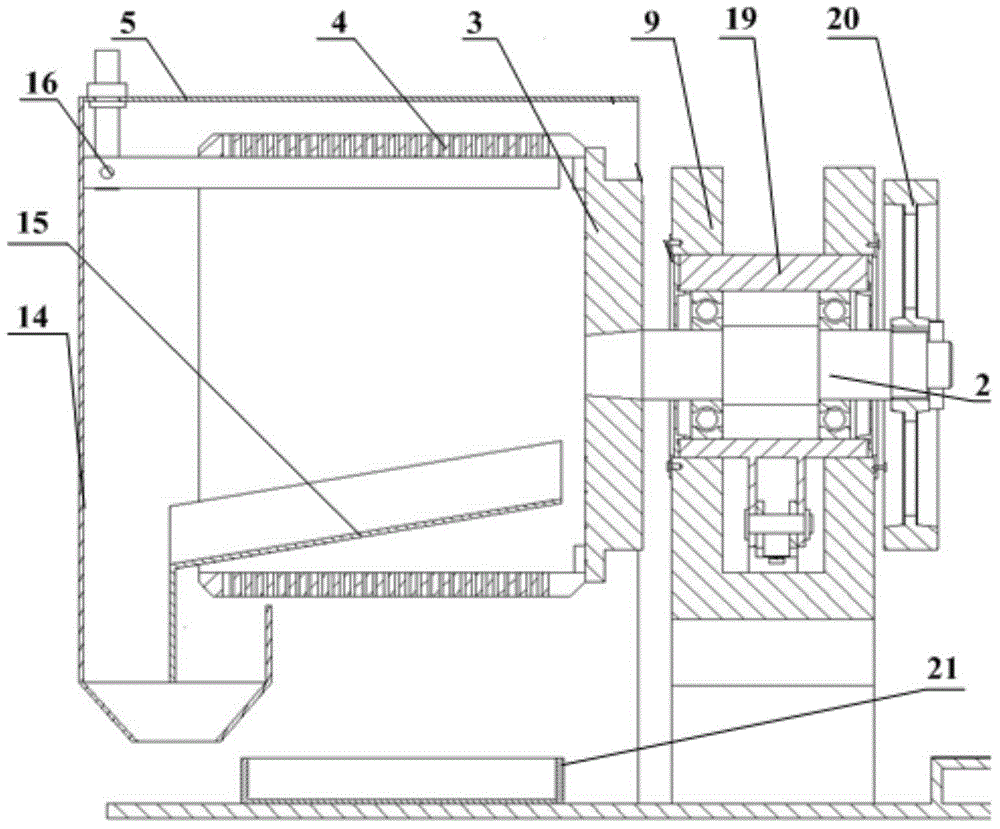

[0038] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0039] to combine Figure 1 to Figure 8 , a double support roller double ring mold granulator, including the first support roller 1, the first rotating shaft 2, the first ring mold 4, the casing 5, the impeller 6, the impeller shaft 7, the hopper 8, the bracket 9, the second Ring die 10, second rotating shaft 12, second support roller 13, door cover 14, collecting trough 15, first scraper 16, second scraper 17, first bearing sleeve 19, first pulley 20, surplus material chute 21 , gear reducer 24, main motor 25, second pulley 26, second bearing sleeve 27, gland 28, first synchronous belt 29, third pulley 30, first pinch pulley 31, second pinch pulley 32, the fourth pulley 33, the second synchronous belt 34, the impeller motor 35.

[0040] The casing 5 is fixed on the frame 9, the first ring mold 4 and the second ring mold 10 are arranged inside the casing 5,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com