Compound fertilizer for solanum tuberosum growth and preparation method thereof

A compound fertilizer and potato technology, which is applied in the field of fertilizers, can solve the problems of insufficient nutrients in organic fertilizers, low protein and amino acid content, and single raw material types, and achieve the effects of preventing harmful bacteria from multiplying, simple preparation methods, and improving soil compaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

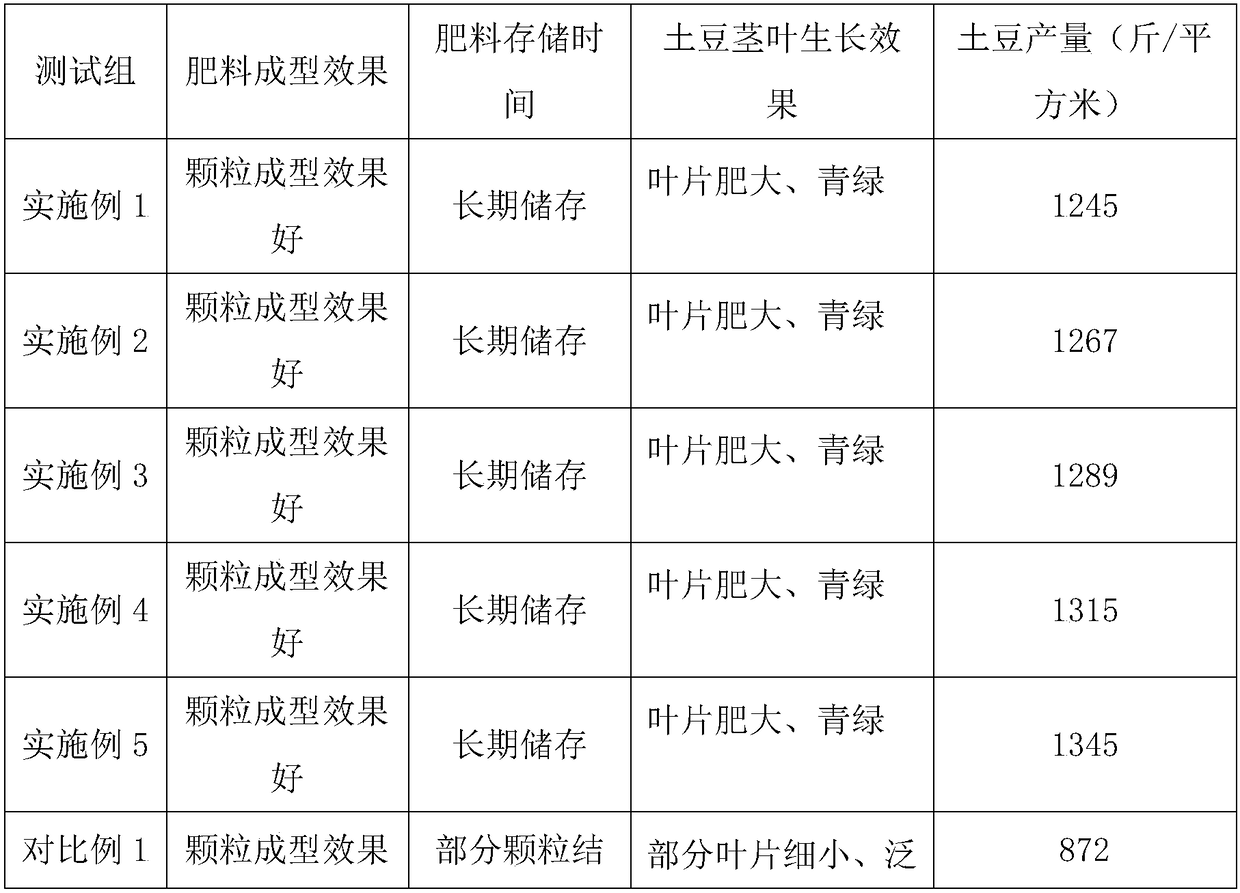

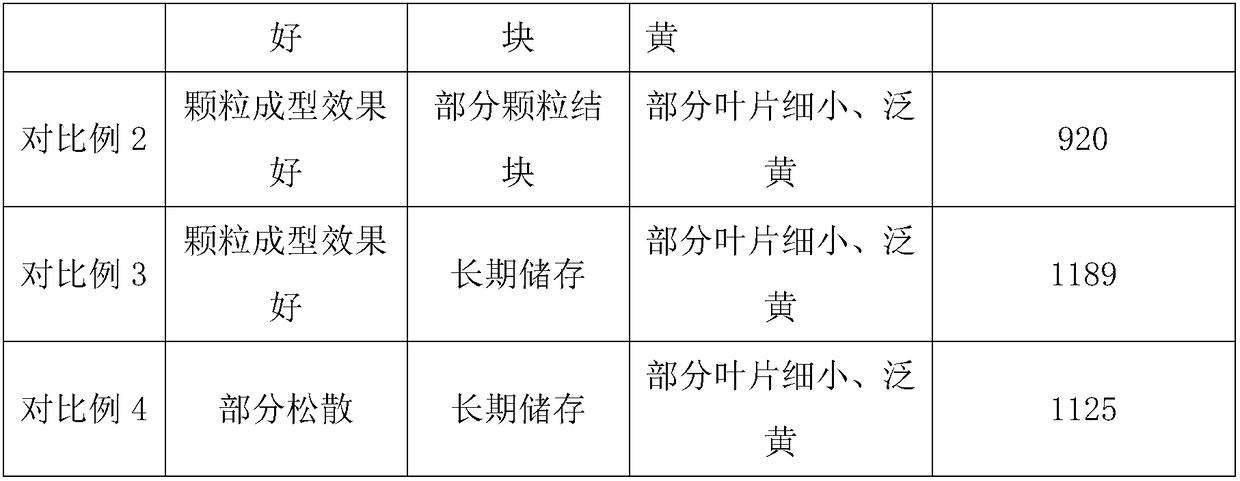

Examples

Embodiment 1

[0031] A compound fertilizer for growing potatoes, comprising the following raw materials in parts by weight:

[0032] 15 parts of seaweed, 7 parts of sawdust, 10 parts of melon vine, 25 parts of manure, 5 parts of calcite powder, 15 parts of modified attapulgite, 5 parts of seafood shell, 5 parts of nut shell, 3 parts of starch residue, 4 parts of bean curd residue , 4 parts of tea residue, 10 parts of peat, 4 parts of neem, 4 parts of Tripterygium wilfordii, 3 parts of trace element additives, and 3 parts of microbial strains.

[0033] The preparation method of modified attapulgite is as follows:

[0034] (a) Attapulgite is placed in a calcination furnace at 350 degrees Celsius, roasted for 4 hours, and cooled to room temperature;

[0035] (b) According to the liquid-solid mass ratio of 2:1, add a sulfuric acid solution with a mass fraction of 45% to the roasted attapulgite, stir and mix evenly, heat up to 70 degrees Celsius, and stir and mix at a speed of 300 rpm. 4 hours...

Embodiment 2

[0047] A compound fertilizer for growing potatoes, comprising the following raw materials in parts by weight:

[0048] 20 parts of seaweed, 12 parts of sawdust, 15 parts of melon vine, 30 parts of feces, 10 parts of calcite powder, 20 parts of modified attapulgite, 10 parts of seafood shell, 10 parts of nut shell, 8 parts of starch residue, 9 parts of bean curd residue , 9 parts of tea residue, 15 parts of peat, 9 parts of neem, 9 parts of Tripterygium wilfordii, 8 parts of trace element additives, and 8 parts of microbial strains.

[0049] The preparation method of modified attapulgite is as follows:

[0050] (a) Attapulgite is placed in a calcination furnace at 450 degrees Celsius, roasted for 4 hours, and cooled to room temperature;

[0051] (b) Add a sulfuric acid solution with a mass fraction of 45% to the roasted attapulgite according to a liquid-solid mass ratio of 2:1, stir and mix evenly, heat up to 80 degrees Celsius, and stir and mix at a speed of 500 rpm for 5 ho...

Embodiment 3

[0063] A compound fertilizer for growing potatoes, comprising the following raw materials in parts by weight:

[0064] 16 parts of seaweed, 9 parts of sawdust, 11 parts of melon vine, 26 parts of manure, 6 parts of calcite powder, 16 parts of modified attapulgite, 6 parts of seafood shell, 6 parts of nut shell, 4 parts of starch residue, 5 parts of bean curd residue , 5 parts of tea residue, 11 parts of peat, 5 parts of neem, 5 parts of Tripterygium wilfordii, 4 parts of trace element additives, and 4 parts of microbial strains.

[0065] The preparation method of modified attapulgite is as follows:

[0066] (a) Attapulgite is placed in a calcination furnace at 380 degrees Celsius, roasted for 4 hours, and cooled to room temperature;

[0067] (b) According to the liquid-solid mass ratio of 2:1, add a sulfuric acid solution with a mass fraction of 45% to the roasted attapulgite, stir and mix evenly, heat up to 75 degrees Celsius, and stir and mix at a speed of 400 rpm for 4.5 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com