A kind of preparation method of non-fired porous ceramsite with high closed porosity

A technology of high closed porosity and porous ceramics, which is applied in the field of solid waste recycling and materials, can solve the problems of adjusting the pore structure without considering decomposition, and achieve the effect of realizing solid waste recycling, reducing emissions, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

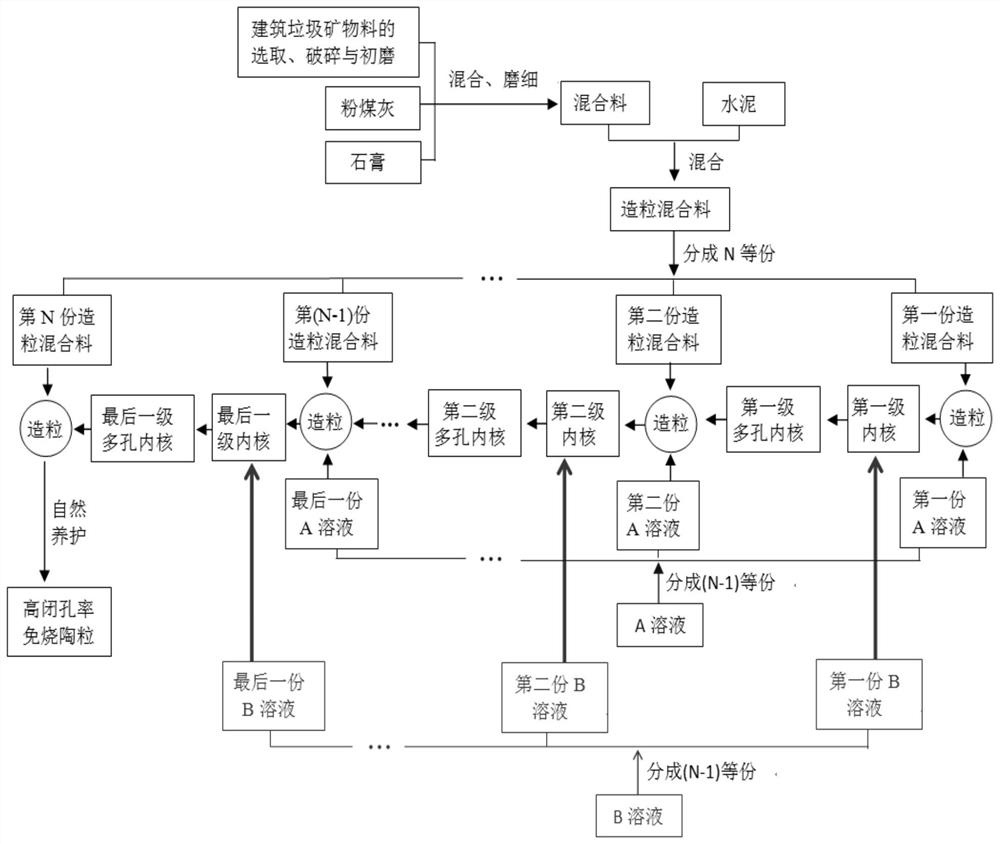

Method used

Image

Examples

Embodiment 1

[0043] (1) Select the mineral material in the construction waste, crush and initially grind to obtain about 100 mesh powder;

[0044] (2) Mix 44 parts of construction waste mineral materials, 20 parts of fly ash, and 1 part of gypsum, and grind the mixture to ~200 mesh;

[0045] (3) Take 15 parts of cement, mix the cement with the mixture obtained in (2) to obtain the granulated mixture, and divide it into 5 equal parts;

[0046] (4) Take 2 parts of ammonium bicarbonate 2; Take 8 parts of water, dissolve 2 parts of ammonium bicarbonate taken in water, obtain A solution, and divide the solution into 4 equal parts;

[0047] (5) Mole ratio is NH 4 + :OH - =1:4 Weigh calcium hydroxide, get 10 parts of water, dissolve calcium hydroxide in water to obtain B solution, and divide it into 4 equal parts;

[0048] (6) Take a portion of the granulation mixture obtained in (3) and place it in a granulator, take a portion of the A solution obtained in (4) and evenly spray it on the powd...

Embodiment 2

[0056] (1) Select the mineral materials in the construction waste, crush and primary grind to obtain ~100 mesh powder;

[0057] (2) Take 50 parts of construction waste mineral materials, 16 parts of fly ash, and 2 parts of gypsum to mix, and grind the mixture to about 200 meshes;

[0058] (3) Take 15 parts of cement, mix the cement with the mixture obtained in (2) to obtain the granulated mixture, and divide it into 5 equal parts;

[0059] (4) Take by weighing 0.5 part of ammonium chloride, 0.5 part of ammonium nitrate (counted as 1 part of blowing agent); Take by weighing 10 parts of water, dissolve 1 part of blowing agent taken by weighing in water, obtain A solution, and Divide the solution into 4 equal parts;

[0060] (5) Mole ratio is NH 4 + :OH - =1:2 Weigh sodium hydroxide, get 6 parts of water, dissolve sodium hydroxide in water to obtain B solution, and divide it into 4 equal parts;

[0061] (6) Take a portion of the granulation mixture obtained in (3) and place ...

Embodiment 3

[0069] (1) Select the mineral material in the construction waste, crush and initially grind to obtain about 100 mesh powder;

[0070] (2) Mix 40 parts of construction waste mineral materials, 22 parts of fly ash, and 3 parts of gypsum, and grind the mixture to ~200 mesh;

[0071] (3) Take 15 parts of cement, mix the cement with the mixture obtained in (2) to obtain the granulated mixture, and divide it into 5 equal parts;

[0072] (4) Take by weighing 0.5 part of ammonium bicarbonate, 0.5 part of ammonium acetate (counted as 1 part of blowing agent); Take by weighing 13 parts of water, dissolve 1 part of blowing agent taken by weighing in water, obtain A solution, and Divide the solution into 4 equal parts;

[0073] (5) Mole ratio is NH 4 + :OH - =1:2 Weigh sodium hydroxide, get 6 parts of water, dissolve sodium hydroxide in water to obtain B solution, and divide it into 4 equal parts;

[0074] (6) Take a portion of the granulation mixture obtained in (3) and place it in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com