Medicinal powder granulating device

A technology of medicinal powder and granulation, which is applied in the direction of making medicines into special physical or taking forms of devices, etc., can solve the problems of affecting production efficiency, low granulation yield, and slow granulation speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

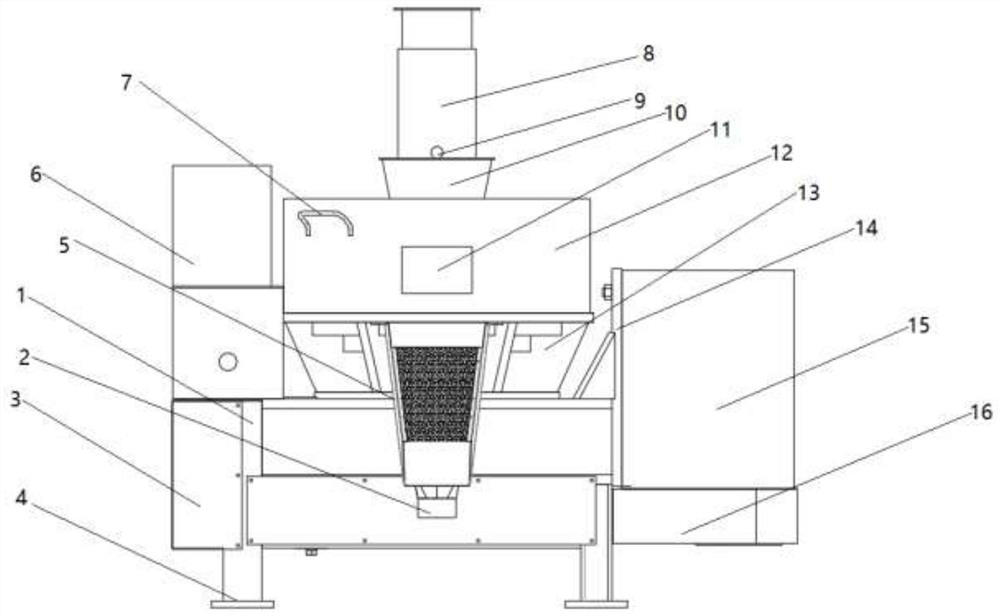

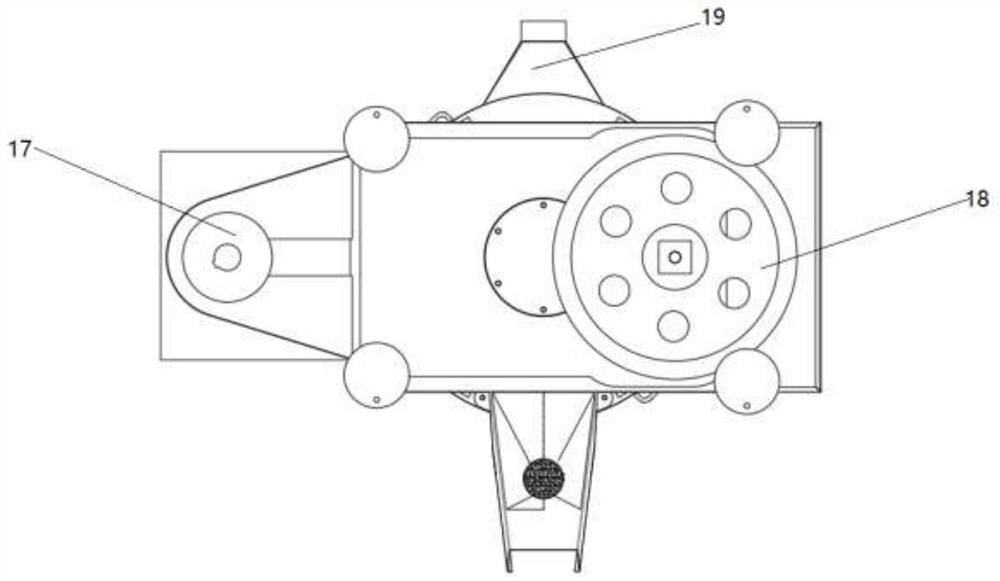

[0020] Such as Figure 1-3 As shown, a medicine powder granulation device includes a main frame 1, a granulation mechanism is installed on the upper end of the main frame 1, and a power mechanism is installed on the lower end of the main frame 1, and the power mechanism drives the granulation mechanism;

[0021] Described main frame 1 comprises four supporting legs 4, and one side of described main frame 1 is equipped with motor mounting plate 14, and the lower end of described motor mounting plate 14 is equipped with belt wheel cover 16, and the other three of described main frame 1 The side covers are respectively fixed with nuts.

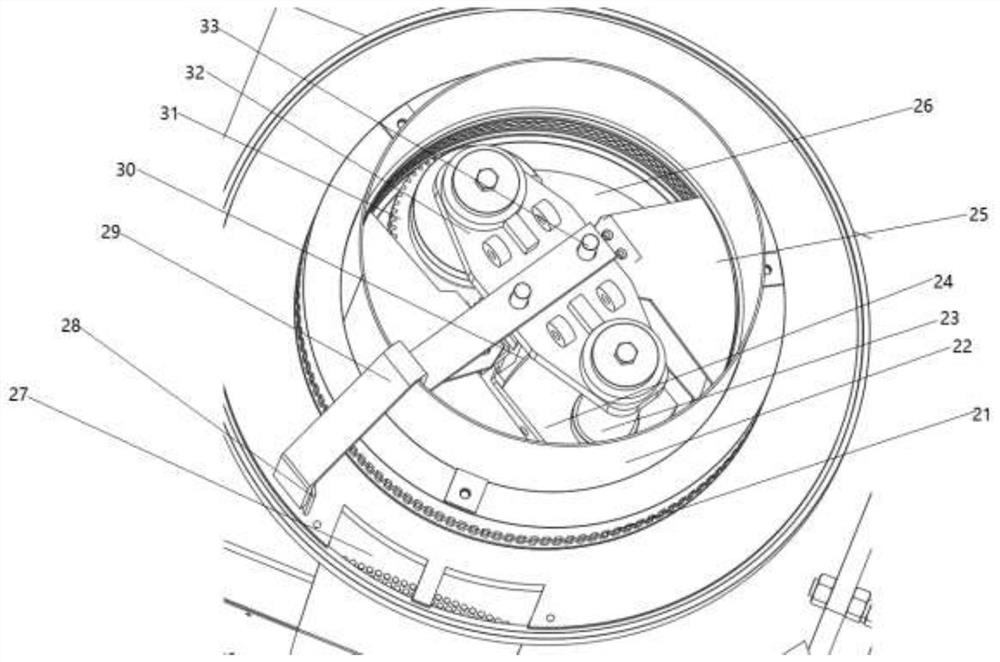

[0022] Described granulation mechanism comprises a lower mold base 13, and described lower mold base 13 is an inverted circular step shape, and fixed mold is installed on the upper end of described lower mold base 13, and described fixed mold is a ring seat , the circumference of the fixed mold 21 is evenly provided with several round holes; the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com