Method and device for preparing tar cracking catalyst through liquid blast furnace slag granulation

A technology of tar cracking and blast furnace slag, applied in the direction of physical/chemical process catalysts, chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problem of reducing catalytic activity, low content of active ingredient iron oxide, etc. problems, to achieve the effect of overcoming a large footprint, reducing the space required for cooling, and accelerating the liquid-solid phase transition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

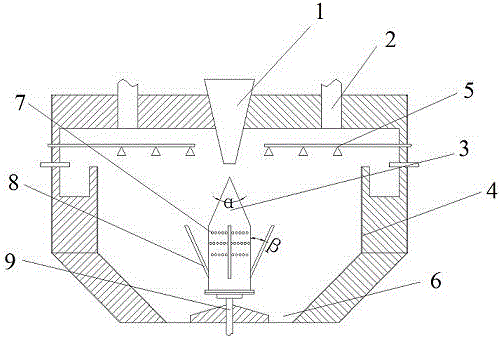

[0024] Such as figure 1 As shown, the present invention provides a liquid blast furnace slag granulation device, the liquid blast furnace slag inlet 1 and the high-temperature air steam outlet 2 are opened on the top of the granulation device, and a conical granulator 3 is provided in the middle; the inner wall of the granulation device is provided with There is an overflow water wall 4, a sprinkler 5 is arranged between the conical granulator 3 and the overflow water wall 4, and a granulated slag outlet 6 is opened at the bottom of the overflow water wall 4; The upper part of the granulator 3 is conical, and the lower part is cylindrical. There are a plurality of small holes 7 on the surface of the cylinder, and a plurality of crushing blades 8 are installed. The bottom of the conical granulator is provided with a high-pressure air inlet 9;

[0025] The cone angle of the conical granulator 3 is 60°, and the cylindrical surface of the lower part of the conical granulator 3 has...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com