Modified polypropylene for automotive interiors and preparation method of modified polypropylene

A polypropylene and high-impact polypropylene technology, which is applied in the field of modified polypropylene for automotive interiors and its preparation, can solve the problems of easy aging and decomposition, poor stability of rubber additives, and impact on the health of users.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

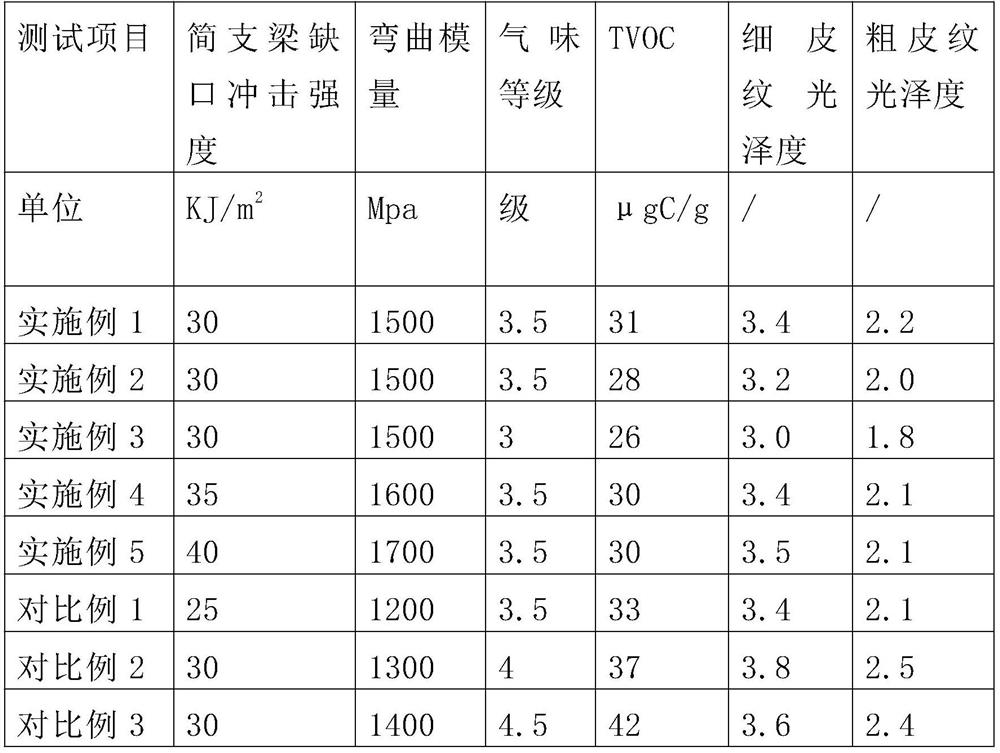

Examples

preparation example

[0027] A method for preparing a low-gloss material masterbatch, comprising the following steps,

[0028] 1) Weigh raw materials according to the following parts by weight: 50 parts of conventional polypropylene, 10 parts of polyolefin elastomer, 0.3 part of antioxidant, 0.5 part of lubricant,

[0029] Polyolefin elastomer, metallocene catalyzed polyethylene, antioxidant and lubricant are added to the high-speed mixer and mixed evenly to form a mixed raw material;

[0030] 2) Put the above-mentioned raw materials into an internal mixer for internal mixing, and the internal mixing temperature of the internal mixer is set to 190° C.;

[0031] 3) Add the raw materials after banburying to a single-screw extruder, and set the temperature of the single-screw extruder to 185° C.; extrude, air-cool, and granulate the raw materials after banburying through the single-screw extruder, and then Form low gloss material masterbatch.

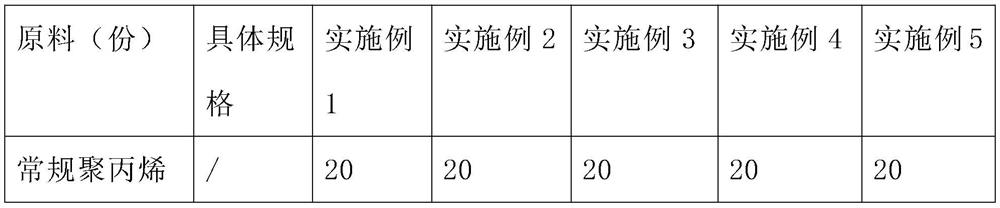

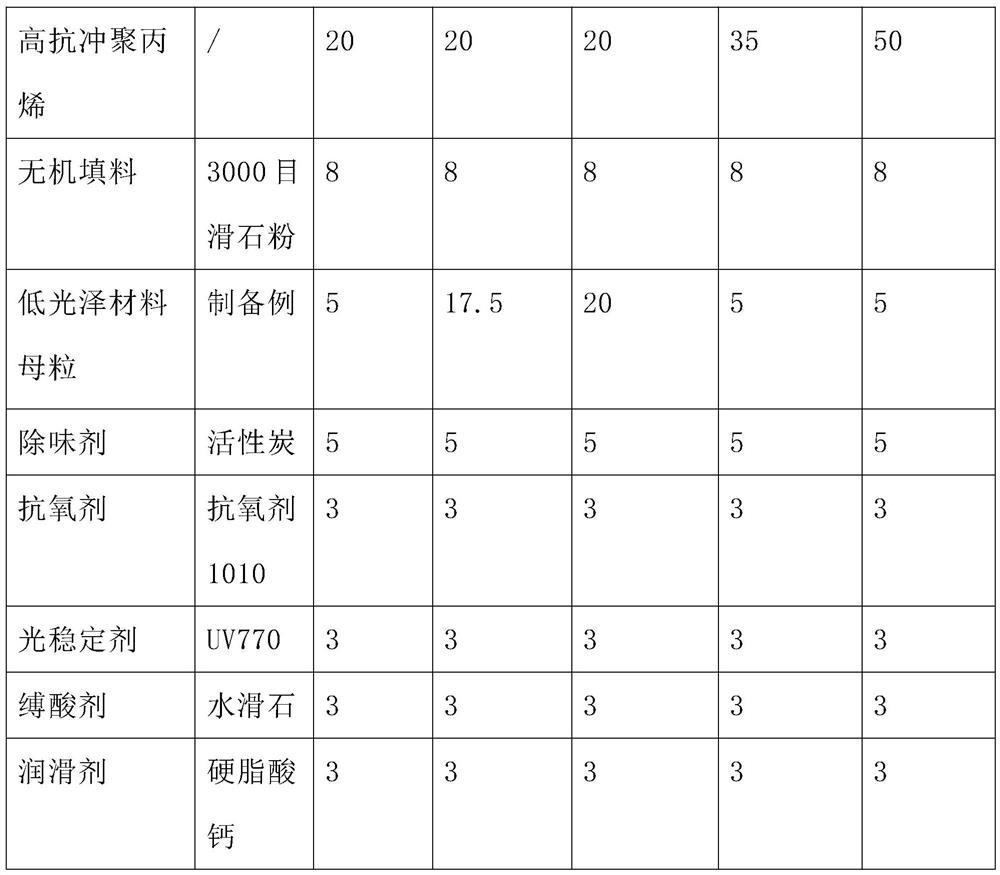

Embodiment 1

[0034] A method for preparing modified polypropylene for automobile interior decoration, comprising the following method steps:

[0035] Step S1, weighing raw materials according to the following parts by mass: 20 parts of conventional polypropylene, 20 parts of high-impact polypropylene, 8 parts of inorganic filler, 5 parts of low-gloss material masterbatch, 5 parts of deodorant, and 3 parts of antioxidant , 3 parts of light stabilizer, 3 parts of acid binding agent, 3 parts of lubricant.

[0036] Add the above raw materials to the twin-screw extruder for extrusion and granulation; the temperature of the twin-screw extruder is set to 200°C; the speed of the twin-screw extruder is set to 400 rpm; the vacuum degree of the twin-screw extruder is set to 0.1MPa;

[0037] Step S2, drying the raw material particles extruded by the twin-screw extruder, and drying at 100°C for 4 hours;

[0038] Step S3, putting the dried raw material particles into an injection molding machine for i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com