Patents

Literature

44results about How to "Fast granulation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Production method of rich-titanium material

ActiveCN103710551ASimple equipmentEasy to operateTitanium dioxideMagnetic separationProduct processingPelletizing

The invention relates to a production method of a rich-titanium material. The production method comprises the following steps: pre-oxidation, pre-reduction, multistage magnetic separation, airtight furnace smelting titanium slag granulation, and finished product processing and grading, wherein the pre-oxidation and the pre-reduction are carried in the same rotary kiln. According to the invention, the process of titanium concentrate-rotary kiln pre-reduction-airtight electric furnace smelting is adopted for the first time and the process of bonding and pelletizing of the titanium concentrate is omitted; besides, the production method of rich-titanium material is simple in used equipment, easy to operate, short in flow process and low in reduction temperature; high metallization ratio can be obtained; consequently, the energy consumption of the electric furnace during smelting is greatly reduced.

Owner:LOMON BILLIONS GRP CO LTD

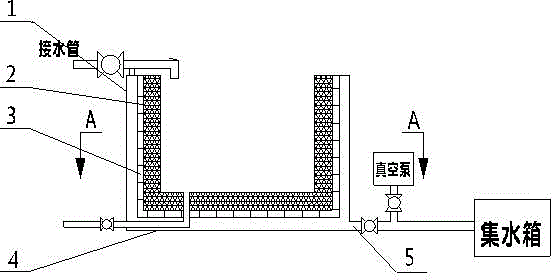

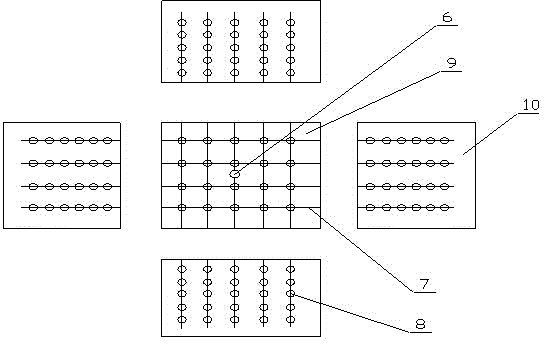

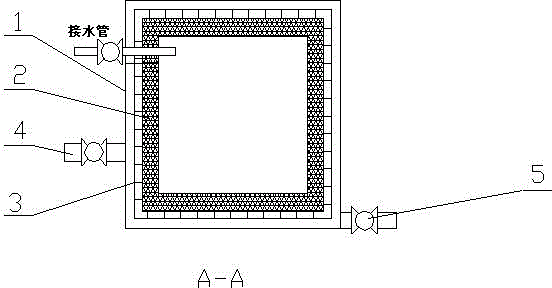

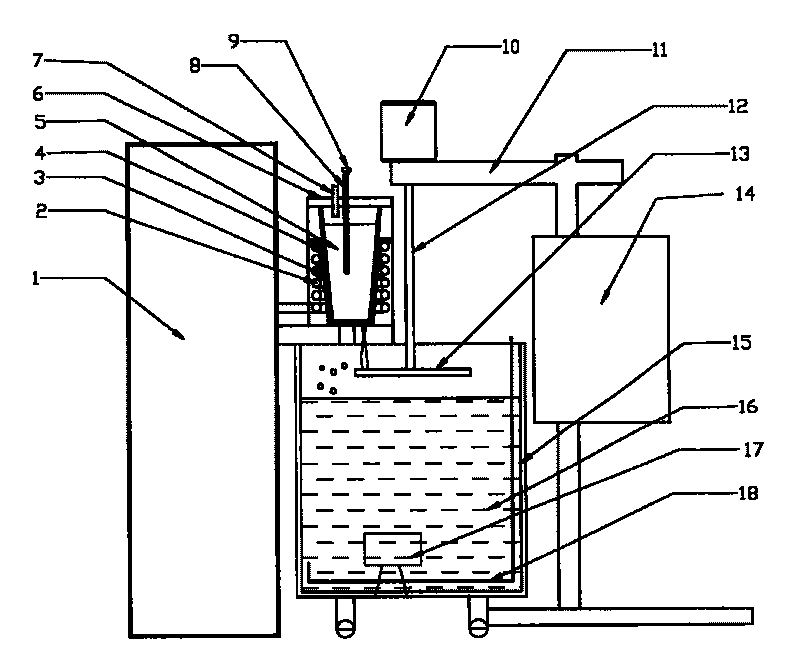

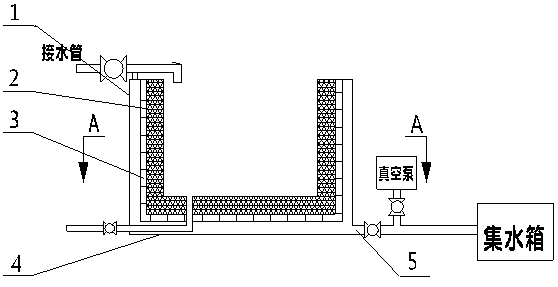

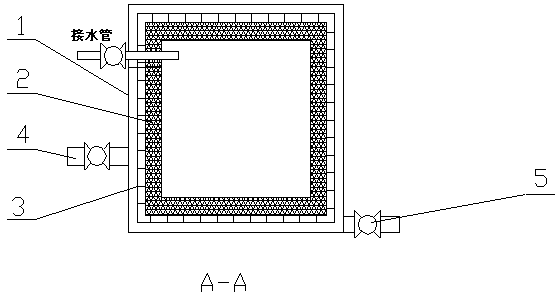

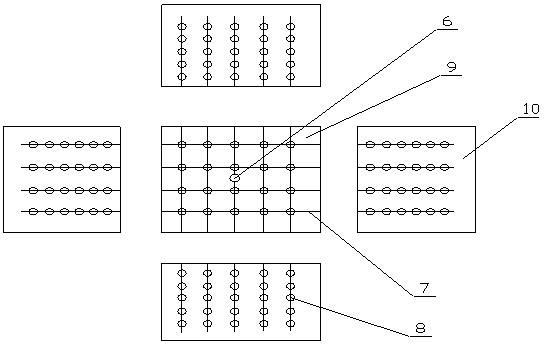

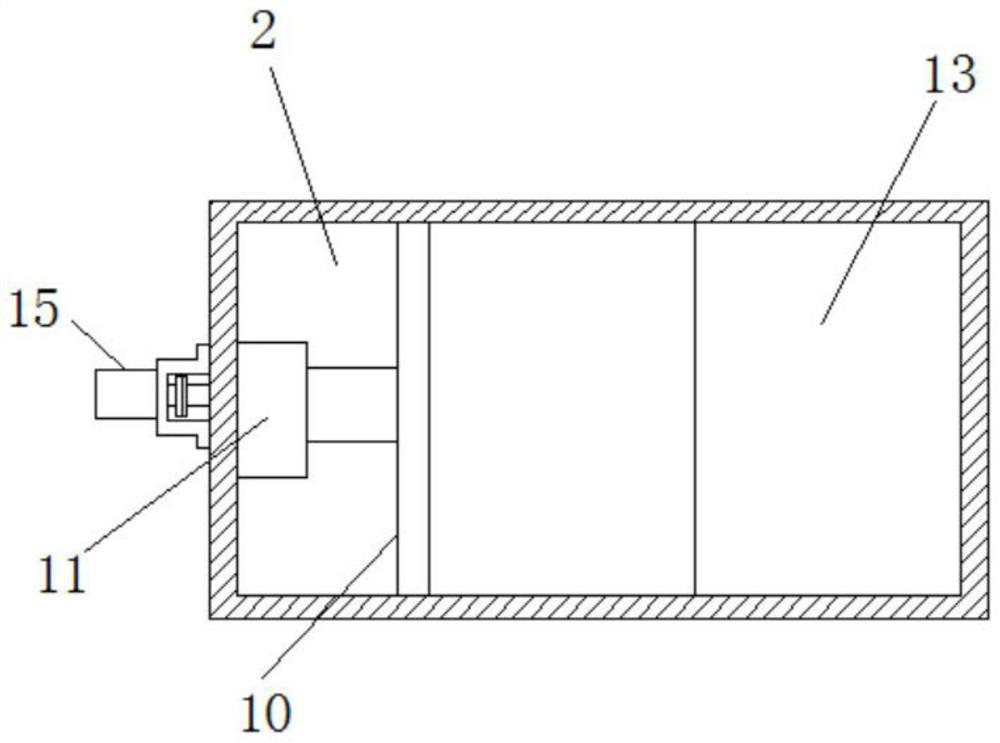

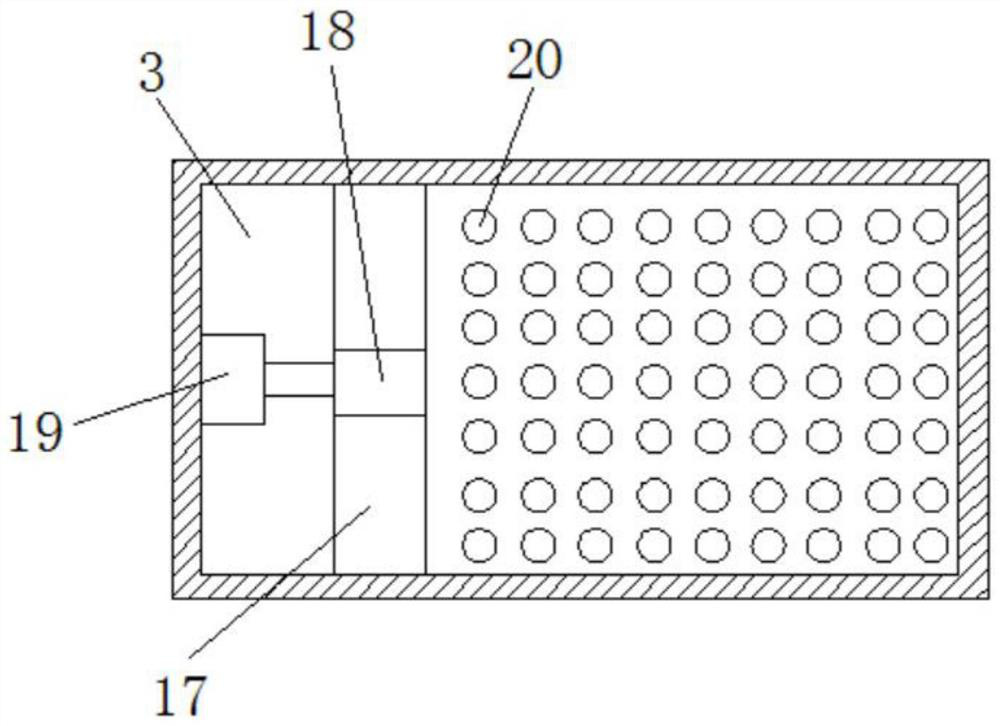

Nitrifying bacterium enrichment culture device and culture method

ActiveCN105713827AReduce sedimentation water exchange timeStable growthBioreactor/fermenter combinationsBiological substance pretreatmentsSludgeWater collection

The invention discloses a nitrifying bacterium enrichment culture device, which comprises an outer drum reactor and a ceramic membrane inner drum, wherein the outer drum reactor is of an opening-type structure, and the ceramic membrane inner drum, which is made from a ceramic membrane plate, is arranged in the outer drum reactor; an aerating system is arranged on the outer wall and the bottom end of the inner drum; the aerating system and sludge are separately arranged on two sides of the ceramic membrane inner drum; during aerating, the sludge is cultured in the ceramic membrane inner drum, and gas enters the inner drum by virtue of ceramic membrane holes, so that oxygen supply is achieved; a drainage port is formed in the bottom of the outer reactor, and a vacuum pump is connected to a sealed water collection tank, so that after culture, the vacuum pump is started, water is discharged to the sealed water collection tank while the sludge is intercepted by the ceramic membrane. A nitrifying bacterium enrichment culture method disclosed by the invention is implemented by virtue of the above culture device. According to the nitrifying bacterium enrichment culture device disclosed by the invention, the ceramic membrane inner drum, which is arranged in the reactor, serves as a nitrifying bacterium culture unit, so that a water changing time of sludge settlement is effectively shortened and a culture cycle is shortened; and meanwhile, sludge floc loss in water drainage is prevented and the steady growth of the sludge is guaranteed.

Owner:CHINA PETROLEUM & CHEM CORP +1

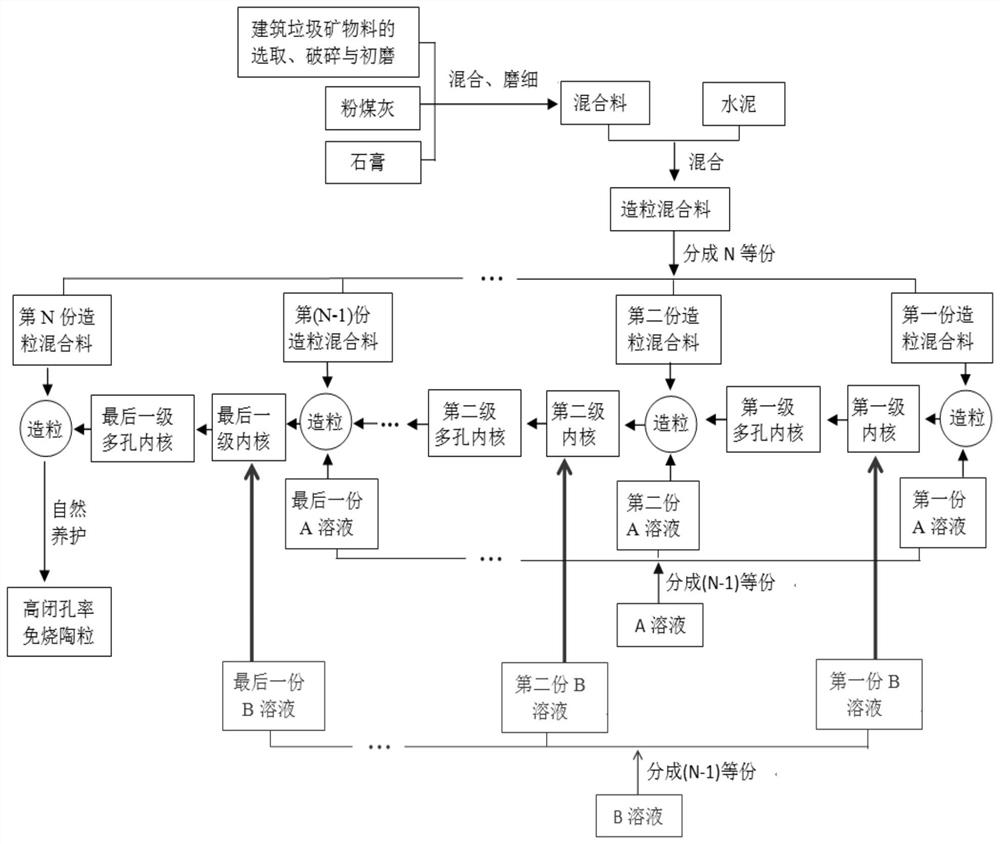

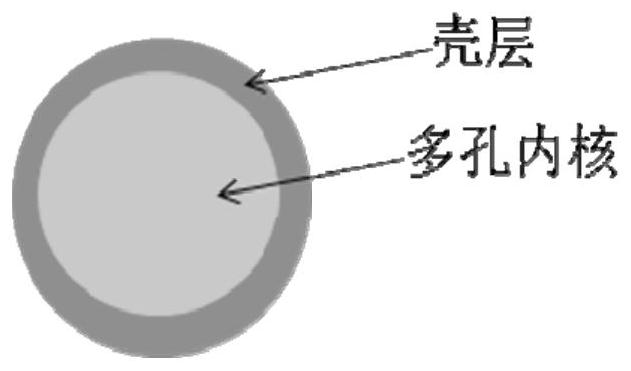

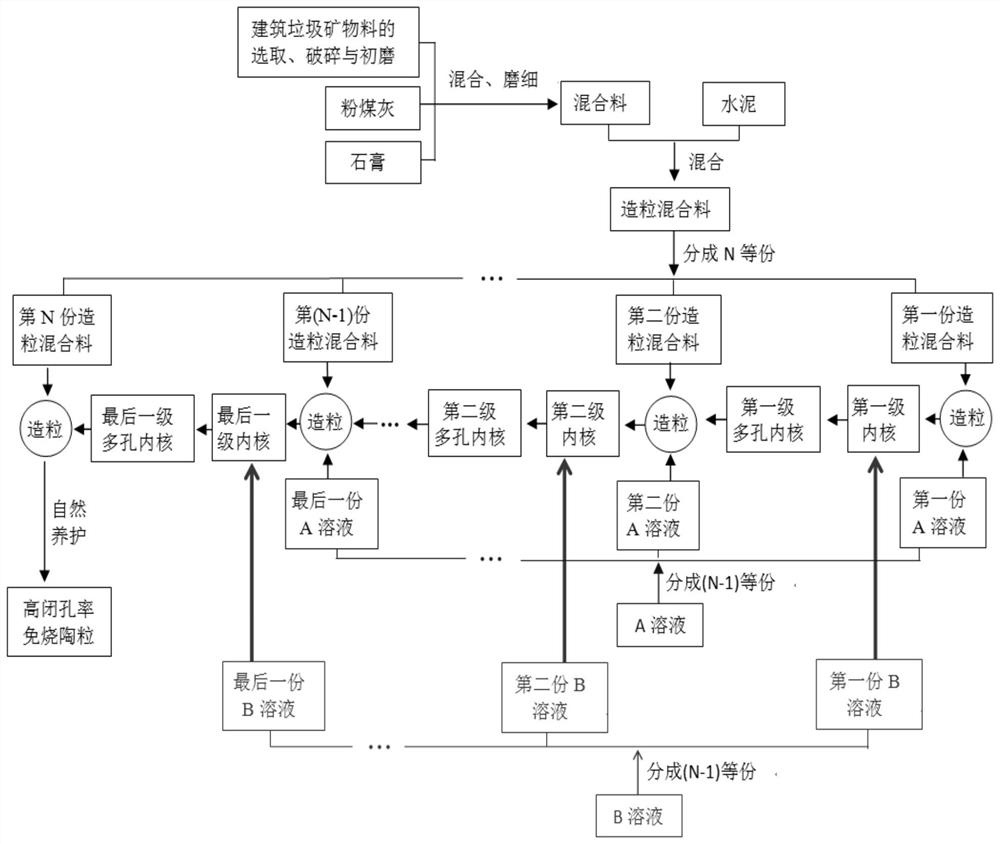

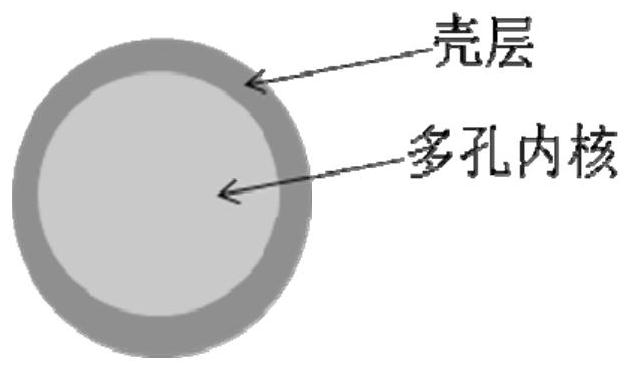

Preparation method of baking-free porous ceramsite with high percentage of closed porosity

ActiveCN112794665ARealize the recycling of solid wasteEmission reductionSolid waste managementClimate change adaptationThermal insulationPelletizing

The invention relates to the technical field of solid waste recycling and materials, in particular to a preparation method of baking-free porous ceramsite with high percentage of closed porosity, step-by-step granulation and step-by-step pore forming are realized by adopting a foaming agent and an inorganic substance for promoting decomposition of the foaming agent, rapid, uniform and thorough pore forming of a ceramsite inner core is promoted, and the porosity is improved; then, the porous inner core and the granulation mixture continue to be granulated, a wrapping layer is formed on the porous inner core, preparation and wrapping of the porous inner core are completed in one step, and the ceramsite with the structure of the porous inner core and the wrapping shell layer is obtained. Firstly, mineral solid waste such as construction waste, tailings and coal ash can be utilized as raw materials, and solid waste recycling is achieved; secondly, the porosity is high, and the thermal insulation performance is good; and finally, the inner core and the wrapping process are completed in one step during granulation, the process is simplified, and the preparation cost is reduced.

Owner:贺州市坤德环保科技有限公司

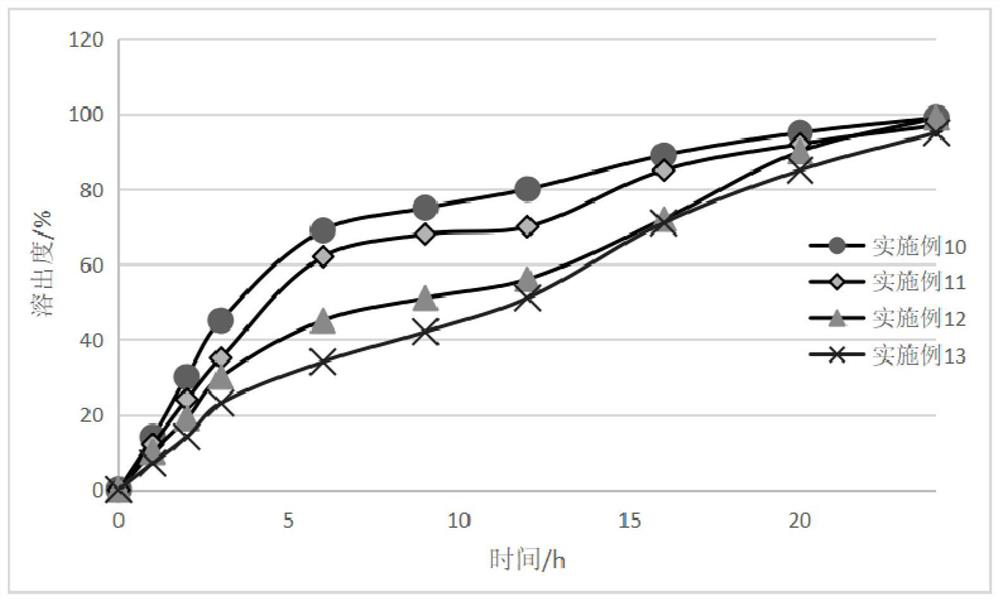

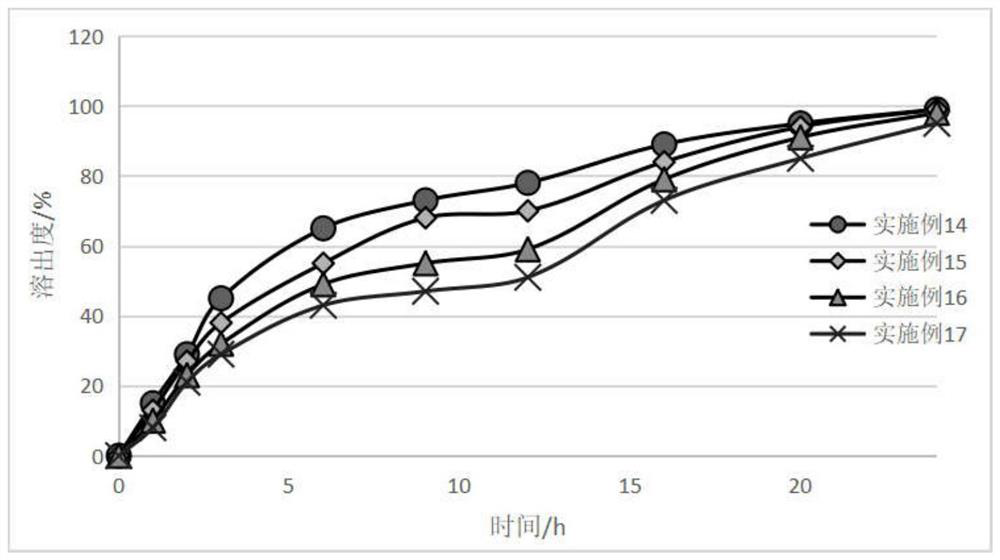

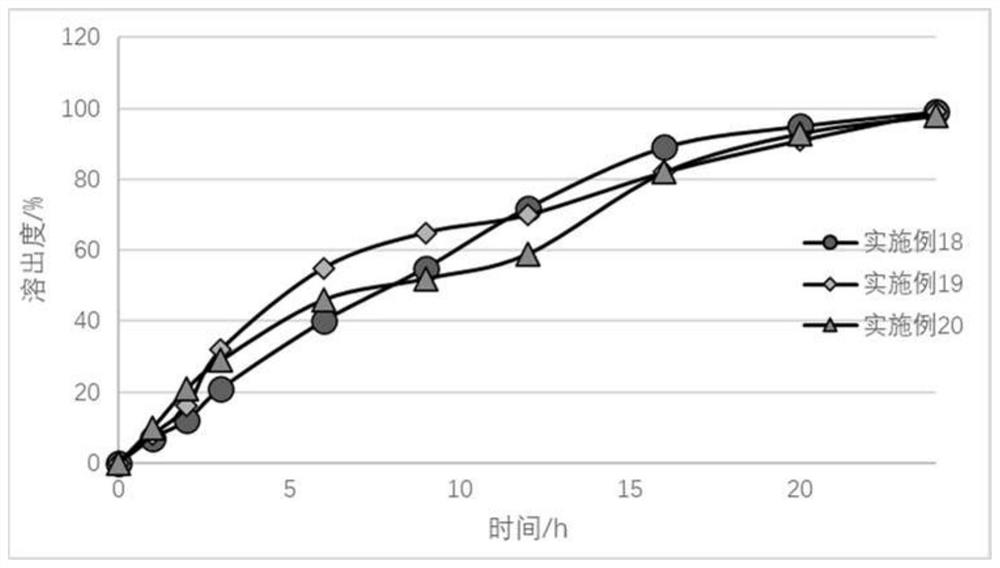

Indissolvable drug oral sustained-release composition and preparation method thereof

ActiveCN111728949AGrow fastAchieve dissolutionOrganic active ingredientsPill deliveryPharmaceutical drugOrganic chemistry

The invention discloses an indissolvable drug oral sustained-release composition, which is especially suitable for low-dose indissolvable drugs. The indissolvable drug oral sustained-release composition comprises sustained-release particles and a gel skeleton, wherein the sustained-release particles comprise an indissolvable drug, an enteric material and a liquid strong adsorption carrier; the gelskeleton comprises a hydrophilic gel skeleton material; and the sustained-release particles are obtained by preparing a suspension from the indissolvable drug and the enteric material and then spraying the suspension onto the liquid strong adsorption carrier. The sustained-release particles are partially wrapped by the gel skeleton to form a multi-sustained-release system technology, the releasetime is prolonged, the preparation process is simple, the efficiency is high, the drug mixing is uniform, and the content loss is less.

Owner:AC PHARMA CO LTD

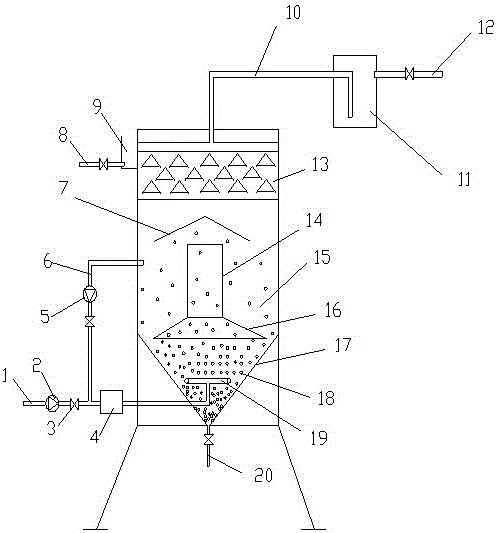

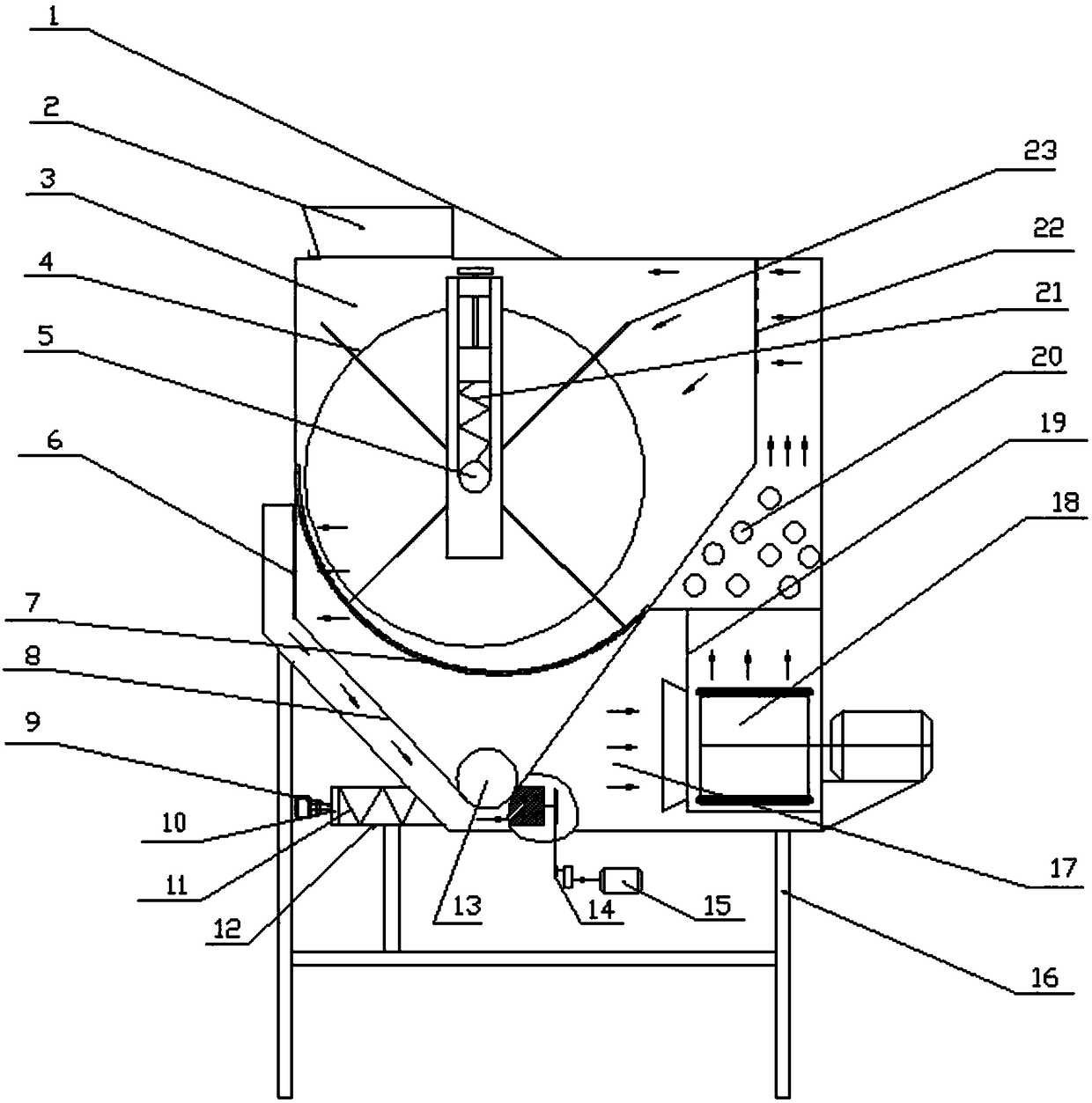

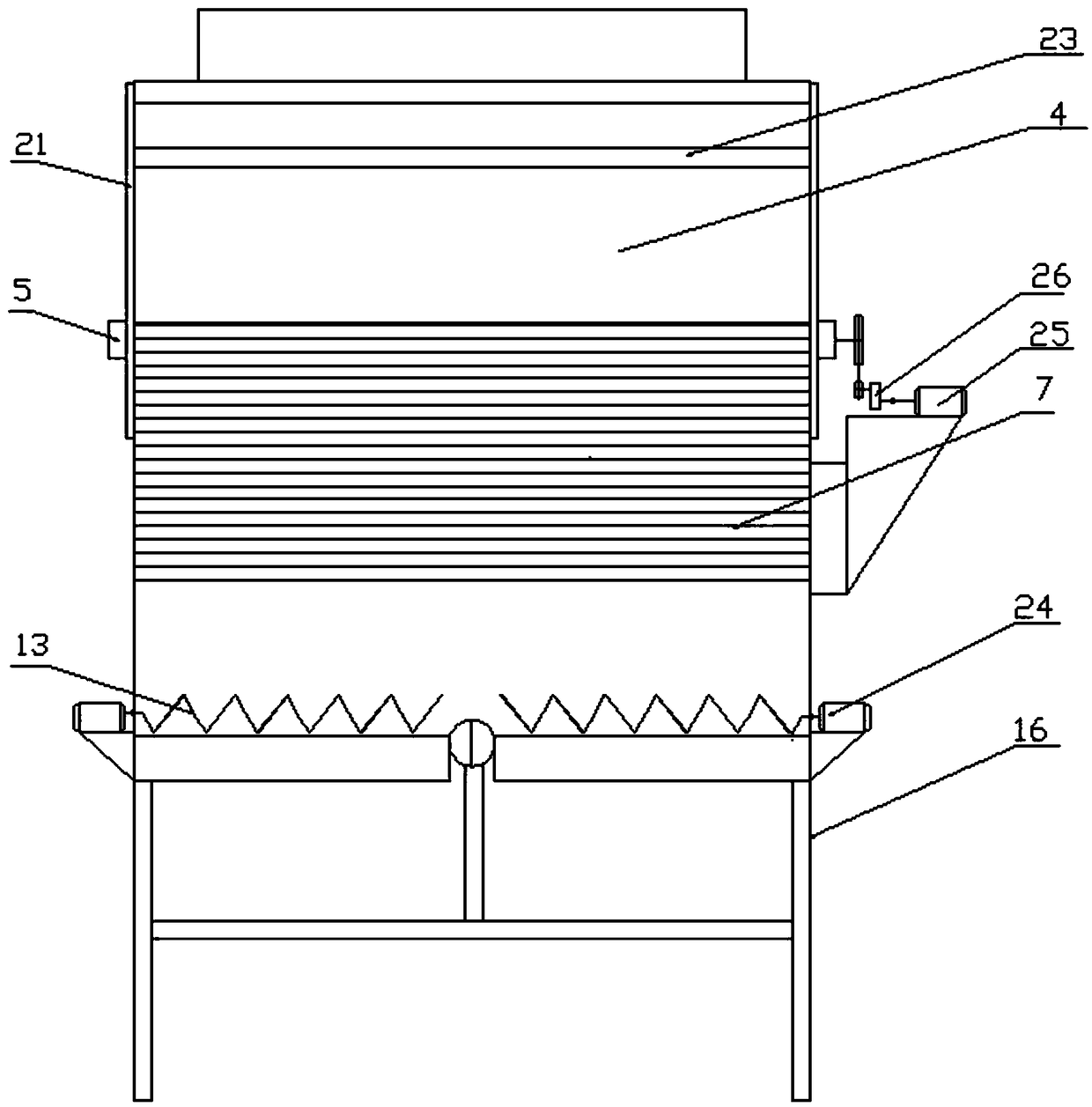

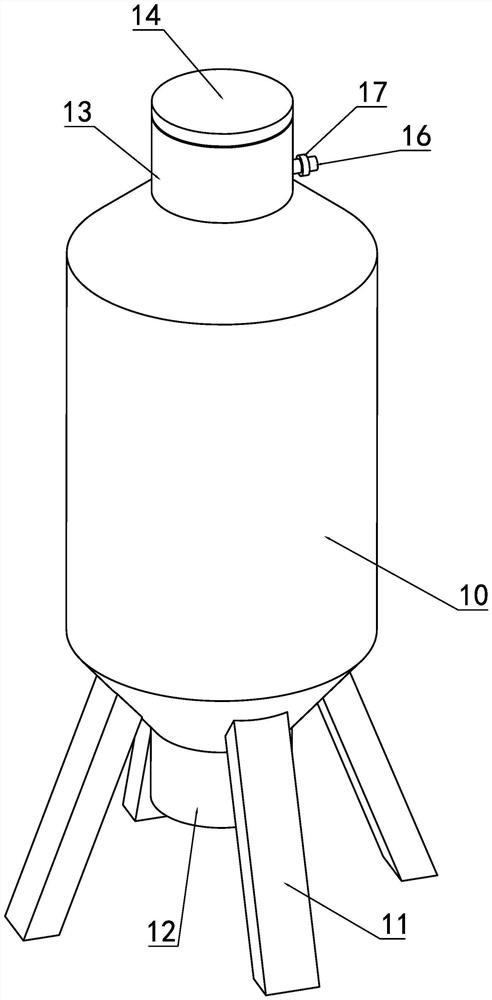

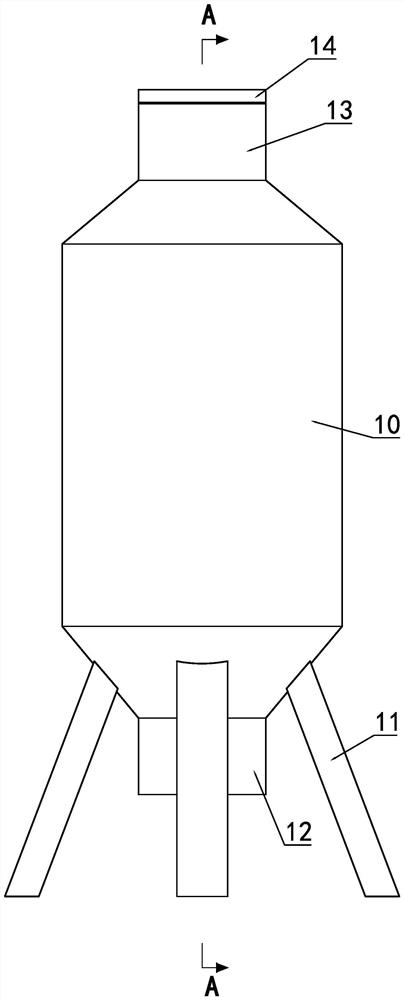

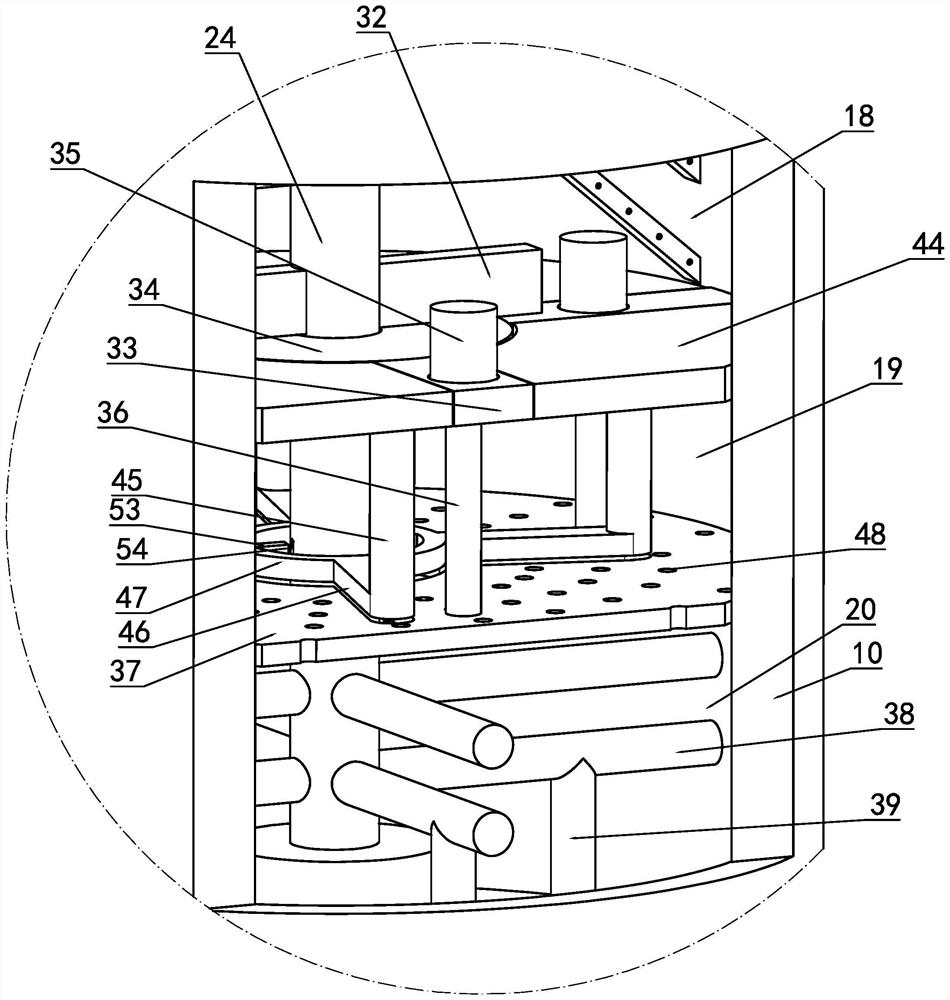

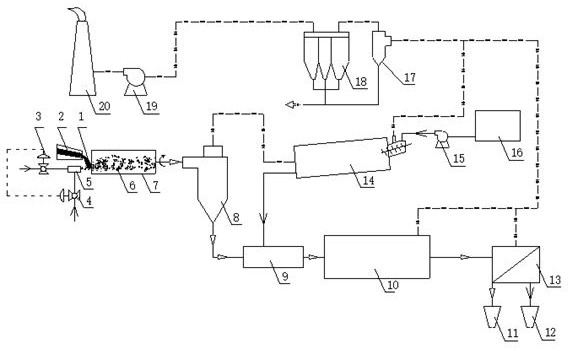

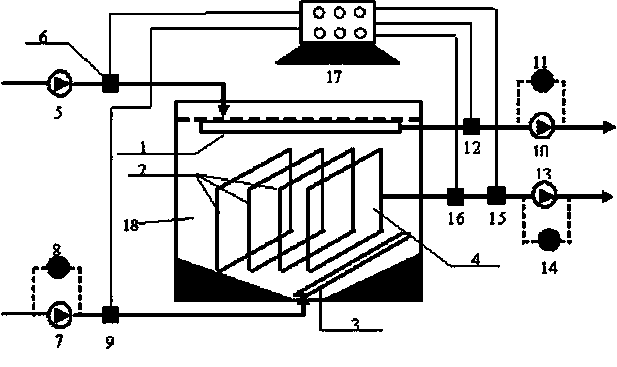

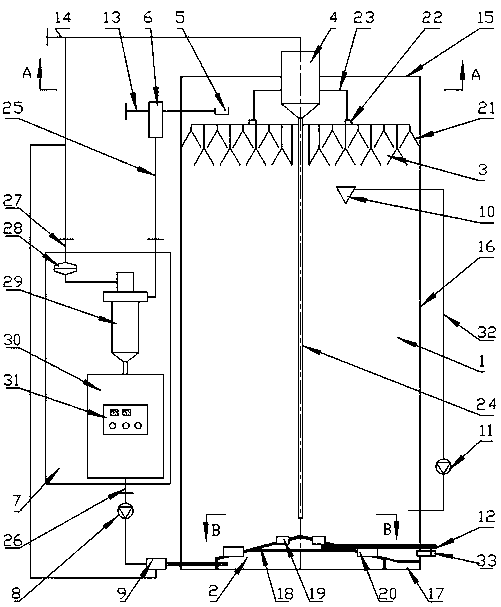

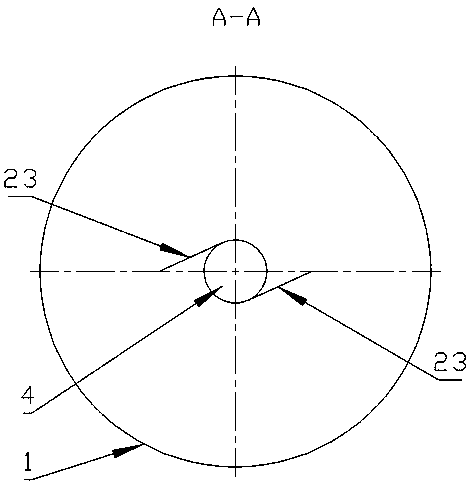

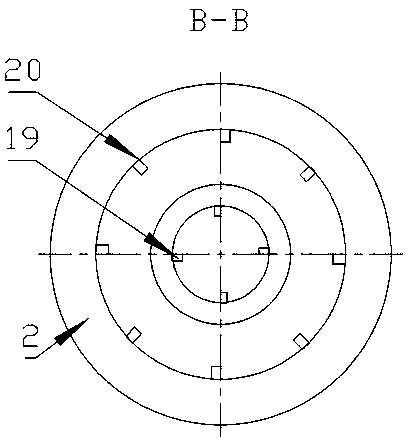

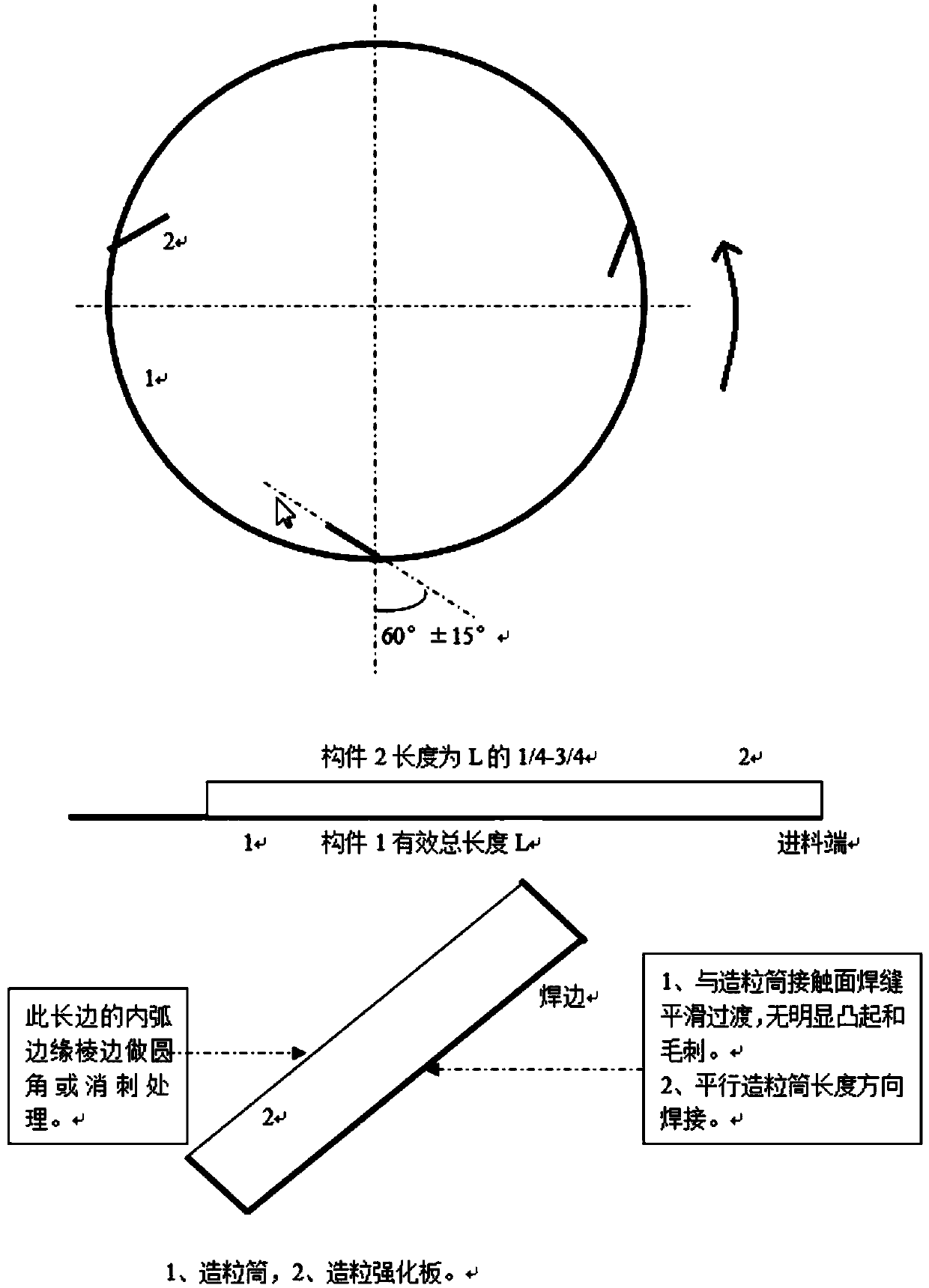

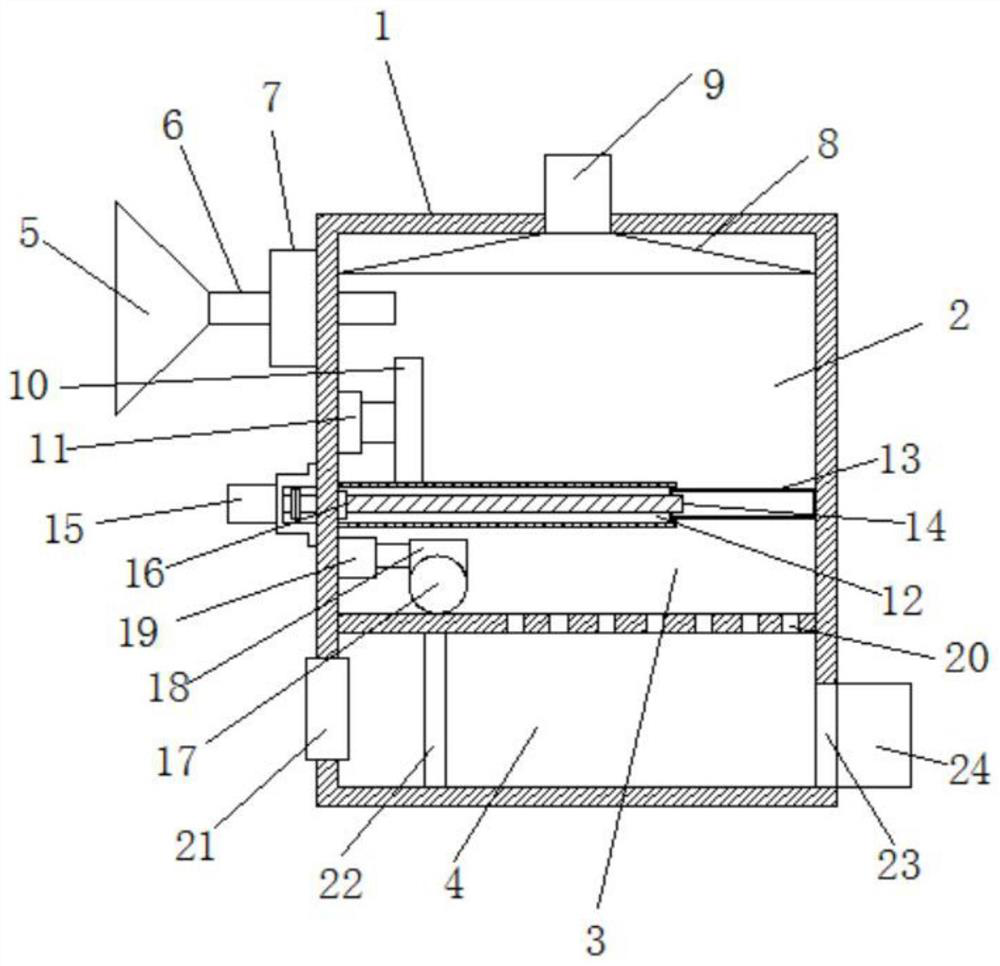

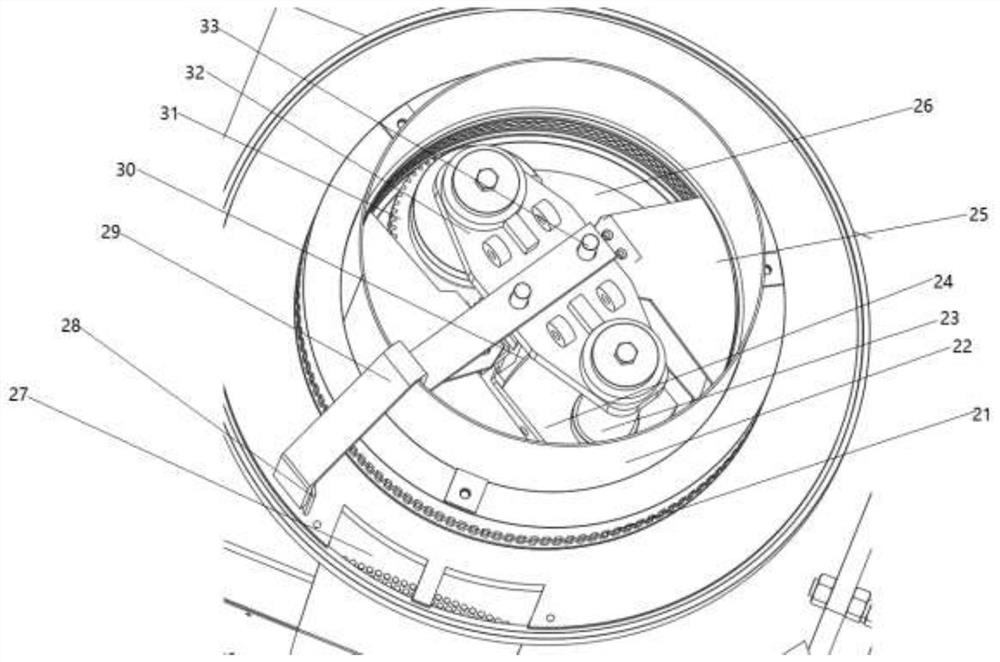

Multi-phase reinforcement and guide type circular and anaerobic granulation reaction processing device

InactiveCN105036325ARealize automatic crushingFully contactedWaste based fuelTreatment with anaerobic digestion processesPulp and paper industryWater circulation

The invention relates to a multi-phase reinforcement and guide type circular and anaerobic granulation reaction processing device applied to high concentrated organic wastewater. The processing device is characterized by comprising a water inlet assembly, a water outlet assembly, a processing device body, a biogas processing assembly and an internal circulation assembly, wherein the biogas processing assembly is arranged on the processing device body, and the internal circulation assembly is arranged in the processing device body; the water inlet assembly is arranged at the lower part of the processing device body, and the water outlet assembly is arranged at the upper part of the processing device body. The processing device has the beneficial effects that the integral structural design is skillful, and the operation is convenient; the rapid granulation of anaerobic sludge in the treatment process of high concentrated organic wastewater is realized by virtue of multiple granulated fillers, internal and external circulation, efficient water distribution and cyclic heating of wastewater, so that the anaerobic debugging time is shortened, meanwhile, the volumetric load and removal rate of an anaerobic reaction device for treating high concentrated organic wastewater are substantially improved, and the construction cost of the anaerobic reaction device is lowered.

Owner:NANJING RUNTRY WATER

Repaired mouth alloy melting granulating method and device for jewelries

InactiveCN101745642AUniform particle sizeEvenly distributed ingredientsMiddle frequencyShielding gas

The present invention relates to repaired mouth alloy melting granulating method and device for jewelries, which belongs to the field of alloy smelter. The repaired mouth alloy melting granulating device comprises a middle-frequency induction power supply, an induction coil, a crucible, a blind device, a cooling water tank, a temperature measuring device and a rotating granulating device. Repaired mouth alloy particles for jewelries are prepared by a middle-frequency induction melting and centrifugal granulating method. The crucible is externally provided with an electric heating induction coil. The argon of protective gas is passed into the top part of a plumbago crucible. A build-in thermocouple is directly inserted into metal liquid to exactly measure the temperature of molten metal. The blind device is arranged at the bottom of the crucible, and blind blocks can be controlled to open and close through a mechanism driving device. The present invention has the advantages of simple operation, reliable running, high granulation speed and without complex vacuum system, can be used for preparing repaired mouth alloy material particles, and can be used for preparing noble metal and non ferrous metal alloy particles.

Owner:中山骏业佳安特电器有限公司

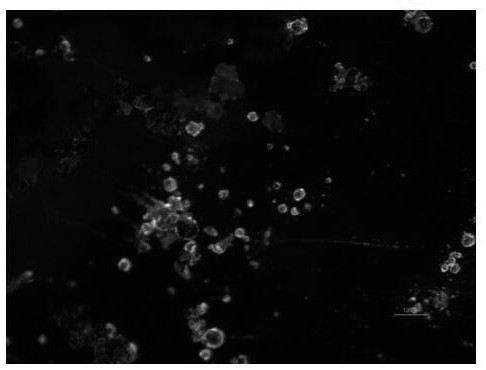

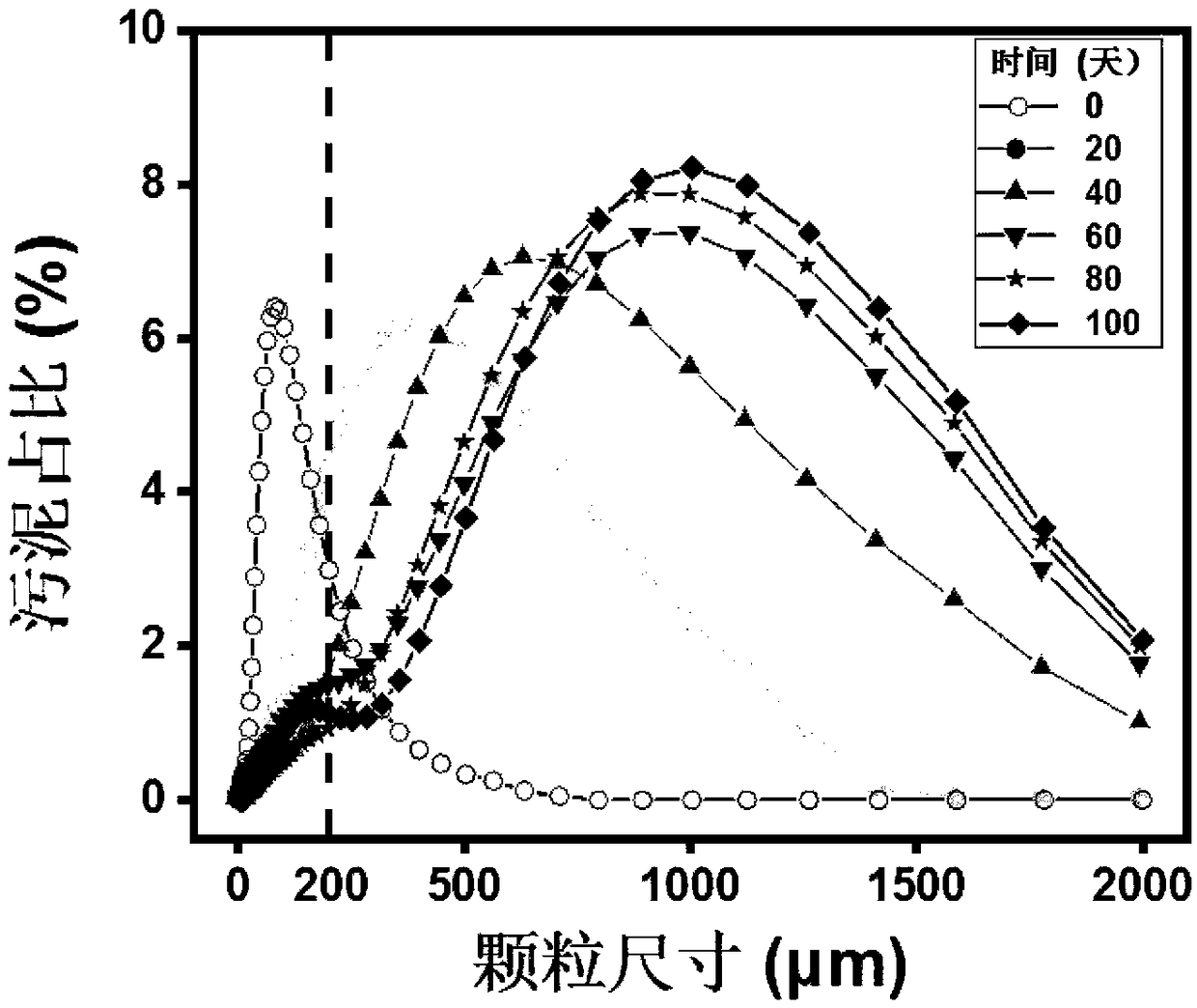

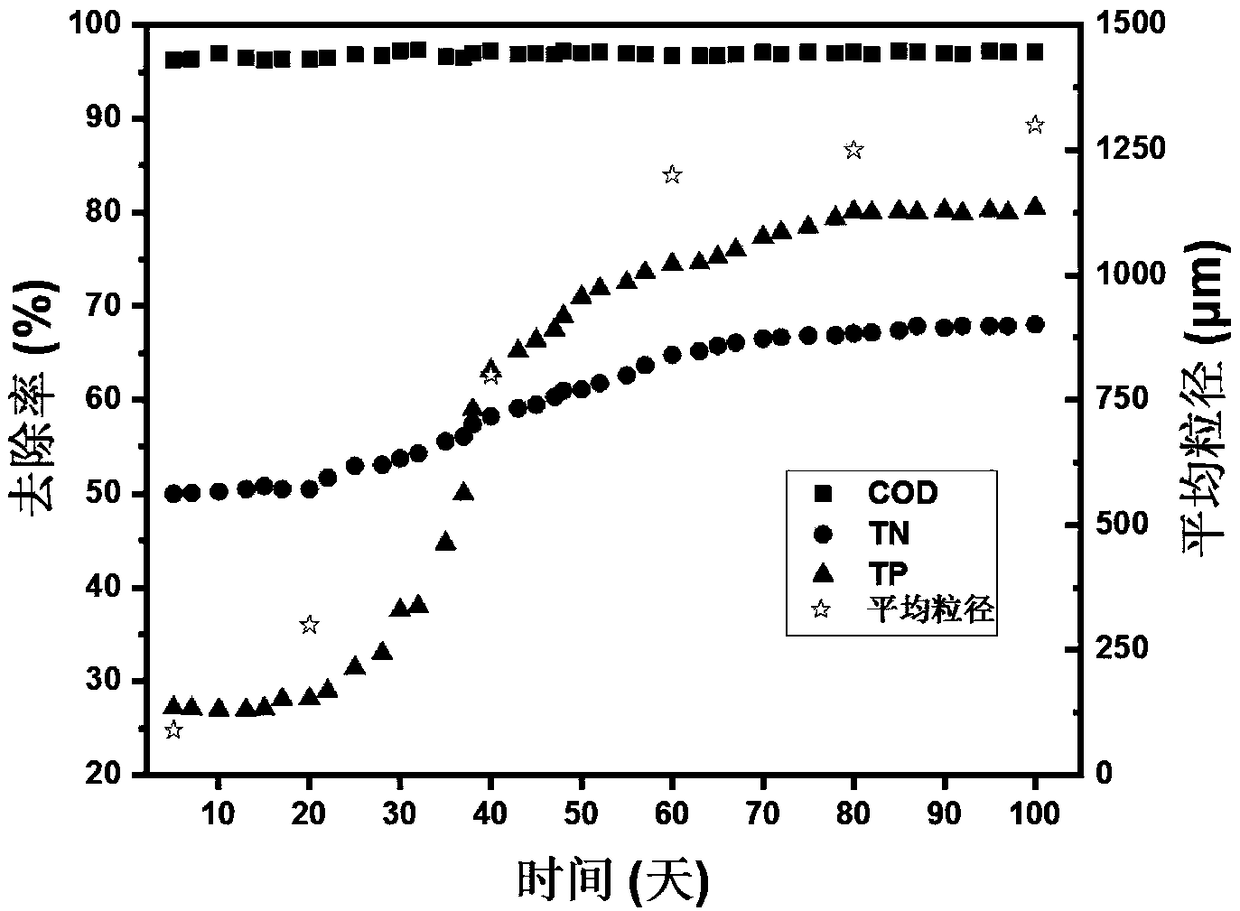

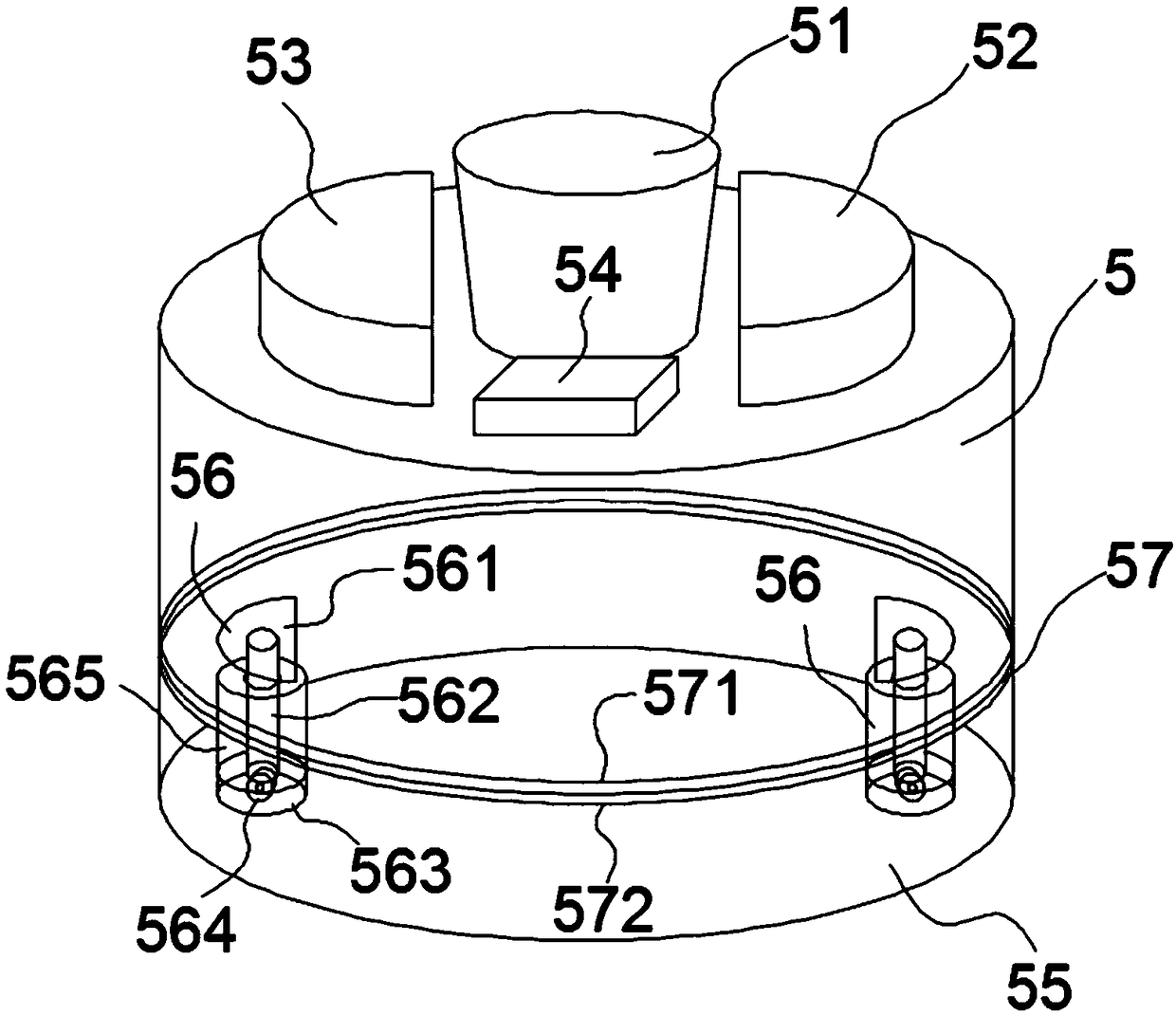

Device and method for promoting aerobic sludge granulation by combining magnetic material with moving magnetic field

PendingCN111747520AStable structureImprove settlement performancePermanent magnetsMagnetic materialsElectric machineGranulation

The invention discloses a device and a method for promoting aerobic sludge granulation by using a magnetic material in combination with a moving magnetic field. The device is reasonable in structuraldesign; and the method comprises the following steps: (1), arranging an activated sludge system reactor according to water inlet, aeration, precipitation, water outlet and idleness; (2), in a water inlet stage, adding a magnetic material into a sludge system of the reactor; (3), controlling the pH value of the tail end of the aeration stage of each period of the reactor to be adjusted to be acidicwithin 30 minutes; (4), at 30 seconds before the aeration stage of each period, automatically controlling a magnet block to move downwards by utilizing a stepping motor to generate a moving magneticfield, and driving a magnetic material and sludge attached to the magnetic material to rapidly sink; and (5), after the SBR operates for 15-30 days, realizing complete granulation, and keeping the aerobic granular sludge a stable structure after long-term operation. The sludge settling performance can be rapidly improved, rapid formation of aerobic granular sludge is promoted, operation is easy and efficient, and practical application is easy.

Owner:ZHEJIANG UNIV OF TECH

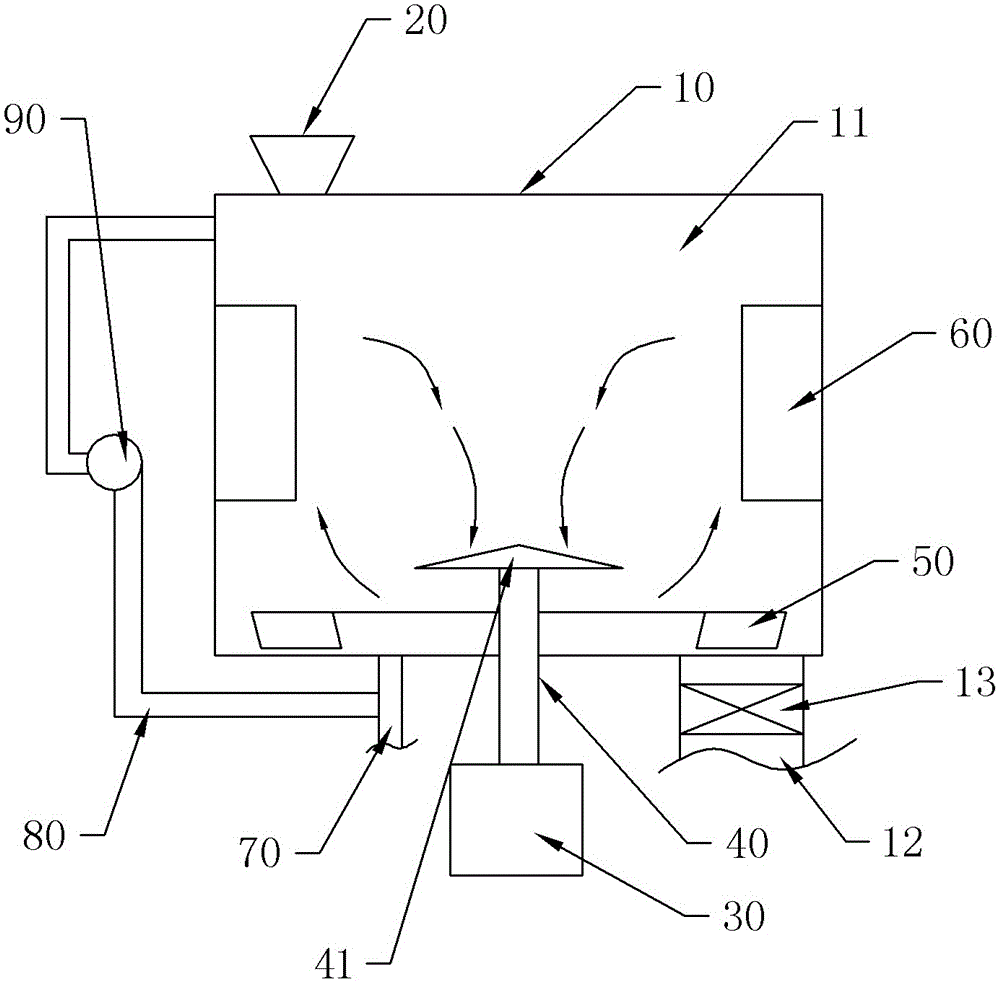

High-speed mixing device used for producing fertilizers

InactiveCN105107412ACross-mixingFast granulationRotary stirring mixersMixer accessoriesImpellerTrace element

The invention discloses a high-speed mixing device used for producing fertilizers. The high-speed mixing device comprises a mixing bucket with a mixing chamber, a motor, an impeller and a drive shaft, wherein a loading hopper is arranged at the upper part of the mixing bucket; a discharge opening is formed in the lower part of the mixing bucket; an output end of the motor is connected with the drive shaft; the impeller is connected on the drive shaft and is arranged at the bottom of the mixing chamber; a steam pipe with one end communicated with the mixing chamber is arranged at the lower part of the mixing bucket; and the other end of the steam pipe is communicated with an external steam source. Trace elements can be uniformly mixed in the fertilizers by adopting the high-speed mixing device, so that the trace elements in the fertilizers have good uniformity.

Owner:CHONGQING YONGCHUAN DISTRICT TIANTANG CHEM PLANT

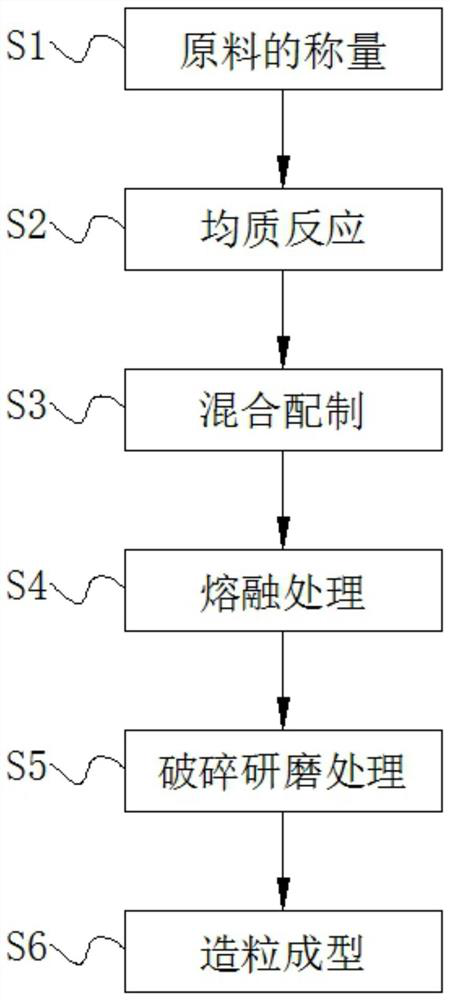

Granulation molding process of secondary element water-soluble fertilizer

InactiveCN111675566AReduce workloadFast granulationCalcareous fertilisersMagnesium fertilisersFertilizerPelletizing

The invention discloses a granulation forming process of a secondary element water-soluble fertilizer, which specifically comprises the following steps: S1, weighing raw materials: respectively weighing the raw materials in required parts by weight through batching equipment, and respectively storing the weighed components into a storage tank for later use, S2, carrying out homogenizing reaction,S3, carrying out mixing and preparing, S4, carrying out melting treatment, S5, carrying out crushing and grinding treatment, and S6, carrying out granulating and molding. The invention relates to thetechnical field of fertilizer processing. According to the granulation forming process of a secondary element water-soluble fertilizer, rapid granulation can be carried out by adopting a one-step heating, melting, granulating and forming method, the purpose of rapid and efficient granulation is well achieved, the granulation process is simple, a large amount of working time of production personneldoes not need to be spent in evaporating the water and fertilizer solution, the workload of the production personnel is greatly reduced, the production efficiency is improved, and thus the water andfertilizer production by people is greatly facilitated.

Owner:HENAN JIENONG BIOLOGICAL & CHEM CO LTD

Method for preparing big-diameter granules from micro and nano powder by means of interfacial polymerization

InactiveCN102085469AWide particle size rangePorosity adjustableMicroballoon preparationMicrocapsule preparationEpoxyPorosity

The invention belongs to the technical field of preparation of big-diameter granules, and particularly relates to a method for preparing big-diameter granules from micro and nano powder by means of interfacial polymerization. The method comprises the following steps of: dispersing the micro and nano powder into aqueous solution of polyamine to obtain solution A, preparing aqueous solution B of water-soluble epoxy compound or polyaldehyde, mixing the solution A and B, and adding the mixed solution into solution C drop by drop through a sieve plate with aperture of 0.01 to 12 millimeters to obtain the big-diameter granules, wherein the solution C is supersaturated organic solution of oil-soluble compound containing multiple acyl chloride or isocyanate functional groups, and the diameter of the granules is 0.1 to 10 millimeters. The method is wide in micro and nano powder application range; the prepared granules have wide diameter range, high real spherical degree, uniform diameter distribution, adjustable internal porosity and high mechanical strength (crushing strength, 150N); and the method is quick in granulation, requires simple equipment, and is particularly suitable for small-size operation.

Owner:ZHENGZHOU UNIV

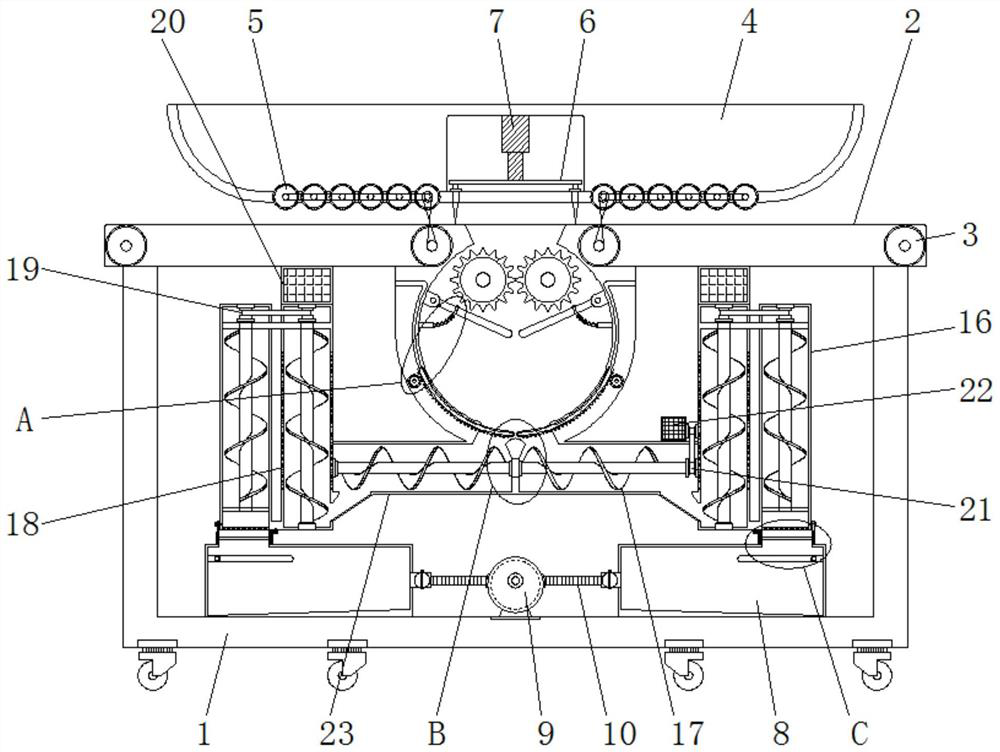

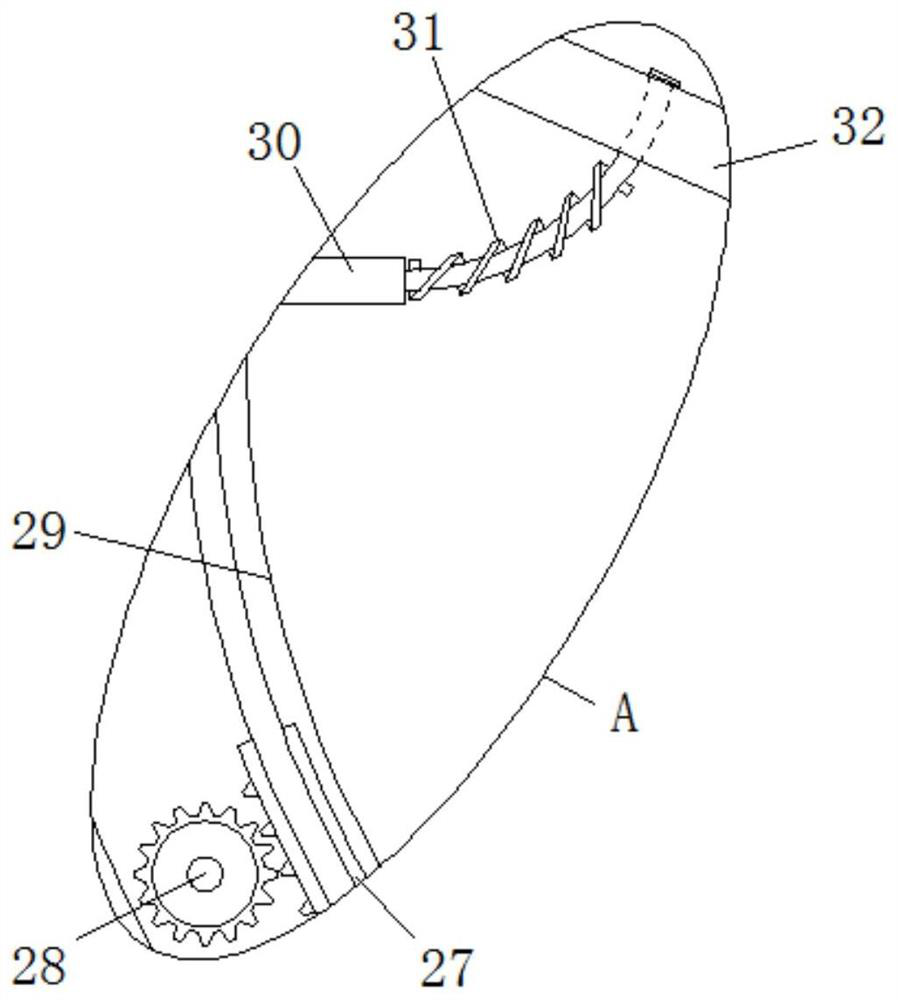

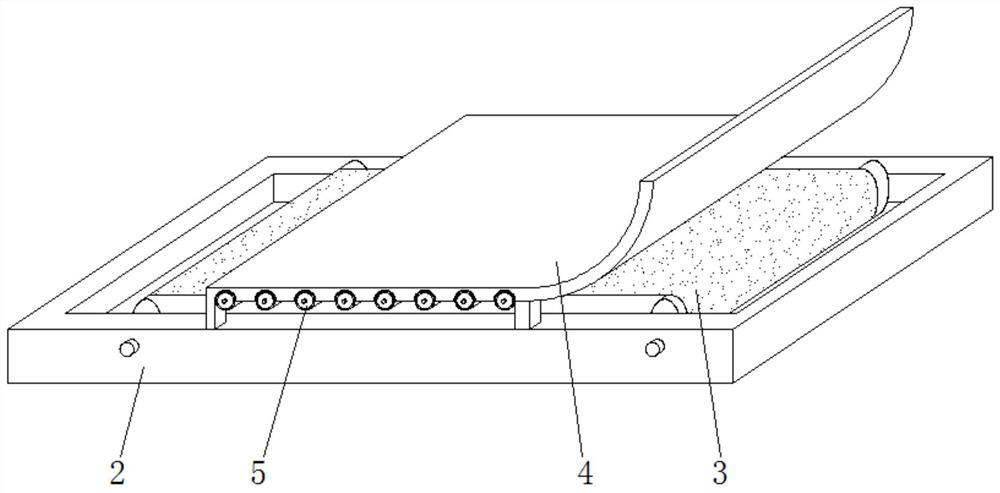

Biomass energy processing granulating device convenient for drying and smashing

InactiveCN112058180AEasy to handle with dust removalEasy to cut and crushCrop conditionersMowersElectric machineGear wheel

The invention discloses a biomass energy processing granulating device convenient for drying and smashing, which comprises a base, an electric telescopic rod, a sucking pump, a heating plate, a firstmotor, a second motor and a third motor, wherein a supporting table is fixedly connected to the upper end of the base, a limiting plate is fixedly installed at the upper end of the supporting table, extrusion hair rollers are rotatably connected to the left side and the right side of the lower surface of the limiting plate correspondingly, a conveying belt and the extrusion hair rollers are in transmission connection through an adjusting belt, the adjusting gear is mounted and connected to the rear end of a smashing roller, the crushing roller is rotatably connected to the interior of a smashing cylinder, and a sealing block is slidably connected to the interior of the lower end of the smashing cylinder. According to the biomass energy processing granulating device convenient for drying and smashing, straw can be fully dried conveniently, and dust prevention treatment can be conducted conveniently when the straw is processed. Meanwhile, biomass energy raw materials such as the straw can be cut off and smashed conveniently, the situation that the sizes are different is avoided, and granulating is convenient.

Owner:李姗姗

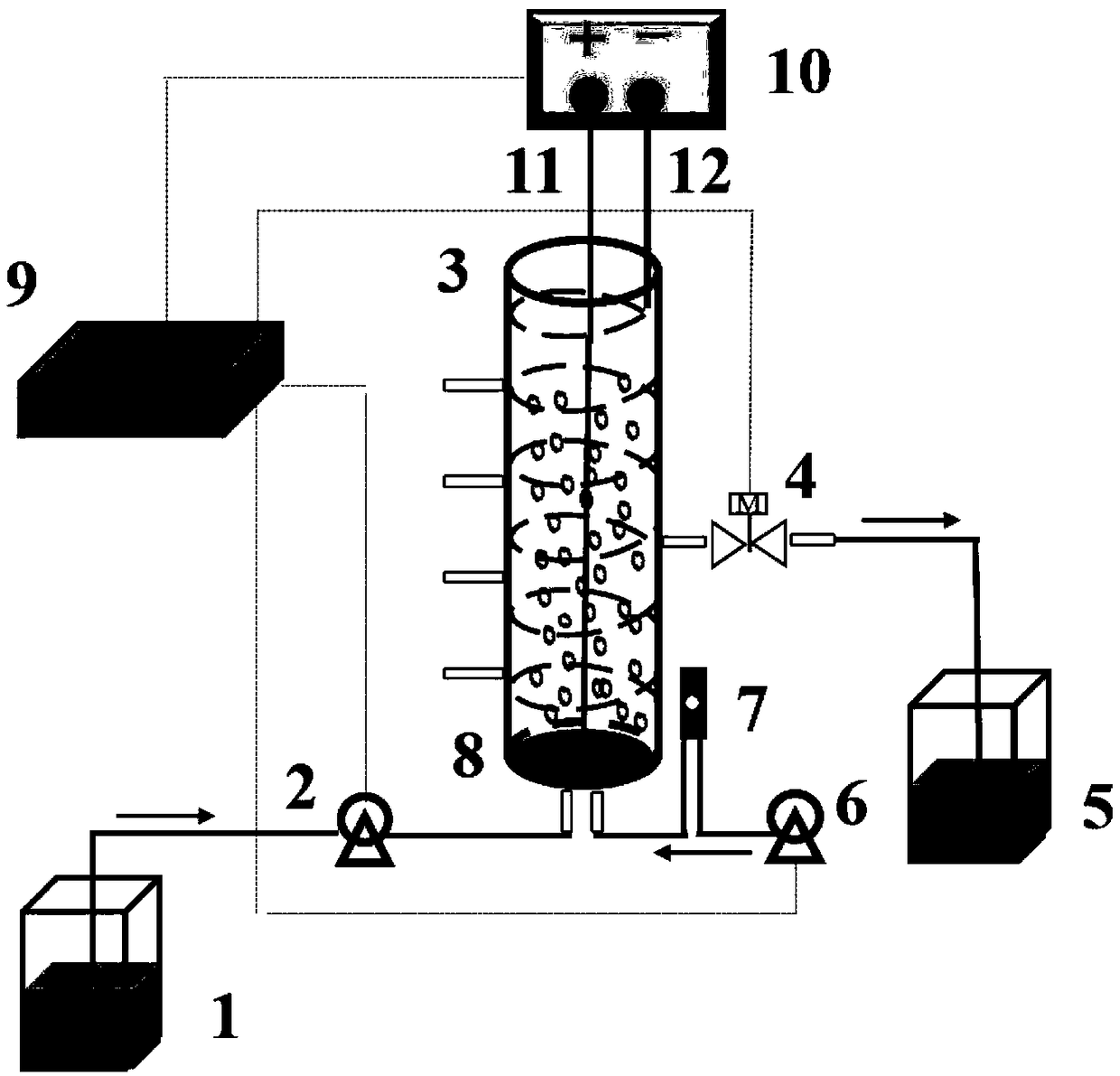

Device and method for strengthening granulation process of aerobic sludge

ActiveCN109319924AAccelerated settlementIncrease biomassTreatment by combined electrochemical biological processesSustainable biological treatmentPeristaltic pumpSludge

The invention discloses a device and method for strengthening a granulation process of aerobic sludge. The device comprises a water inlet unit, a reactor, an aeration unit and a water outlet unit, wherein the water inlet unit comprises a water inlet tank and a water inlet peristaltic pump; a water outlet pipe of the water inlet peristaltic pump is connected with a water inlet at the bottom of thereactor; an inert titanium cathode is arranged on an inner wall of the reactor; an active iron anode is arranged at the center of the reactor; tail ends of the inert titanium cathode and the active iron anode are connected with a direct-current voltage-stabilization power supply through lead wires; the aeration unit comprises an air pump, a rotor flow meter and a sand filtering aeration head whichare connected in sequence; the sand filtering aeration head is arranged at the bottom of the reactor; the water outlet unit comprises a water outlet tank and a water outlet solenoid valve connected with the water outlet tank; the water outlet solenoid valve is connected with a water outlet formed in the middle of the reactor through a water outlet pipe. According to the device disclosed by the invention, rapid granulation of the aerobic sludge and long-period stable operation of an aerobic granular sludge system can be realized at the same time.

Owner:HARBIN INST OF TECH

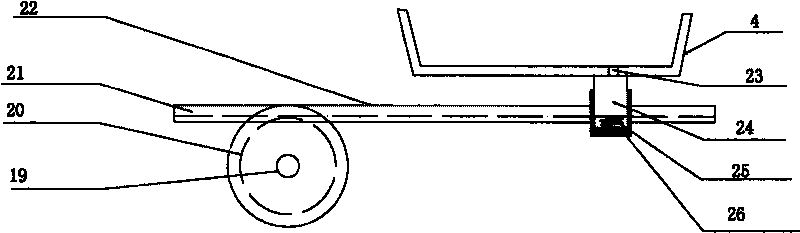

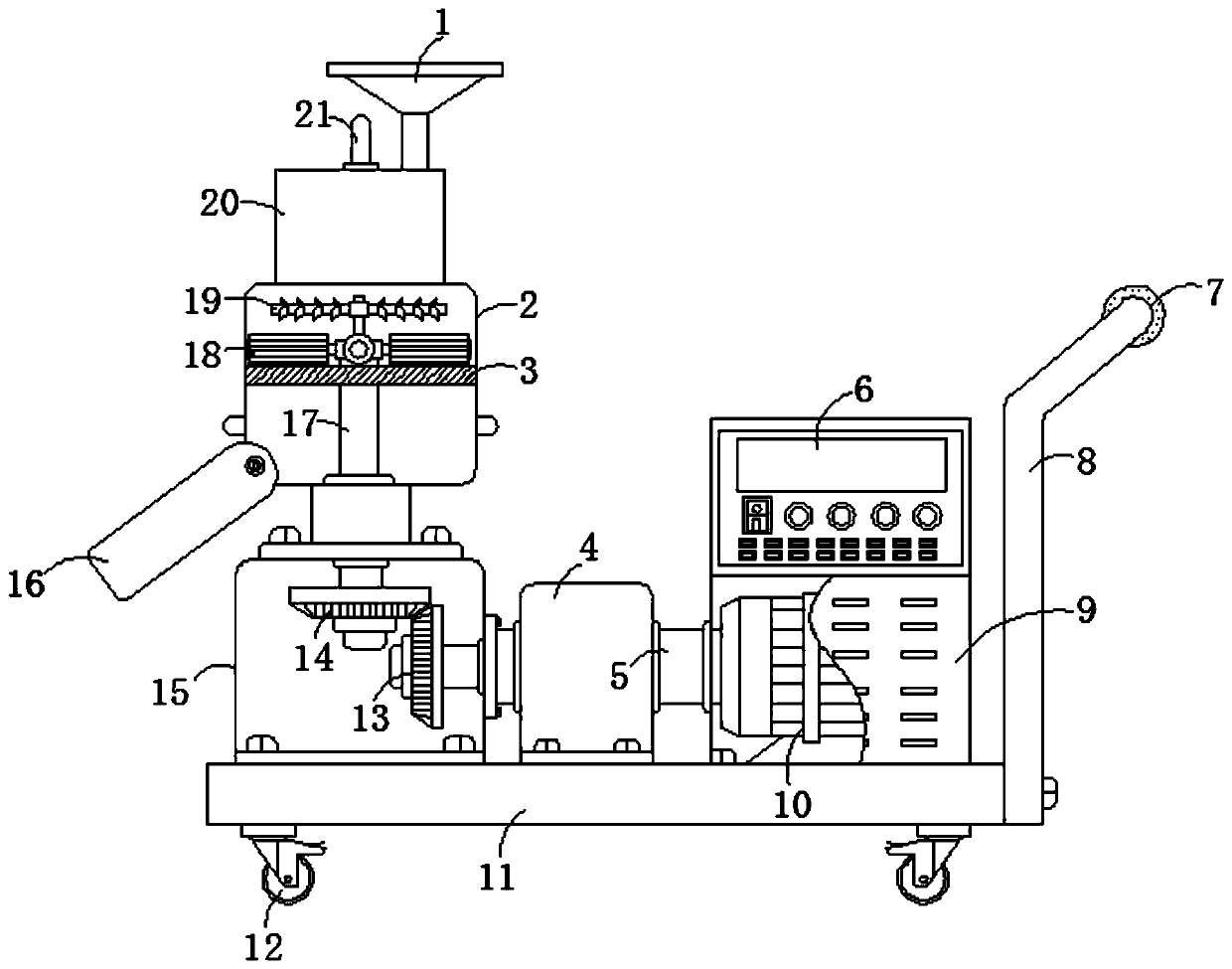

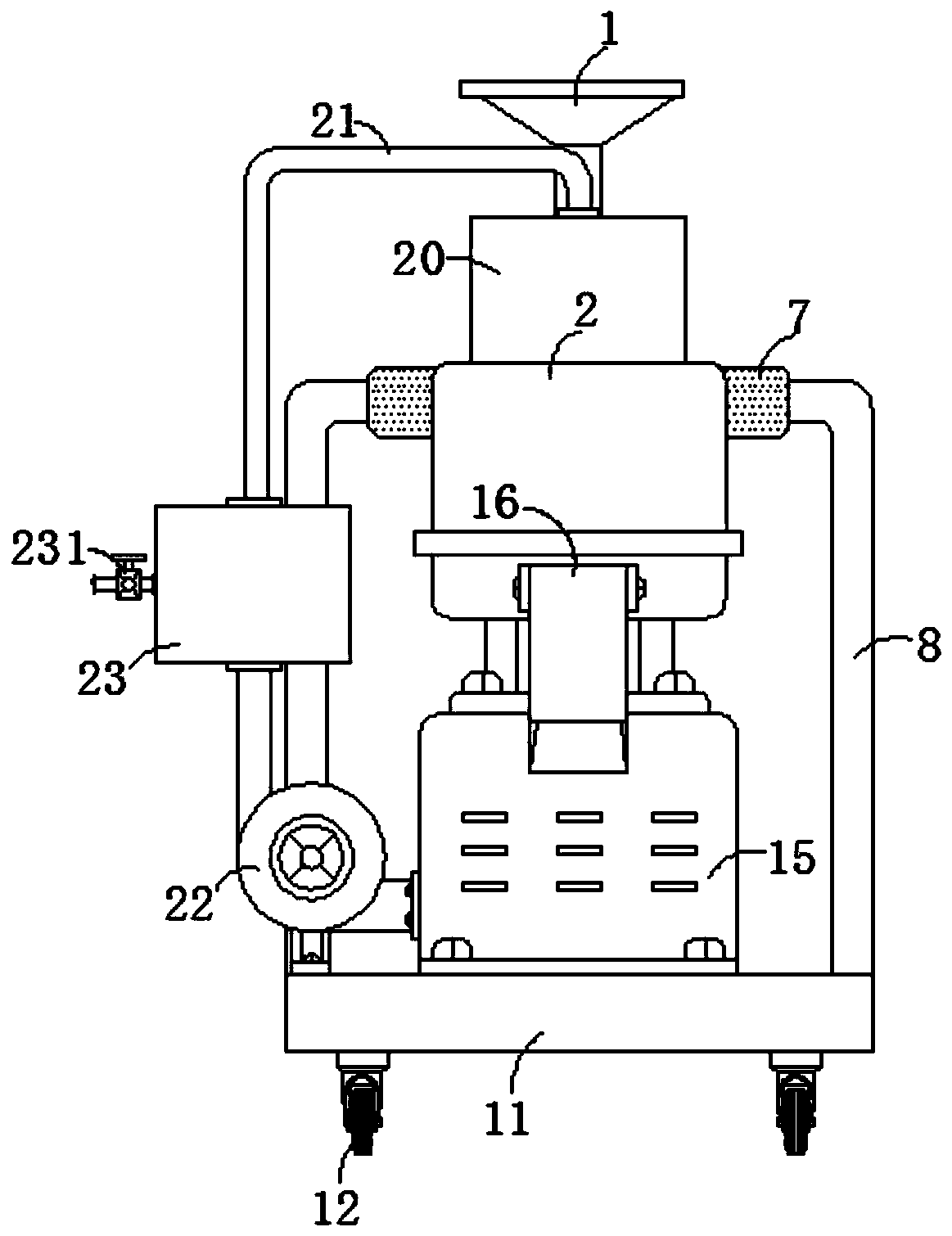

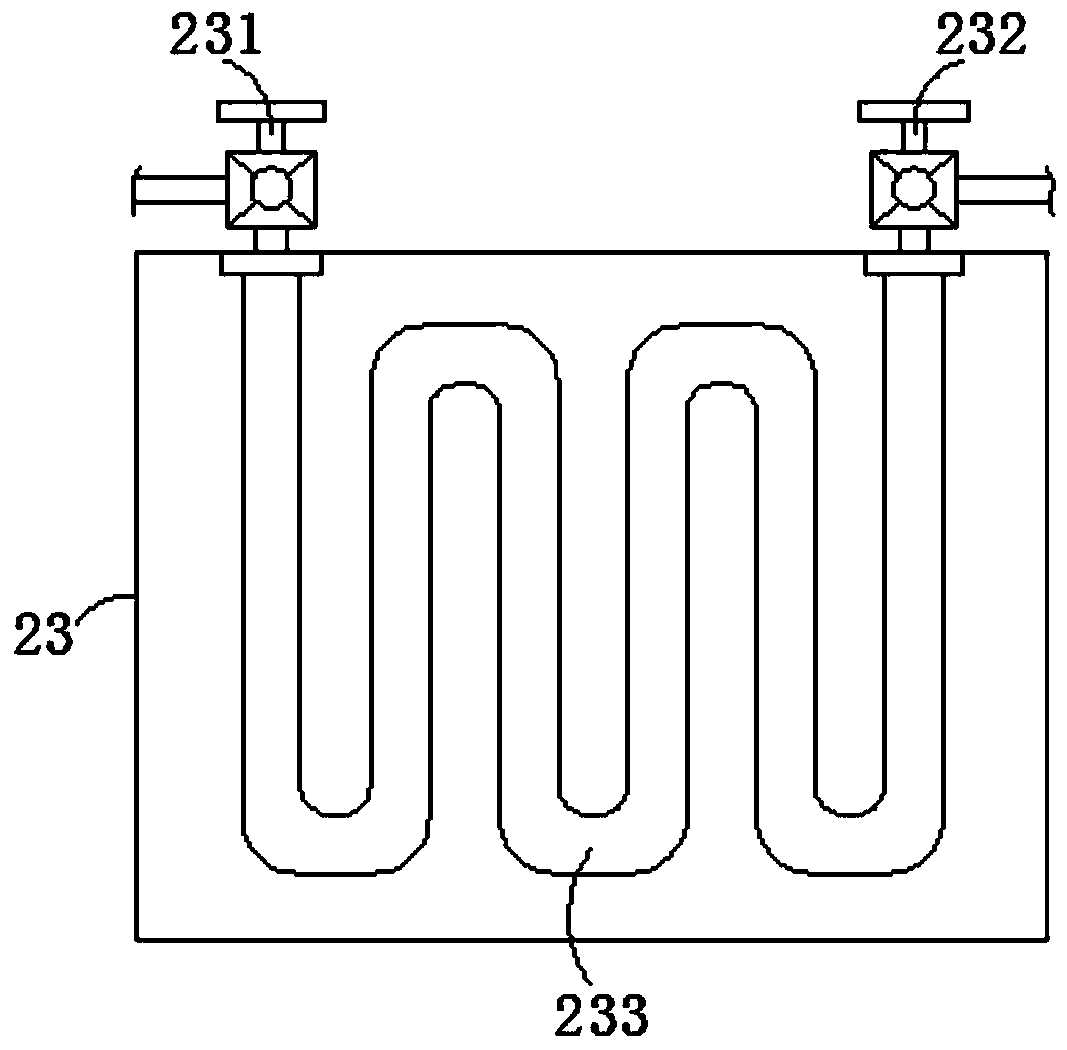

Horizontal hot-air-melting waste plastic recycling and granulating machine

PendingCN108515637AAvoid secondary pollutionImprove working environmentWorking environmentEngineering

The invention discloses a horizontal hot-air-melting waste plastic recycling and granulating machine, wherein a box cover is arranged above a melting chamber. A material hopper is fixedly welded to the upper part of one side of the box cover. A V-shaped receiver hopper is fixedly welded to the lower end of the melting chamber and is fixedly installed on a machine frame. A hot air circulation box body is arranged on the external part of the right side of the melting chamber and below the V-shaped receiver hopper. Spring devices are fixedly installed on the outer walls of the front and rear sides of the melting chamber. A roller shaft is disposed in the melting chamber, wherein two ends of the roller shaft are fixedly installed on the spring devices. A roller is fixedly welded to the rollershaft. Stirring blades are arranged on the outer wall of the roller. An arc-shaped screen mesh is arranged below the roller. The waste plastic can be directly melted by hot air, so that working environment is improved and secondary pollution is prevented; meanwhile, the hot air can be circulated to reduce energy consumption. In addition, through a bush die and a granule cutting mechanism, quick granulation is achieved, thereby increasing work efficiency.

Owner:NANCHANG UNIV

Production method of rich-titanium material

ActiveCN103710551BReduce processIncrease metallization rateTitanium dioxideMagnetic separationMethods of productionProduct processing

The invention relates to a production method of a rich-titanium material. The production method comprises the following steps: pre-oxidation, pre-reduction, multistage magnetic separation, airtight furnace smelting titanium slag granulation, and finished product processing and grading, wherein the pre-oxidation and the pre-reduction are carried in the same rotary kiln. According to the invention, the process of titanium concentrate-rotary kiln pre-reduction-airtight electric furnace smelting is adopted for the first time and the process of bonding and pelletizing of the titanium concentrate is omitted; besides, the production method of rich-titanium material is simple in used equipment, easy to operate, short in flow process and low in reduction temperature; high metallization ratio can be obtained; consequently, the energy consumption of the electric furnace during smelting is greatly reduced.

Owner:LOMON BILLIONS GRP CO LTD

Chemical fertilizer mixing granulator

PendingCN114100512AWell mixedMix completelyGranulation by material expressionAgricultural engineeringWater flow

The invention belongs to the field of chemical fertilizer production, and relates to a chemical fertilizer mixing granulator which comprises a shell, supporting columns are fixedly arranged on the front portion, the rear portion, the left portion and the right portion of the lower side of the shell respectively, a discharging port is fixedly formed in the lower side of the shell, a feeding port is fixedly formed in the upper side of the shell, and a piston is slidably arranged in the feeding port; a piston is arranged in the shell, an upper cover is fixedly arranged on the upper side of the piston, a stirring cavity is formed in the upper side in the shell, an extrusion cavity is formed in the middle in the shell, a drying cavity is formed in the lower side in the shell, and a stirring device is arranged in the stirring cavity. Chemical fertilizer raw materials can be fully mixed and stirred, water is sprayed out through a water flow channel in a stirring rod, so that the raw materials can be fully mixed with the water, in addition, the raw materials can be rapidly extruded and granulated through an extrusion device, then granules are dried through heat generated by a motor, energy is saved, and the production efficiency is improved. Energy waste is avoided, and meanwhile the motor can be cooled.

Owner:谭军

A kind of nitrifying bacteria enrichment culture device and culture method

ActiveCN105713827BHEPA filterReduce the time for subsidence to change waterBioreactor/fermenter combinationsBiological substance pretreatmentsAeration systemSludge

Owner:CHINA PETROLEUM & CHEM CORP +1

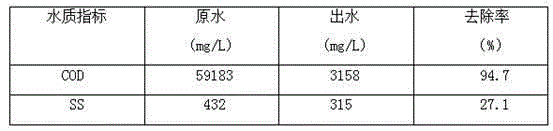

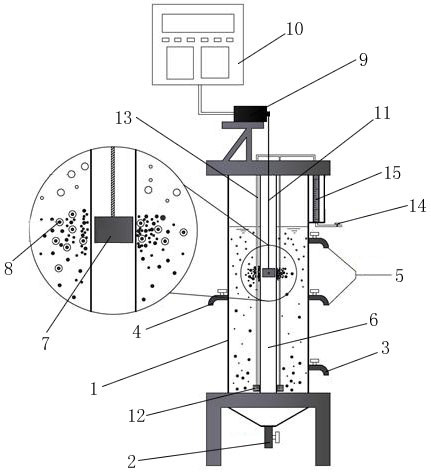

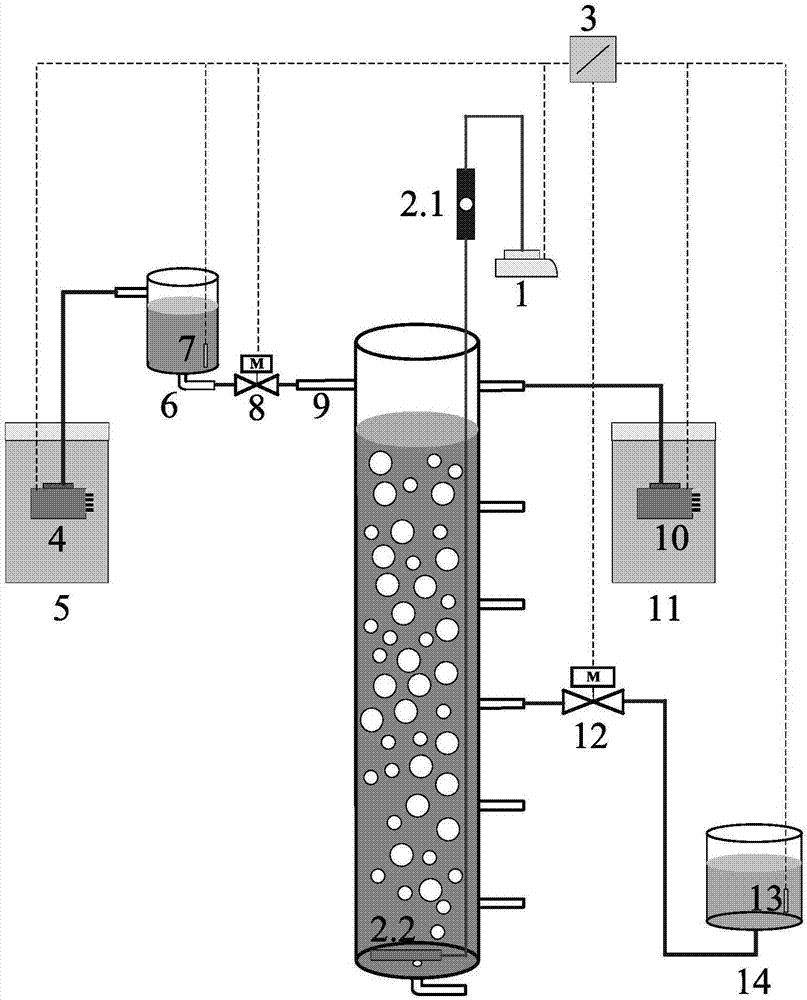

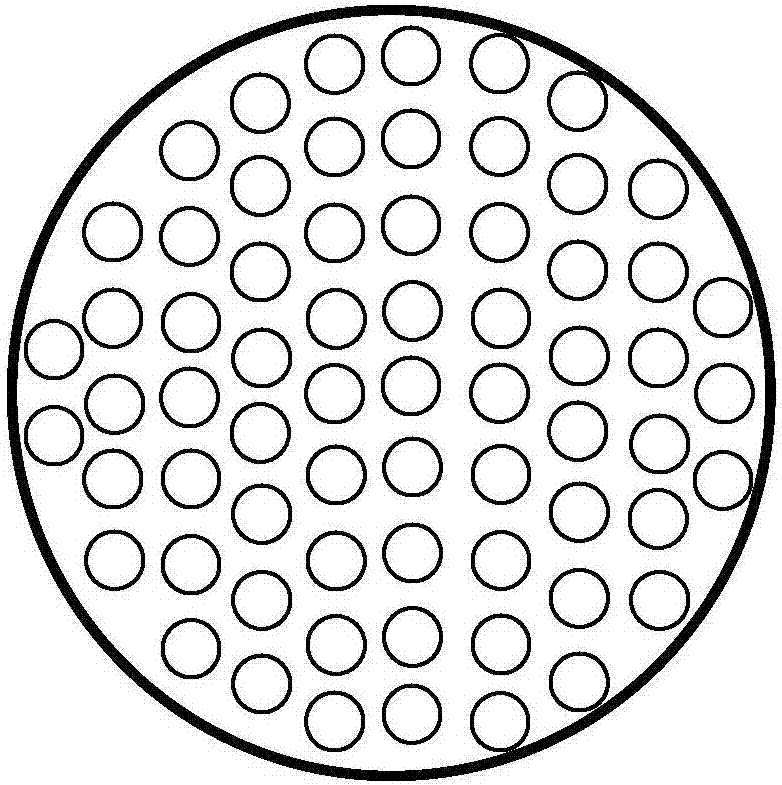

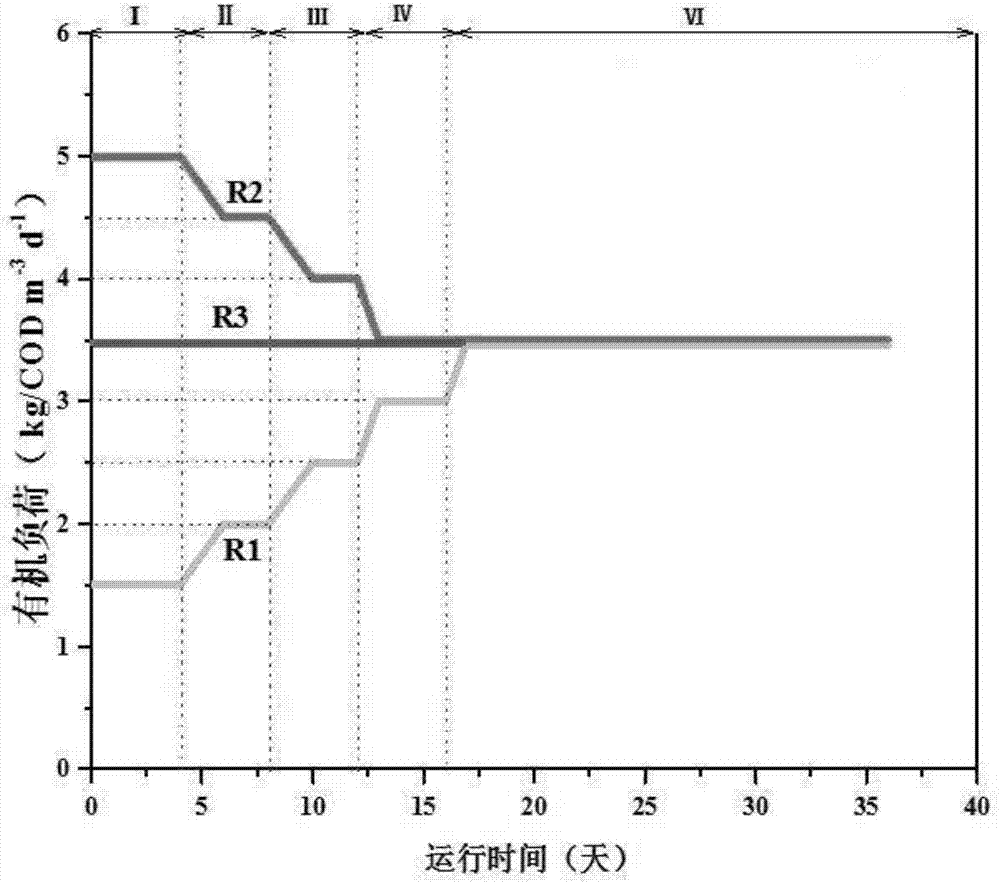

Device for rapidly granulating aerobic sludge and method thereof

InactiveCN107381791AFast granulationAccelerate trainingBiological treatment apparatusEnergy based wastewater treatmentAutomatic controlSludge

The invention discloses a device for rapidly granulating aerobic sludge and a method thereof and belongs to the technical field of wastewater biological treatment. The device comprises a water inlet unit, a reactor main body, an aeration unit, a water outlet unit and a control unit, wherein the water inlet unit comprises a matrix inlet bucket, a clear water inlet bucket and a matrix regulation tank, a reactor organic load regulates volume control of matrix entering into water by virtue of a liquid level sensor located at the bottom of the matrix regulation tank, and organic load change is determined by virtue of a water quality sensor in a water outlet bucket. The device disclosed by the invention can realize automatic control of the reactor organic load and guarantees that the reactor organic load is decreased progressively in gradient, so that aerobic granular sludge with larger granule diameter, higher settling velocity, stable structure and abundant bacterial groups is formed, and the ubiquitous problems in the prior art that a granulation period is long, sludge can be easily bulked in an operational process and long-term system operation is unstable are solved.

Owner:ZHEJIANG UNIV

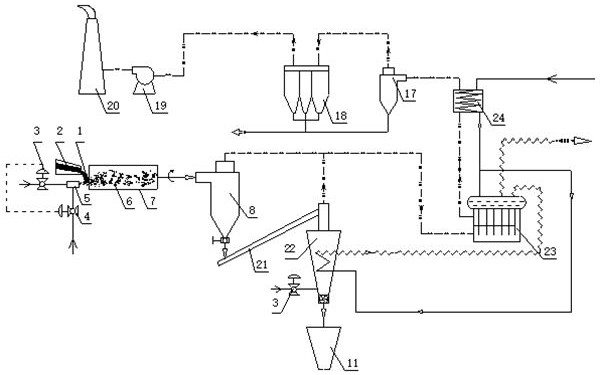

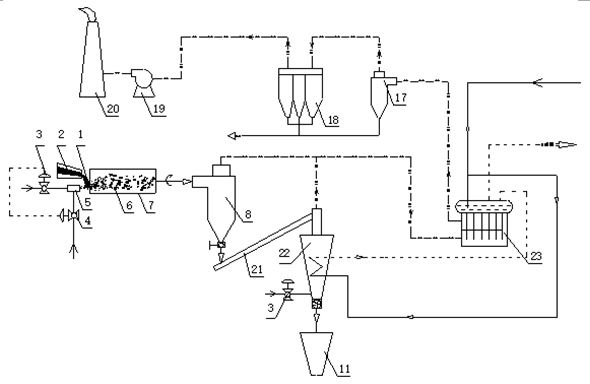

Device and method for granulating blast furnace slag and recycling waste heat

PendingCN113322360AAvoid it happening againImprove waste heat recovery efficiencyBlast furnace componentsBlast furnace detailsSludgeAerosol Mist

The invention discloses a device and method for granulating blast furnace slag and recycling waste heat. The device comprises an aerial fog granulation nozzle assembly, a fluid director (7), a cyclone separator (8) and a waste heat recoverer. The aerial fog granulation nozzle assembly comprises a slag flow controller (2), a compressed air flow control valve (3), a water quantity control valve (4) and an aerial fog spray gun (5). Mixing heat exchange of medium-temperature gas and high-temperature granular slag (6) and solidification of the high-temperature granular slag are realized in the fluid director, and the medium-high-temperature gas and the high-temperature granular slag after heat exchange are guided into the cyclone separator. The cyclone separator is used for separating medium-high-temperature gas and high-temperature granular slag and conveying the medium-high-temperature gas and the high-temperature granular slag into the waste heat recoverer. Complete granulation of the blast furnace slag is achieved, slag sensible heat recovery is organically coupled with sludge drying, high-temperature steam preparation, power generation and low-temperature hot water preparation, waste heat recovery of medium-temperature gas and high-temperature granulated slag in the slag granulation treatment process is achieved, and the waste heat recovery and utilization efficiency is improved.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD +1

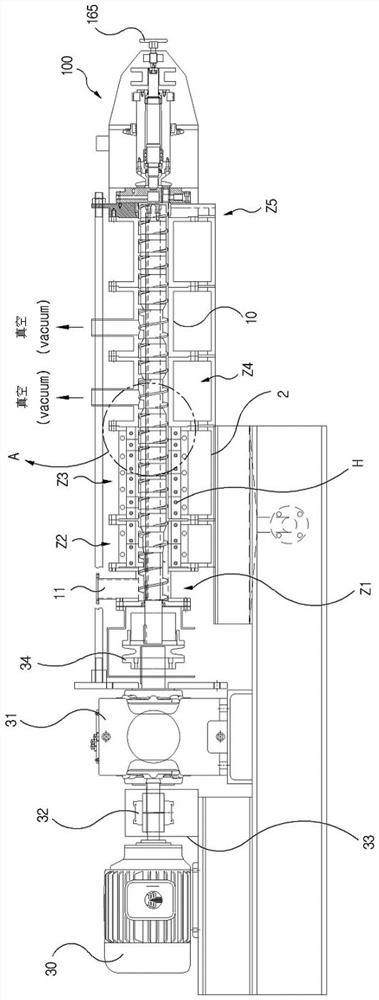

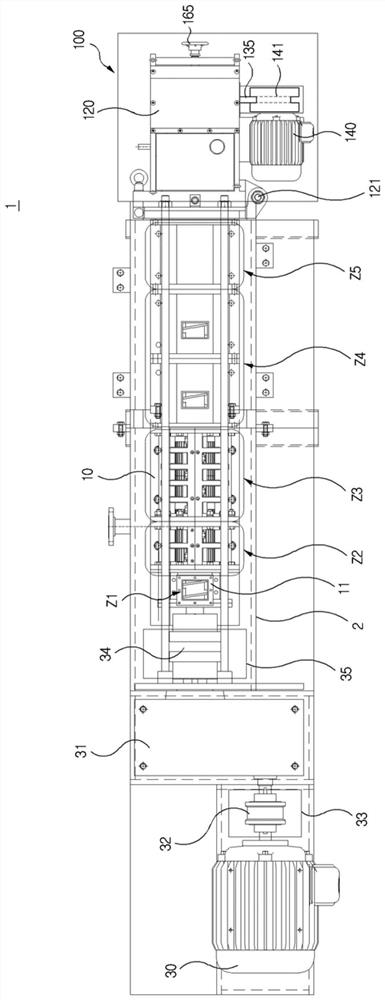

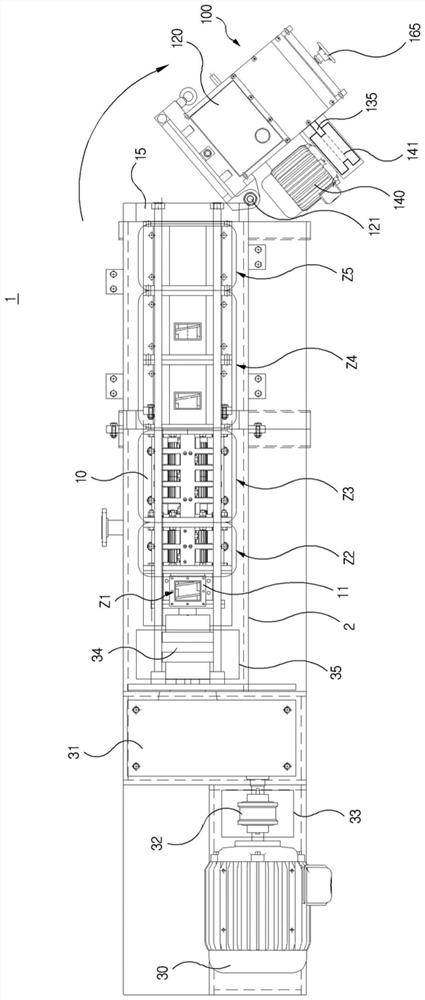

Dewatering screw extruder

PendingCN114055664ARapid mass productionImprove dehydration effectSolid waste disposalTransportation and packagingSpiral bladeProcess engineering

The present invention relates to a screw-type dewatering extruder that simultaneously applies a screw dewatering method and an extrusion method. A feeding zone, primary and secondary dewatering zones by compression, a tertiary dewatering zone by vacuum, and a high-pressure extrusion zone are integrally formed. A pellet forming unit is configured to be rotatable on the rear side of a cylinder. Therefore, the dewatering ability can be greatly increased, and a separate extruder is not required at the rear end, unlike the existing dewatering device, so equipment and costs for a downstream drying process can be significantly reduced. A material that has undergone the dewatering and extrusion processes can be produced quickly and easily into pellets of a cut size. In addition, when a lead screw is rotated in the forward direction, powder moves from the front to the rear direction of the cylinder, at this time, a reverse spiral blade serves to prevent the movement of the powder, and as a result, the dewatering effect of the powder can be further increased. In addition, by rapidly pelletizing the powder by spraying cooling air to the powder extruded through a die hole in a cooling air injection unit, mass production is possible. The screw-type dewatering extruder comprises a cylinder, a lead screw, a lead screw driving unit, and a pellet forming unit.

Owner:S TECH CO LTD +1

Method for quickly granulating aerobic activated sludge in membrane bioreactor

InactiveCN102674538BReduce or eliminate pollutionReduce processing timeSustainable biological treatmentBiological water/sewage treatmentActivated sludgeSewage

Owner:SHANGHAI HUAFON NEW MATERIAL R&D TECH CO LTD +1

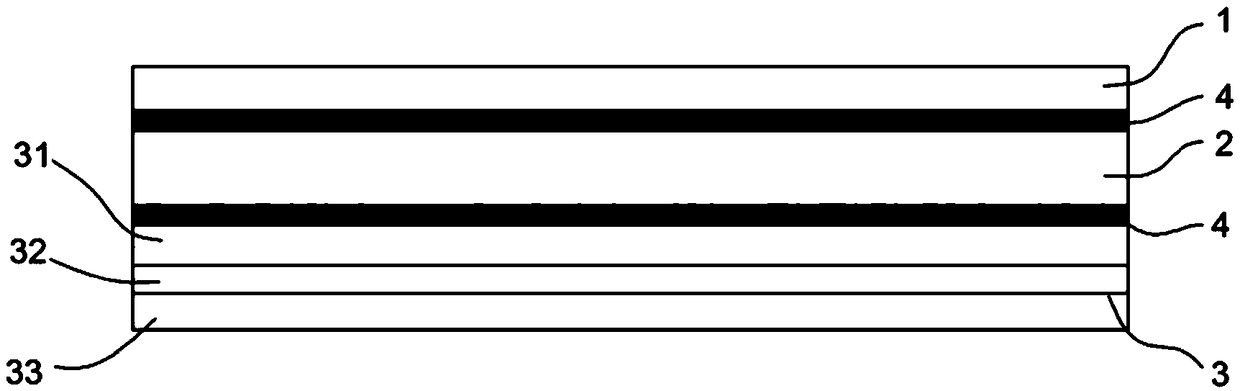

A manufacture method of a novel improved decorative board

ActiveCN108894455AMeet daily needsImprove the quality of lifeCovering/liningsSynthetic resin layered productsAdhesiveEngineering

The invention discloses a production method of a novel improved decorative board, characterized by, the decorative panel comprises a decorative layer, impact resistant layer, composite layer and adhesive layer, the adornment lay, the anti-impact layer and the composite layer are arranged from the top to the bottom in turn, An adhesive lay is arranged between each of that two layer, and extruding it by 1200N pressure to obtain a decorative board, The composite layer is divided into a refractory layer, an acoustic insulation layer and an insulating layer, wherein the refractory layer, the acoustic insulation layer and the insulating layer are arranged from the top to the bottom in sequence; the refractory layer, the acoustic insulation layer and the insulating layer are coated with an adhesive; the pressure of 750N is used to extrude between each two layers; and the outer periphery of the refractory layer is also coated with an alkali-resistant sealing layer. In a word, the method of theinvention is reasonable, and the refractory, sound insulation and heat preservation aspects of the decorative board are improved and strengthened, and the device of the invention has the advantages of high automation degree, simplified operation process, saving manpower and the like.

Owner:浙江海纳蓝新材料科技股份有限公司

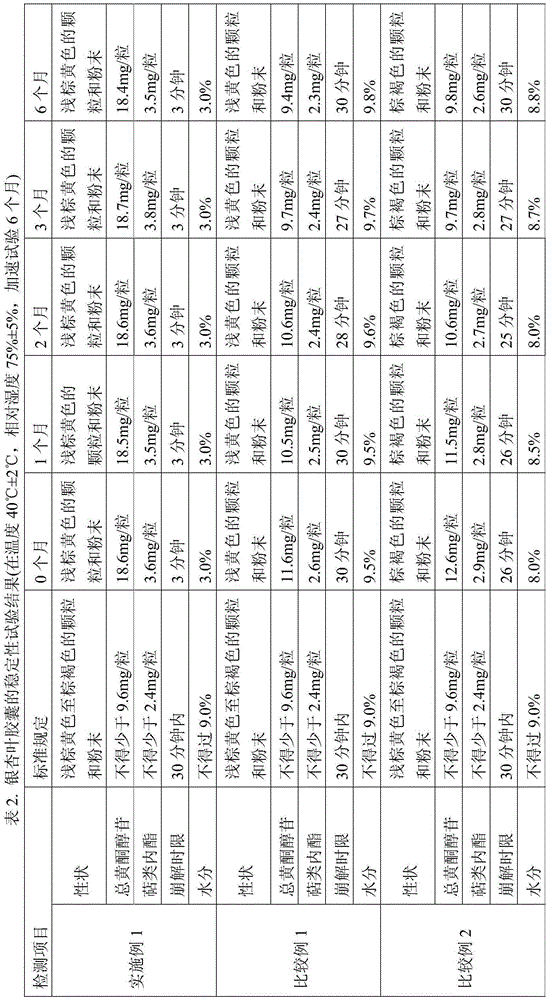

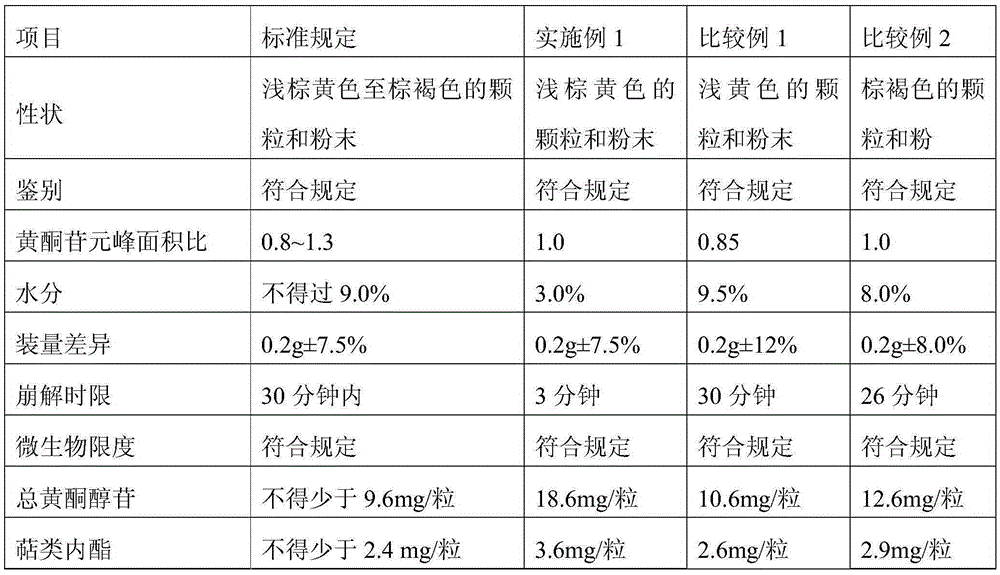

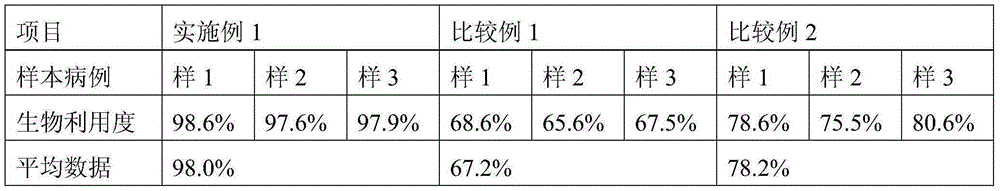

A kind of ginkgo leaf capsule and preparation method thereof

ActiveCN103520225BUniform sizeRound shapeNervous disorderPharmaceutical non-active ingredientsSolubilityClinical efficacy

The invention provides a ginkgo leaf capsule. The ginkgo leaf capsule comprises, by weight, 30 to 50 parts of a ginkgo leaf extract, 120 to 180 parts of beta-cyclodextrin, 7 to 12 parts of talcum powder and 0.5 to 1.5 parts of magnesium stearate. A granule is prepared from the above-mentioned raw materials and then fills a hard capsule shell so as to prepare the ginkgo leaf capsule. The ginkgo leaf capsule prepared in the invention has more stable performance and a better clinical curative effect. The invention further provides a preparation method for the ginkgo leaf capsule. The method comprises the following steps: preparing spraying slurry from beta-cyclodextrin and ethanol; subjecting the raw materials to one-step drying and granulation by using a fluid bed granulating and drying machine; and filling the obtained granule to prepare the capsule. The method can overcome disadvantages of the prior art and substantially improves bioavailability, solubility and chemical and physical stability of a drug.

Owner:桂林原承制药有限责任公司

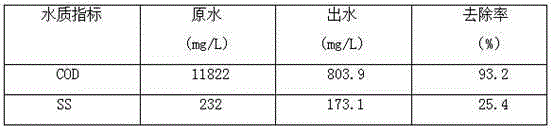

Anaerobic reactor for treating high-concentration organic wastewater

PendingCN110803765AIncrease concentrationFully granulatedWater contaminantsTreatment with anaerobic digestion processesHigh concentrationWater flow

An anaerobic reactor for treating high-concentration organic wastewater is based on basic principles of an up-flow anaerobic sludge bed reactor, gas stripping desulfurization and deamination and the like, and achieves SRT and HRT separation through a three-phase separator to obtain a high sludge concentration; and sludge and water are in full contact through disturbance of a large amount of biogasand internal and external circulating water flow of a tower type rotational flow water distribution structure, so rapid granulation of the sludge is achieved. The anaerobic reactor has the advantagesof improvement of the suspended matter resistance, the load impact resistance, the salt resistance and the toxicity resistance, reduction of the granular sludge inoculation cost, shortening of the sludge acclimation period, good mass and heat transfer effect, high volume load reaching 5-30 kg COD / m<3>, stability and reliability in running, high treatment efficiency, investment saving, large height-diameter ratio reaching 3-6, and low capital construction investment cost, and occupies a smaller area than a UASB anaerobic reactor. The biogas is utilized, so that the self-heating balance of thesystem is realized, the medium-temperature (35-38 DEG C) environment in a tank is ensured, and the running cost is low.

Owner:辽宁博创环保技术有限公司

A kind of strengthening agent for titanium concentrate granulation and a kind of granulation method of titanium concentrate

The invention provides a titanium concentrate prilling enhancer which comprises polyvinyl alcohol, pitch and a plant adhesive. The invention further provides a titanium concentrate prilling method. The titanium concentrate prilling method comprises the following steps that titanium concentrate and the enhancer are mixed to obtain an initial mixture; the enhancer comprises the polyvinyl alcohol, the pitch and the plant adhesive; the initial mixture is subject to prilling to obtain titanium concentrate molding wet particles; and the titanium concentrate molding wet particles are dried to obtain titanium concentrate molding dry particles. According to the dewatering characteristic of the titanium concentrate, the complete physical bonding organic molding enhancer is used for prilling, the proportion of the prepared titanium concentrate particles with the grain size ranging from 1 mm to 5 mm is larger than 90%, the falling strength is larger than 5 times per meter, the problem of raise dust in titanium concentrate transferring and electric furnace smelting process is effectively solved, the normal smelting rate is guaranteed, and the electric furnace equipment operation rate and the material yield are improved.

Owner:SICHUAN PAN YAN TECH

A high-efficiency dust treatment device for wheat deep processing equipment

ActiveCN111773857BSimple structureEasy to useUsing liquid separation agentDrying gas arrangementsRapid processingEnvironmental engineering

The invention discloses a high-efficiency dust processing device for wheat deep processing equipment, comprising: a dust processing box for quickly processing dust generated by wheat deep processing, an agglomeration bin for aggregating the floating dust, and an agglomeration bin for aggregating The granulation bin for granulation and collection of dust and the drying bin for drying and collecting the granulated dust. The coagulation bin, the granulation bin and the drying bin are arranged inside the dust treatment box. The structure of the present invention is simple and easy to use. The dust treatment box with multiple dust treatment functions absorbs dust into the dust treatment box during use, and the dust is sequentially condensed and dried by a granulator, which solves the problem of low efficiency and high labor intensity in the existing wheat processing dust treatment method The separation of dust and dust is not clean, and a lot of dust will adhere to the wheat repeatedly if it is not treated thoroughly. It is time-consuming and laborious to completely separate it. Processing unclean wheat into flour will also lead to the problem of unqualified flour products.

Owner:枣庄市东粮生物科技发展有限公司

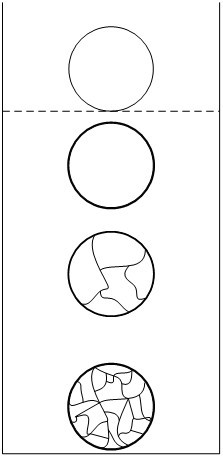

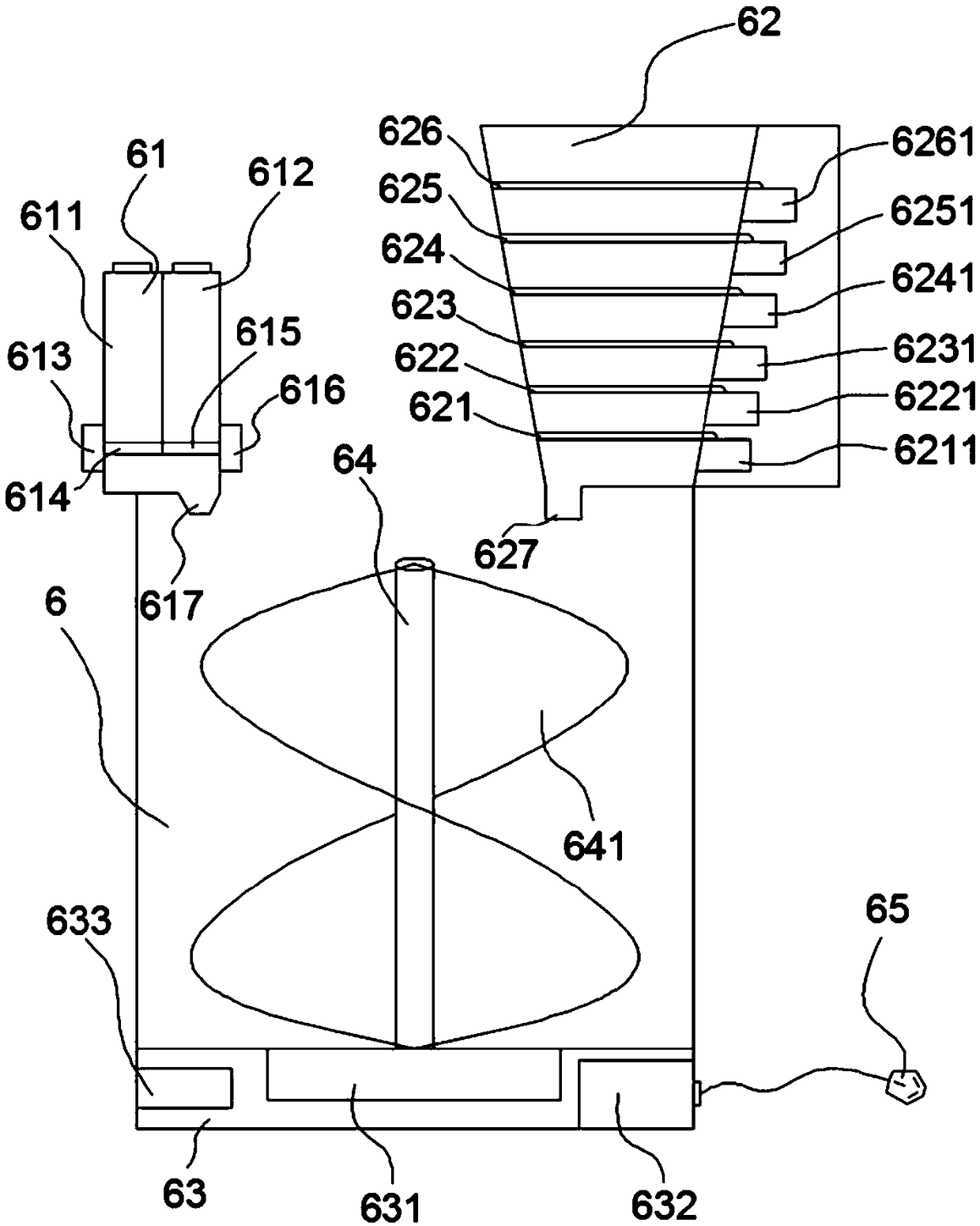

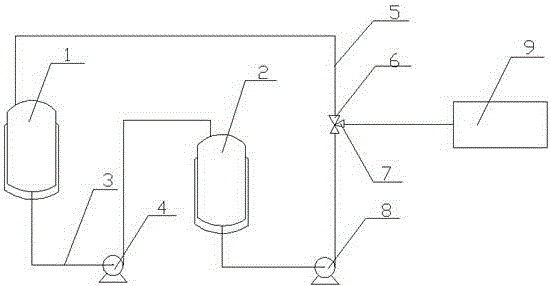

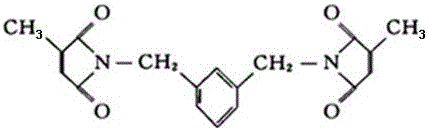

Granulation method and granulation system of 1,3-bis(citraconimidemethyl)benzene

ActiveCN105032283BIncreased flow viscosityGranulation speedOrganic chemistryMaterial granulationBenzenePolymer science

The invention discloses a granulation method for 1, 3-bis(citraconoyl formimino) benzene. The method comprises the following steps: heating the 1, 3-bis(citraconoyl formimino) benzene to be completely molten into a liquid state; then carrying out heat preservation on the liquid-state 1, 3-bis(citraconoyl formimino) benzene for 1-2 hours at 43-45 DEG C, so that the liquid-state 1, 3-bis(citraconoyl formimino) benzene is converted into glassy-state 1, 3-bis(citraconoyl formimino) benzene; adding the glassy-state 1, 3-bis(citraconoyl formimino) benzene into a granulator, and carrying out granulation. The invention also discloses a granulation system. Continuous granulation can be realized by the granulation system. According to the granulation method and the granulation system, the defects that an existing granulation method is long in extrusion and granulation time and incapable of realizing continuous production are overcome; the 1, 3-bis(citraconoyl formimino) benzene is converted into a glassy state and is then granulated, so that the operation environment is greatly improved, and the production efficiency is improved; the granulation method and the granulation system have a favorable market prospect.

Owner:SHANDONG YANGGU HUATAI CHEM

A kind of preparation method of non-fired porous ceramsite with high closed porosity

ActiveCN112794665BHigh porositySimple manufacturing processSolid waste managementClimate change adaptationThermal insulationExpanded clay aggregate

The invention relates to the technical field of solid waste recycling and materials, and relates to a preparation method of non-fired porous ceramsite with a high closed cell rate, which uses a foaming agent and an inorganic substance that promotes the decomposition of the foaming agent to realize step-by-step granulation and step-by-step manufacturing. Pores, promote rapid, uniform and thorough pore formation in the ceramsite core, and increase porosity; then, continue to granulate with the porous core and granulation mixture, and form a wrapping layer on the porous core, and complete the preparation and wrapping of the porous core in one step , to obtain ceramsite with a "porous core + wrapped shell" structure. Firstly, the raw materials can use mineral solid waste such as construction waste, tailings, fly ash, etc. to realize solid waste recycling; secondly, the porosity is high, and the thermal insulation performance is good; finally, the kernel and wrapping process are one-step during granulation Finished, the process is simplified, and the preparation cost is reduced.

Owner:贺州市坤德环保科技有限公司

Medicinal powder granulating device

InactiveCN112773716AFast granulationHigh granulation molding ratePharmaceutical product form changeProcess engineeringBiology

The invention relates to the field of medicine production and particularly relates to a medicinal powder granulating device. The medicinal powder granulating device is characterized by comprising a main rack, wherein a granulating mechanism is mounted at the upper end of the main rack, a power mechanism is mounted at the lower end of the main rack, and the granulating mechanism is driven by the power mechanism. The medicinal powder granulating device can be used for carrying out rapid granulating and is high in forming degree of granulation.

Owner:管燕

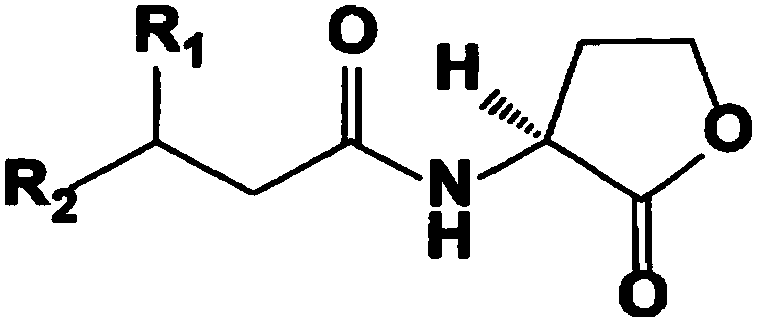

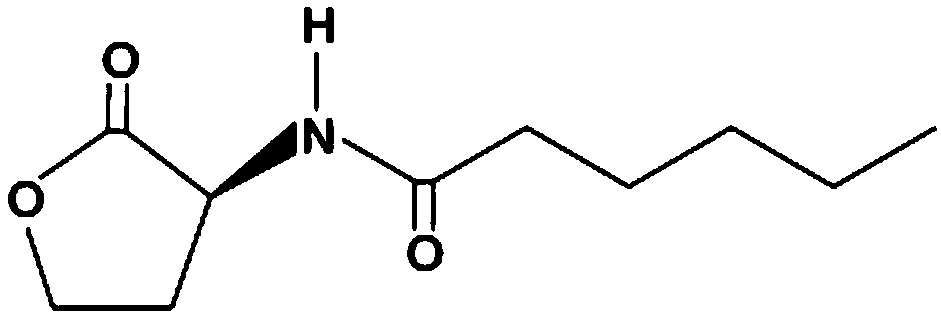

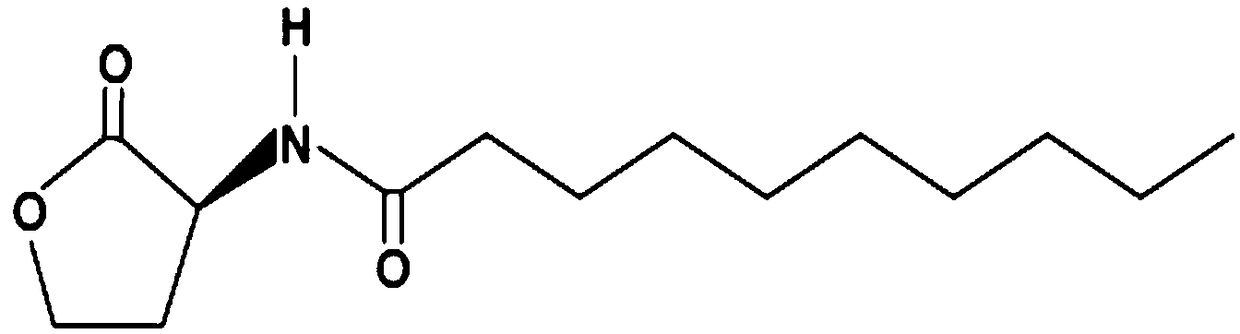

A device and operation method for rapidly forming anammox particles using quorum sensing mechanism

ActiveCN105923760BPromote rapid formationThe implementation method is simpleWater contaminantsTreatment with anaerobic digestion processesParticulatesThin shells

Owner:BEIJING TANSI ENVIRONMENTAL PROTECTION TECHCO

A high-efficiency and environment-friendly straw processing granulator

ActiveCN108854846BUniform feedingFalling smoothlyGranulation by pressingAgricultural engineeringProcess engineering

The invention discloses a high-efficiency and environment-friendly type straw particle processing machine. The high-efficiency and environment-friendly type straw particle processing machine comprisesa bottom plate, wherein a gear box is fixedly arranged at one side of the upper surface of the bottom plate; a main shaft box is arranged at the top end of the gear box through a fixed seat; a material charge bin is fixedly arranged at the upper surface of the main shaft box; a main shaft is arranged in the middle part of the bottom part of the interior of the main shaft box; a material feed hopper is arranged at one side of the upper surface of the material charge bin; the main shaft penetrates through the main shaft box, and extends into the gear box; a first connecting roll and a second connecting roll are fixedly arranged at one end of the main shaft. The high-efficiency and environment-friendly type straw particle processing machine has the advantages that by arranging a stirrer, a material is uniformly fed, so that the blockage of the equipment by the fed material is prevented, and the processing efficiency is improved; by arranging an energy recycling device, the heat energy ofair can be recycled, the loss of heat energy resources is prevented, and the secondary pollution to environment by the exhaust of hot air is avoided; more energy-saving and environment-friendly effects are realized, the blockage of the equipment is prevented, the straw particles are quickly discharged, and the equipment processing is more efficient.

Owner:宋晴

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com