Anaerobic reactor for treating high-concentration organic wastewater

A technology of organic wastewater treatment and anaerobic reactor, which is applied in the field of anaerobic reactor, can solve the problems of high cost of granular sludge inoculation, weak salt resistance, weak toxicity resistance, poor load impact resistance, etc., and achieve good mass transfer Heat transfer effect, high volume load, stable and reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

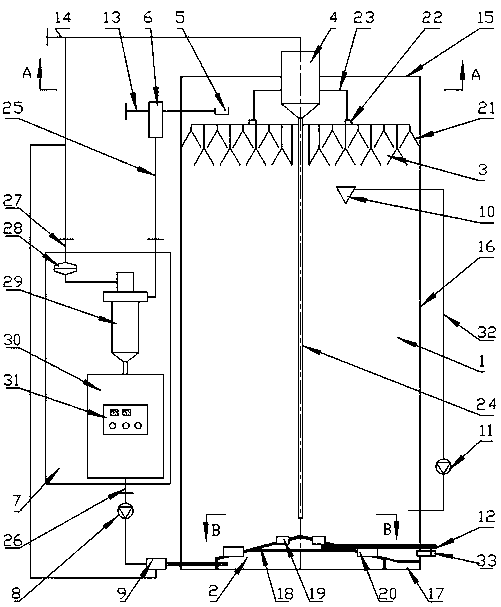

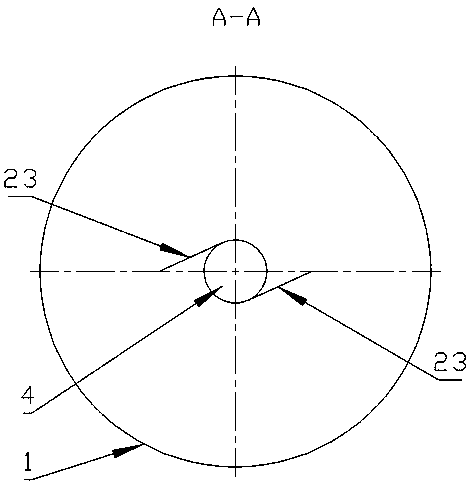

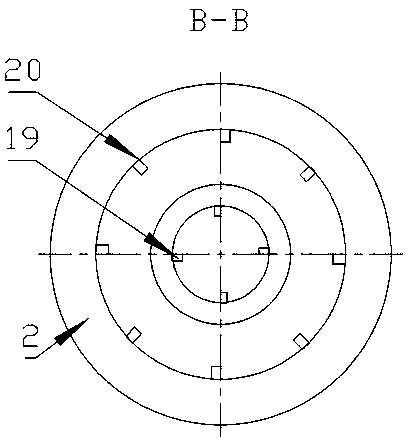

[0038] An anaerobic reactor for the treatment of high-concentration organic wastewater, comprising: a tank body 1, a sludge tower 2, a three-phase separator 3, a gas-liquid separator 4, an outlet weir 5, an outlet water distributor 6, and a heat storage device 7. External circulation pump 8, gas-liquid mixer 9, reflux collector 10, internal circulation pump 11, water inlet pipe 12, water outlet pipe 13, biogas pipe 14, liquid rising pipe 23, downcomer pipe 24, external circulation pipe 25, The hot liquid outlet pipe 26, the air inlet pipe 27, the internal circulation pipe 32 and the sludge discharge outlet 33; the tank body 1 is composed of: the irrigation top 15, the cylinder body 16 and the tank bottom 17; the sludge tower 2 is a tower structure, and the tower body 18 1. The water inlet distributor 19 and the outer circulation distributor 20 are composed; the three-phase separator 3 is composed of a separation screen 21 and an air collection chamber 22; it is characterized in...

Embodiment 2

[0056] The difference between embodiment 2 and embodiment 1 of an anaerobic reactor for the treatment of high-concentration organic wastewater is:

[0057] The upper part of the tower body 18 on the sludge tower 2 is a conical structure, and its apex angle is 120-165 degrees.

[0058] The setting of the conical apex angle at the top of the sludge tower 2 is to improve the mixing effect of water and air and to discharge water and air evenly into the tank, which is beneficial to the mixing of water and mud.

[0059] work process

[0060] An anaerobic reactor for the treatment of high-concentration organic wastewater. After injecting high-concentration organic wastewater mixed with microorganisms into the inner cavity of the tank body 1 through the sludge tower 2, the organic waste in the sewage is degraded by microorganisms. Pollutants are removed and biogas is generated, and then through the separation of gas, liquid and solid by the three-phase separator 3, the degraded sewag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com