Patents

Literature

30results about How to "Granulation speed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

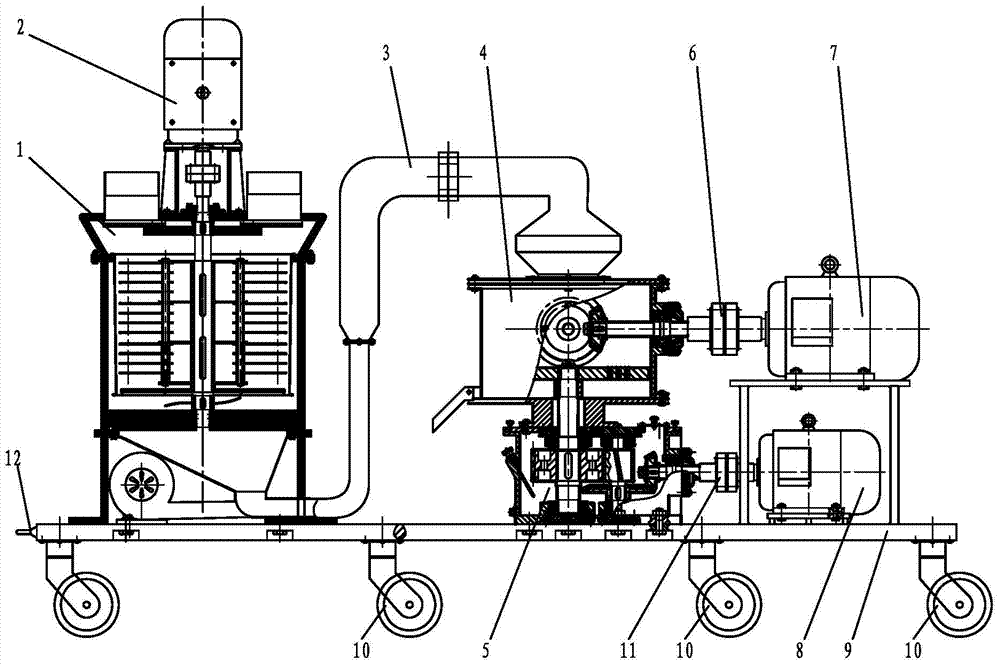

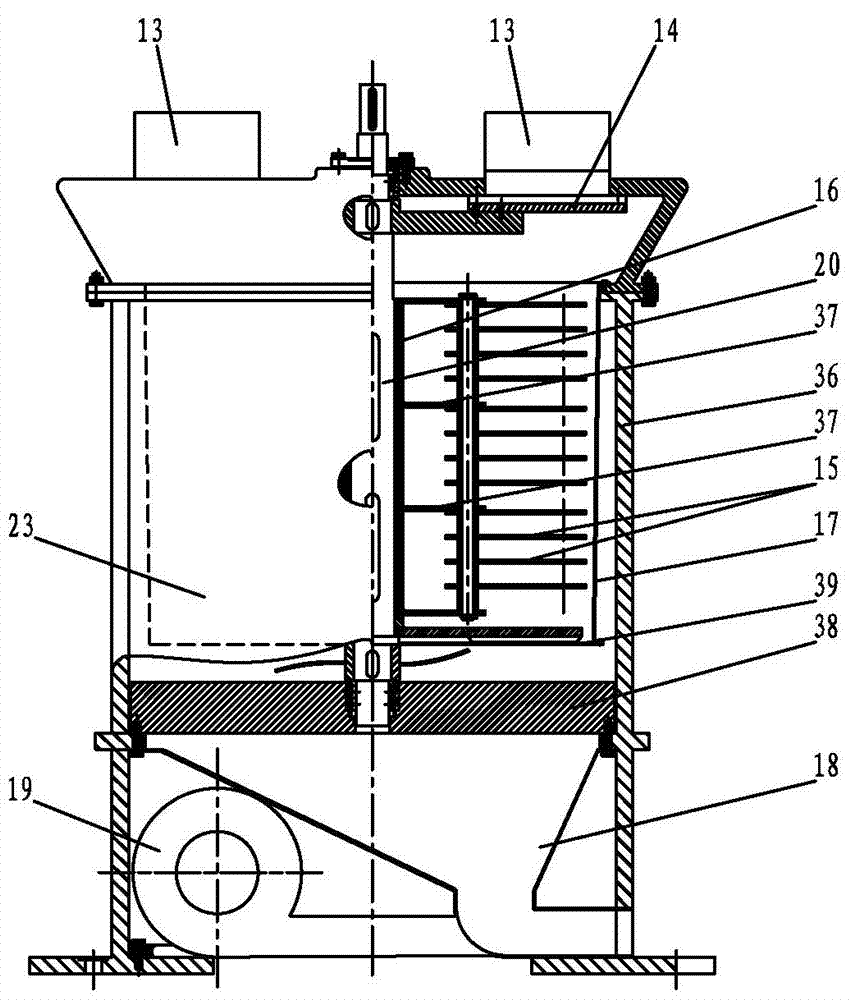

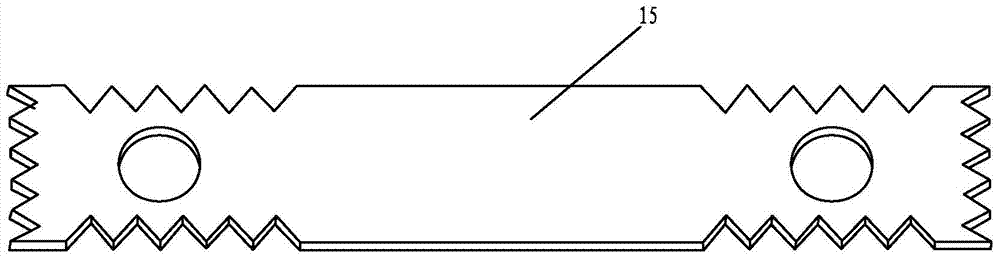

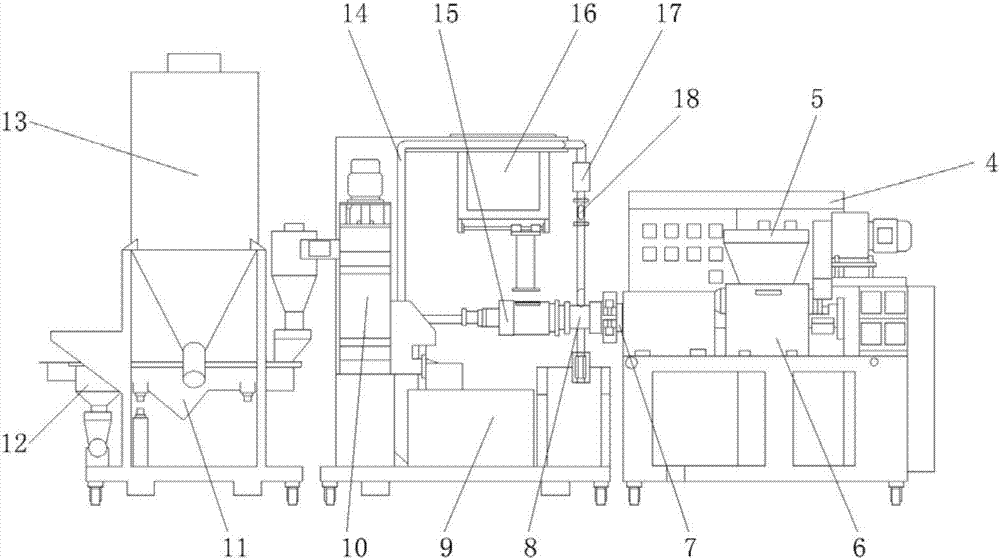

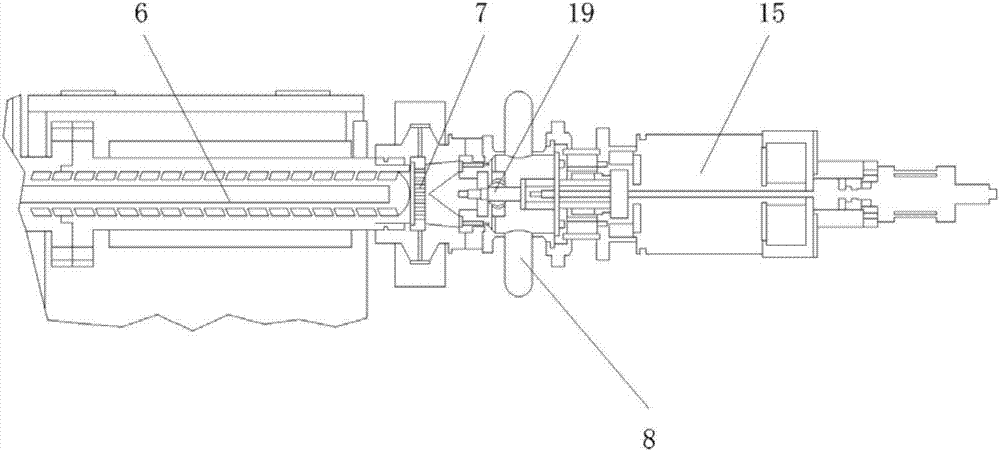

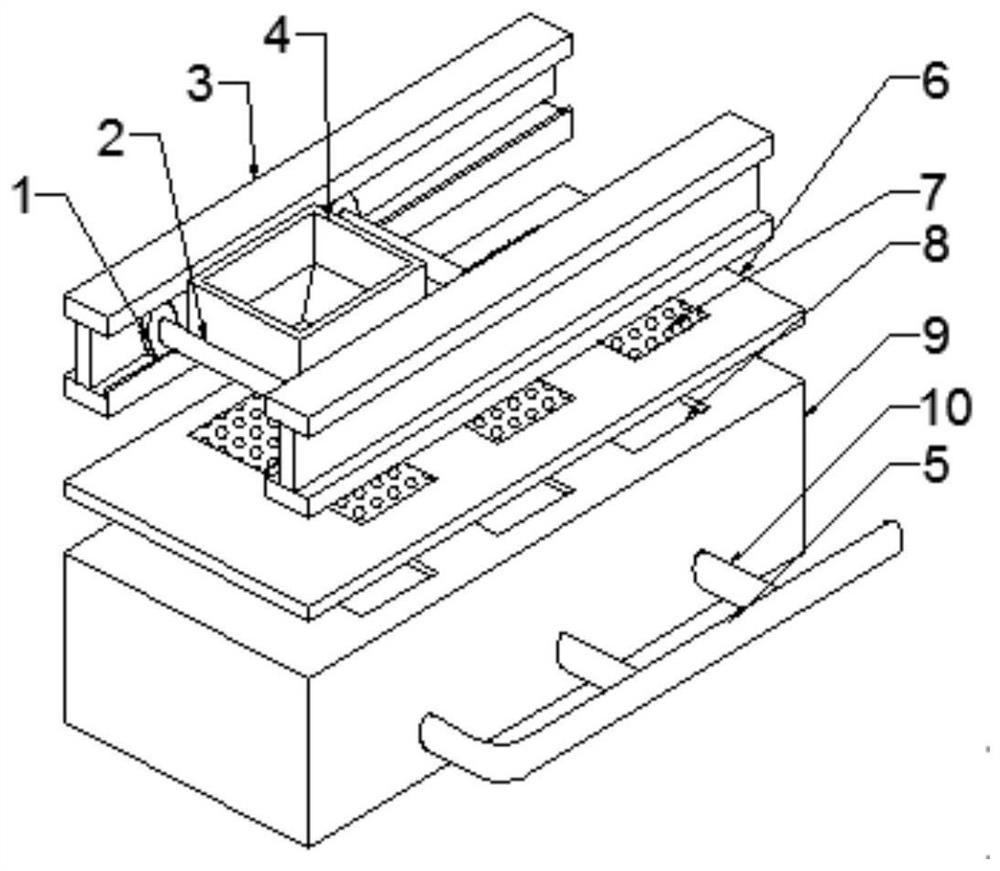

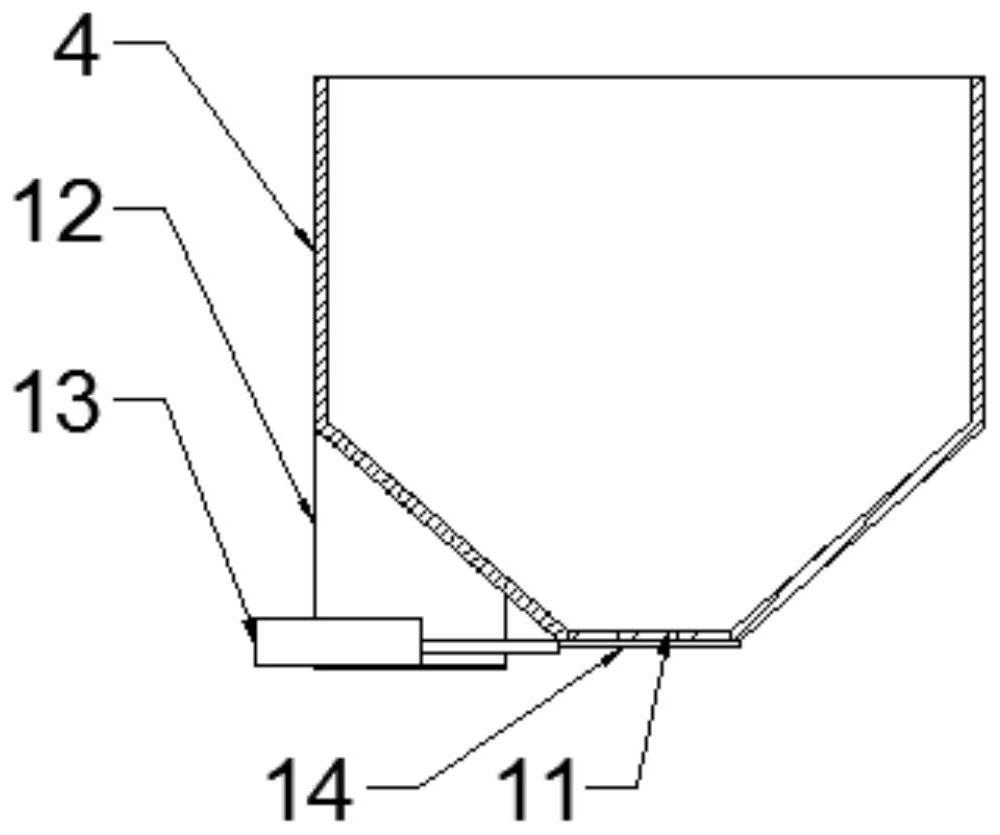

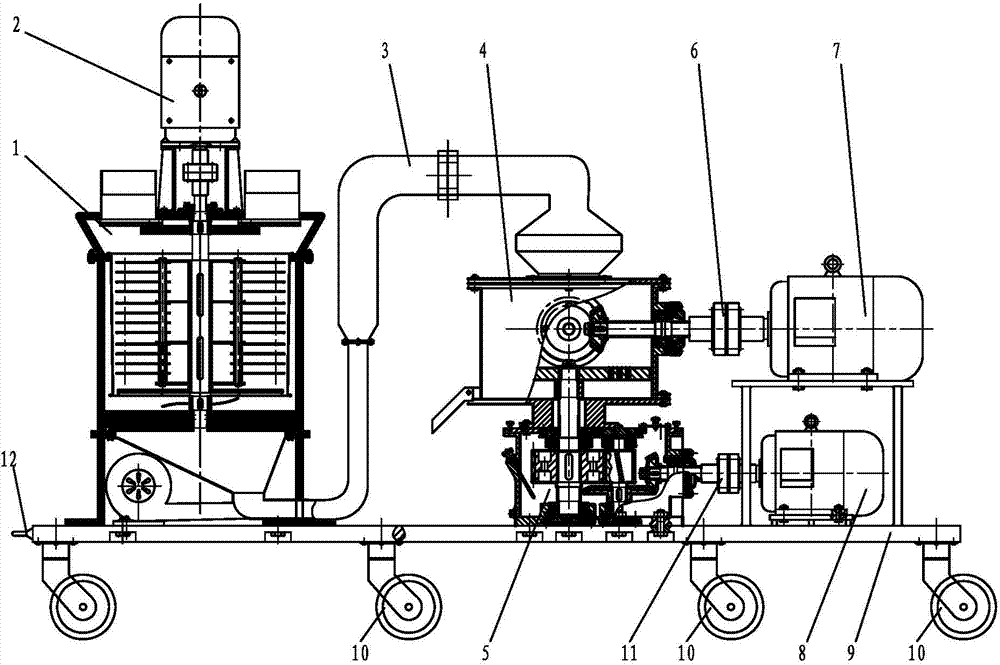

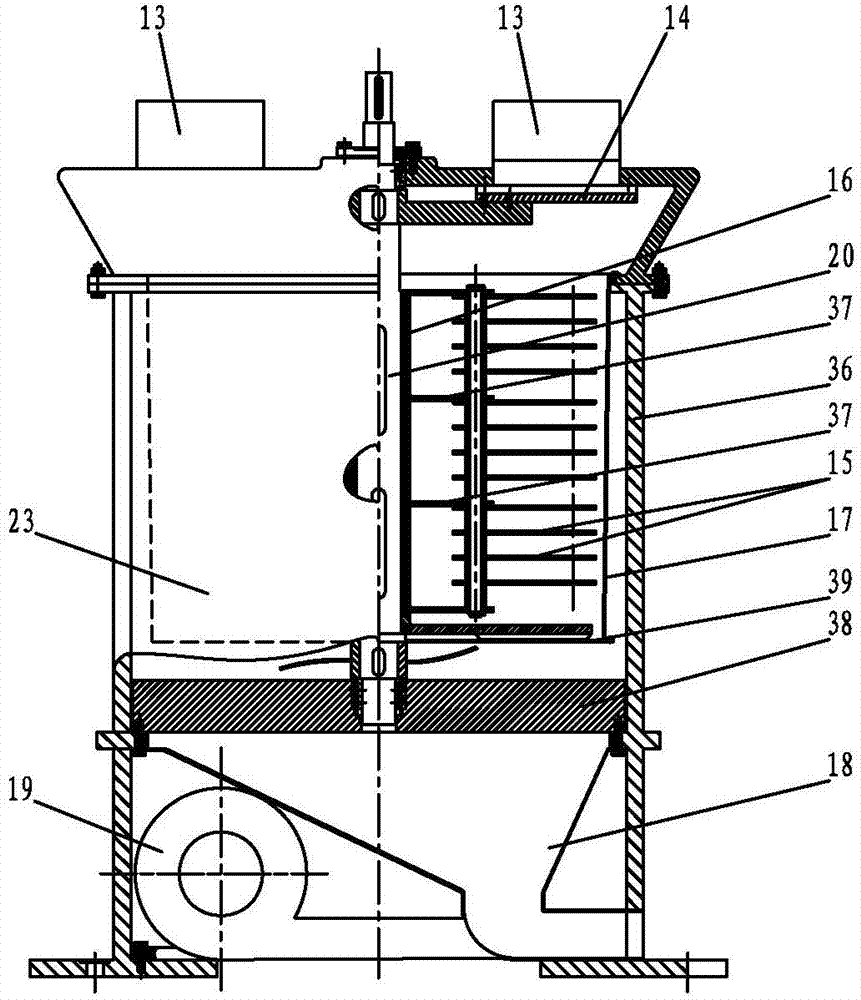

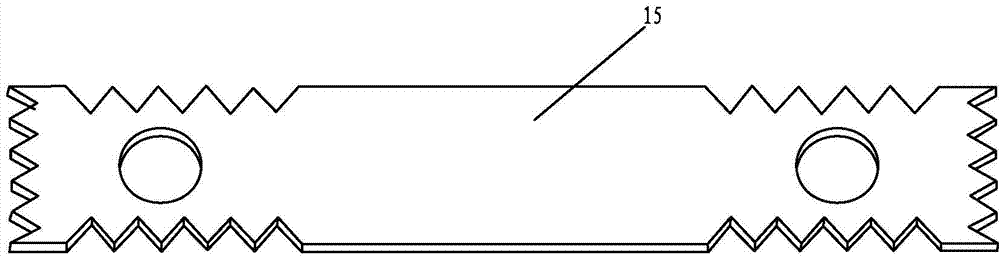

Biomass straw smashing and forming all-in-one machine

InactiveCN103495484ABig hitImprove crushing efficiencyGranulation by pressingGrain treatmentsWork cycleAir blower

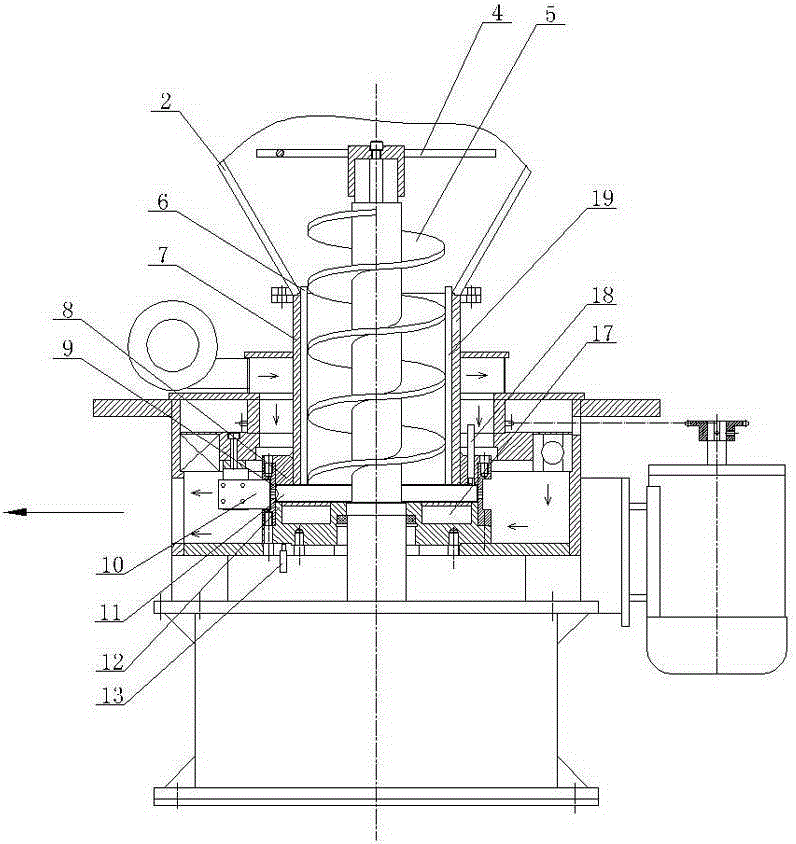

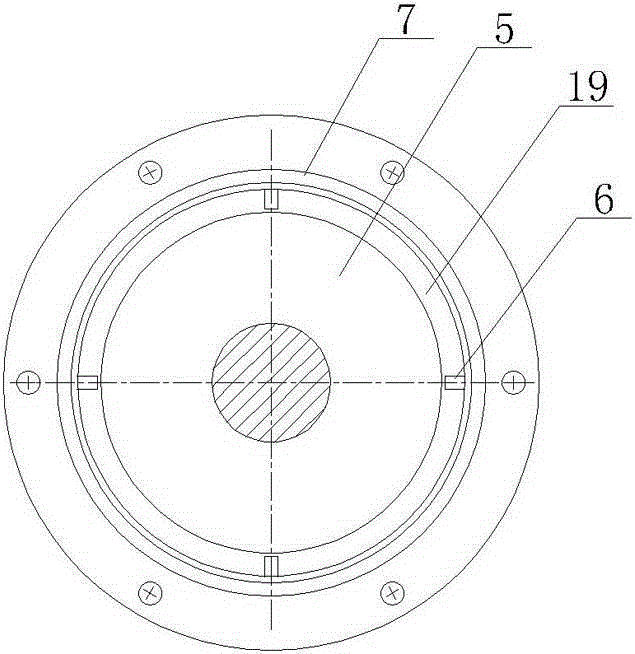

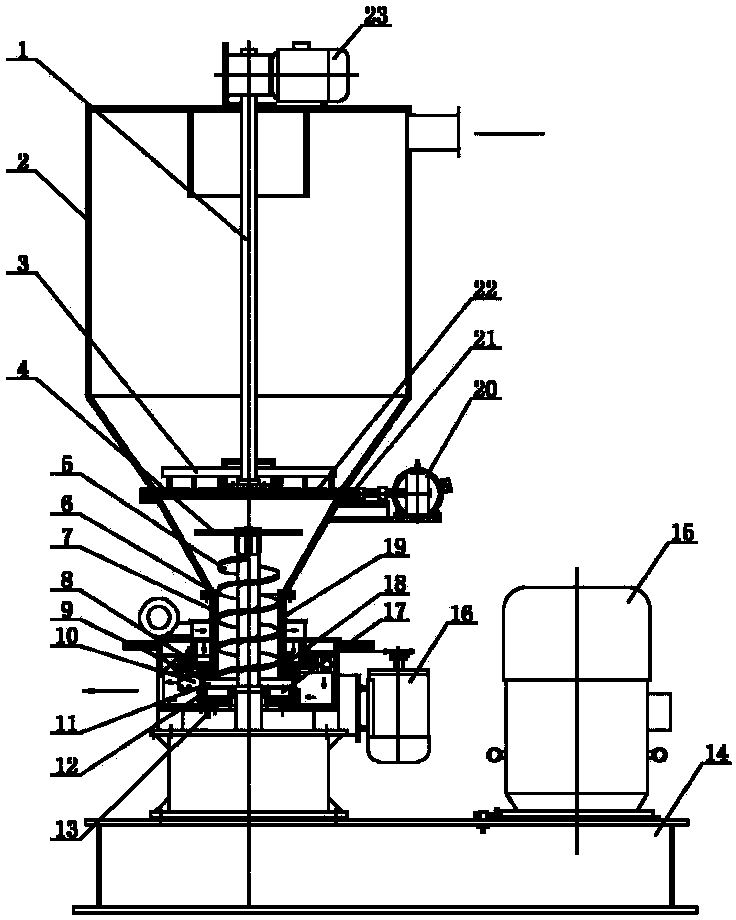

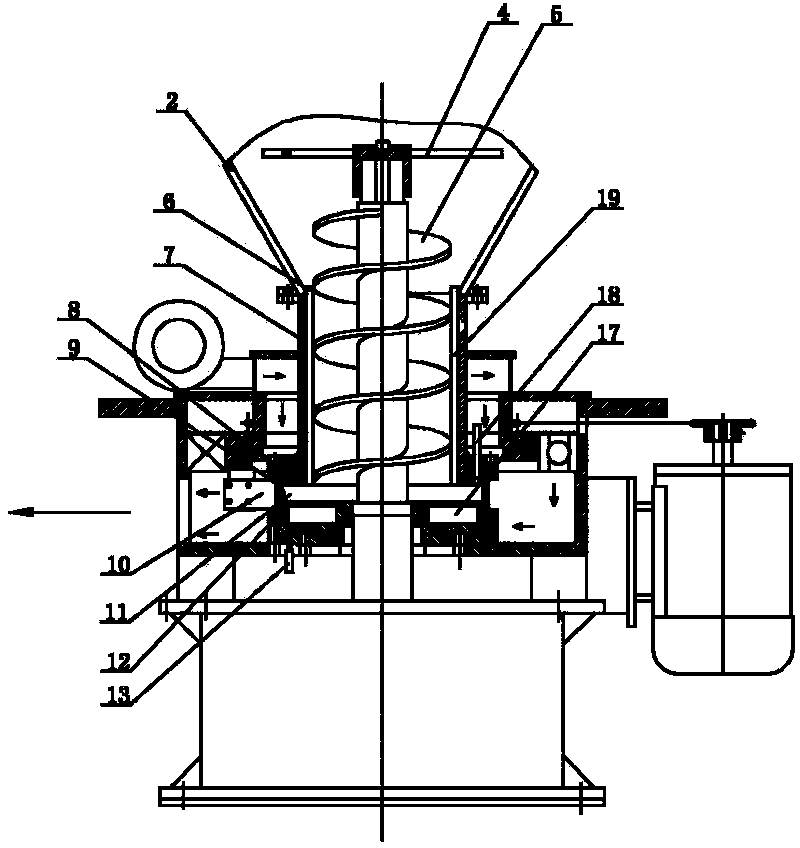

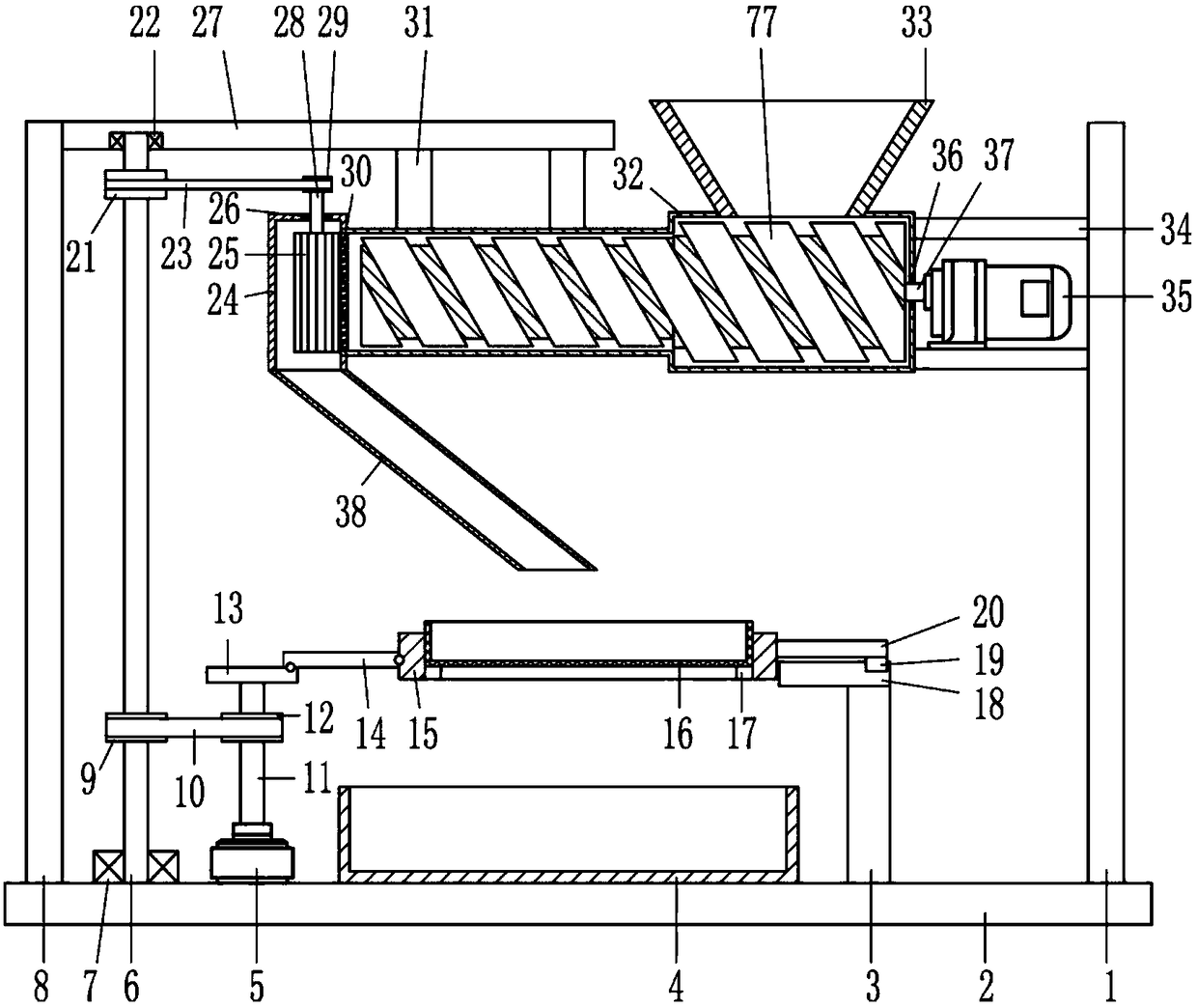

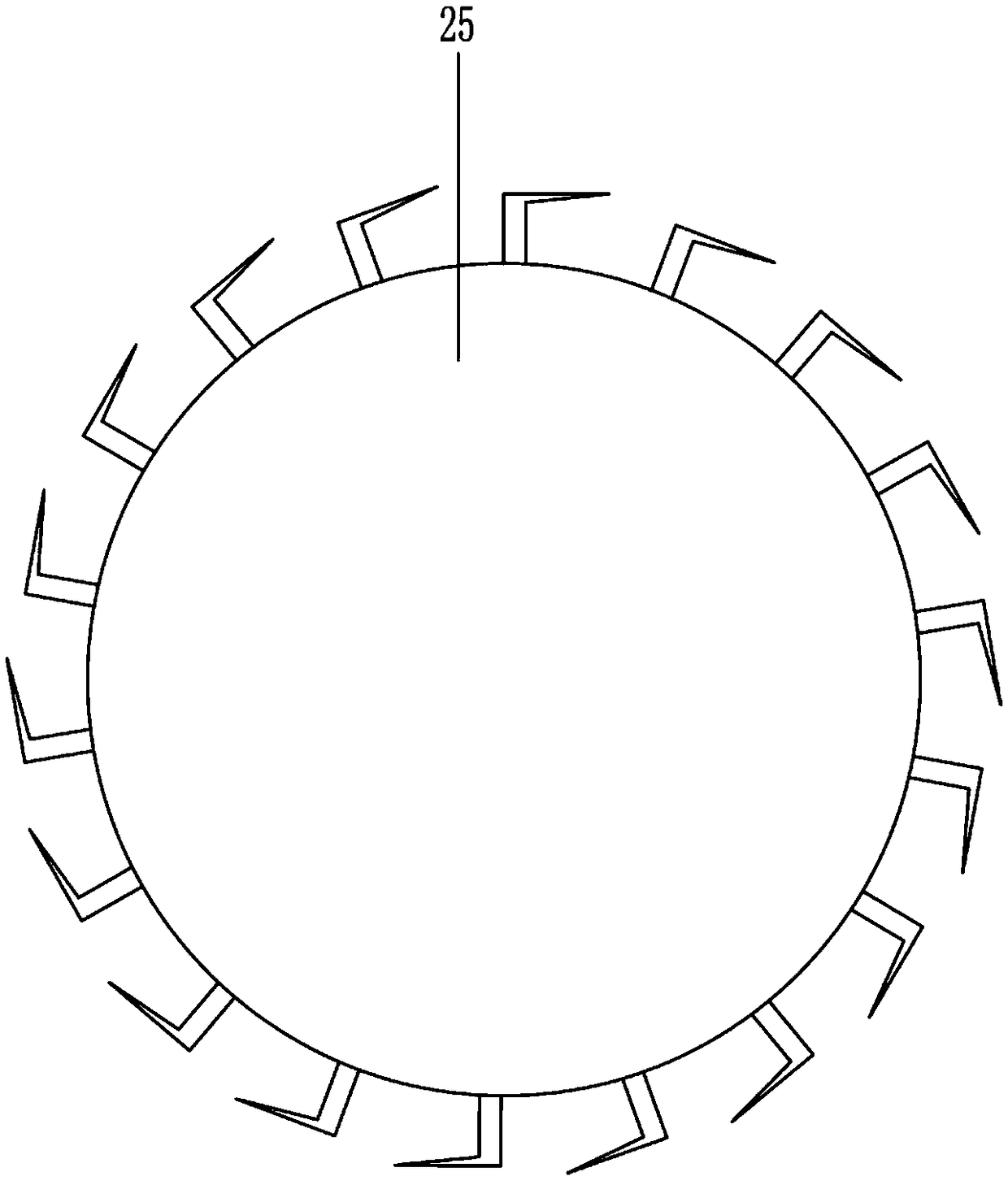

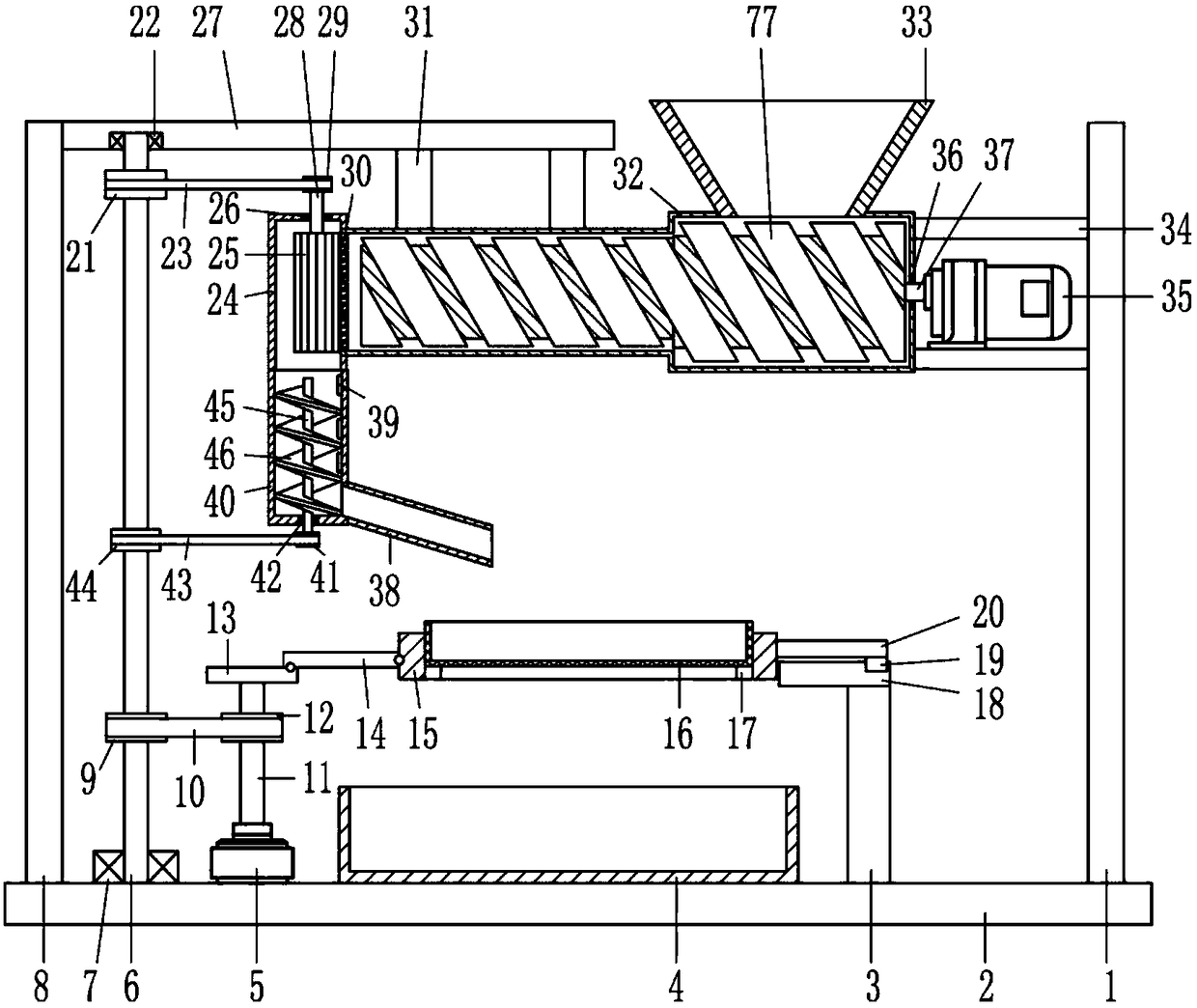

The invention provides a biomass straw smashing and forming all-in-one machine, and relates to a straw smashing and forming device. The biomass straw smashing and forming all-in-one machine solves the problems that in an existing straw forming fuel production process, the straw smashing procedure and the compressing and compacting forming procedure are independently completed through a smashing device and a squeezing forming device respectively, the power consumption is high, the logistics cost is high, and the working cycle is long. The vertical smashing device and the squeezing forming device are arranged on a walking plate in parallel from front to back, walking wheels are arranged below the walking plate, a blade is arranged at the bottom of a feed port of the vertical smashing device, a main shaft of the smashing machine is sleeved with a sleeve, hammer carrier plates are arranged on the sleeve from top to bottom, a hammer set is arranged between every two adjacent hammer carrier plates in an annular mode, hammers of each hammer set are evenly arranged in the vertical direction, each hammer is of a multi-tooth-edge rectangular structure, an air blower is arranged at the bottom of a machine shell and communicate with a material storage hopper, and the material storage hopper is communicated with an inlet of the squeezing forming device through an air duct. The biomass straw smashing and forming all-in-one machine is used for smashing and forming biomass straw.

Owner:NORTHEAST FORESTRY UNIVERSITY

Baking-free cylindrical attapulgite fire-retarding ceramsite

The invention discloses baking-free cylindrical attapulgite fire-retarding ceramsite. The key point of the technical scheme is that the baking-free cylindrical attapulgite fire-retarding ceramsite consists of high-viscosity attapulgite clay powder, attapulgite clay tailing powder, granulated blast-furnace slag powder, iron tailing powder, coal gangue powder, bauxite tailing powder, kieselguhr tailing powder and aluminate cement. The baking-free cylindrical attapulgite fire-retarding ceramsite is produced by the following steps of mixing the ingredients, granulating, maintaining, sieving and packaging. The baking-free cylindrical attapulgite fire-retarding ceramsite has a rough and hard surface, and is high in compression strength, low in heat conductivity, high in refractoriness and corrosion resistance and good in heat-preserving and sound-insulating effect; and a large amount of fine pores are formed in the ceramsite,. The baking-free cylindrical attapulgite fire-retarding ceramsiteis produced by utilizing multiple tailings comprehensively, so that the utilization rate of resources is improved, waste materials are changed into wealth, and environment is protected. Besides, the baking-free cylindrical attapulgite fire-retarding ceramsite is suitable for producing fire-retarding ceramsite concrete and heat-preserving and sound-insulating materials.

Owner:NANGTONG HAODI ANTICORROSION EQUIP

Method of pelletizing high temperature alloy liquid

The present invention relates to a kind of pelletizing high temperature alloy liquid. The production process includes pelletizing in rotary table as one a rotation part and water quenching the pellets. The production process is simple and has alloy temperature of 200-2000 deg.c, stable alloy pellet size of 0.5-5 mm, low investment in equipment, low power consumption and low cost.

Owner:KUNYANG PHOSPHATE FERTILIZER PLANT YUNNAN PROV

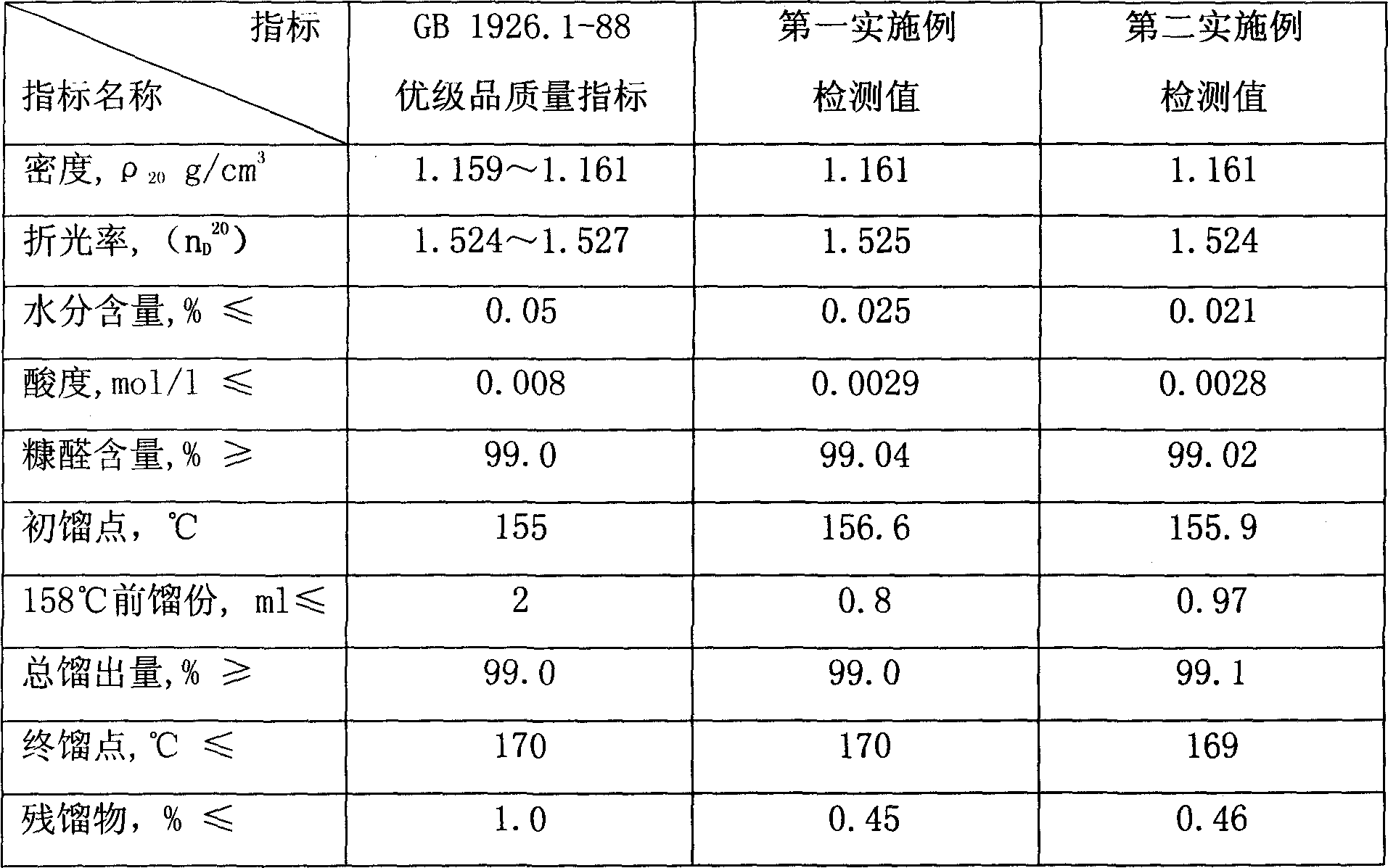

Method for producing furol by plant stalk pelletizing

InactiveCN1858044ASuitable for industrial productionStable and reliable productionOrganic chemistryDistillationPlant stalk

The plant stalk pelletizing process for producing furol belongs to the field of furol preparing technology. The process includes the following steps: cutting plant stalk into 2-4 cm long segments, controlling water content, crushing into powder, pelletizing, mixing with acid, hydrolysis to raw furol liquor, leading the raw furol liquor to the primary distillation tower to obtain raw furol and refining in a furol refining apparatus to obtain furol product. The production process is stable, reliable, low in production cost, high in furol yield and high in furol quality.

Owner:JINAN SHENGQUAN GROUP SHARE HLDG

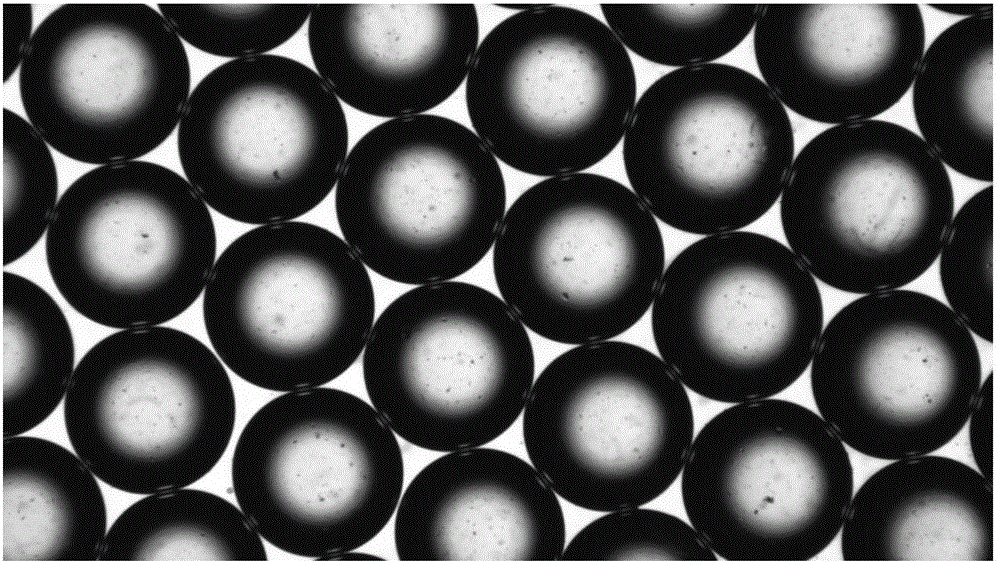

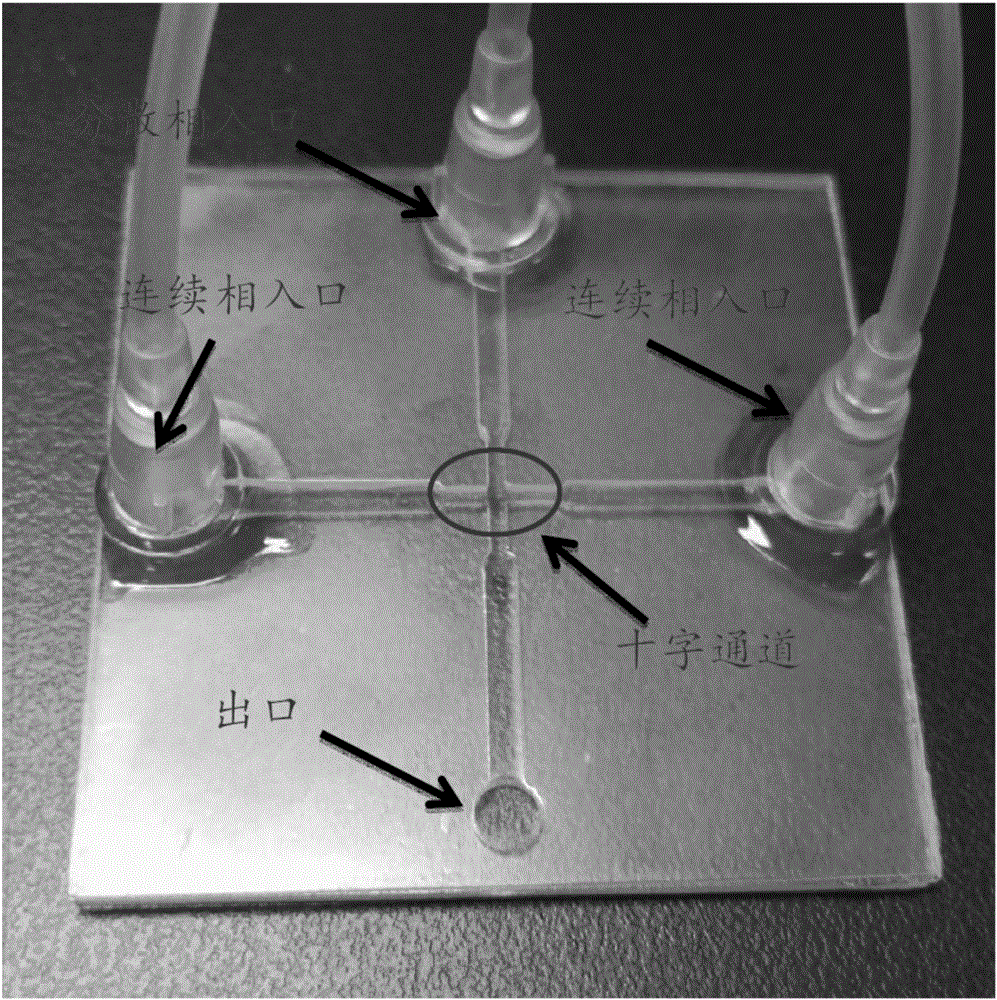

Microfluidic one-step synthesis method of chitosan microspheres for heavy metal wastewater treatment

InactiveCN105709696AShort manufacturing processSimple methodOther chemical processesWater contaminantsMicrofluidic chipAqueous solution

The invention provides a chitosan microsphere microfluidic one-step synthesis method for heavy metal wastewater treatment, the method comprising the following steps: a. preparing chitosan aqueous solution as the dispersed phase; b. preparing the oil added with cross-linking agent phase as the continuous phase; c. passing the obtained continuous phase and the dispersed phase into the microfluidic chip for shearing, forming chitosan droplets, and cross-linking and curing; and d. the obtained cross-linking and curing chitosan particles After washing, dry to obtain chitosan microspheres.

Owner:EAST CHINA UNIV OF SCI & TECH

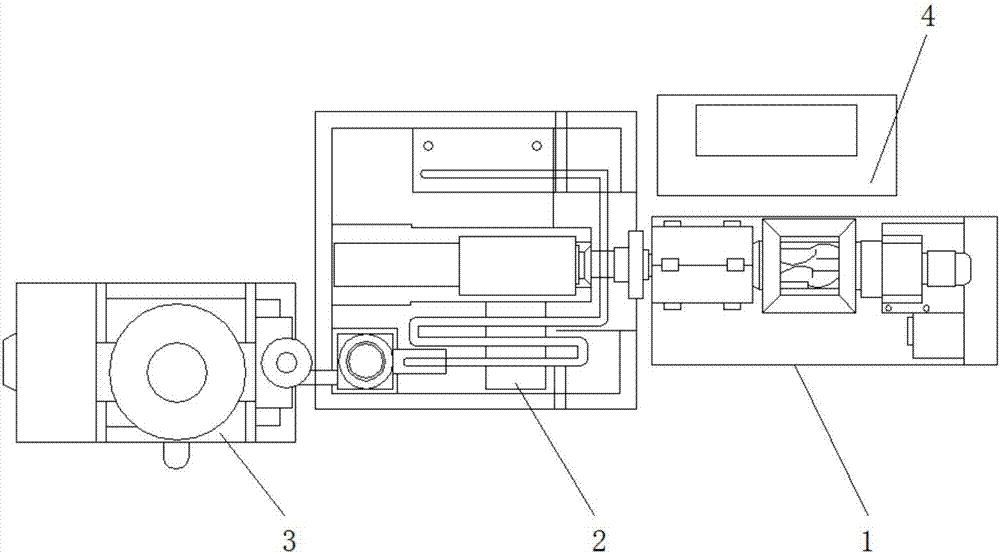

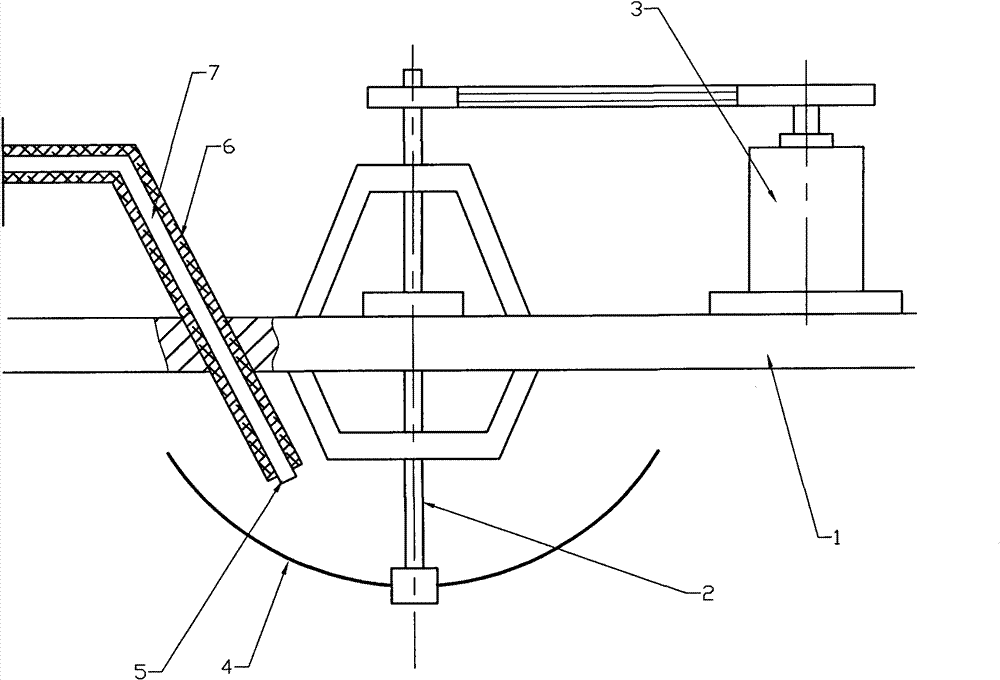

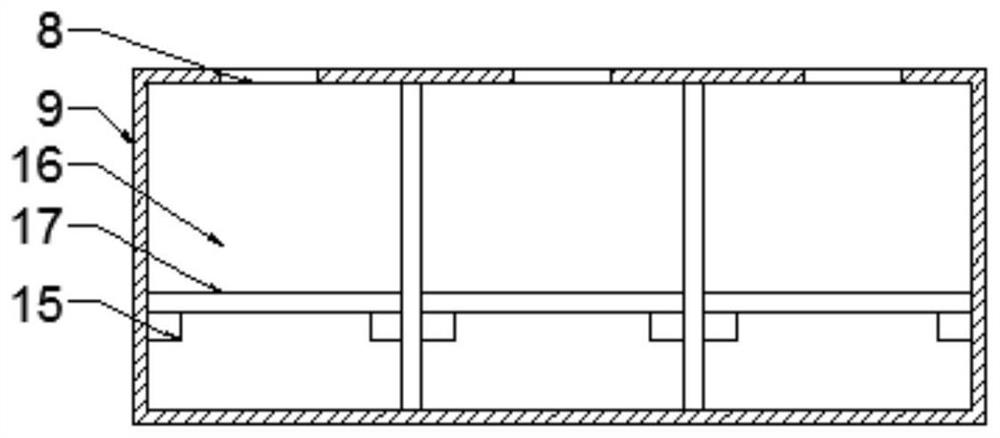

Full-automatic underwater pelletizing unit

PendingCN107283667AReasonable structureNo pollution in the processCoatingsAutomatic controlWater storage tank

The invention discloses a full-automatic underwater pelletizing unit. The full-automatic underwater pelletizing unit comprises an extrusion mechanism, a pelletizing template and a water removing machine. The left side of the extrusion mechanism is connected with a pelletizing water removing mechanism. The left side of the pelletizing water removing mechanism is provided with a drying storage mechanism. An electrical control cabinet is arranged behind the extrusion mechanism. A pelletizing motor is connected to the side face of a pelletizing chamber. The water removing machine is connected with a lower water storage tank. The left side of the water removing machine is connected with a vibration screen together. The side face of the vibration screen and a storage tank are fixedly installed together through a draught fan. According to the full-automatic underwater pelletizing unit, water cooling circulation usage is adopted, an impurity filtering system is arranged in the water tank, the whole machine does not discharge water outwards, and resources are saved. Meanwhile, viscosity of materials can be ignored during underwater pelletizing, the pelletizing speed is high, efficiency is high, and dust and smoke pollution is avoided; and meanwhile, through a PLC touch screen, full-automatic production control is achieved for the whole machine, pelletizing work can be better conducted, and development of the pelletizing machine industry is promoted.

Owner:JINJIANG LUGANG PLASTIC MACHINERY

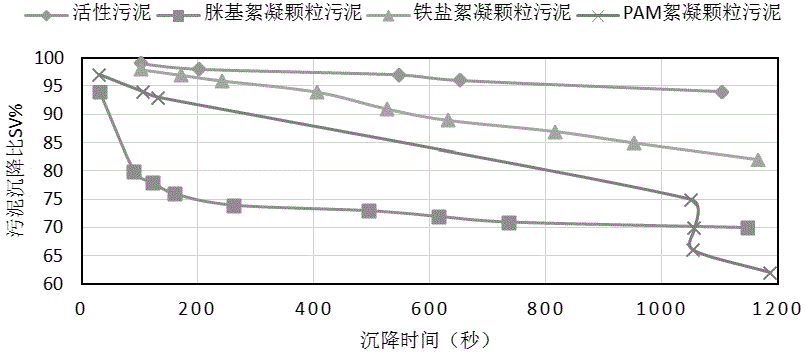

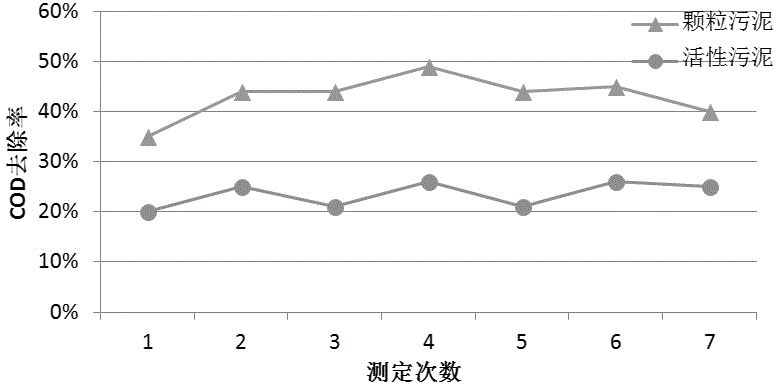

Preparation method for aerobic granular sludge

InactiveCN105585112ASave floor spaceSave investmentOther chemical processesSustainable biological treatmentActivated sludgeOxygen

The invention belongs to the technical field of water treatment, and particularly relates to a preparation method for aerobic granular sludge. The preparation method comprises the steps that firstly, activated sludge in a secondary settling pond is pumped out, then a proper quantity of guanyl containing positive ion macromolecular chemical agent is added into the activated sludge, stirring or fully aeration mixing is carried out, and the needed granular activated sludge can be formed within 30 min. The preparation method has the advantages that compared with the activated sludge, the granular sludge formed by adding a screened guanyl compound is good in settling property, settling time is saved, meanwhile, the biological activity of the sludge is not affected by the added chemical agent, and the efficiency of a waste water treatment system can be improved. According to the method, the pelleting speed for generating the granular sludge is high, the period is short, the system is stable, and the granular sludge can be fast used for engineering practice.

Owner:FUDAN UNIV +1

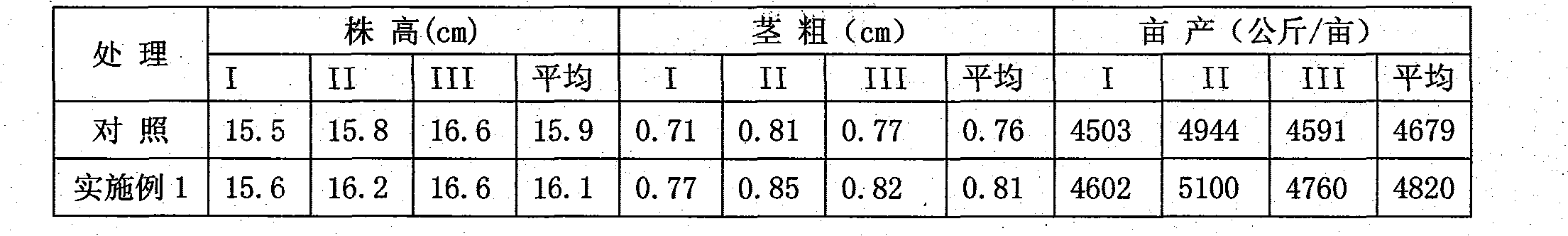

Special fertilizer for oilseed rapes and preparation method of special fertilizer

InactiveCN106431776AIncrease productionGood yieldBioloigcal waste fertilisersFertilizer mixturesDiseaseGround temperature

The invention discloses a special fertilizer for oilseed rapes and a preparation method thereof. The special fertilizer for the oilseed rapes is prepared from the following raw materials in parts by weight: 100 to 150 parts of straw powder, 30 to 50 parts of animal bone meal, 30 to 45 parts of rapeseed dregs, 20 to 35 parts of powdered rock phosphate, 15 to 30 parts of potassium superphosphate, 18 to 25 parts of humus, 4 to 8 parts of saccharides, 0.6 to 1.2 parts of EM stock solution, 10 to 18 parts of modified vermiculite power, 4 to 8 parts of borax, 5 to 9 parts of sepiolite powder, 0.5 to 1 part of plant growth regulator, 15 to 25 parts of traditional Chinese medicine dregs, and 2 to 4 parts of polyvinyl alcohol. According to the special fertilizer for the oilseed rapes and the preparation method thereof provided by the invention, the formula is reasonable, the occurrence rate of rapeseed diseases and insect pests is reduced, the stress resistance of the oilseed rapes is improved, meanwhile, the ecological environment of soil is improved, the damage of overmuch ground temperature change on root parts of the oilseed rapes is effectively relieved, the rapeseed quality is improved, and the yield of the oilseed rapes is increased.

Owner:李梦

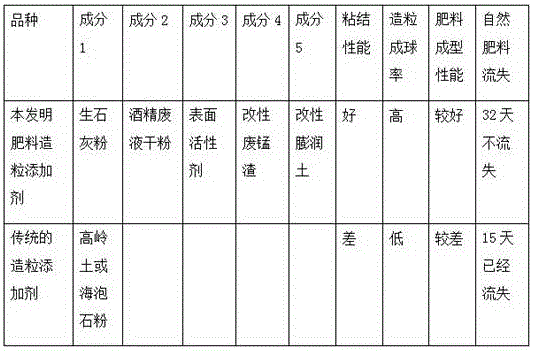

Fertilizer granulation additive and preparation method thereof

InactiveCN106045698AEasy access to resourcesIncrease resourcesCalcareous fertilisersBioloigcal waste fertilisersAlcoholSodium Bentonite

The invention relates to a fertilizer granulation additive and a preparation method thereof. The fertilizer granulation additive is prepared from, in percentage by weight, 3%-5% of quicklime powder, 3%-5% of alcohol waste liquid dry powder, 0.2%-0.5% of a surfactant, 0.5%-1% of modified waste manganese slag and the balance of modified bentonite. The prepared fertilizer granulation additive has high adsorption activity and binding power and contains rich fertilizer effect ingredients. The fertilizer granulation additive is added in the fertilizer granulation process, the fertilizer caking property can be greatly increased, the granulation and balling rate is increased, the granulation speed and the yield of a fertilizer are increased, the granule strength is increased, the water content of the fertilizer can further be reduced, fertilizer caking is prevented, the fertilizer keeps good looseness, and transportation, storage and use of the fertilizer are facilitated. The fertilizer granulation additive is used for granulation of the fertilizer, nutrients of the prepared granule fertilizer can be increased, the synergism effect of the fertilizer is remarkable, the nutrients in the fertilizer can be slowly released, fertilizer waste is reduced, the utilization efficiency of the fertilizer is improved, and the function of improving the soil environment can be realized.

Owner:广西美耕生物科技有限公司

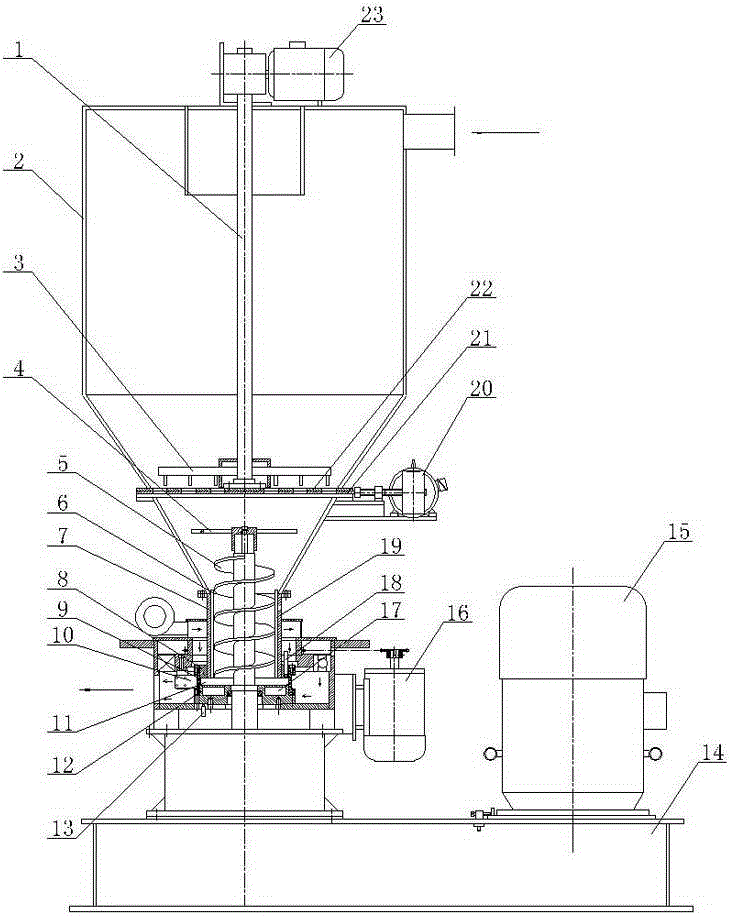

Energy-saving and high-efficiency plastic granulator

The invention discloses an energy-saving efficient plastic granulator, a feeding screw rod is rotationally arranged in a feed barrel, a scraper plate is rotationally arranged in a granulation extrusion cavity, a scraping block is arranged on the excircle of the scraper plate, the scraping block is closely attached to the inner cylinder wall of an extrusion die cylinder, the cylinder wall of the extrusion die cylinder is provided with extrusion holes, and a rotational cut-off tool is arranged on the outer cylinder wall of the extrusion die cylinder; the energy-saving efficient plastic granulator is characterized in that: the inner cylinder wall of the feed barrel is provided with a plurality of vertical ribs, the vertical ribs pass through, from up to down, the whole feed cylinder height, the top circle of the vertical ribs is matched with the excircle of the feeding screw rod, adjacent vertical ribs, and the inner cylinder wall of the feed barrel and the excircle of the feeding screw rod enclose a space to form an inner air circulation channel of the feed barrel. The energy-saving efficient plastic granulator uses the scraping block to grind a material to produce heat to melt the material for plastic granulation, the energy-saving efficient plastic granulator can always smoothly exhaust in the working process, and the unique scraper plate is designed to avoid local overheating of the material so as to avoid obstruction of heat transfer, so that automatic control of blanking and feeding can be achieved, and the entire normal high-speed granulation process and high granulation quality can be ensured.

Owner:RUIAN OULI MACHINE

Energy-saving efficient plastic granulator

The invention discloses an energy-saving efficient plastic granulator, a feeding screw rod is rotationally arranged in a feed barrel, a scraper plate is rotationally arranged in a granulation extrusion cavity, a scraping block is arranged on the excircle of the scraper plate, the scraping block is closely attached to the inner cylinder wall of an extrusion die cylinder, the cylinder wall of the extrusion die cylinder is provided with extrusion holes, and a rotational cut-off tool is arranged on the outer cylinder wall of the extrusion die cylinder; the energy-saving efficient plastic granulator is characterized in that: the inner cylinder wall of the feed barrel is provided with a plurality of vertical ribs, the vertical ribs pass through, from up to down, the whole feed cylinder height, the top circle of the vertical ribs is matched with the excircle of the feeding screw rod, adjacent vertical ribs, and the inner cylinder wall of the feed barrel and the excircle of the feeding screw rod enclose a space to form an inner air circulation channel of the feed barrel. The energy-saving efficient plastic granulator uses the scraping block to grind a material to produce heat to melt the material for plastic granulation, the energy-saving efficient plastic granulator can always smoothly exhaust in the working process, and the unique scraper plate is designed to avoid local overheating of the material so as to avoid obstruction of heat transfer, so that automatic control of blanking and feeding can be achieved, and the entire normal high-speed granulation process and high granulation quality can be ensured.

Owner:RUIAN OULI MACHINE

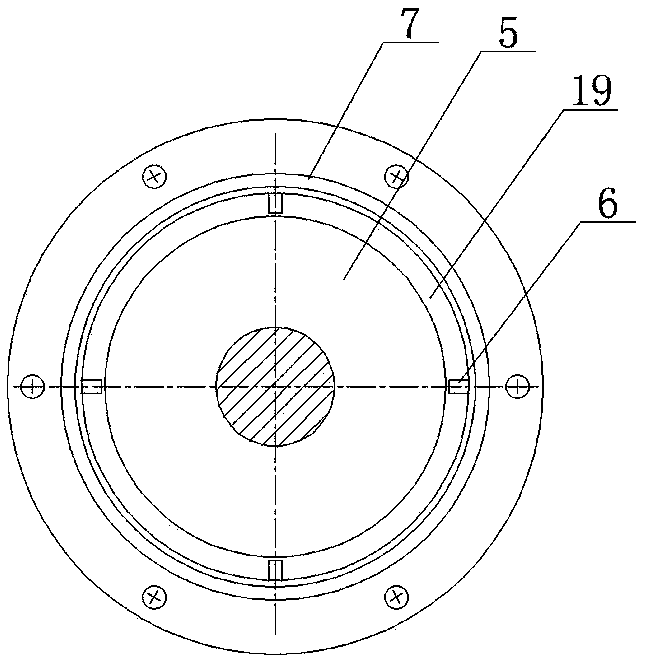

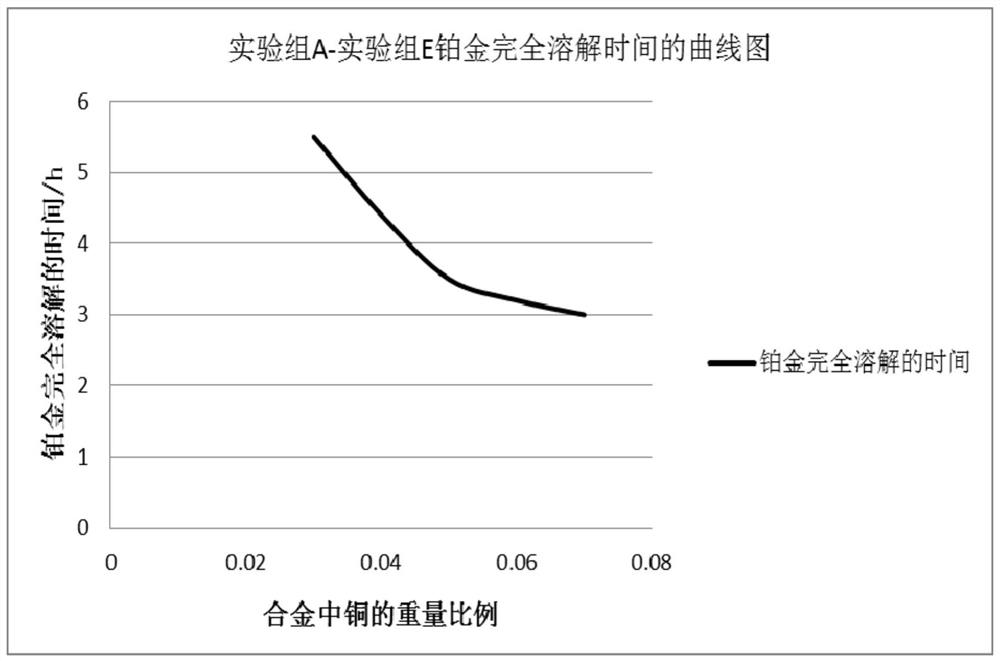

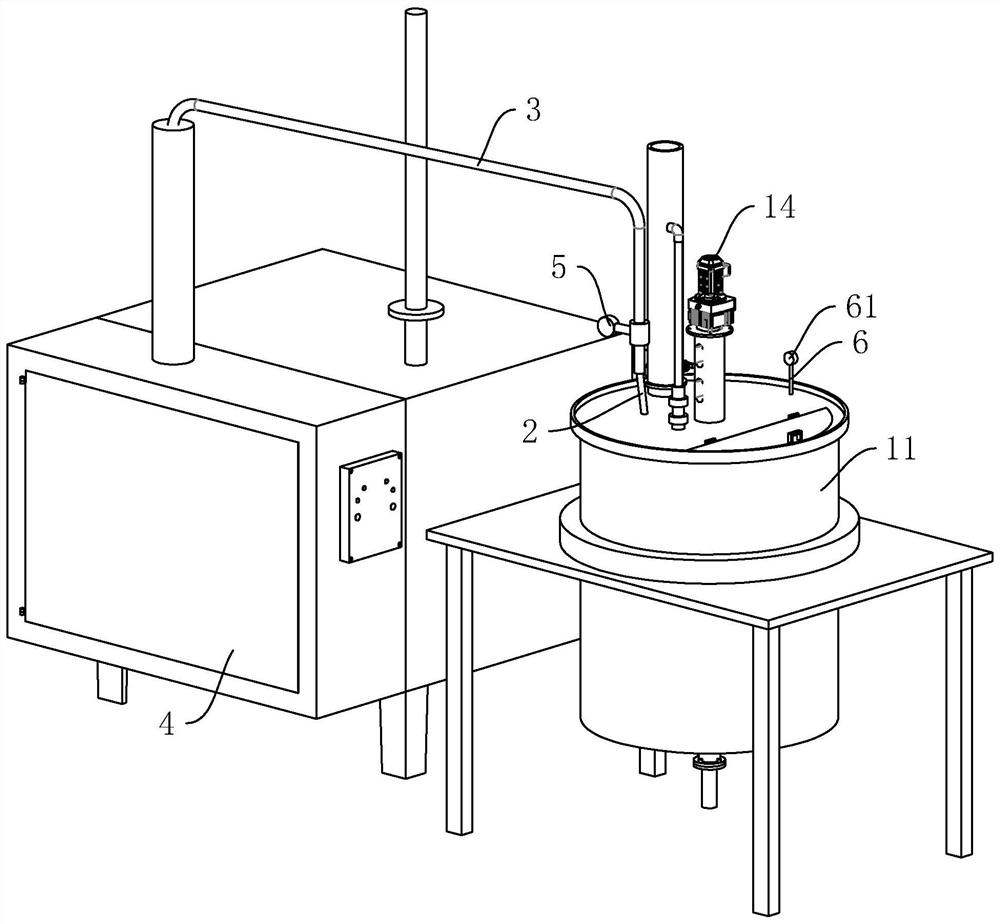

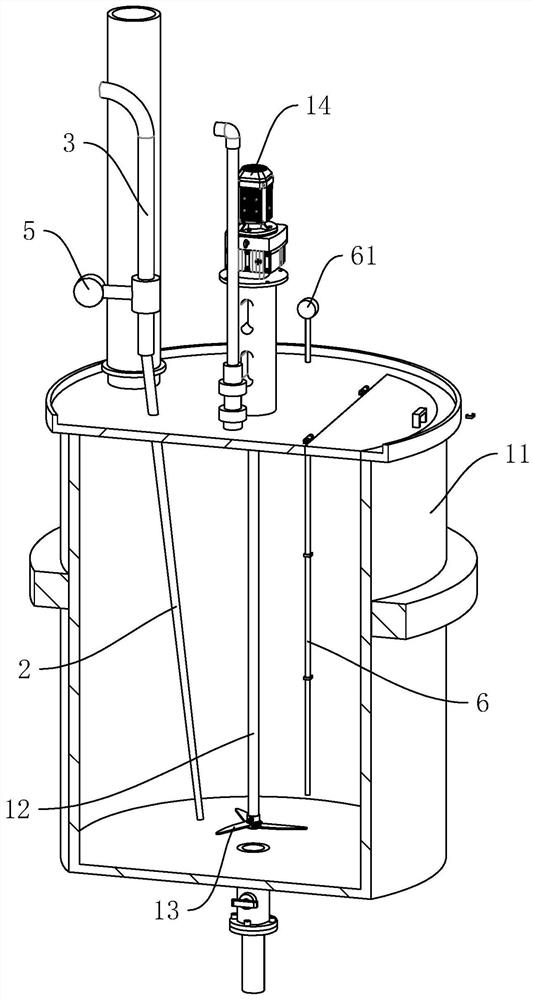

Platinum purification method and reaction kettle

InactiveCN111690819ALarge specific surface areaHigh purityChemical/physical/physico-chemical stationary reactorsDissolution reactionAqua regia

The invention relates to a platinum purification method and a reaction kettle. The problem that in an existing platinum purification technology, the recovery rate of platinum and the purity of spongyplatinum are not easily balanced is solved. The platinum purification method comprises the following steps that a platinum ingot and base metal are mixed together, molten to form liquid gold and processed to form gold grains; the gold grains and aqua regia are added to a dissolution reaction kettle, stirred and heated to enable the gold grains to be dissolved, and dissolved platinum liquid is obtained; the dissolved platinum liquid is added to a separation reaction kettle, ammonium chloride is added, and stirring operation and heating operation are conducted so that platinum ions in a solutioncan be deposited to form ammonium chloroplatinate; residual liquid in the separation reaction kettle is filtered away, the deposited ammonium chloroplatinate is washed and filtered by an ammonium chloride solution; and a reducing agent and the washed deposited ammonium chloroplatinate are added to the separation reaction kettle, ammonium chloroplatinate is reduced, and the pure spongy platinum isobtained, specifically, the weight ratio of the content of platinum in the platinum ingot to ammonium chloride is 1:(1-1.7). The platinum purification method has the advantages of saving the cost andbeing high in platinum primary recovery rate and high in purity of the spongy platinum.

Owner:广东金正龙科技有限公司

Sewage processing process using microbial carrier

ActiveCN110981079ANo swellingSolve the bloat problemWater treatment parameter controlWater treatment compoundsSludgeSewage

The present invention relates to a sewage processing process using a microbial carrier, and belongs to the technical field of sewage processing, and the sewage processing process comprises the following process steps: S1: sewage flows into a primary sedimentation tank for primary sedimentation to obtain primarily precipitated sewage; S2, the primarily precipitated sewage in the step S1 is filteredthrough a grid and then flows into a granulation sludge tank to be treated; S3, the sludge treated by the granulated sludge tank in the step S2 is discharged into a secondary sedimentation tank for secondary sedimentation; and S4, the sewage with qualified water quality indexes after sedimentation processing in the secondary sedimentation tank in the step S3 is discharged. The sewage processing process has higher incoming water high-low impact resistance and is not prone to sludge bulking.

Owner:浙江永续环境工程有限公司

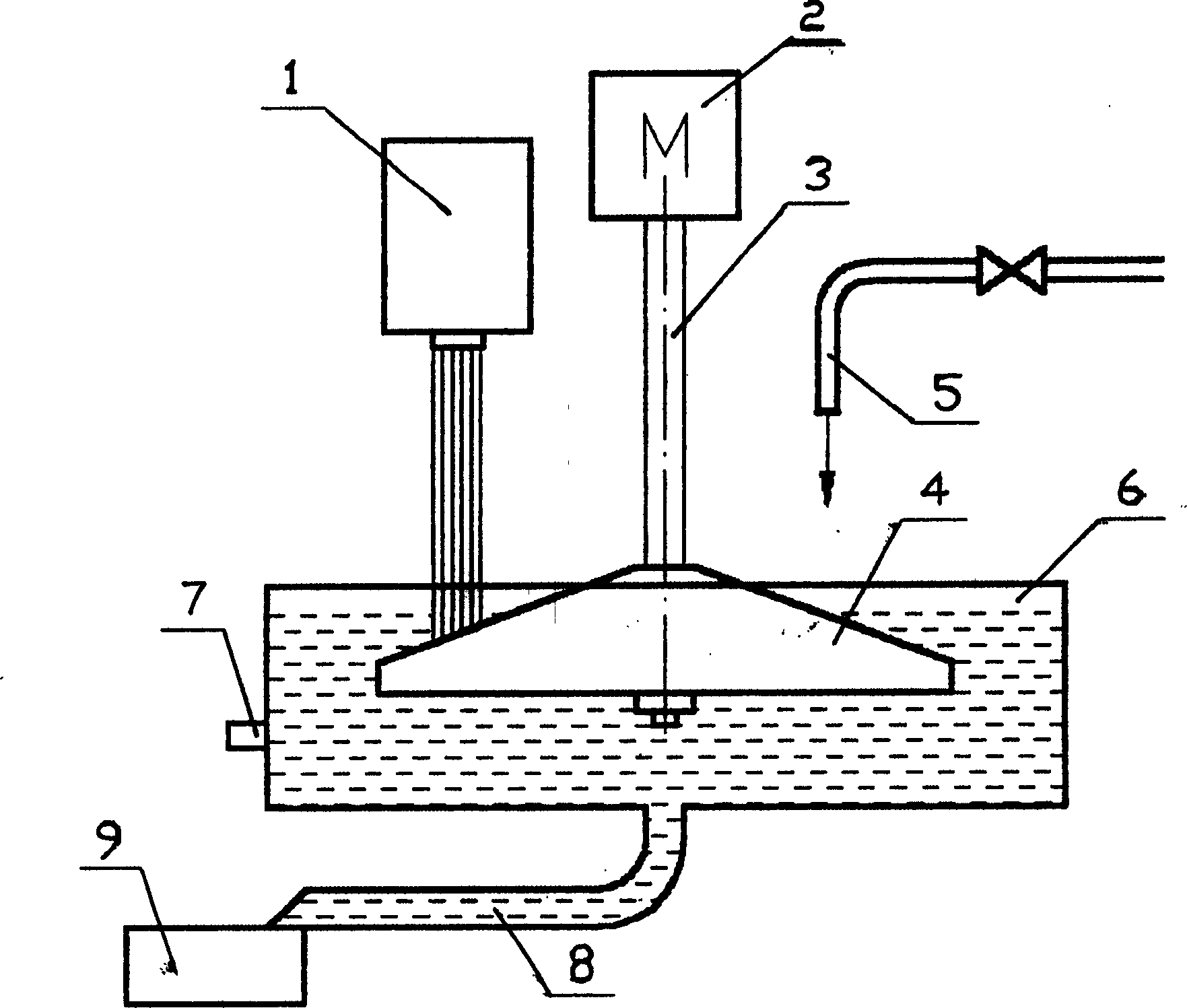

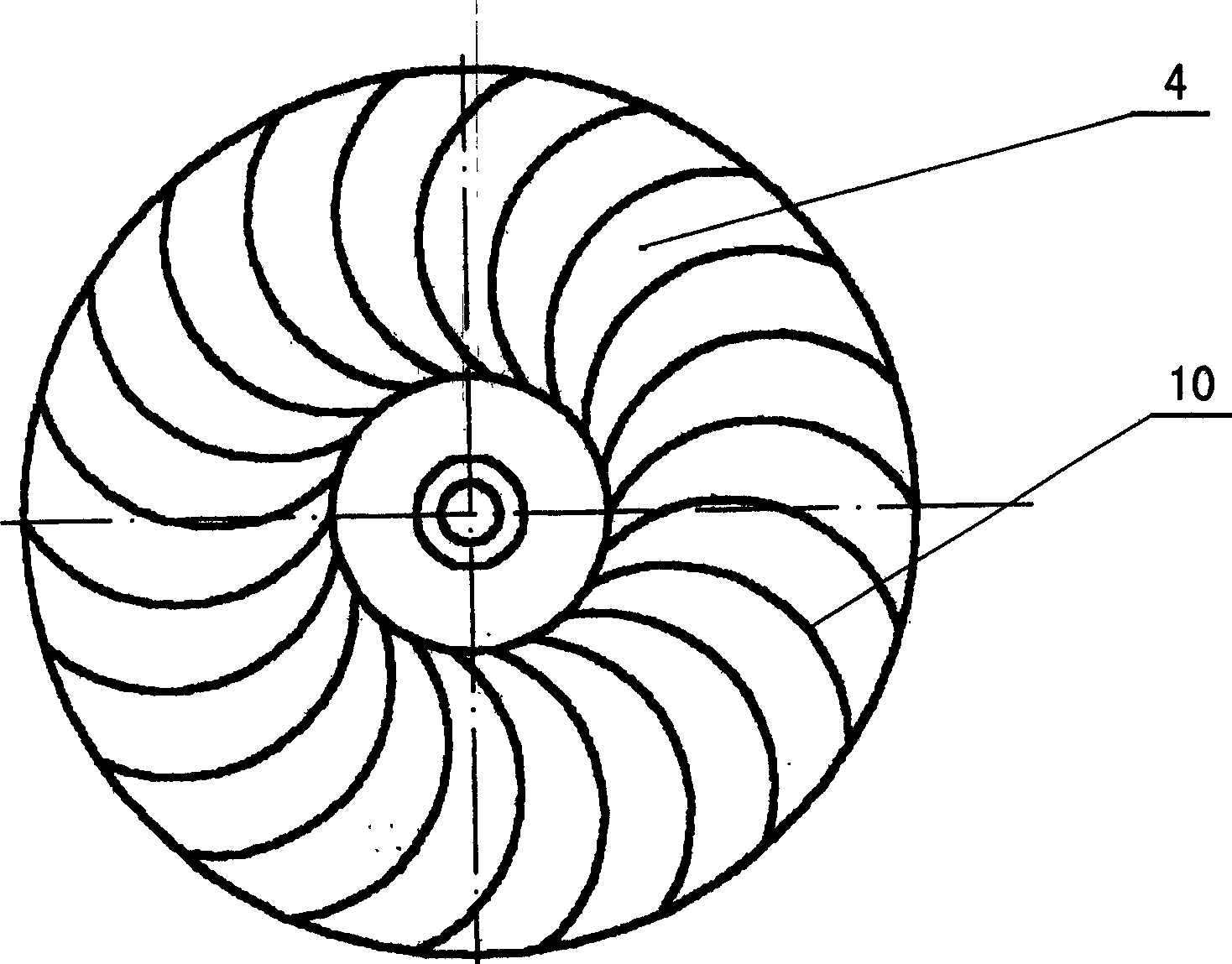

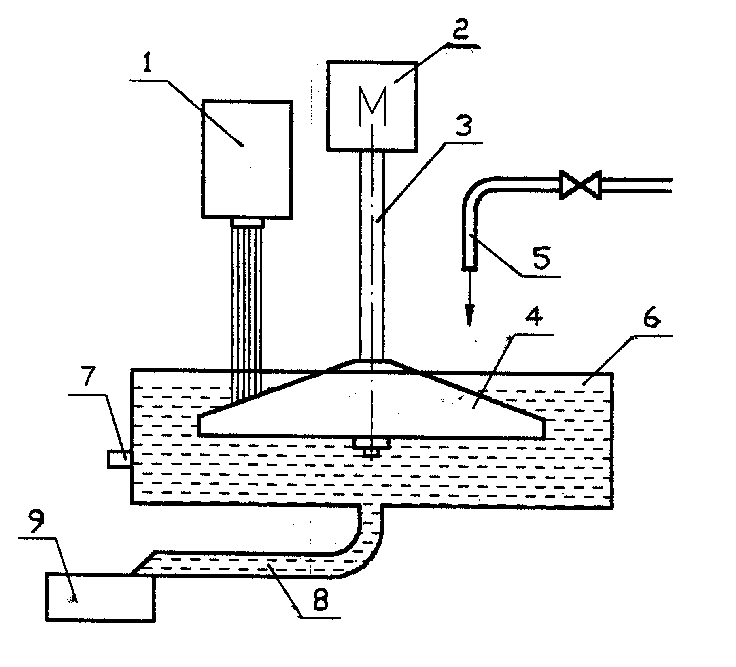

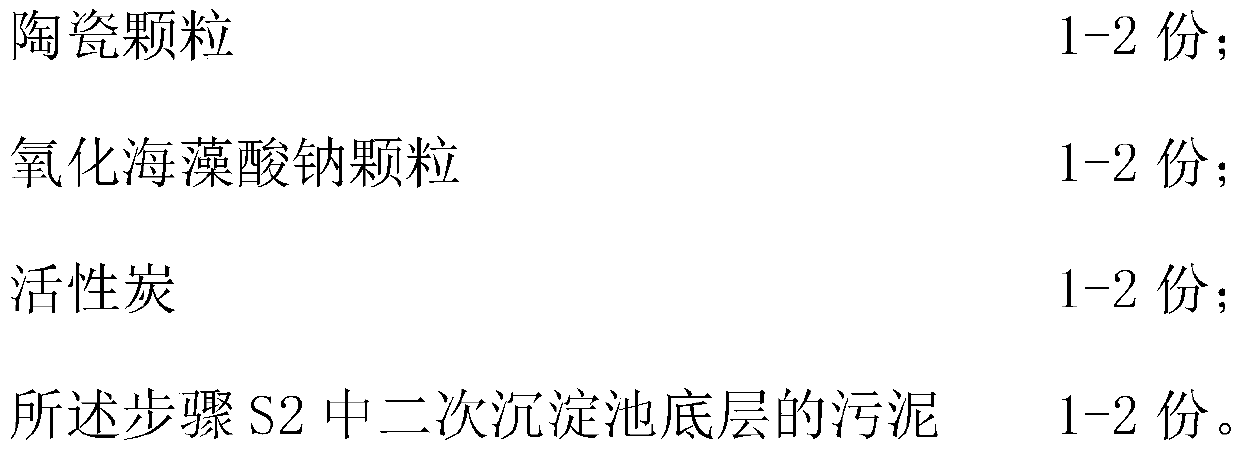

Globular asphalt granulating device and granulating method

ActiveCN101870880BSimple structureReduce manufacturing costWorking-up pitch/asphalt/bitumen by solidifying/disintegratingManufacturing technologyThermal insulation

The invention relates to the manufacturing technology of asphalt, in particular to a globular asphalt granulating device and a granulating method. The device comprises a vertical rotating shaft installed on a rack, the rotating shaft can be driven to rotate by a power plant, the lower end of the rotating shaft is connected with the center of a centrifuge boiler of which the surface of the inner chamber is hemispheric, and can drive the centrifuge boiler to rotate; an asphalt discharge hole is arranged on the side above the centrifuge boiler and is connected with an asphalt storage device usedfor storing liquid asphalt by a section of thermal insulation discharge tube coated with thermal insulation material. The equipment of the invention has simple structure, low manufacturing cost, low operation cost and small pollution for technical operation process, can regulate prilling grain diameter by controlling centrifugation revolution and raw material flow, has high prilling speed and good quality and is suitable for requirements of mass production.

Owner:镇江新光新材料科技有限公司

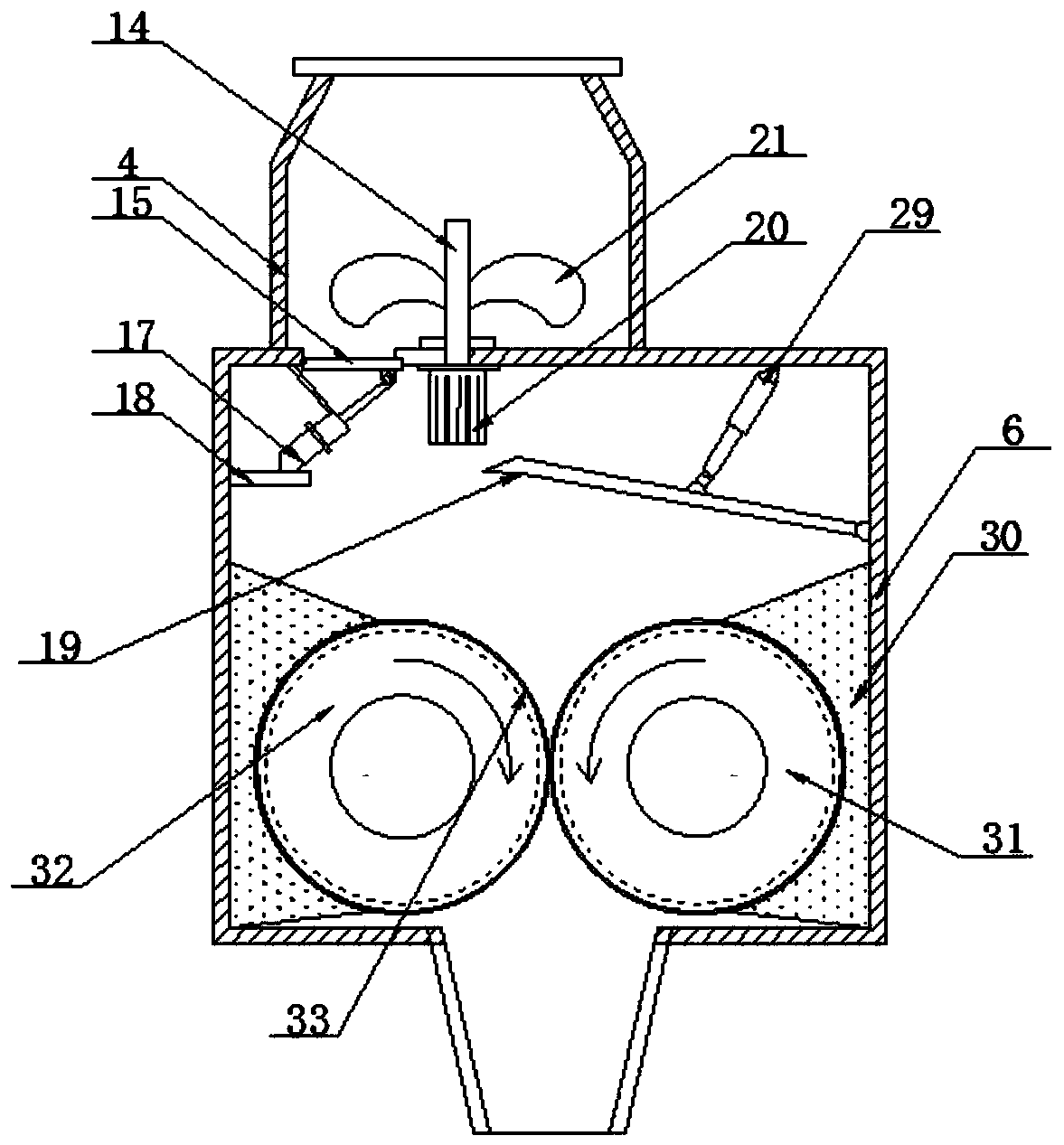

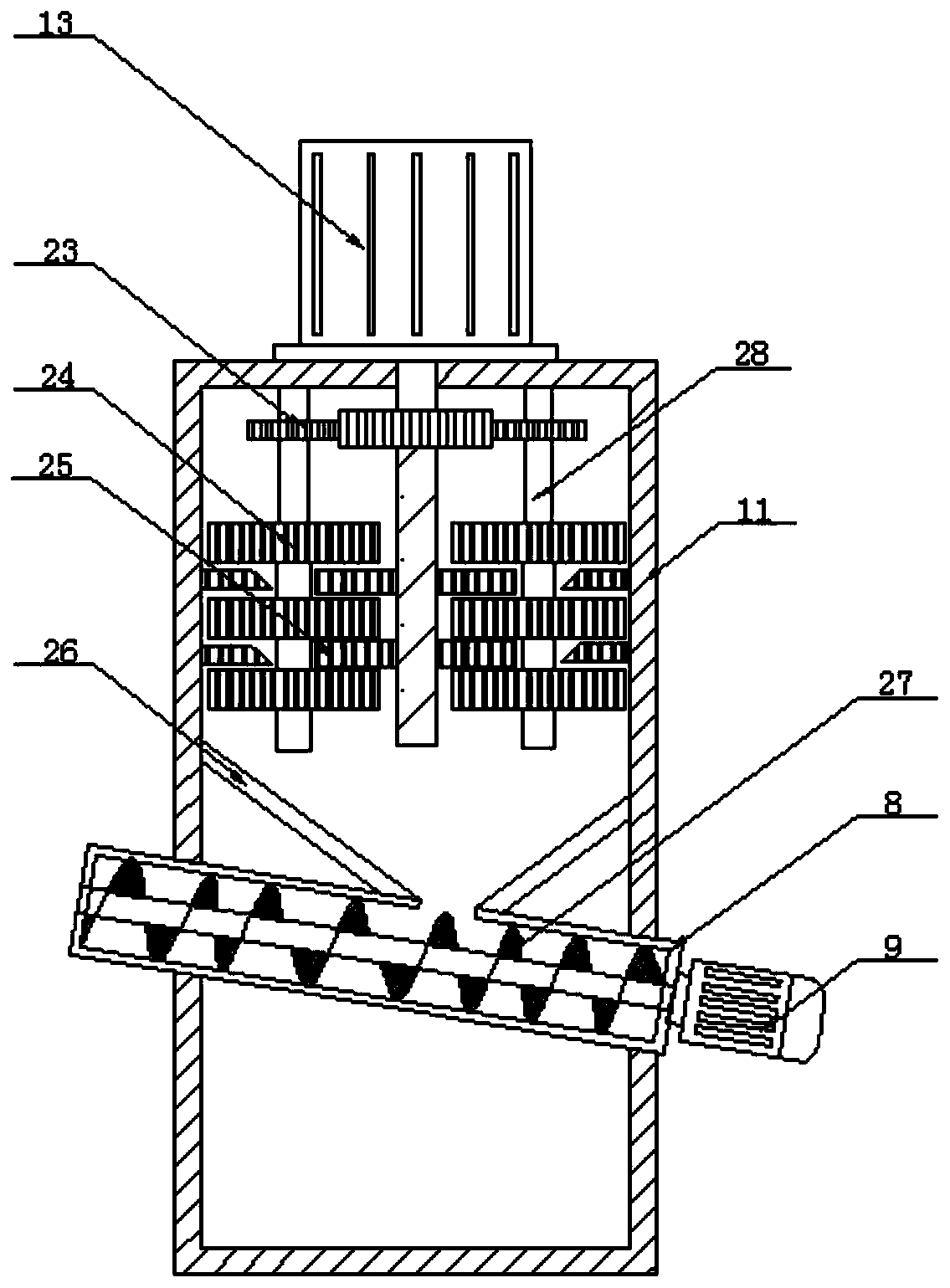

Clean and environment-friendly biomass heating particle preparation equipment

InactiveCN111420601AGuaranteed crushing effectGranulation speedTransportation and packagingMixersBiomassMineralogy

The invention relates to the technical field of particle preparation, in particular to clean and environment-friendly biomass heating particle preparation equipment. According to the invention, a clean and environment-friendly biomass material is finely crushed before granulation; problems that the biological material contains impurities which are not crushed thoroughly, granulation is difficult during granulation, or the granules are changed into powder by slight shaking after being granulated are solved; a porous main millstone and a porous auxiliary millstone are used for grinding, filtering and blanking; the crushing performance can be effectively guaranteed, a first granulation roller and a second granulation roller rotate in opposite directions at a certain speed difference, cylindrical particles are automatically broken through the speed difference, equipment does not need to be cut off, granulation is achieved through the extrusion effect of the granulation rollers, the granulation speed is high, needed energy consumption is small, and the granulation capacity is improved.

Owner:宋婷

Rare earth ceramsite and preparation method thereof

InactiveCN111875345ACorrosion resistantAntioxidantMaterial granulationFiltration separationFiltrationAdhesive

The invention discloses rare earth ceramsite and a preparation method thereof, and belongs to the technical field of environmental protection treatment. Main materials comprise kaolin and potassium feldspar, and the auxiliary materials comprise a pore-forming agent and an adhesive. The rare earth ceramsite is good in adsorption performance and high in dirt carrying capacity, and the problems thata natural filter material is single in specific gravity and prone to breakage and argillization, SiO2 is generated, and organic carbon remains for secondary pollution are solved. The rare earth ceramsite can be widely used as a filter medium in single-layer filter tanks, multi-layer filter tanks and mechanical filtration, can be used for treating various industrial sewage, industrial water, urbantap water, urban sewage, pure water and soft water, and can also be used as a biological filter material for treating organic water. In addition, the rare earth ceramsite can be used as a filter material for treating various industrial dust and boiler smoke dust.

Owner:贵州宝鑫实业有限公司

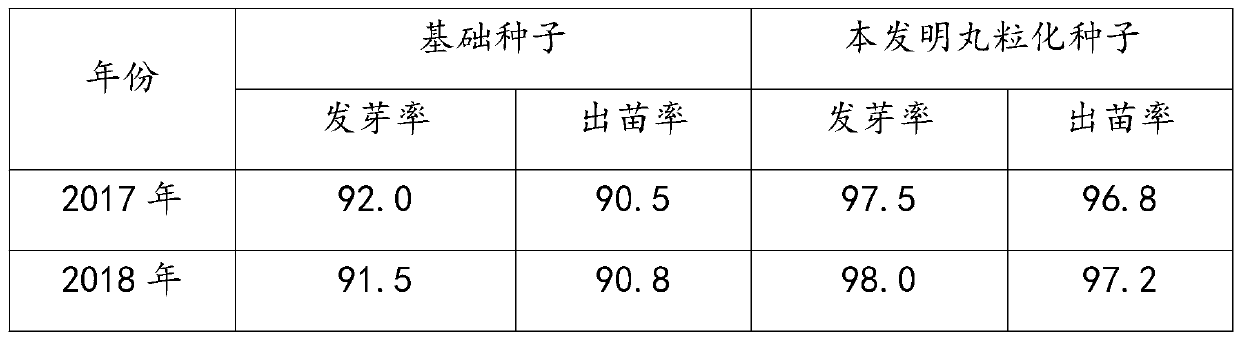

Beet seed pelleting formula and processing method

PendingCN111084181AHigh granulation rateGranulation speedBiocidePlant growth regulatorsGibberellic acidCellulose

The invention discloses a beet seed pelleting formula and a processing method, and relates to the field of beet seed pelleting treatment. The pelleting formula comprises a powder material A, a powdermaterial B, a powder material C and a liquid material D, wherein the powder material A comprises an inert filling material, an adhesive and a granulating agent; the powder material B is an additive formed by mixing thiram, zinc sulfate, manganese sulfate, borax, gibberellic acid and brassinolide; the powder material C is formed by mixing the powder material A and the powder material B according toa weight ratio of 15: 1; and the liquid material D comprises a colorant, namely a pure acrylic emulsion, carboxymethyl cellulose, warning color, pearl powder and water. According to the invention, byadoption of the granulating agent, the granulation rate of beet coating seeds can be improved; the granulation speed of the beet coating seeds is reinforced; high granulation strength is achieved; and the growth of plants can be promoted. By adoption of the adhesive, the compressive strength of a single pellet seed can be improved; and the single pellet seed is not easy to be broken. By adoptionof various additives coated around the seeds to be slowly released, a micro-element fertilizer required by plant growth is provided; the stress resistance is enhanced; and the emergence rate of beet pelletized seeds is increased.

Owner:石河子农业科学研究院

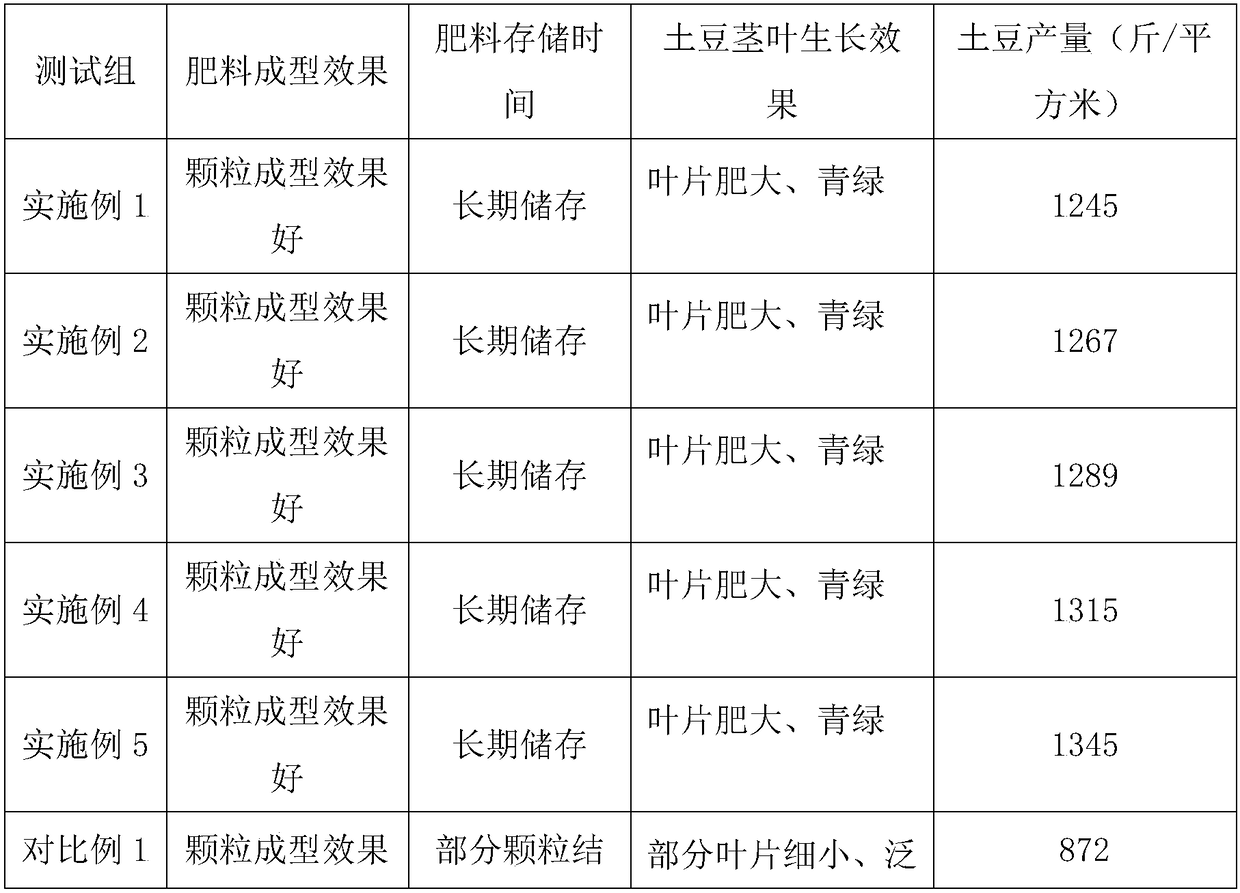

Compound fertilizer for solanum tuberosum growth and preparation method thereof

InactiveCN108530198ARich in nutrientsFertilizer effect for a long timeCalcareous fertilisersBio-organic fraction processingSolanum tuberosumPlant growth

The invention discloses a compound fertilizer for solanum tuberosum growth and a preparation method thereof, and relates to the field of fertilizers. The compound fertilizer is prepared from, by weight, 15-20 parts of seaweed, 7-12 parts of sawdust, 10-15 parts of melon vine, 25-30 parts of faeces, 5-10 parts of calcite, 15-20 parts of modified attapulgite, 5-10 parts of seafood shell, 5-10 partsof nut shell, 3-8 parts of starchy residue, 4-9 parts of tofukasu, 4-9 parts of tealeaf residue, 10-15 parts of grass carbon, 4-9 parts of melia azedarach, 4-9 parts of thunder god vine, 3-8 parts oftrace element additive and 3-8 parts of microbial strain. The compound fertilizer for the solanum tuberosum growth and the preparation method thereof have the advantages that the fertilizer has abundant nutrient substances, the fertilizer efficiency action period is long, the fertilizer not only can be provided for the growth and adsorption of plants, but also can improve soil activity and loosenthe soil, the sources are wide, and the preparation method is simple.

Owner:合肥慧明瀚生态农业科技有限公司

Multifunctional pelletizer for organic fertilizer

InactiveCN109126629AImprove granulation efficiencyExtend the movement timeGranulation by material expressionAgricultural engineeringOrganic manure

The invention belongs to the field of production of organic fertilizers, and particularly relates to a multifunctional pelletizer for an organic fertilizer. By the multifunctional pelletizer for the organic fertilizer, four operations including pelletizing, drying, cooling and sieving can be carried out simultaneously, the pelletizing efficiency of the fertilizer is improved, and the yield of fertilizer particles is ensured. The multifunctional pelletizer for the organic fertilizer comprises a screw extrusion rod, a first mounting plate, an extrusion frame, a feeding hopper, a second connecting plate, a second motor, a fourth bearing block, a fourth rotating shaft, a discharging hopper and the like; the first mounting plate is fixedly connected to a side of a second mounting plate, and a third mounting plate is fixedly connected to another side of the second mounting plate; and a fourth mounting plate is fixedly connected to the top of the third mounting plate. The fertilizer is integrally treated by the four steps of pelletizing, drying, cooling and sieving, and the pelletizing efficiency of the organic fertilizer is improved.

Owner:邹乐文

Organic inorganic compound fertilizer

InactiveCN106348937AGranulation speedUniform particlesAlkali orthophosphate fertiliserExcrement fertilisersChemistryNitrogen fertilizer

The invention discloses an organic inorganic compound fertilizer in order to solve the technical problems of low pelleting rate and odor of the present organic inorganic compound fertilizer. The organic inorganic compound fertilizer comprises the following components in parts by weight: 20-27 parts of nitrogen fertilizer, 9-10 parts of phosphor nitrogen compound fertilizer, 5-8 parts of potash fertilizer, 22-25 parts of fermented fowl manure, 15-25 parts of cabo powder and 8.5-10 parts of bentonite. The auxiliary materials for promoting fertilizer effect and the deodorizing anti-bacteria materials are added into the fertilizer; the caking property of the fertilizer is excellent; the fertilizer can be conveniently pelleted; the soil environment can be modified.

Owner:GUANGDONG RUNTIAN FERTILIZER CO LTD

Unburned spheroidal attapulgite fire-resistant ceramic grain

The invention discloses an unburned spheroidal attapulgite fire-resistant ceramic grain. According to the technical scheme, the unburned spheroidal attapulgite fire-resistant ceramic grain is composed of high-viscosity attapulgite clay powder, attapulgite clay tailing powder, grained blast furnace slag powder, iron tailing powder, gangue powder, bauxite tailing powder, kieselguhr tailing powder and aluminate cement. The raw materials of the unburned spheroidal attapulgite fire-resistant ceramic grain are mixed, pelletized, maintained and screened, and then are packed as the unburned spheroidal attapulgite fire-resistant ceramic grain. The unburned spheroidal attapulgite fire-resistant ceramic grain is spheroidal in shape, has a rough and hard surface, is provided with fine pores inside and is the fire-resistant ceramic grain with high compression strength, low coefficient of heat conductivity, high fire resistance, corrosion resistance and excellent heat-insulating and sound-insulating effect. Various tailings are comprehensively utilized to produce the unburned spheroidal attapulgite fire-resistant ceramic grain, so that the use ratio of resources is increased, the waste is turned into the wealth, and the environmental protection is achieved. The unburned spheroidal attapulgite fire-resistant ceramic grain is suitable for the production of fire-resistant ceramic grain concretes and heat-insulating and sound-insulating materials.

Owner:NANGTONG HAODI ANTICORROSION EQUIP

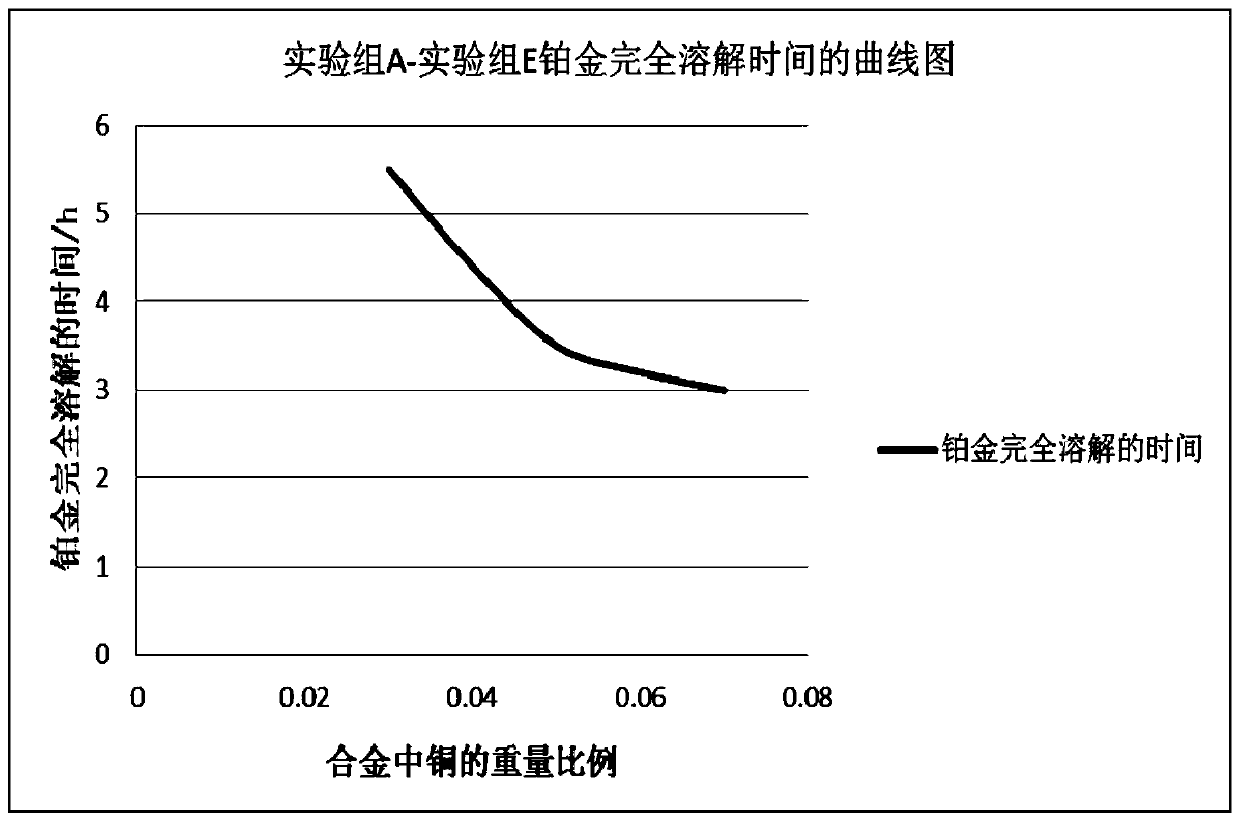

Method for accelerating platinum dissolution

The invention relates to the field of platinum purification, and particularly relates to a method for accelerating platinum dissolution. The method solves the problem of high cost caused by excessiveaddition amount of base metal in the existing platinum dissolution process. The method comprises the following steps that S1, platinum ingots and base metal are mixed together to be molten into moltengold; S2, the molten gold is slowly poured into a container downwards, and the falling molten gold is impacted horizontally through high-pressure water, so that the molten gold is broken into gold particles; and S3, the gold particles and aqua regia are added into a reaction kettle and are stirred and heated to a slightly boiling state, and stirring and dissolution are carried out in the slightlyboiling state; and the weight ratio of the platinum ingots to the base metal is (0.93-0.97) to (0.07-0.03). According to the method, the required amount of the base metal is greatly reduced while theplatinum dissolving speed can be guaranteed, and the effect of saving cost is achieved.

Owner:广东金正龙科技有限公司

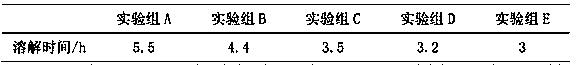

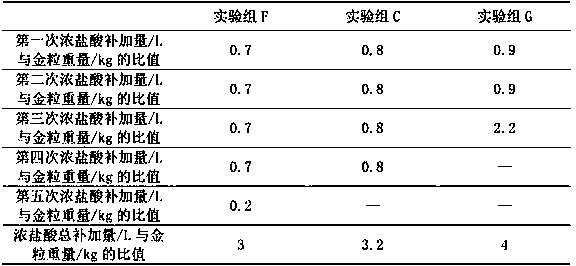

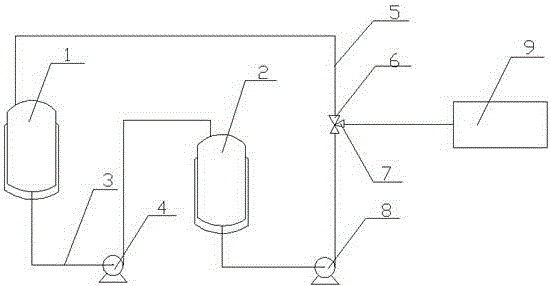

Granulation method and granulation system of 1,3-bis(citraconimidemethyl)benzene

ActiveCN105032283BIncreased flow viscosityGranulation speedOrganic chemistryMaterial granulationBenzenePolymer science

The invention discloses a granulation method for 1, 3-bis(citraconoyl formimino) benzene. The method comprises the following steps: heating the 1, 3-bis(citraconoyl formimino) benzene to be completely molten into a liquid state; then carrying out heat preservation on the liquid-state 1, 3-bis(citraconoyl formimino) benzene for 1-2 hours at 43-45 DEG C, so that the liquid-state 1, 3-bis(citraconoyl formimino) benzene is converted into glassy-state 1, 3-bis(citraconoyl formimino) benzene; adding the glassy-state 1, 3-bis(citraconoyl formimino) benzene into a granulator, and carrying out granulation. The invention also discloses a granulation system. Continuous granulation can be realized by the granulation system. According to the granulation method and the granulation system, the defects that an existing granulation method is long in extrusion and granulation time and incapable of realizing continuous production are overcome; the 1, 3-bis(citraconoyl formimino) benzene is converted into a glassy state and is then granulated, so that the operation environment is greatly improved, and the production efficiency is improved; the granulation method and the granulation system have a favorable market prospect.

Owner:SHANDONG YANGGU HUATAI CHEM

Baking-free cylindrical attapulgite fire-retarding ceramsite

The invention discloses baking-free cylindrical attapulgite fire-retarding ceramsite. The key point of the technical scheme is that the baking-free cylindrical attapulgite fire-retarding ceramsite consists of high-viscosity attapulgite clay powder, attapulgite clay tailing powder, granulated blast-furnace slag powder, iron tailing powder, coal gangue powder, bauxite tailing powder, kieselguhr tailing powder and aluminate cement. The baking-free cylindrical attapulgite fire-retarding ceramsite is produced by the following steps of mixing the ingredients, granulating, maintaining, sieving and packaging. The baking-free cylindrical attapulgite fire-retarding ceramsite has a rough and hard surface, and is high in compression strength, low in heat conductivity, high in refractoriness and corrosion resistance and good in heat-preserving and sound-insulating effect; and a large amount of fine pores are formed in the ceramsite,. The baking-free cylindrical attapulgite fire-retarding ceramsiteis produced by utilizing multiple tailings comprehensively, so that the utilization rate of resources is improved, waste materials are changed into wealth, and environment is protected. Besides, the baking-free cylindrical attapulgite fire-retarding ceramsite is suitable for producing fire-retarding ceramsite concrete and heat-preserving and sound-insulating materials.

Owner:NANGTONG HAODI ANTICORROSION EQUIP

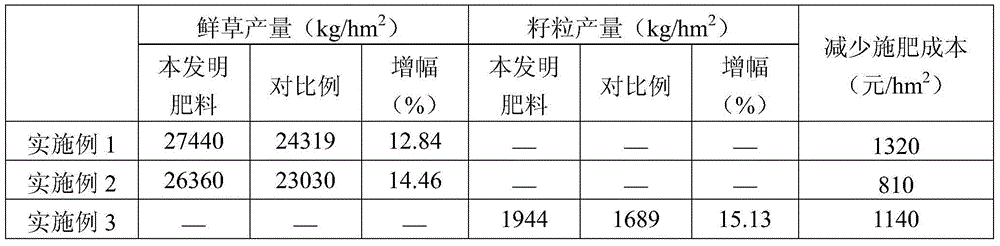

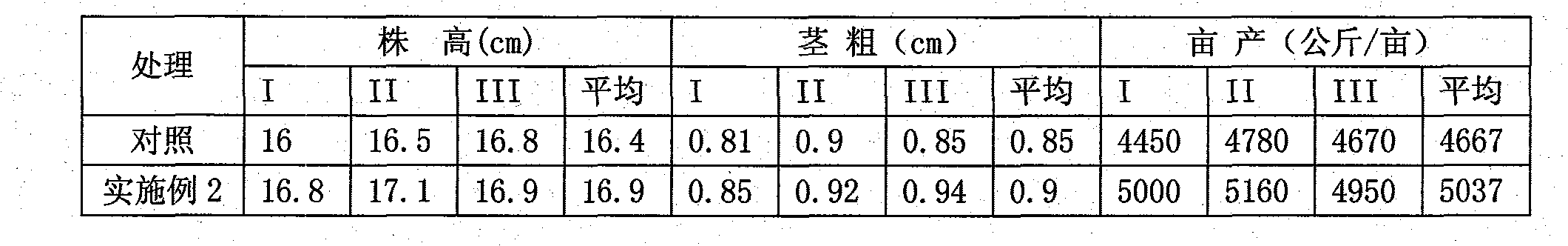

Common fertilizer special for sesbania in medium and low-yield fields in Huang-Huai-Hai region

ActiveCN103910580BReasonable ratioImprove current quarter utilizationFertilizer mixturesSoil sciencePhosphate fertilizer

The invention discloses a common fertilizer special for sesbania in medium and low-yield fields in a Huang-Huai-Hai region and belongs to the field of fertilizer preparation. An organic matrix, an inorganic matrix, a nitrogen fertilizer, a phosphate fertilizer, a potassic fertilizer and a trace element chelating agent serve as basic raw materials. The preparation method comprises the following steps: spraying, granulating activating agents and preparing the fertilizer through disc granulation, wherein the nitrogen fertilizer, the phosphate fertilizer and the potassic fertilizer are mixed according to a mass ratio 5-9:14-20:0-2 of N:P2O5:K2O. The common fertilizer special for sesbania serving as a base fertilizer is applied at a time, is simple in production process, low in cost, environment-friendly, high in utilization rate and obvious in yield-increasing effect and is suitable for needs of common fertilizer special for sesbania in medium and low-yield fields in the Huang-Huai-Hai region and feed or particle production.

Owner:SHANDONG CROP GERMPLASM CENT

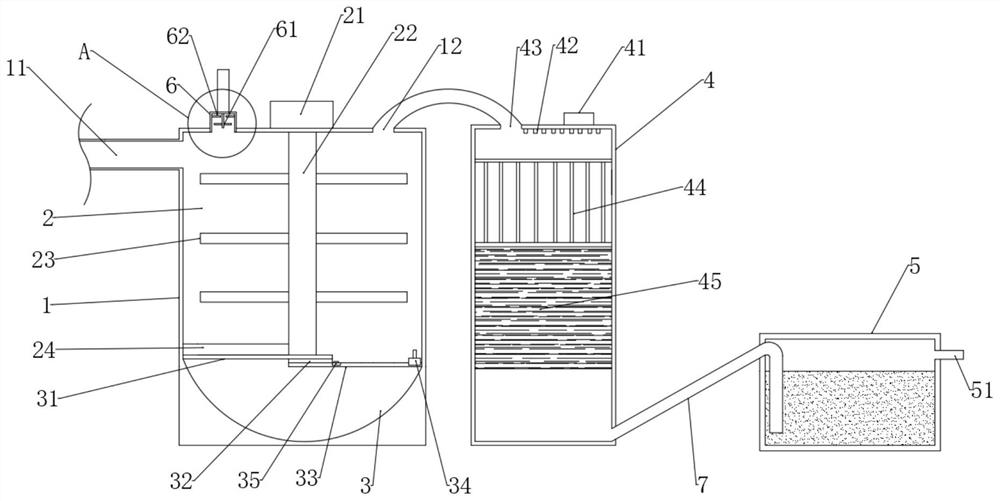

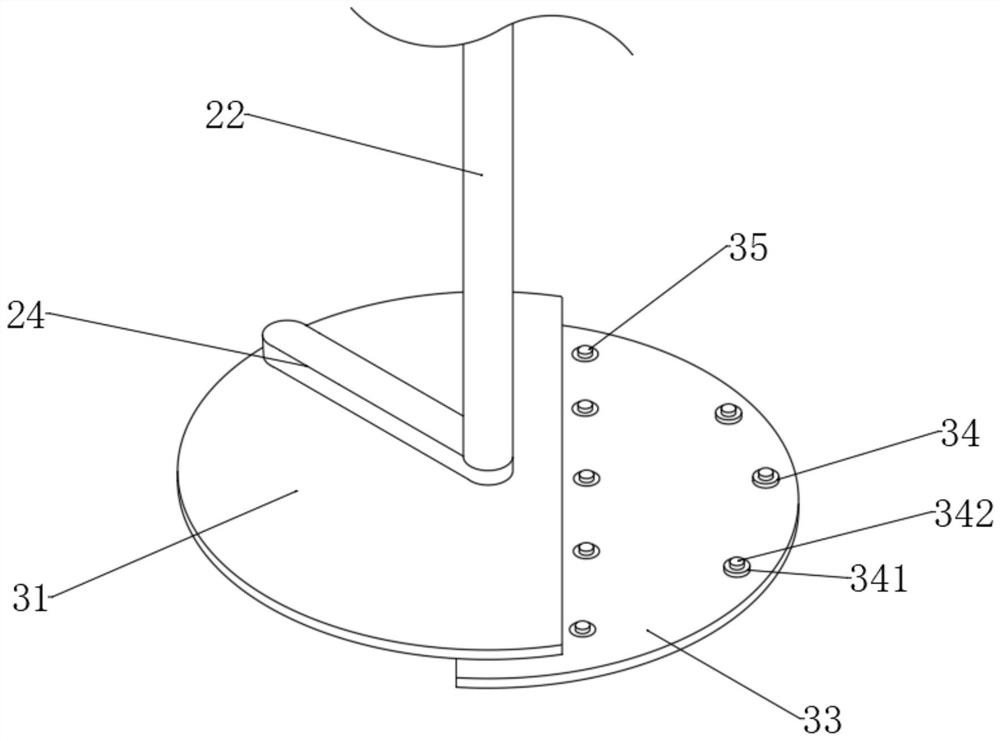

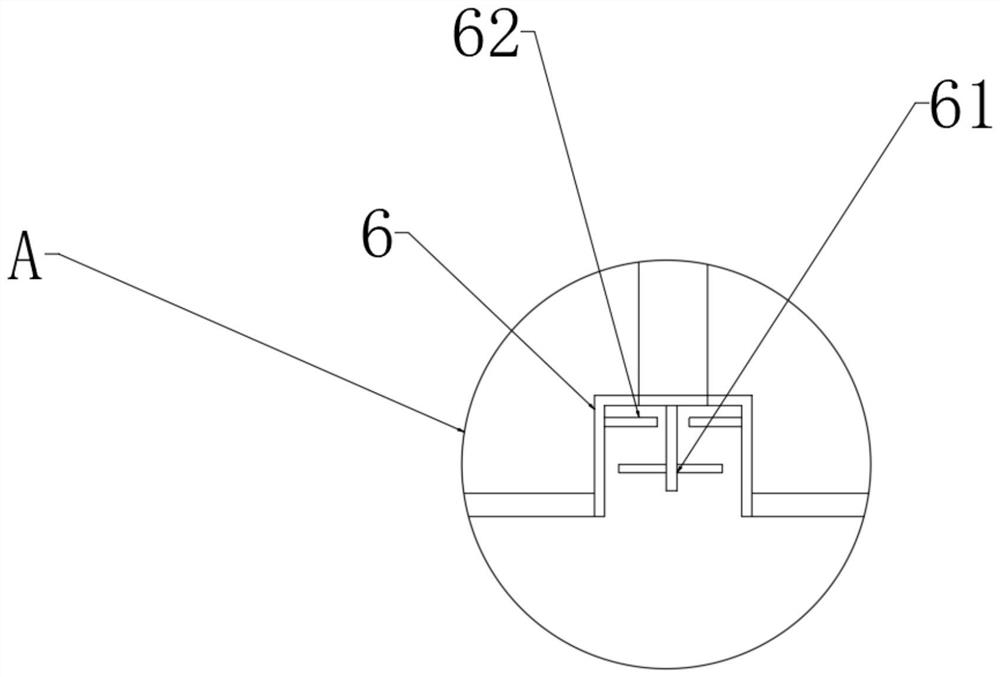

Sludge mixing granulation device and method

PendingCN112808162AEasy dischargeShorten ignition timeCombination devicesSludge treatment by de-watering/drying/thickeningSludgeElectric machine

The invention relates to the technical field of granulation devices, and concretely relates to a sludge mixing granulation device and method. The sludge mixing granulation device comprises a granulation device body, a purification device and a water tank, the granulation device body is of a cylindrical hollow structure, a mixing and stirring device is arranged on the upper portion of the granulation device body, and a feeding pipe is arranged on the side edge of the top of the mixing and stirring device; a motor is fixedly welded to the top of the mixing and stirring device, a stirring rod is welded to the output end of the motor, a granulating device is arranged on the lower portion of the granulating device body, a baffle is arranged between the granulating device and the mixing and stirring device, a bearing is arranged on the lower portion of the baffle, the baffle is rotationally connected with a rotating plate through the bearing, and a telescopic rod and a contraction rod are arranged at the top of the rotating plate; and an air heating device is arranged on the upper portion of the granulation device body, and the purification device is arranged on the side edge of the granulation device body. Sludge is stirred through the mixing and stirring plate device and then granulated, sludge odor is purified through the purification device, and the environment is protected.

Owner:新沂市新南环保产业技术研究院有限公司

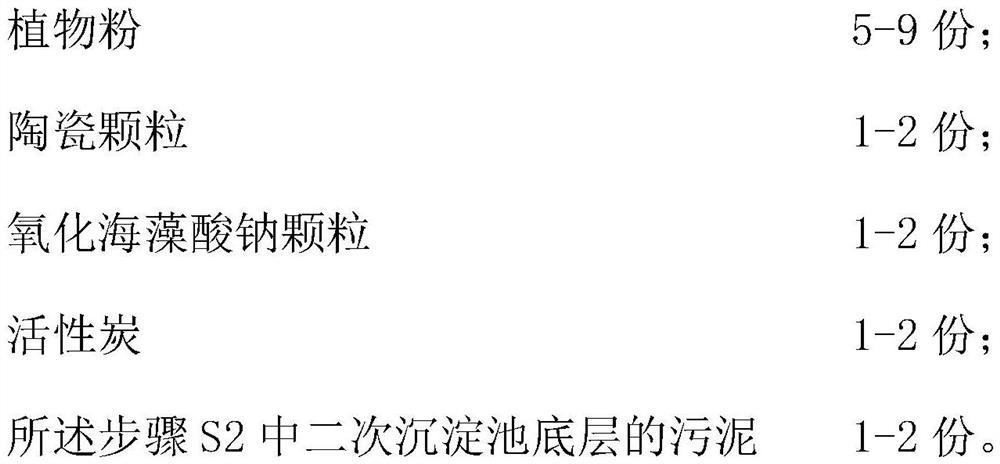

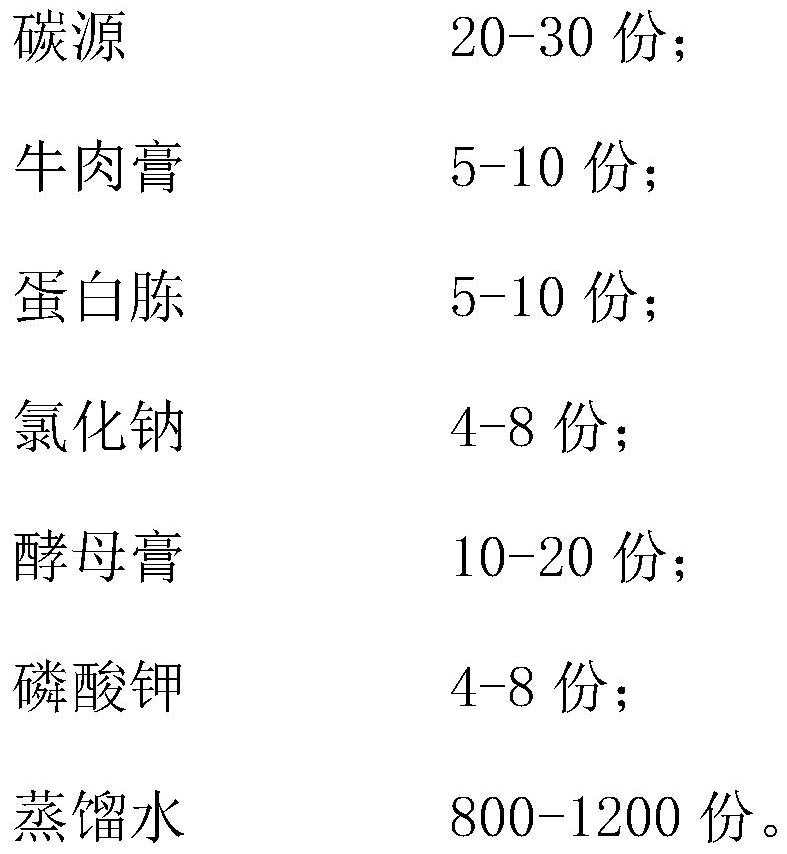

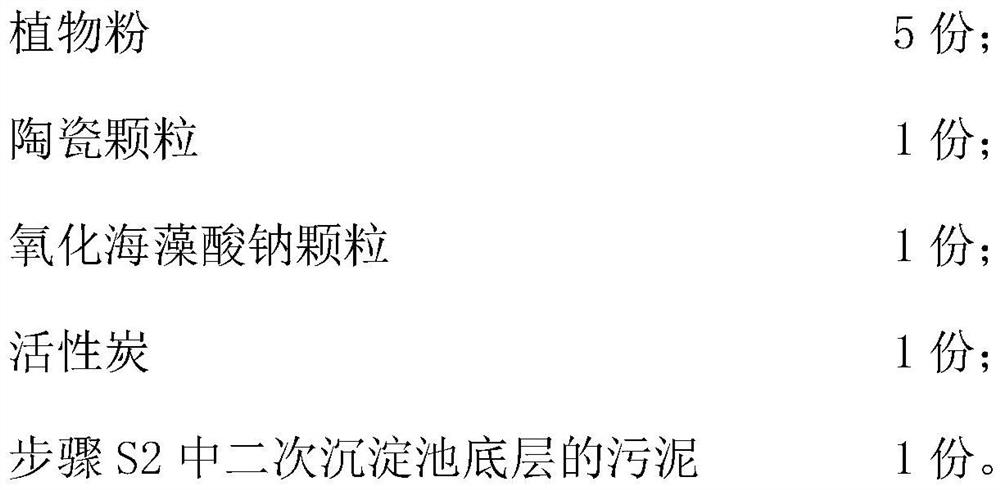

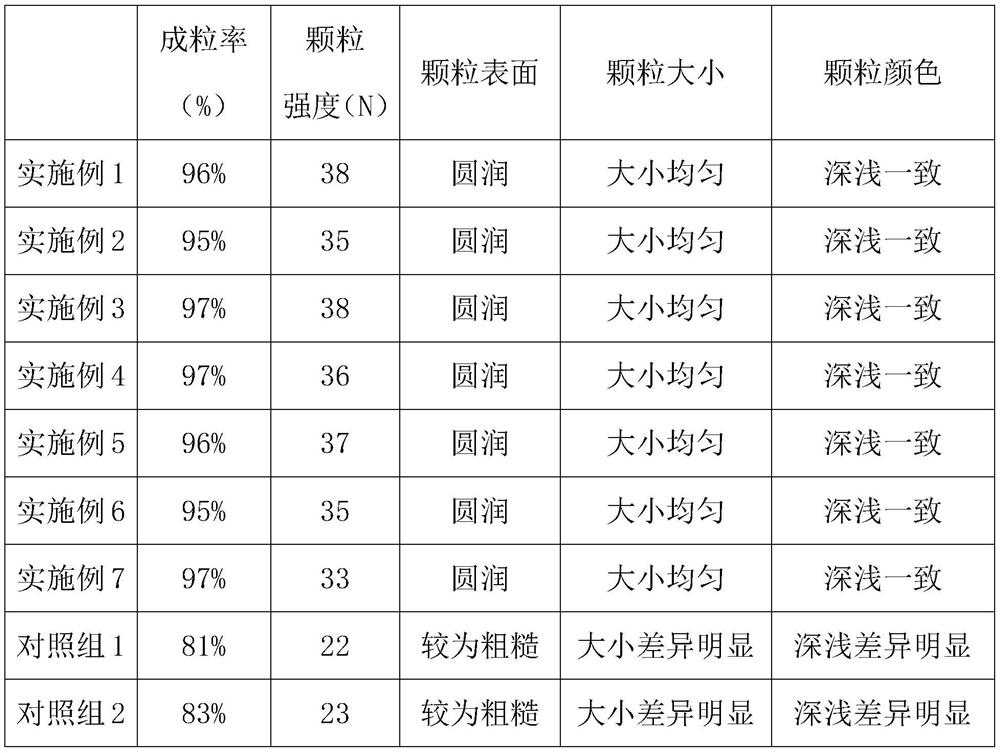

A sewage treatment process using microbial carrier

ActiveCN110981079BNot prone to swellingHigh water resistanceWater treatment parameter controlWater treatment compoundsMicroorganismSludge

The invention relates to a sewage treatment process using a microbial carrier, which belongs to the technical field of sewage treatment and includes the following process steps: S1: sewage flows into a primary sedimentation tank for primary precipitation to obtain primary precipitated sewage; S2: after the initial precipitation in step S1 The sewage is filtered through the grid and then flows into the granulated sludge tank for treatment; S3: The sludge treated in the granulated sludge tank in step S2 is discharged into the secondary sedimentation tank for secondary sedimentation; S4: after the secondary sedimentation in step S3 After the sedimentation treatment in the secondary sedimentation tank, the sewage with qualified water quality indicators is discharged. The invention has higher high and low impact resistance of incoming water, and is not easy to produce the effect of sludge bulking.

Owner:浙江永续环境工程有限公司

Granulation method of high-tower melt high-phosphorus compound fertilizer

PendingCN113880671AImprove density uniformityImprove mixing uniformityAlkali orthophosphate fertiliserAmmonium orthophosphate fertilisersMelting tankSlurry

The invention provides a granulation method of a high-tower melt high-phosphorus compound fertilizer, and relates to the technical field of compound fertilizer production, the granulation method comprises the following steps: a, a raw material preparation process: preparing urea, ammonium phosphate, potassium chloride, sodium sulfate and a granulation additive for later use; b, urea melting: feeding urea into a melting tank, and melting to prepare urine; c, primary mixing: conveying the urine into a primary mixing tank, adding ammonium phosphate, and stirring and mixing to prepare slurry; d, secondary mixing: conveying the mixed slurry of ammonium phosphate and urine into a secondary mixing tank, adding potassium chloride, sodium sulfate and a granulation additive, and stirring and mixing to prepare slurry; and e, granulation: conveying the secondarily mixed slurry to a granulator for granulation, and adding an emulsification step between the step e and the step d, so that the fineness of the slurry is improved, and the proportion of powdery materials during mixing can be increased.

Owner:世纪云天(黑龙江)化学有限公司

Special-purpose fertilizer for green cucumber

The invention relates to a fertilizer specially used for cucumbers, aiming at providing a fertilizer used for cucumbers with reasonable mixture ratio of N, P and K, high utilization ratio of nutrient and nutrient release rate conforming to the fertilizer requiring rule of cucumbers. The technical proposal is that: the weight ratio of N : P2O5 : K2O in a compound / mixed fertilizer is 1 : 0.2 to 0.5: 1.2 to 1.6, the compound / mixed fertilizer contains 4 to 10 percent of fertilizer synergist, and the fertilizer synergist is attapulgite irradiated by ultrasonic wave of more than 20KHz and less than 50KHz for 1 to less than 5 min. The fertilizer specially used for cucumbers has wide applicability, can meet the requirement of the cucumbers in a whole growing season and is applied as a base fertilizer for one time, with obvious fertilizer-saving and production-increasing effects.

Owner:JIANGSU ABOLUO COMPOUND FERTILIZER

Biomass straw smashing and forming all-in-one machine

InactiveCN103495484BSimple processReduce energy consumptionGranulation by pressingGrain treatmentsWork cycleEngineering

The invention provides a biomass straw smashing and forming all-in-one machine, and relates to a straw smashing and forming device. The biomass straw smashing and forming all-in-one machine solves the problems that in an existing straw forming fuel production process, the straw smashing procedure and the compressing and compacting forming procedure are independently completed through a smashing device and a squeezing forming device respectively, the power consumption is high, the logistics cost is high, and the working cycle is long. The vertical smashing device and the squeezing forming device are arranged on a walking plate in parallel from front to back, walking wheels are arranged below the walking plate, a blade is arranged at the bottom of a feed port of the vertical smashing device, a main shaft of the smashing machine is sleeved with a sleeve, hammer carrier plates are arranged on the sleeve from top to bottom, a hammer set is arranged between every two adjacent hammer carrier plates in an annular mode, hammers of each hammer set are evenly arranged in the vertical direction, each hammer is of a multi-tooth-edge rectangular structure, an air blower is arranged at the bottom of a machine shell and communicate with a material storage hopper, and the material storage hopper is communicated with an inlet of the squeezing forming device through an air duct. The biomass straw smashing and forming all-in-one machine is used for smashing and forming biomass straw.

Owner:NORTHEAST FORESTRY UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com