Patents

Literature

30 results about "Single pellet" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

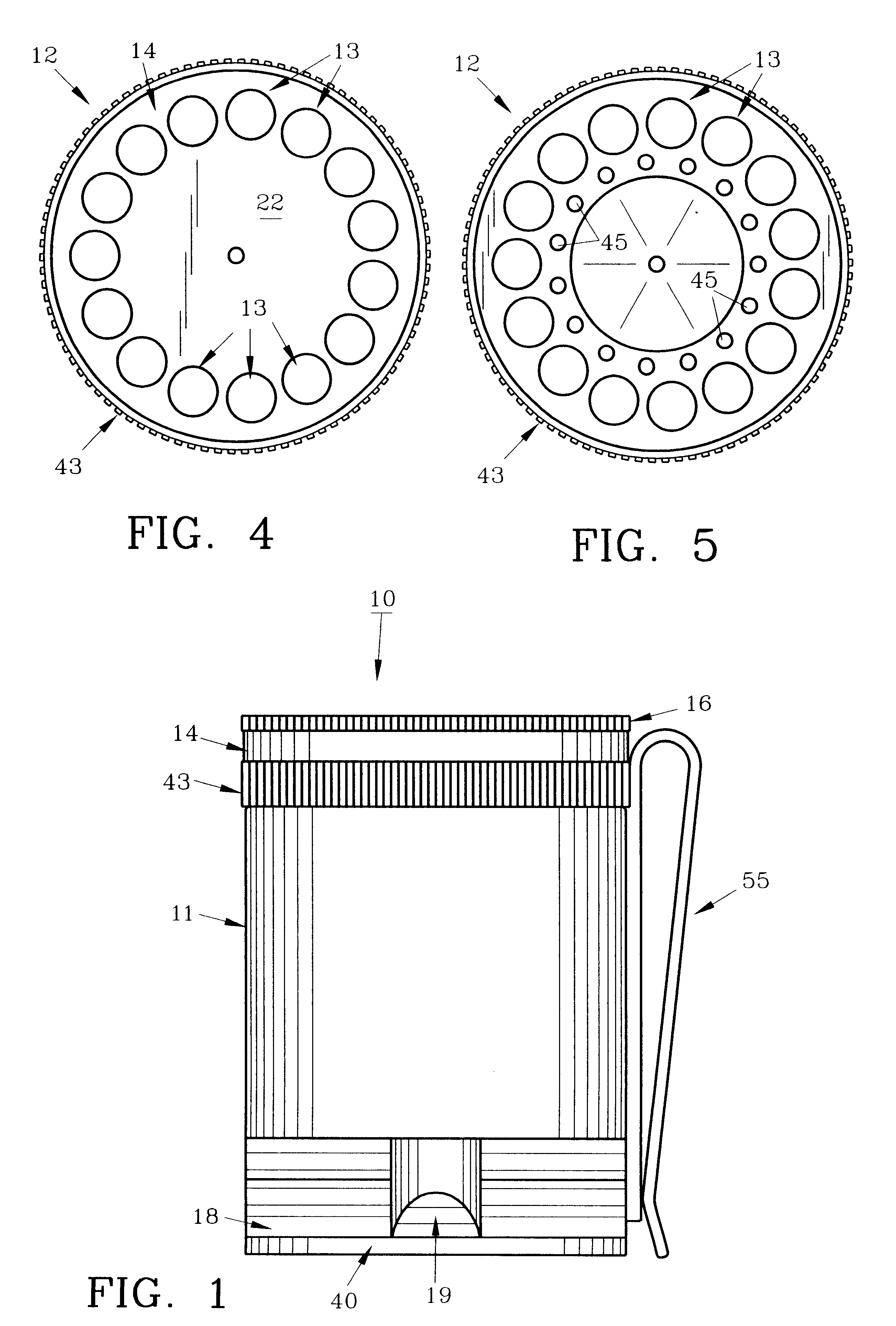

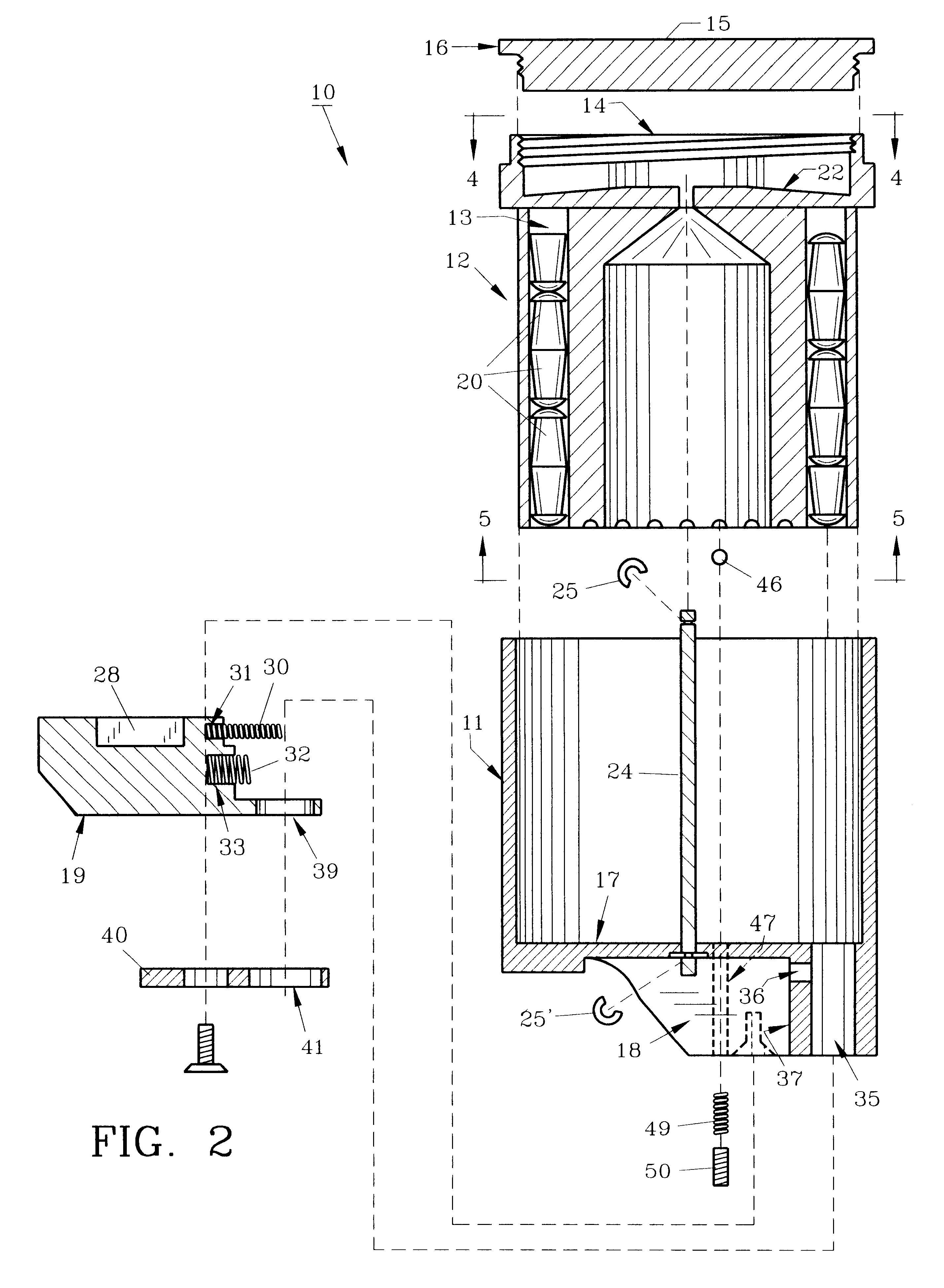

Pellet dispenser and method

InactiveUS6824011B1Easy loadingCheap manufacturingCoin-freed apparatus detailsCompressed gas gunsSingle pelletEngineering

A pellet dispensing device includes a rotatable cylinder having a plurality of chambers and a trigger mechanism for dispensing pellets therefrom, one at a time. The device further includes a clasp for attachment to the belt or otherwise of a wearer where it is readily accessible. Pellets are placed in a hopper atop the rotatable cylinder which allows each chamber to be completely filled. A resilient member engages each pellet before it passes through an exit conduit to insure single pellet dispensing.

Owner:WOEMPNER MACHINE

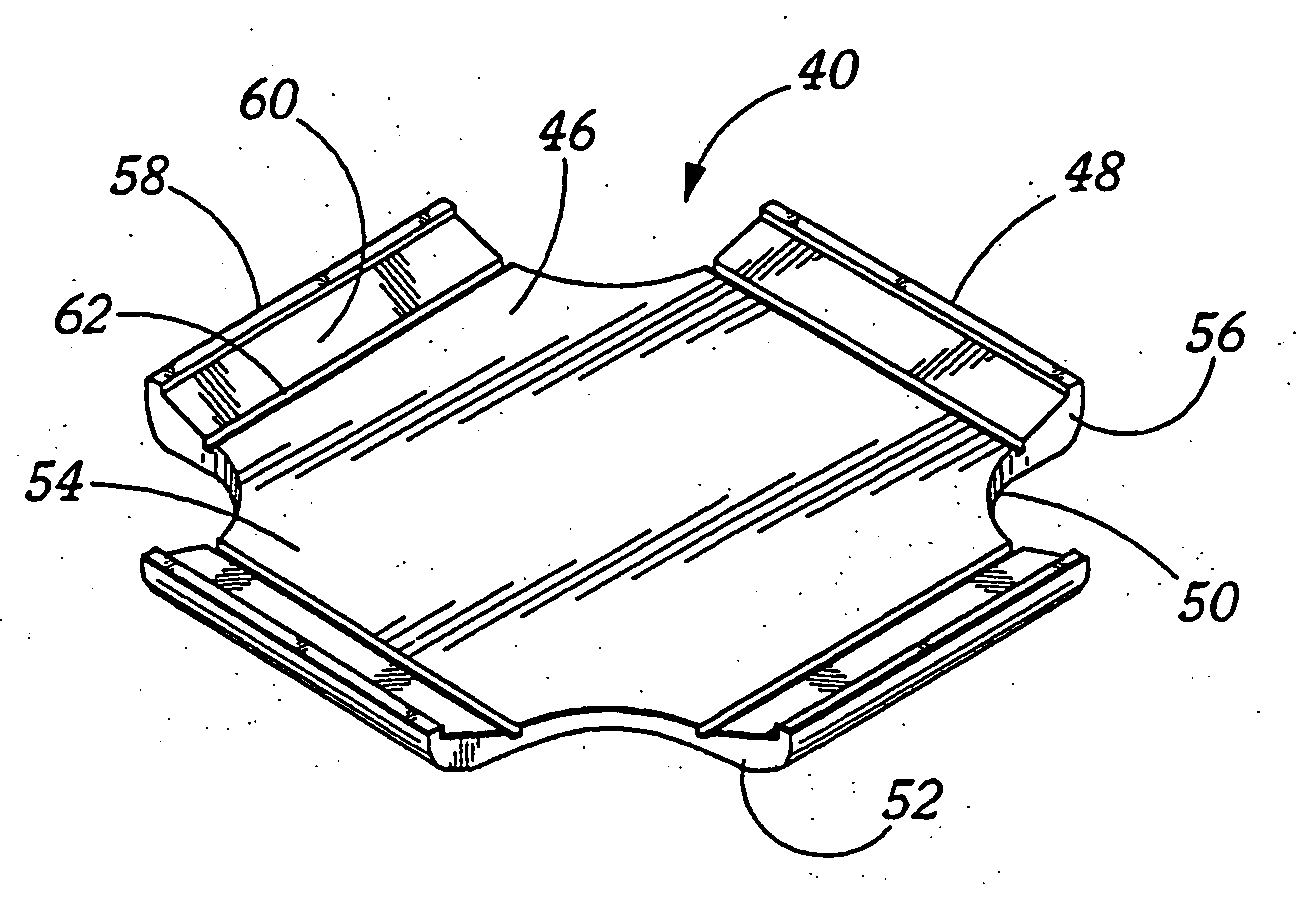

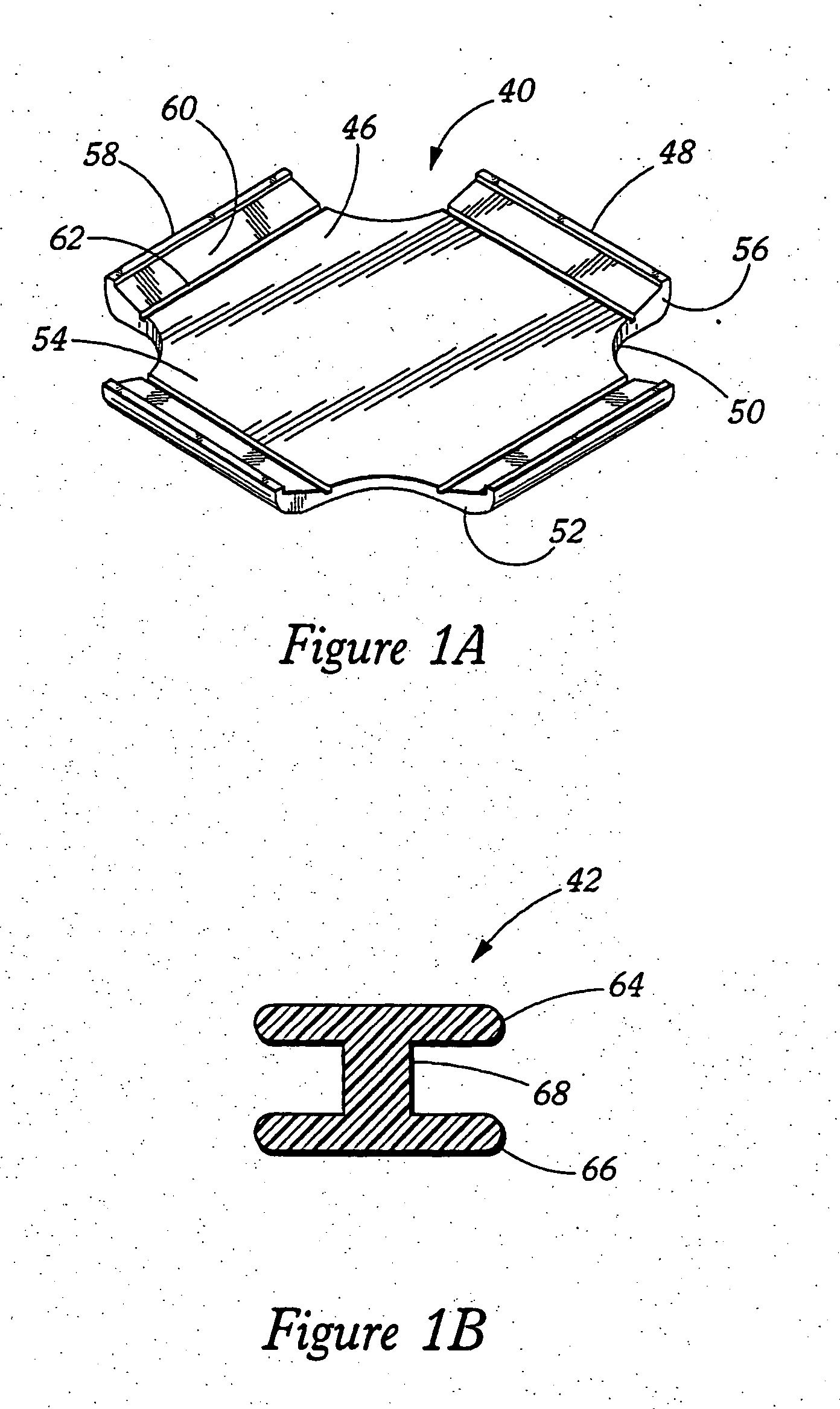

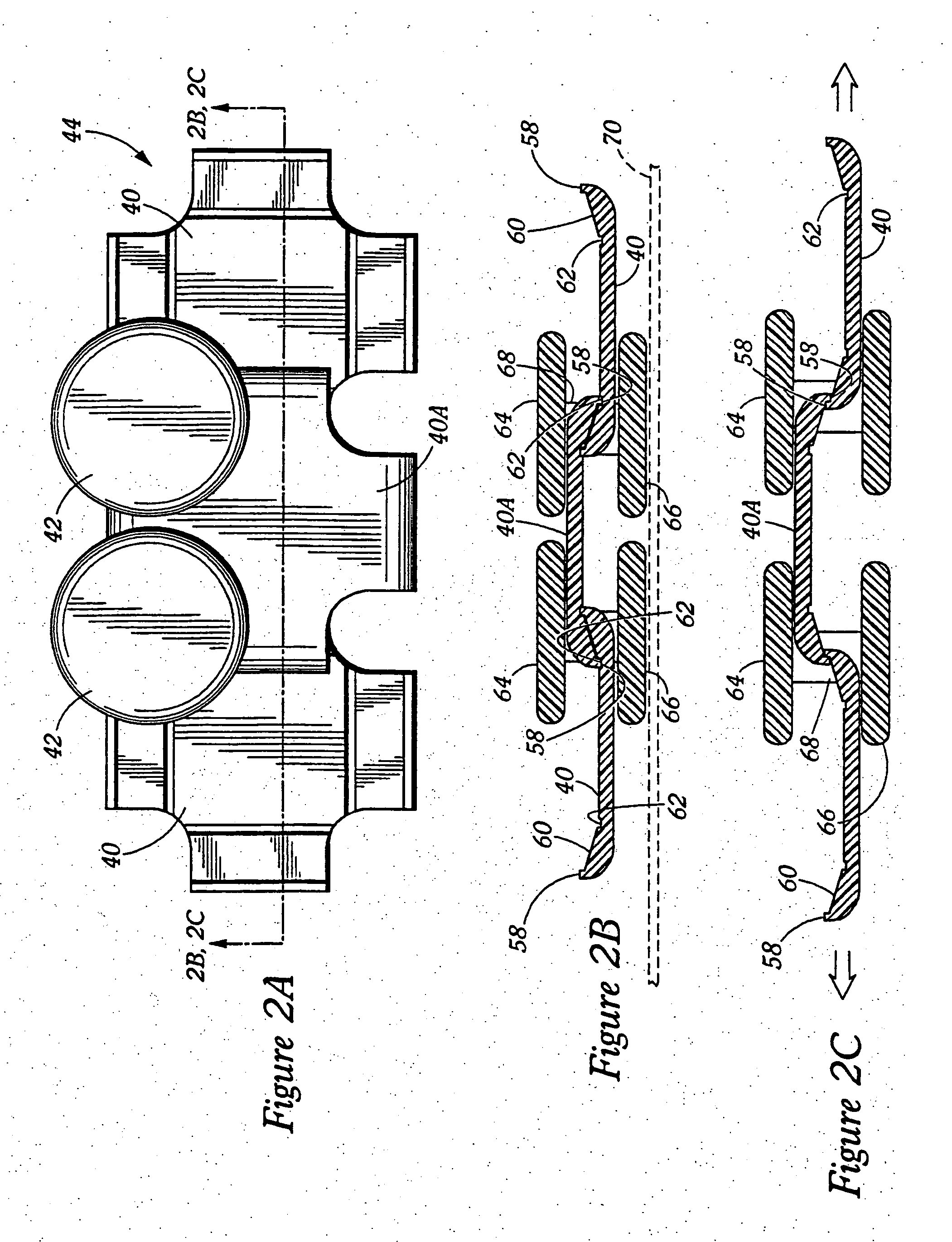

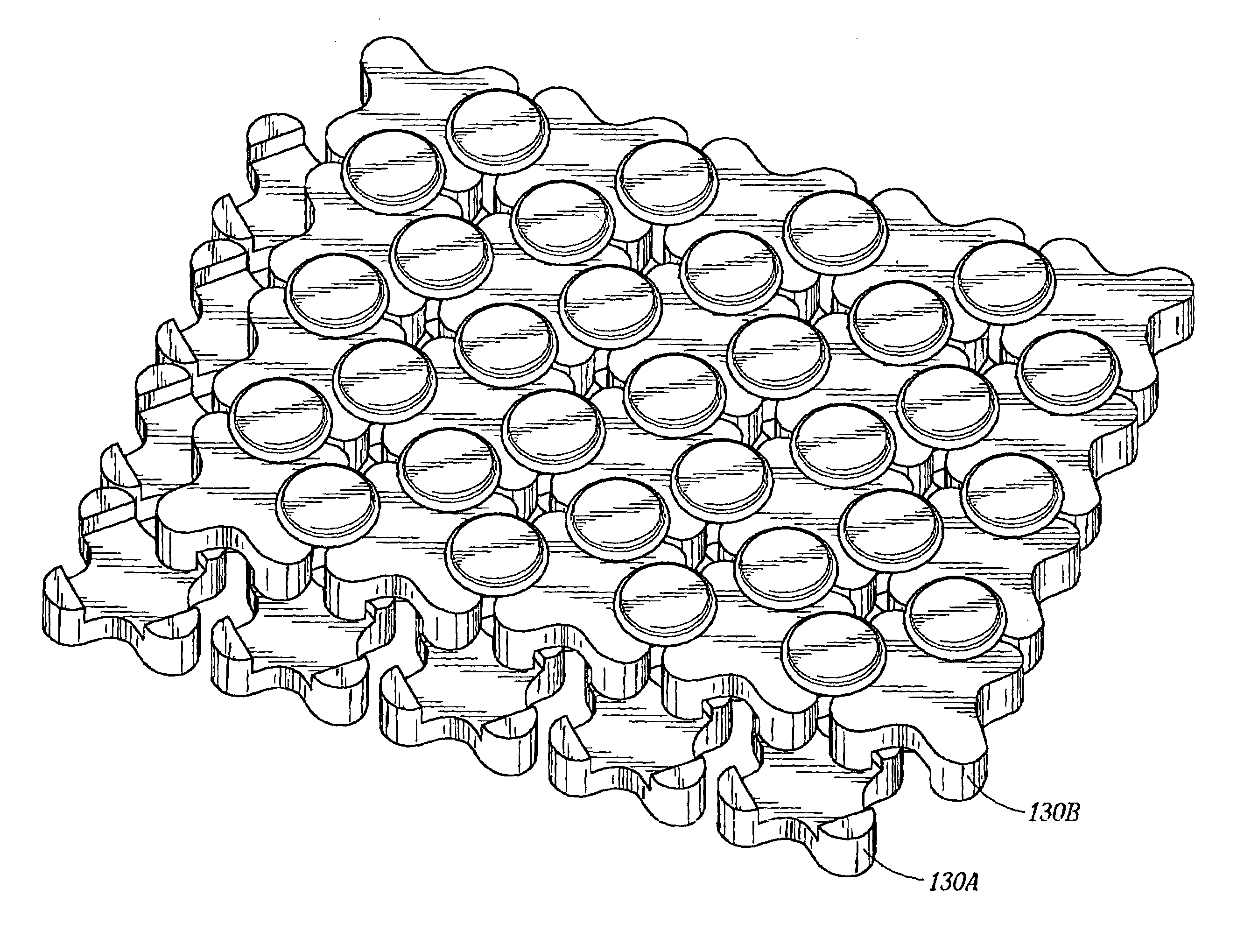

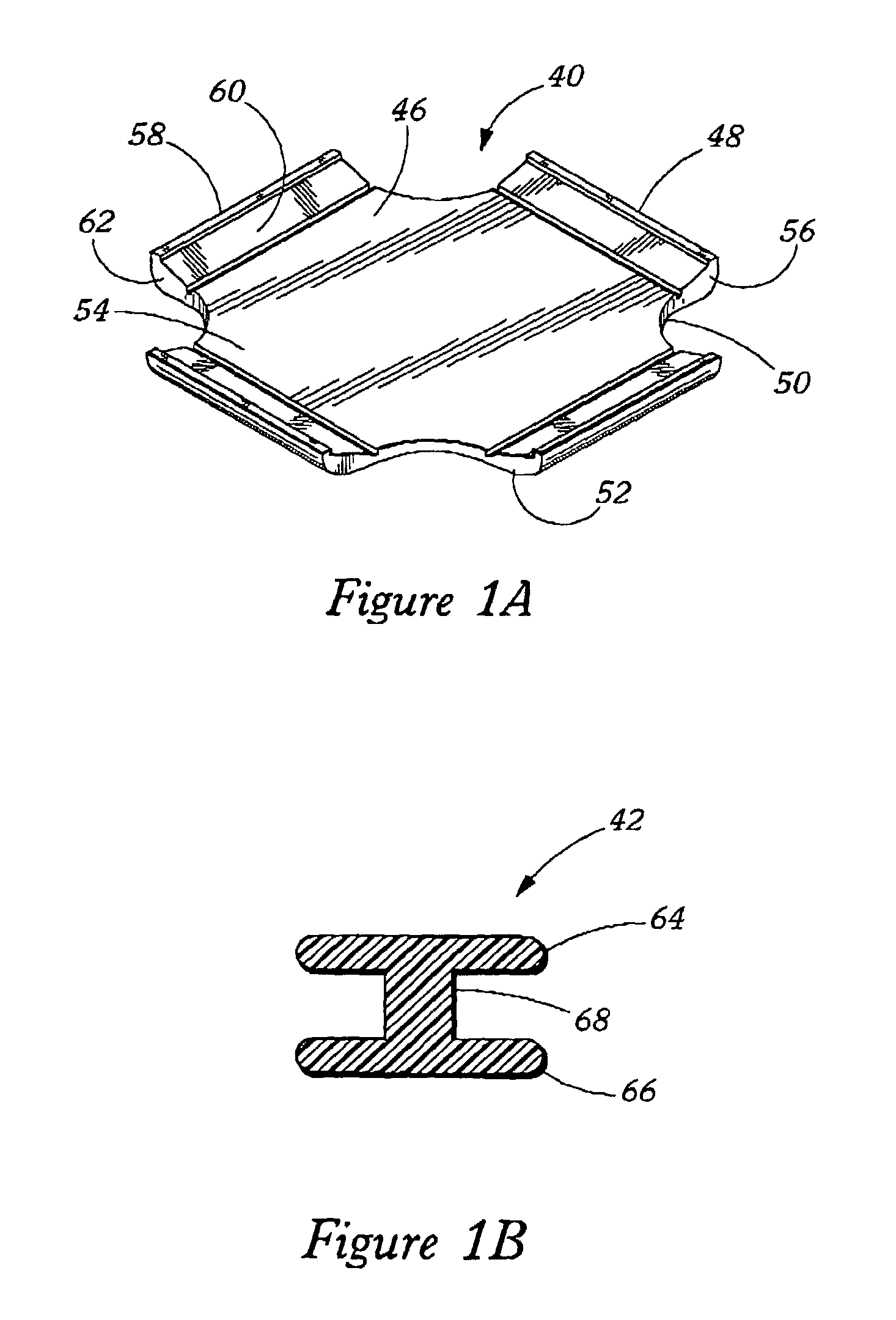

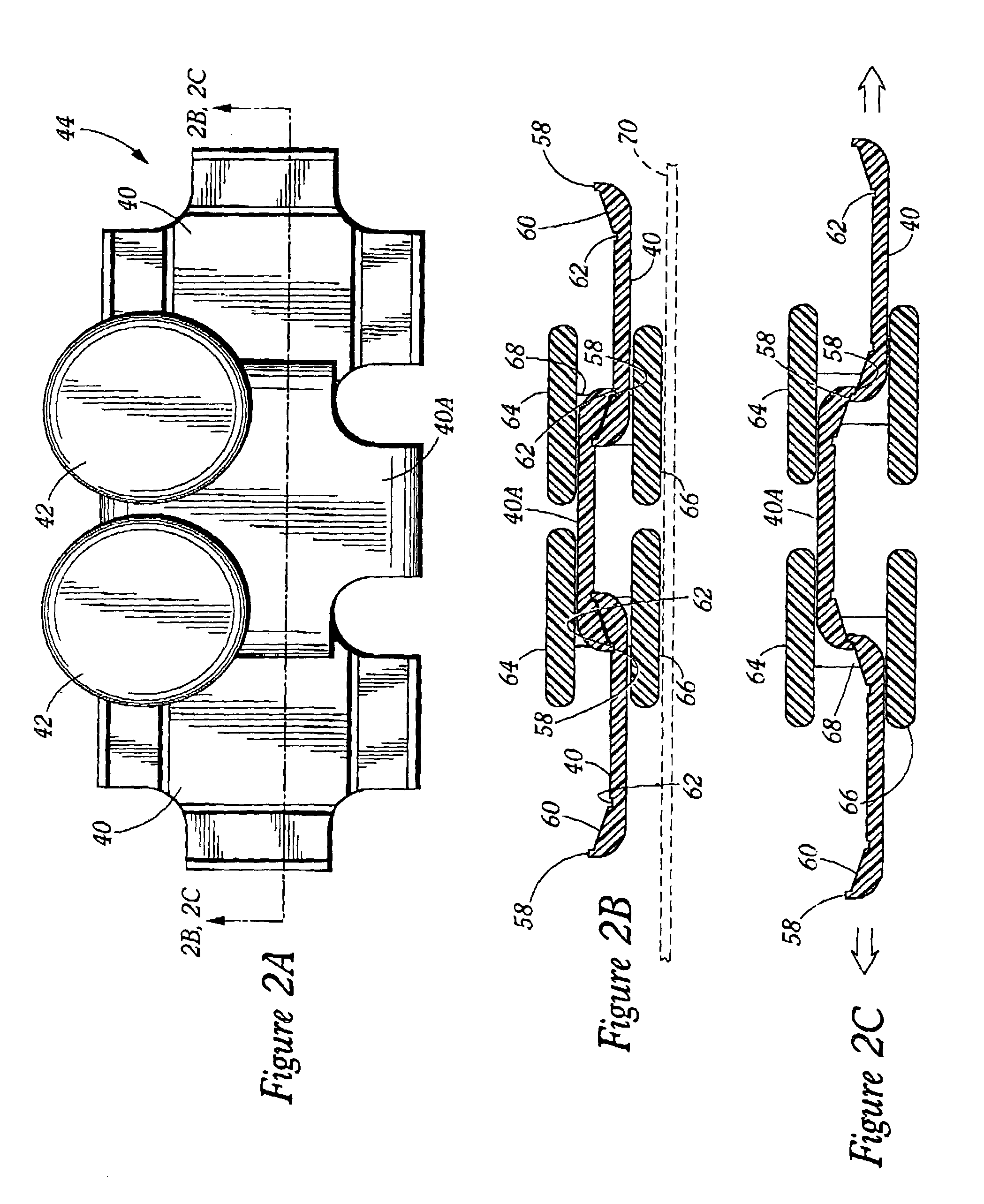

Direct forming of non-textile fabric elements from thermoplastic pellets or the like

InactiveUS20050214499A1Reduce labor costsReduce scrap costsMeasurement devicesLayered productsSingle pelletBriquette

An inventive solid phase forming process, and related structure, using conventional pelletized thermoplastic compositions to form the of a non-textile fabric by coining a single pellet or briquette of the polymer into an individual element in a single forming step. The steps of the process generally include: a) positioning a pellet in or adjacent to a mold cavity, and b) forcing the pellet into contact with the mold surfaces of the mold cavity to plastically deform the pellet to cause the pellet to adapt the shape of the mold cavity. The mold cavity has a shape to form the desired element, and its volume is substantially the same as the volume of the pellet. The forcing step or act preferably uses an energy and speed where the pellet superplastically deforms to substantially fill the volume of the mold cavity. This process is repeated with the particular element being formed in the appropriate order to form interconnected plates and rivets, as an example, with the final result being a non-textile fabric. The elements formed by the inventive process can have any of a variety of shapes, and can form base units for the formation of the non textile fabric of two, three or more elements. This inventive process eliminates the need to first form the pelletized polymer into a sheet or other type of preform prior to the forming of the final product.

Owner:OCONNOR GREGORY W +1

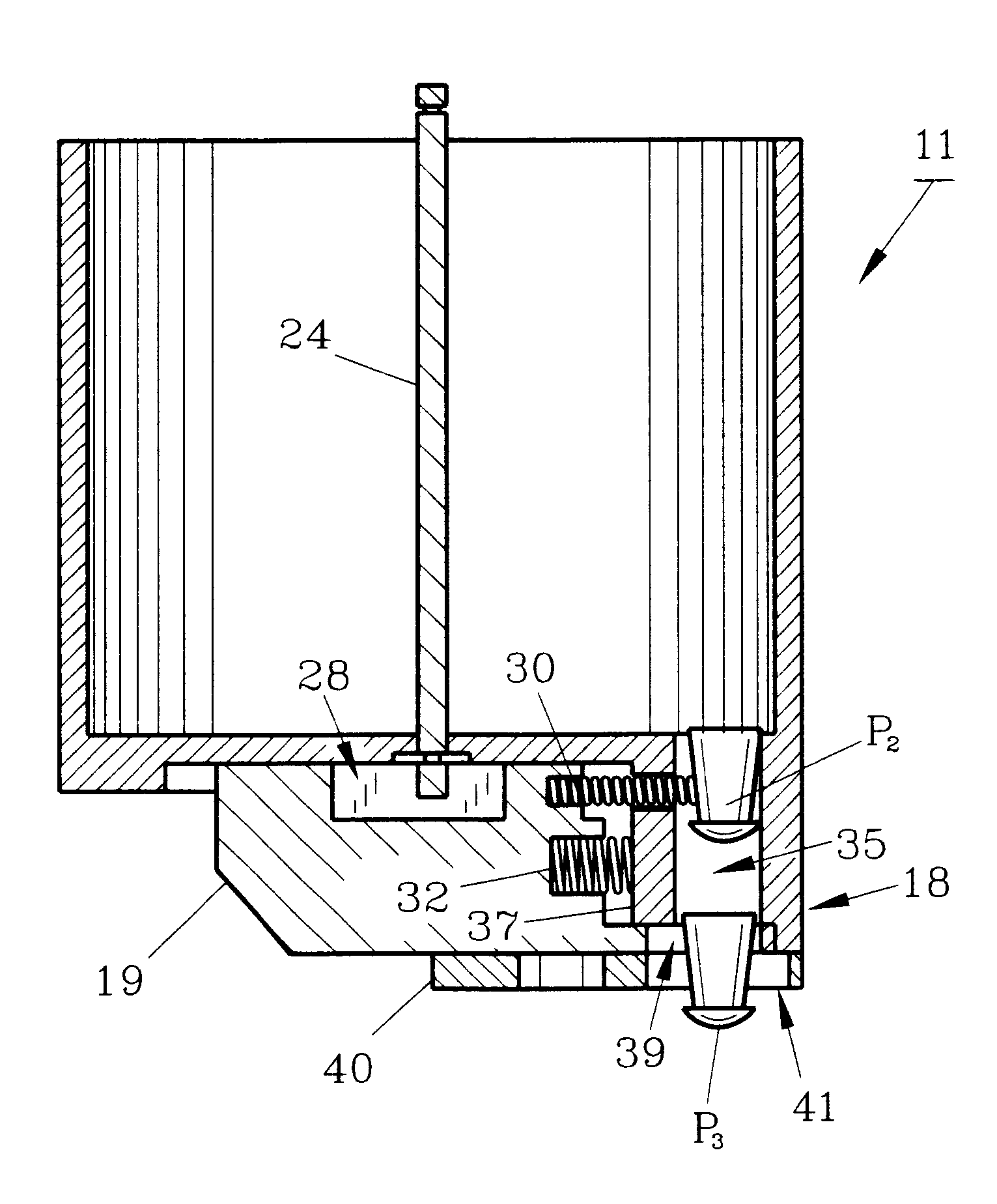

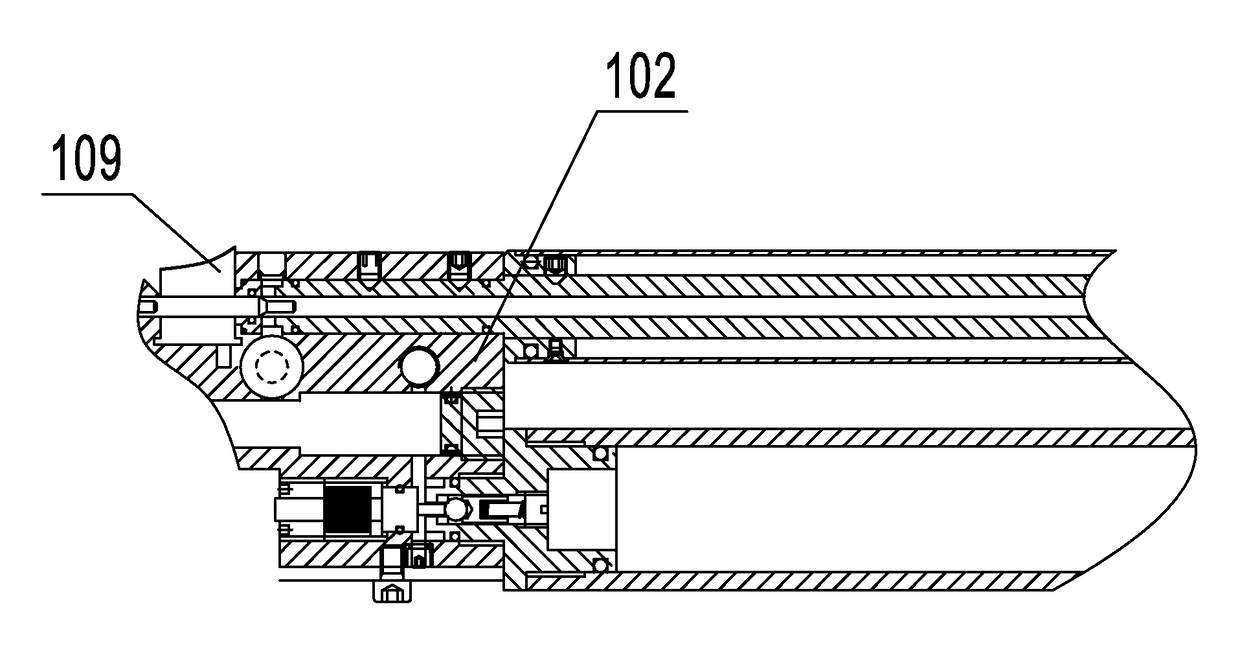

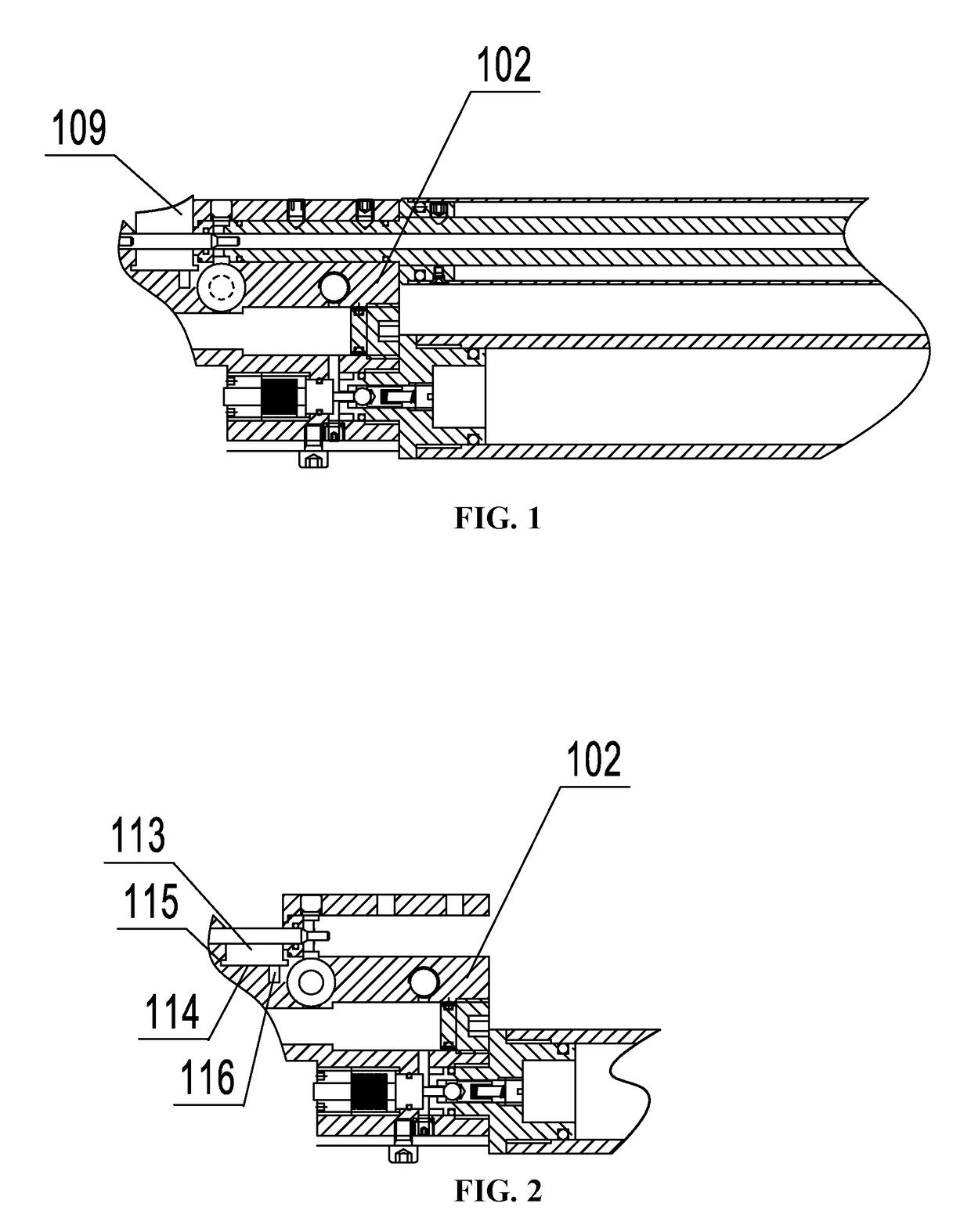

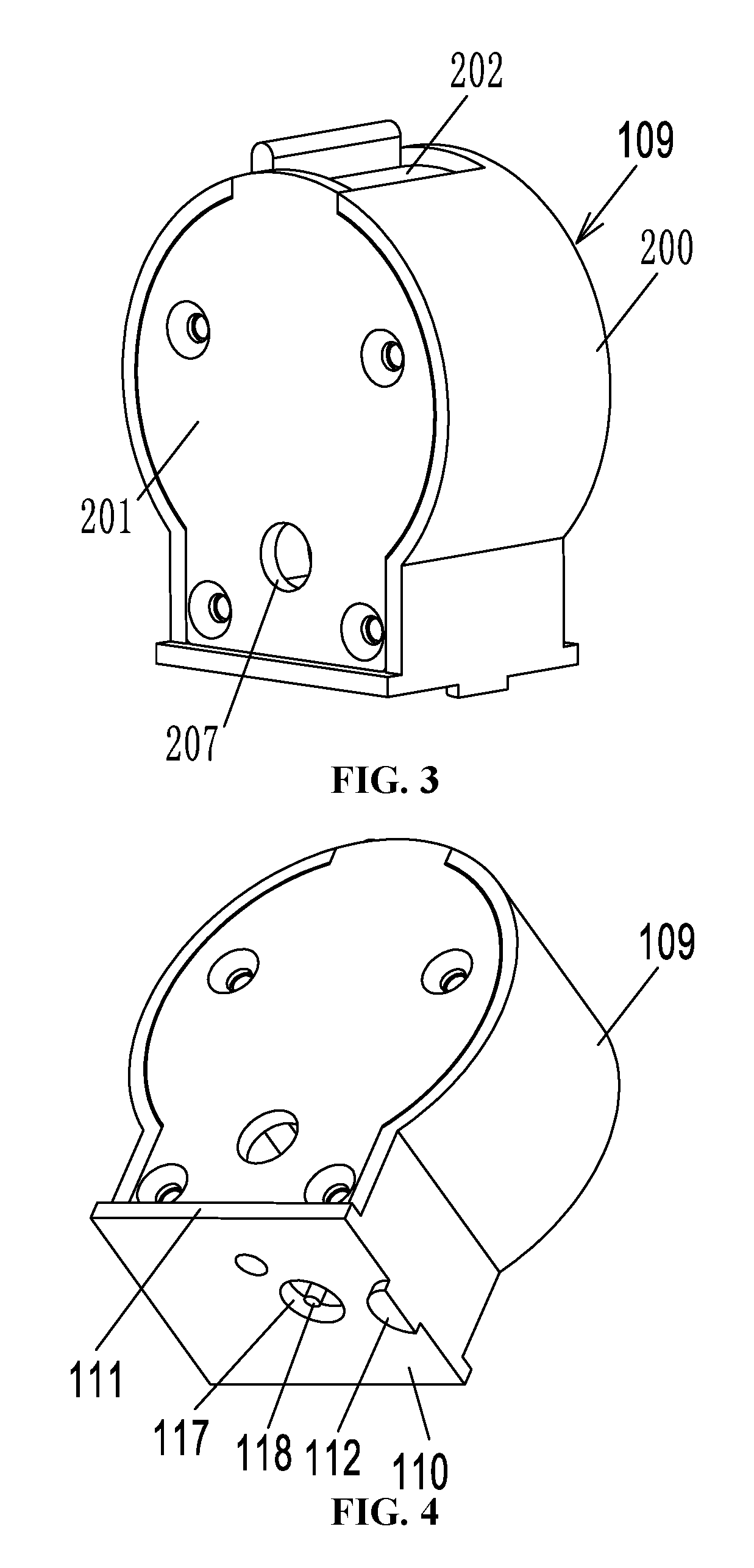

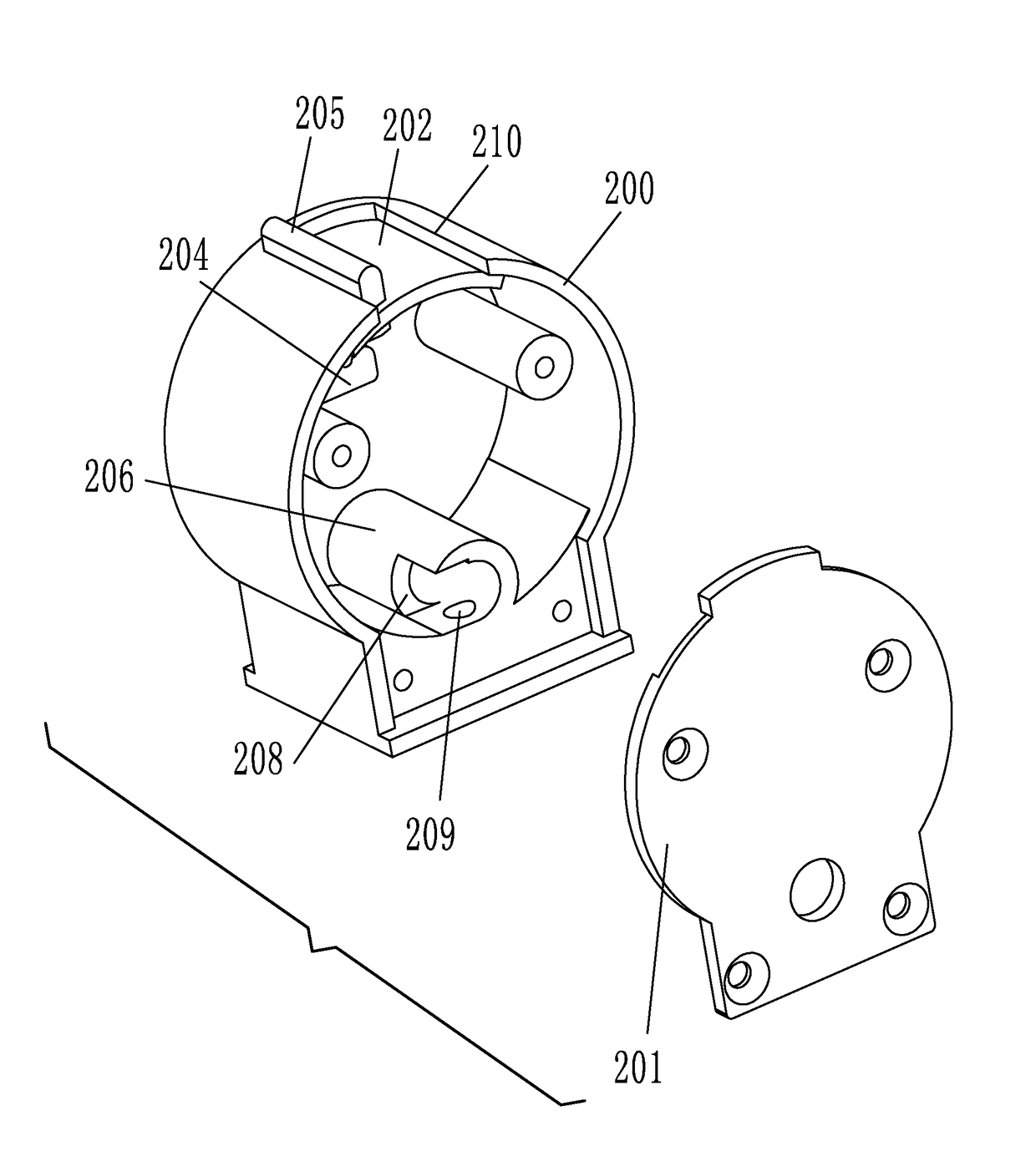

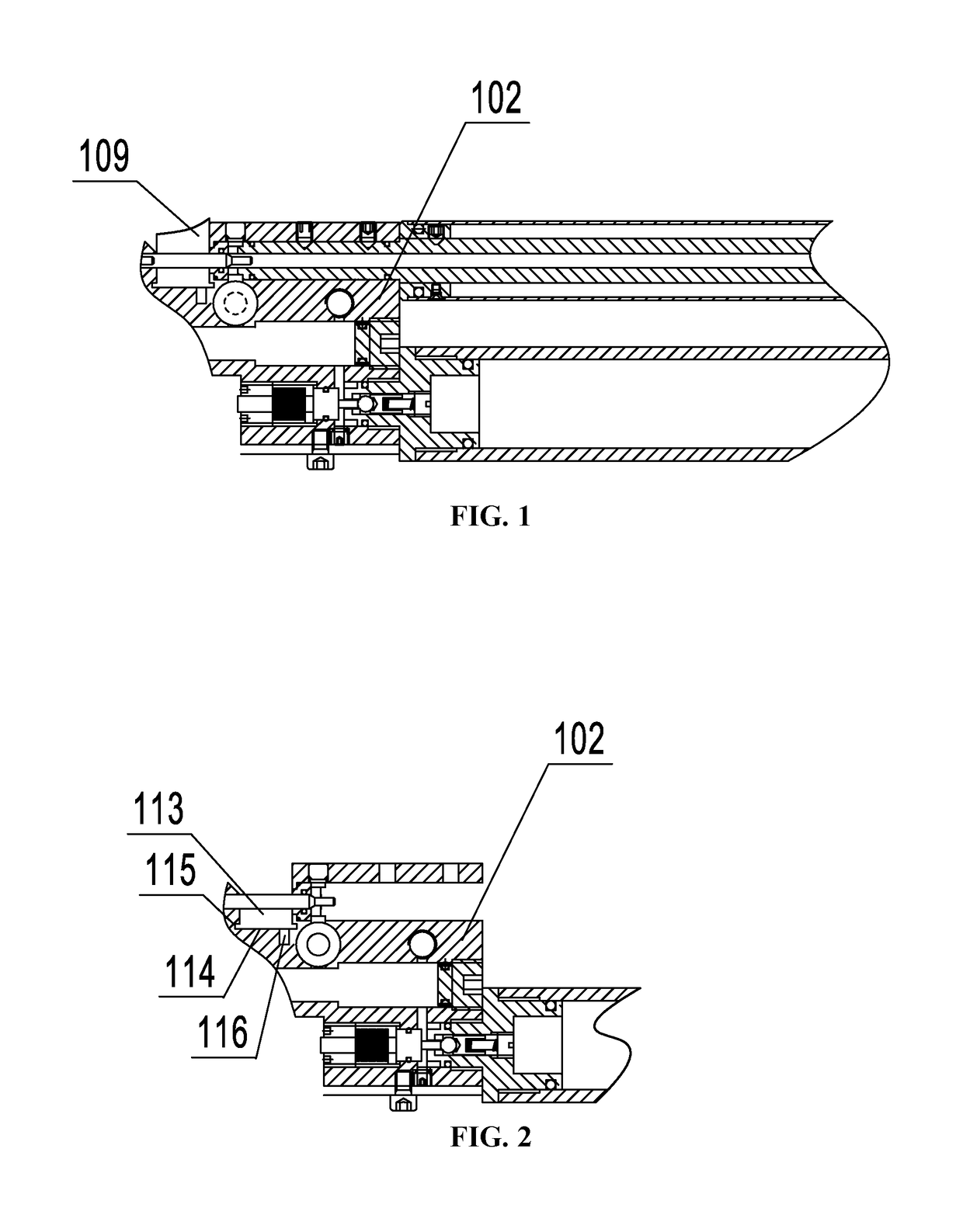

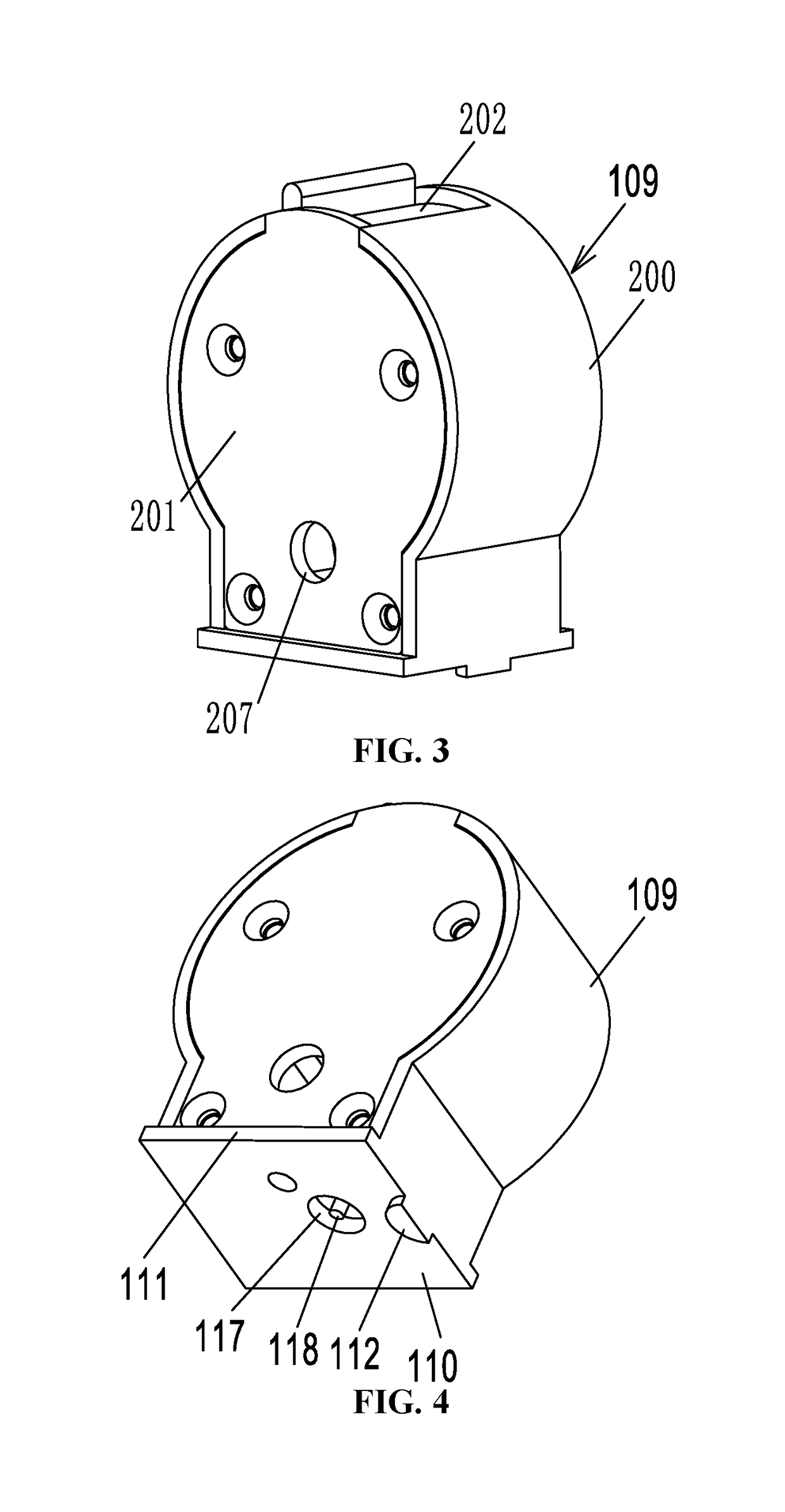

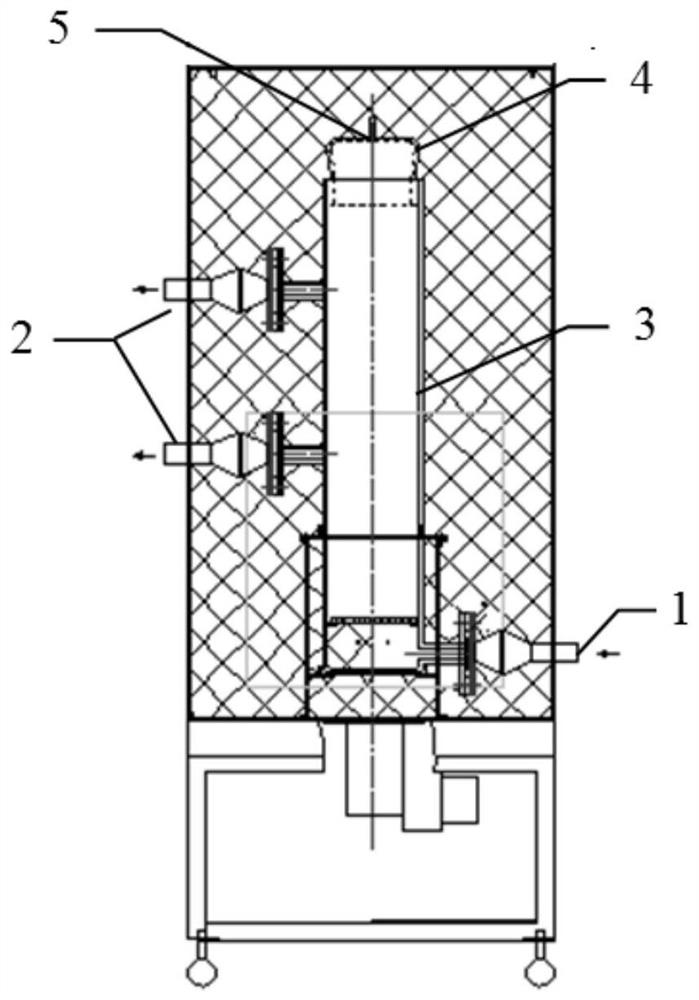

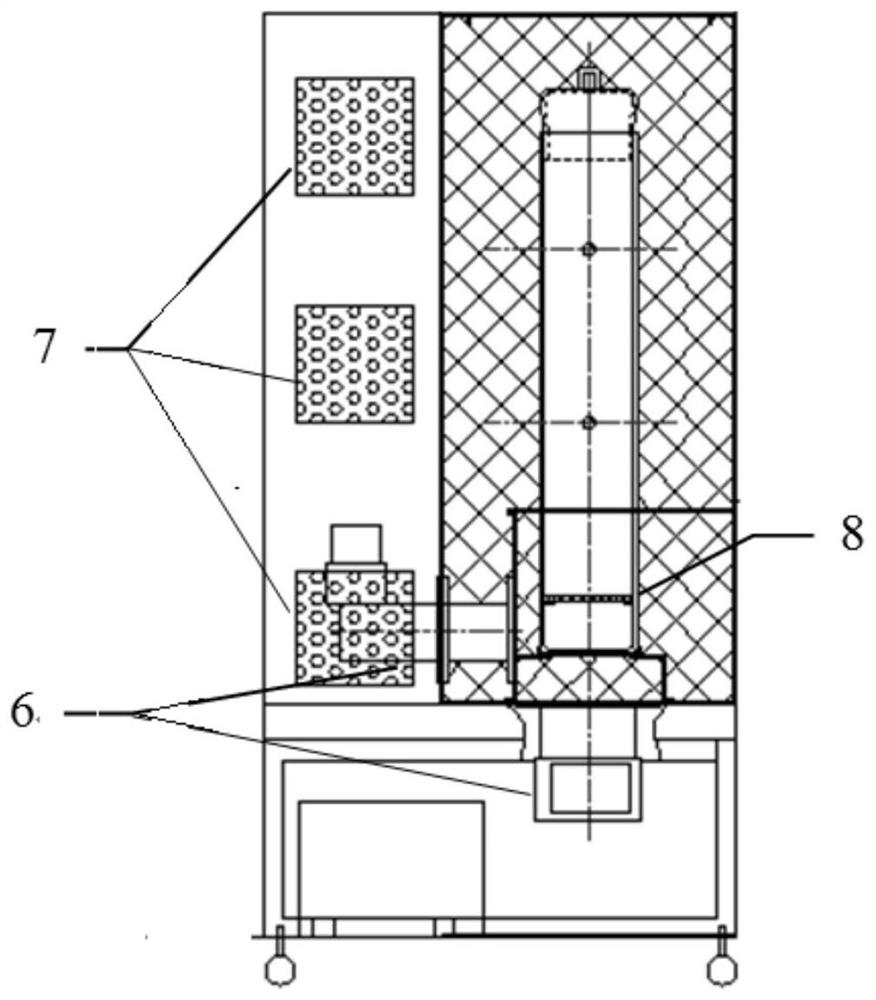

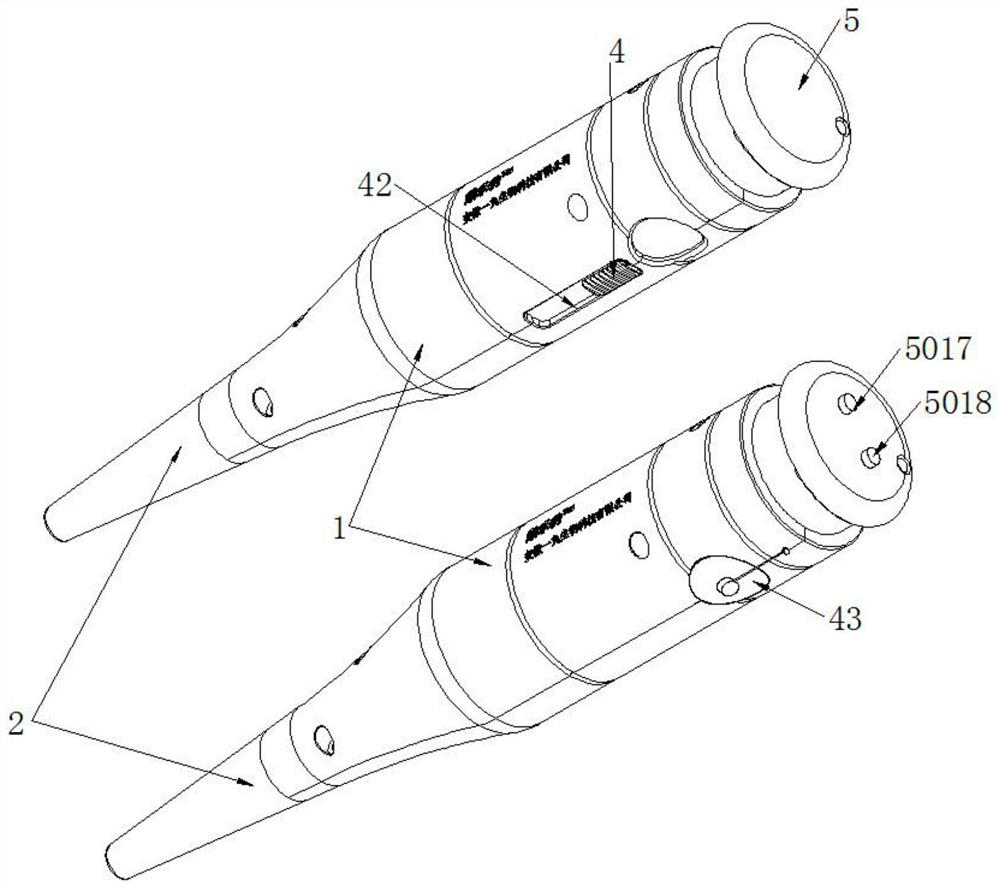

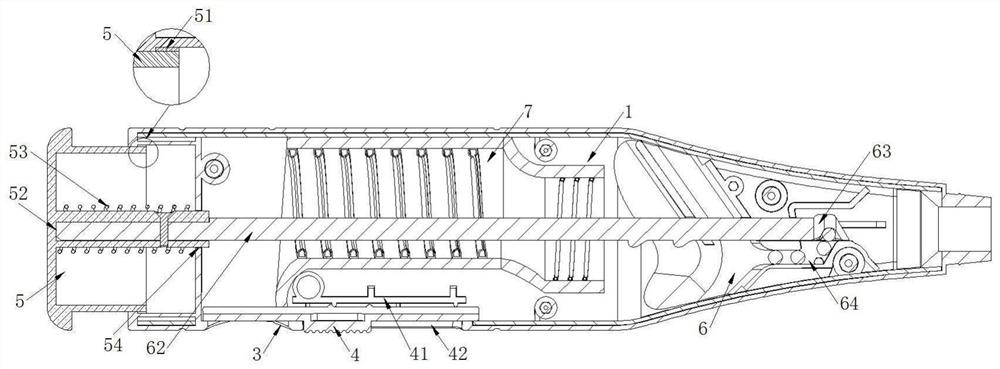

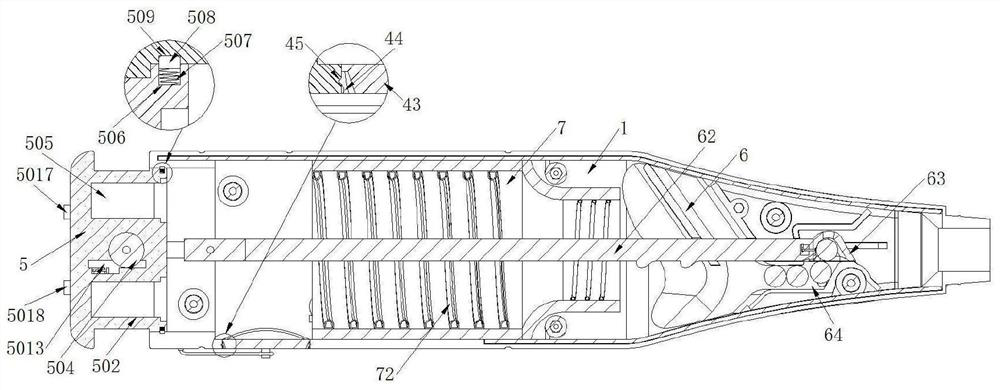

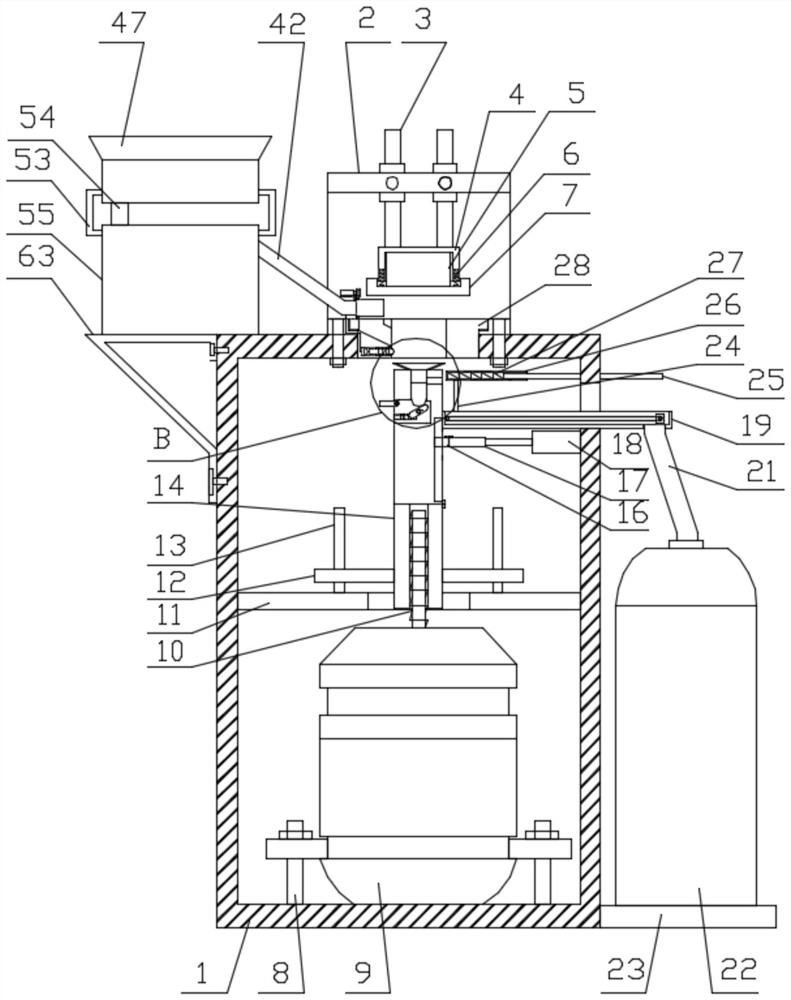

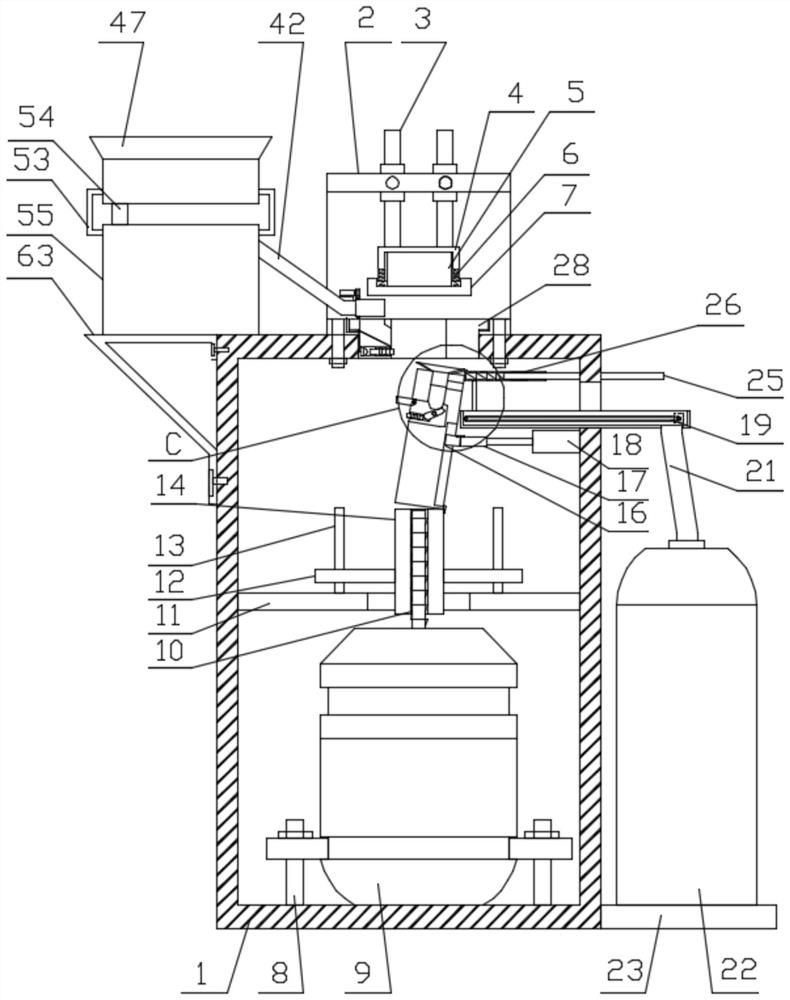

Automatic pellet loader of pneumatic air gun

ActiveUS10066896B2Easy to carryAvoid error introductionAmmunition loadingCompressed gas gunsSingle pelletMechanical engineering

An automatic pellet loader of a pneumatic air gun, including a pellet clip seat, a pellet clip lid, a pellet clip closure, and a magnetic shaft. The pellet clip seat and the pellet clip lid are connected to form a magazine case that includes a pellet inlet. The pellet clip closure is rotatably connected to the magazine case for opening or closing the pellet inlet. The bottom side wall of the pellet clip seat is provided with a loading sleeve that extends to the pellet clip lid. A center hole of the loading sleeve perpendicularly penetrates through the pellet clip seat. The pellet clip lid includes a loading channel allowing the pull-bolt thimble to pass through. The loading sleeve includes an opening close to an exit side of the loading channel through which a single pellet can slip autonomously into the loading channel.

Owner:ZHONG SHAN NEW SWAN TECH CO LTD

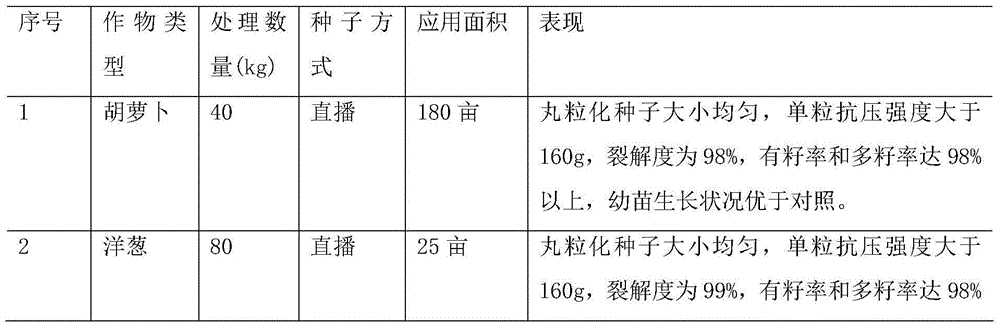

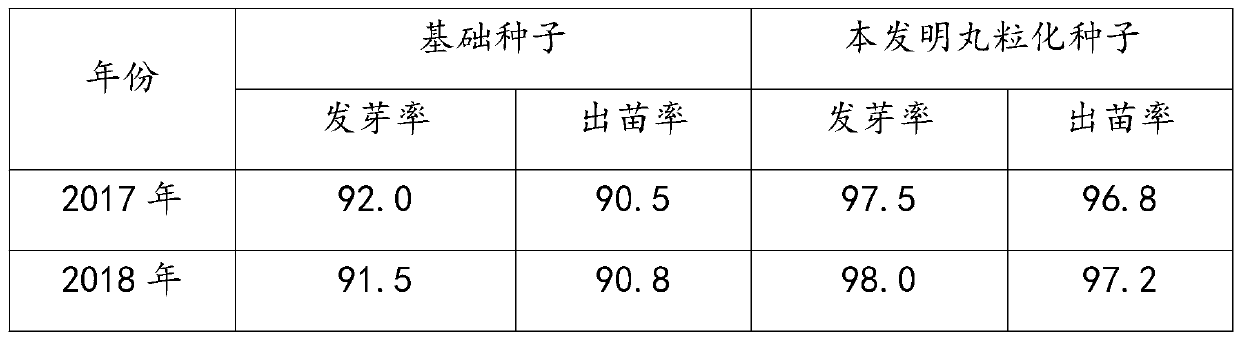

Pelletization processing technology for seeds

InactiveCN105723869AHigh granulation rateUniform sizeSeed immunisationSeed coating/dressingSingle pelletCompressive strength

The invention provides a pelletization processing technology for seeds, which includes the following seven steps: seed fine selection, disinfection, core forming, pellet strength enhancement, screening and classification, polishing and coloring, heat-drying and metering package. The technology has high pelletizing rate of seeds, can automatically classify the pellets, is uniform in pellet size and high in pellet quality, and can satisfy requirement in practical production in single pellet compressive strength, single seed ratio and available seed ratio.

Owner:TIANJIN ZHONGTIAN DADI SCI & TECH CO LTD

Direct forming of non-textile fabric elements from plastic pellets

InactiveUS7972549B2Reduce labor costsReduce scrap costsFilament/thread formingLaminationSingle pelletBriquette

A process, and related structure, uses conventional pelletized compositions to form the elements of a non-textile fabric by coining a single pellet or briquette of a polymer into an individual element in a single forming step. The steps of the process generally include: a) positioning a pellet in or adjacent to a mold cavity, and b) forcing the pellet into contact with the mold surfaces of the mold cavity to plastically deform the pellet to the shape of the mold cavity. The forcing step preferably uses an energy and speed where the pellet superplastically deforms to substantially fill the mold cavity. This process is repeated with the elements being formed in the appropriate order to form a non-textile fabric. The elements thus formed can have a variety of shapes, and can form base units for the formation of the non-textile fabric of two, three or more elements.

Owner:SAMSONITE IP HLDG SARL

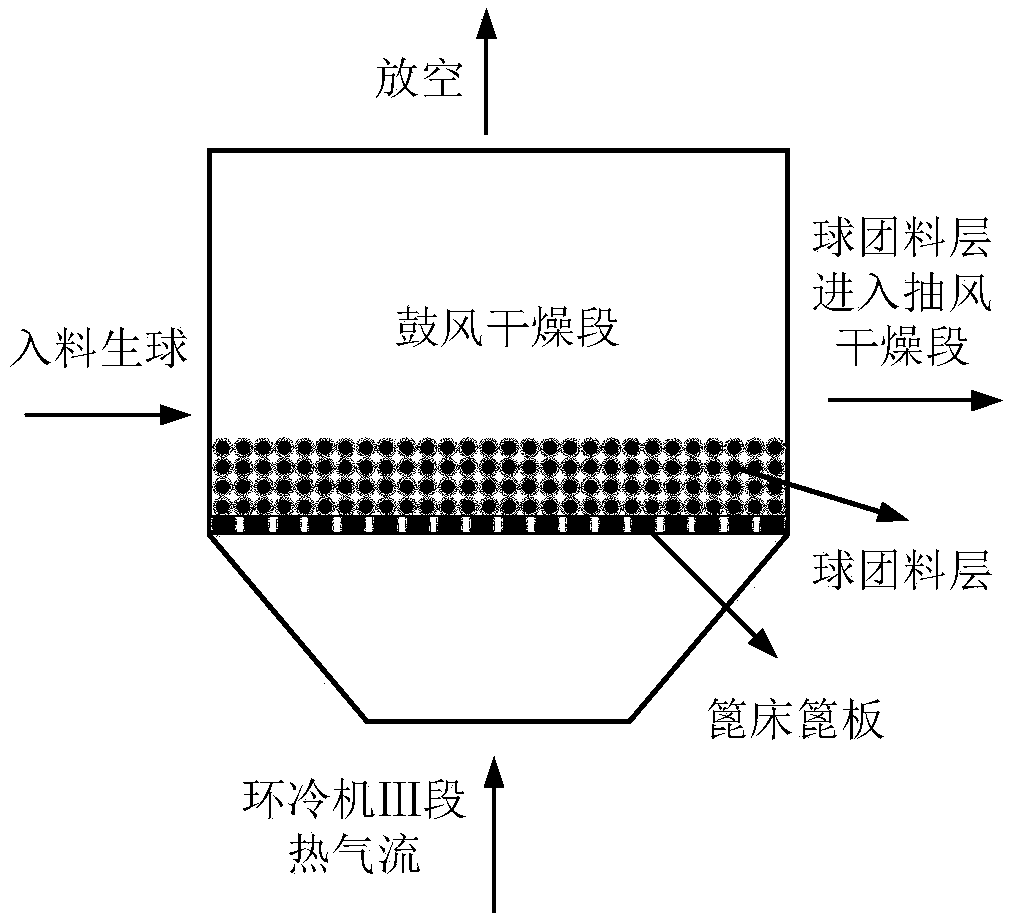

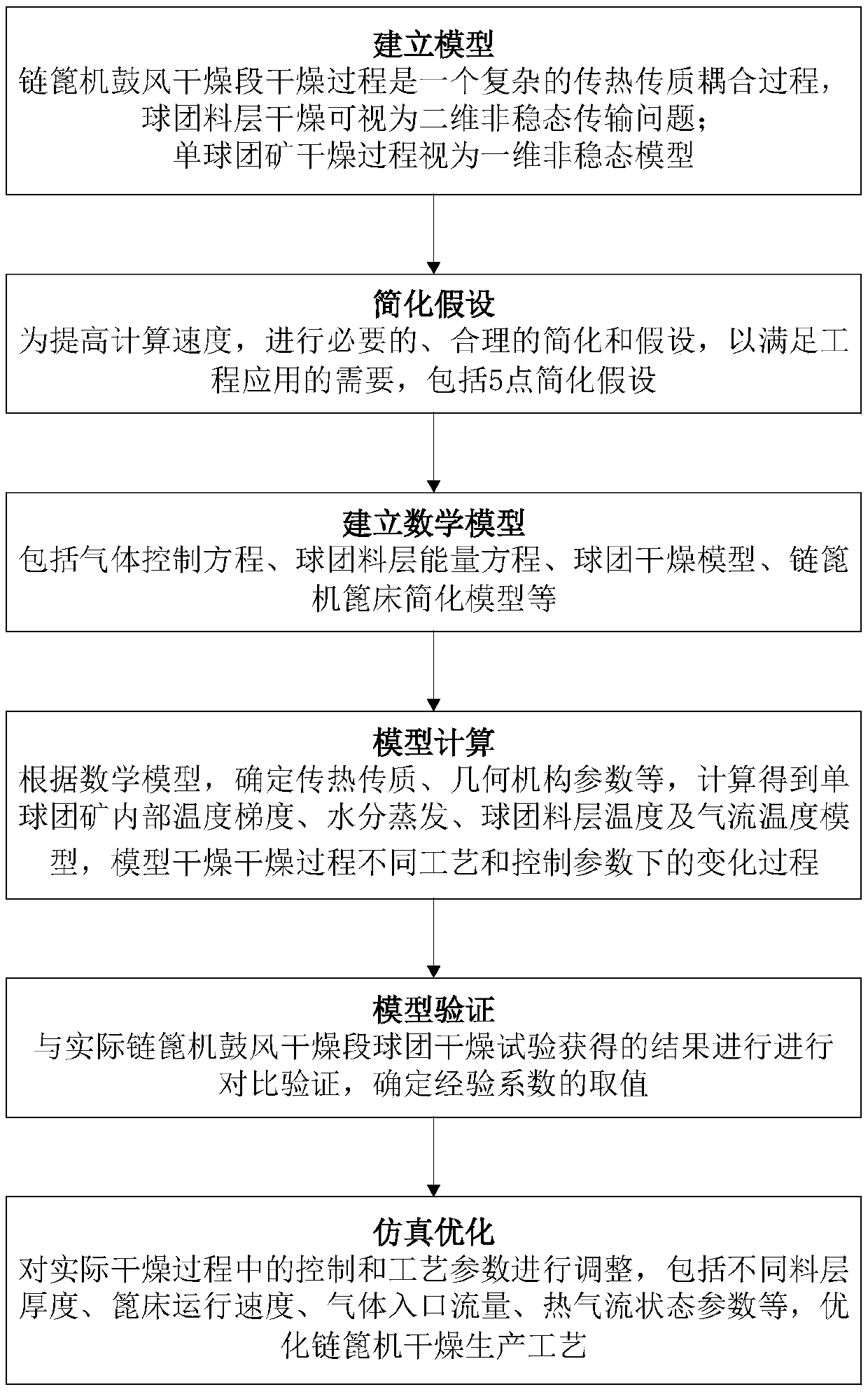

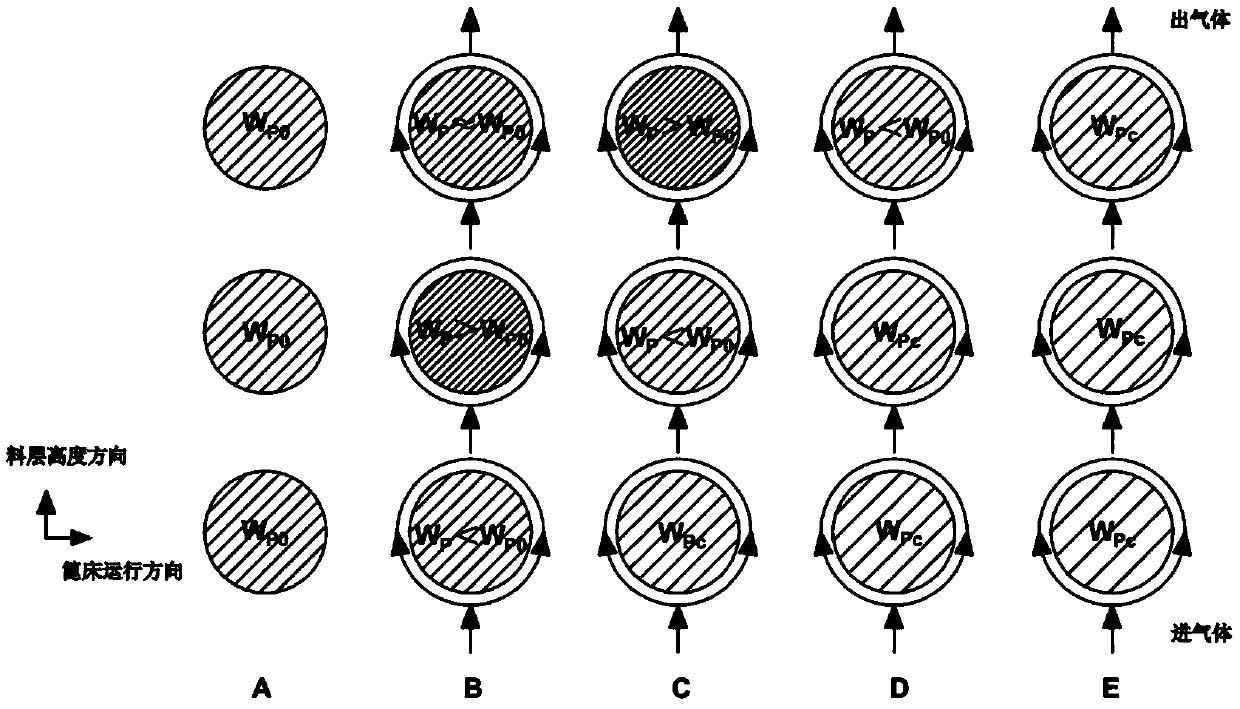

Numerical method for predicting pellet drying process in grate blast drying section

ActiveCN109063320AImprove simulation accuracyHave application valueDesign optimisation/simulationSpecial data processing applicationsSingle pelletSteam condensation

The invention discloses a numerical calculation method for predicting the pellet drying process of a grate blast drying section, which comprises the following steps: (1) establishing a two-dimensionalunsteady mathematical model of the pellet layer heat coupling process of the grate blast drying section; One-dimensional unsteady mathematical model of heat transfer in single pellet considering steam condensation as an important process of moisture transfer; (2) In order to improve the calculation speed, the drying process of grate blast drying section is simplified and assumed reasonably; (3) establishing mathematical model, including single pellet drying mathematical model, pellet bed drying mathematical model and so on; (4) calculating a model, according to the mathematical model, determining parameters of heat and mass transfer, geometry structure and the like, and simulating changes of drying process under different drying processes and control parameters of the grate blast drying section; (5) performing model verification, comparing with the actual pellet drying test results, to determine the value of empirical coefficients; (6) Simulation and optimization, adjusting the control and process parameters in the actual drying process, optimizing the pellet drying process.

Owner:JIANGSU UNIV

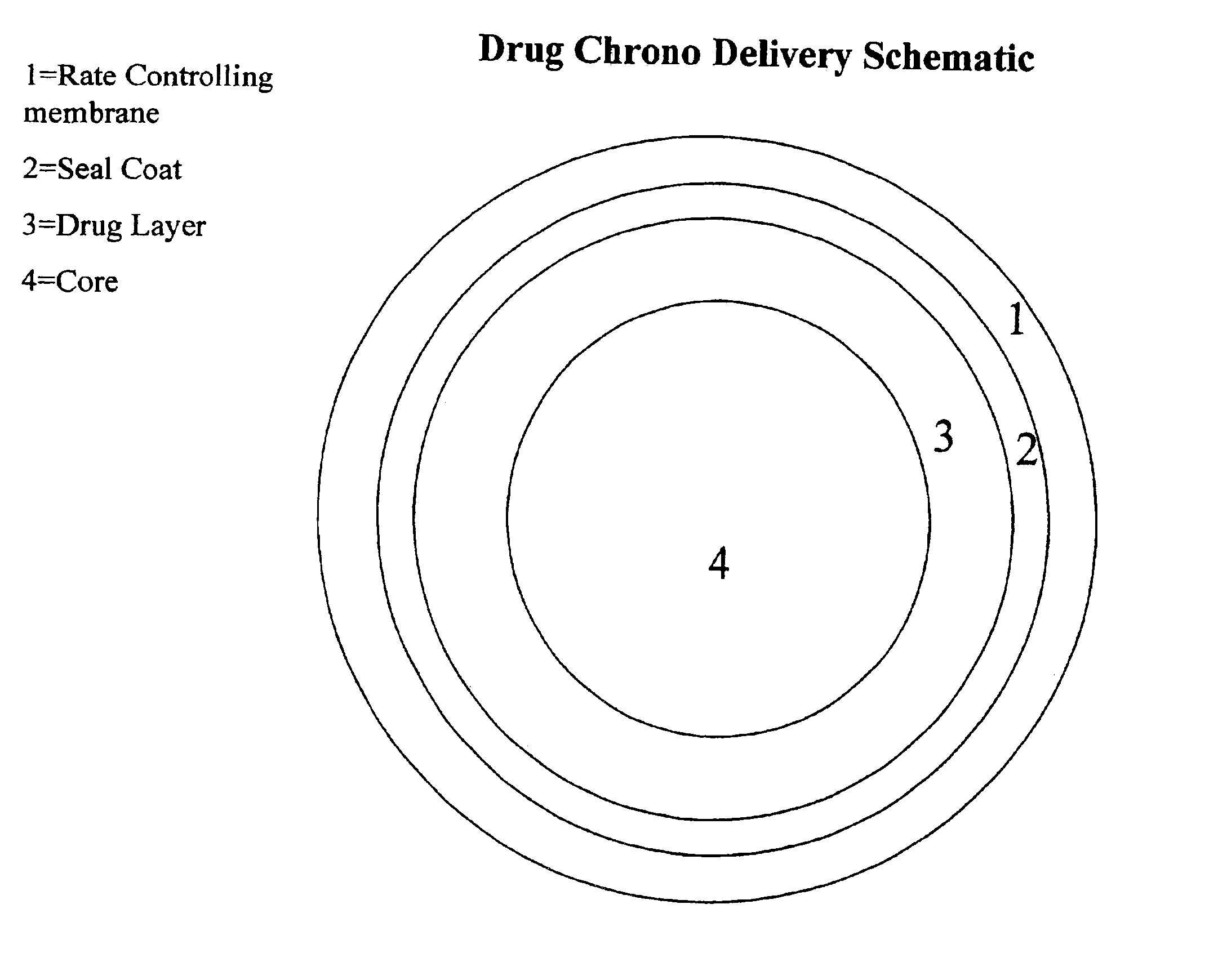

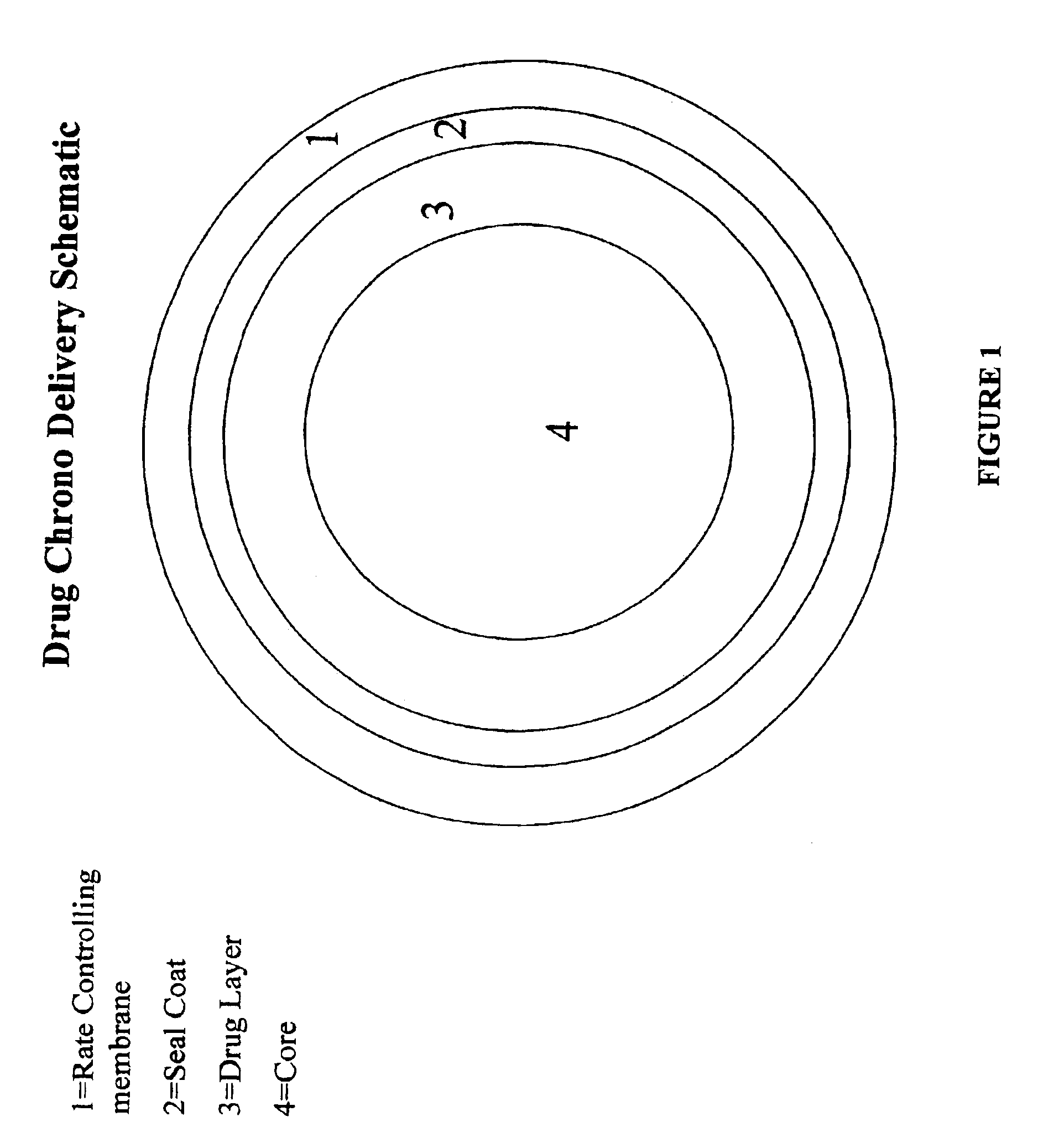

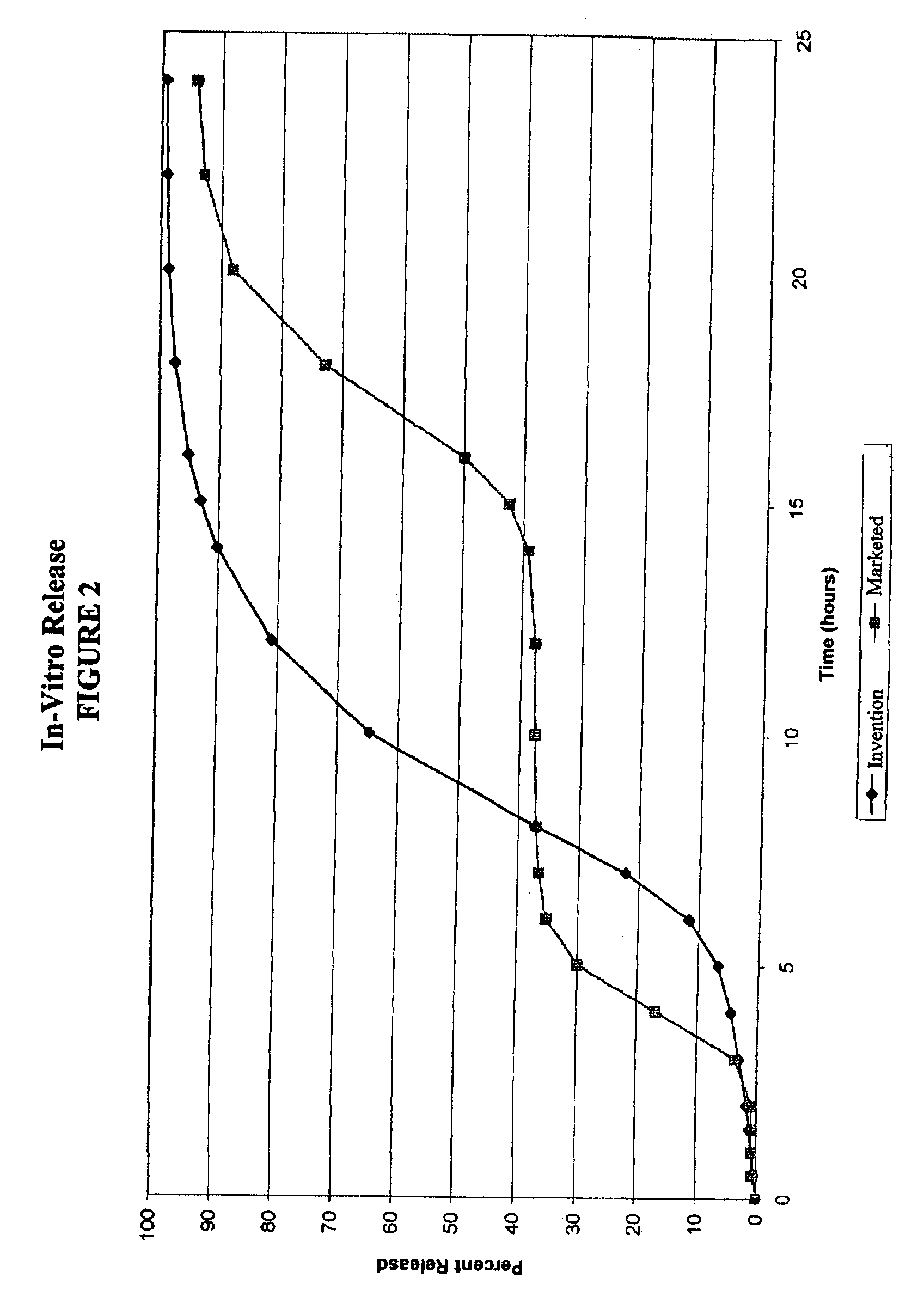

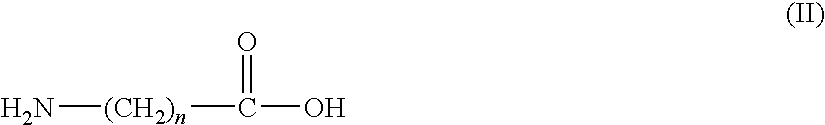

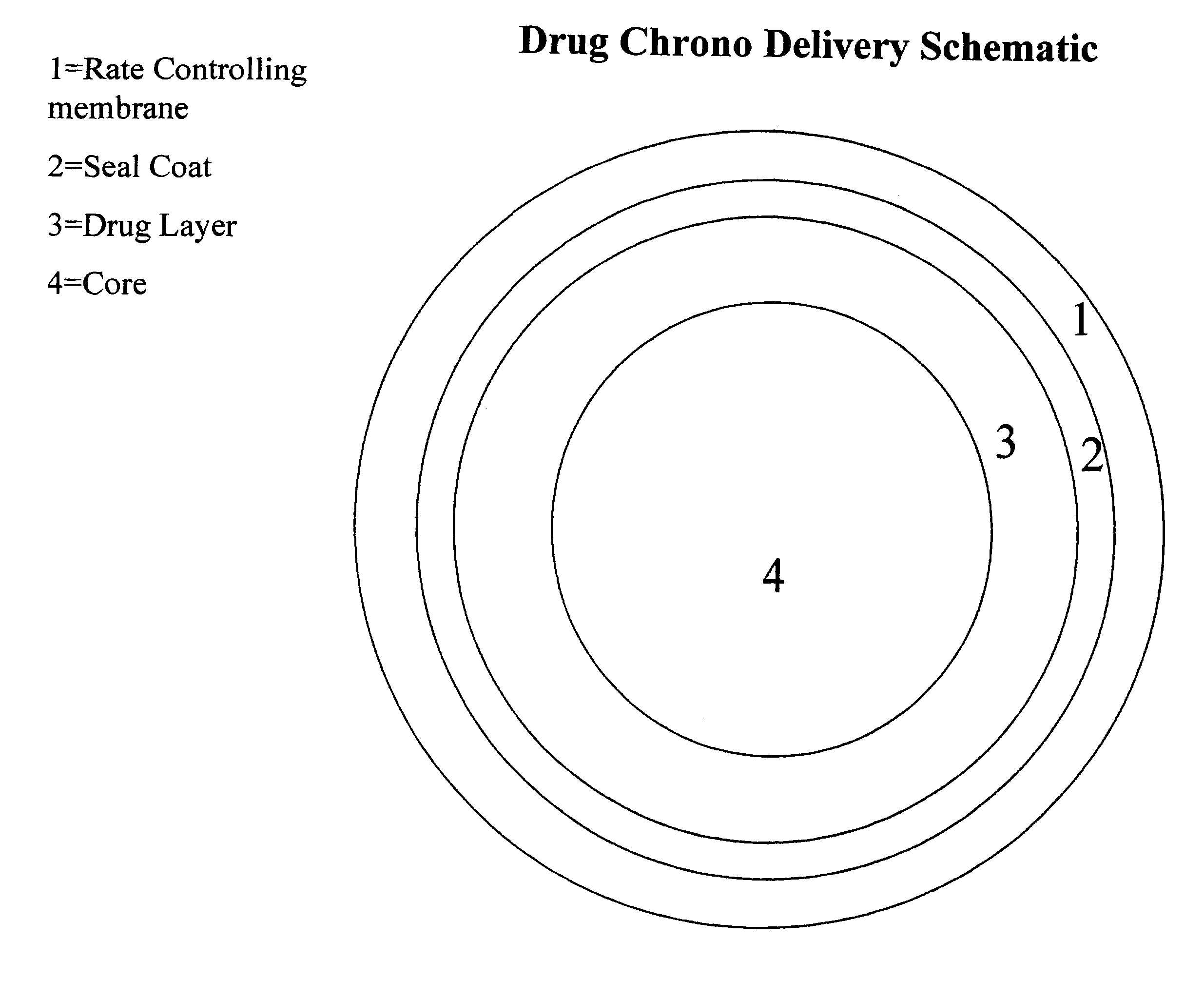

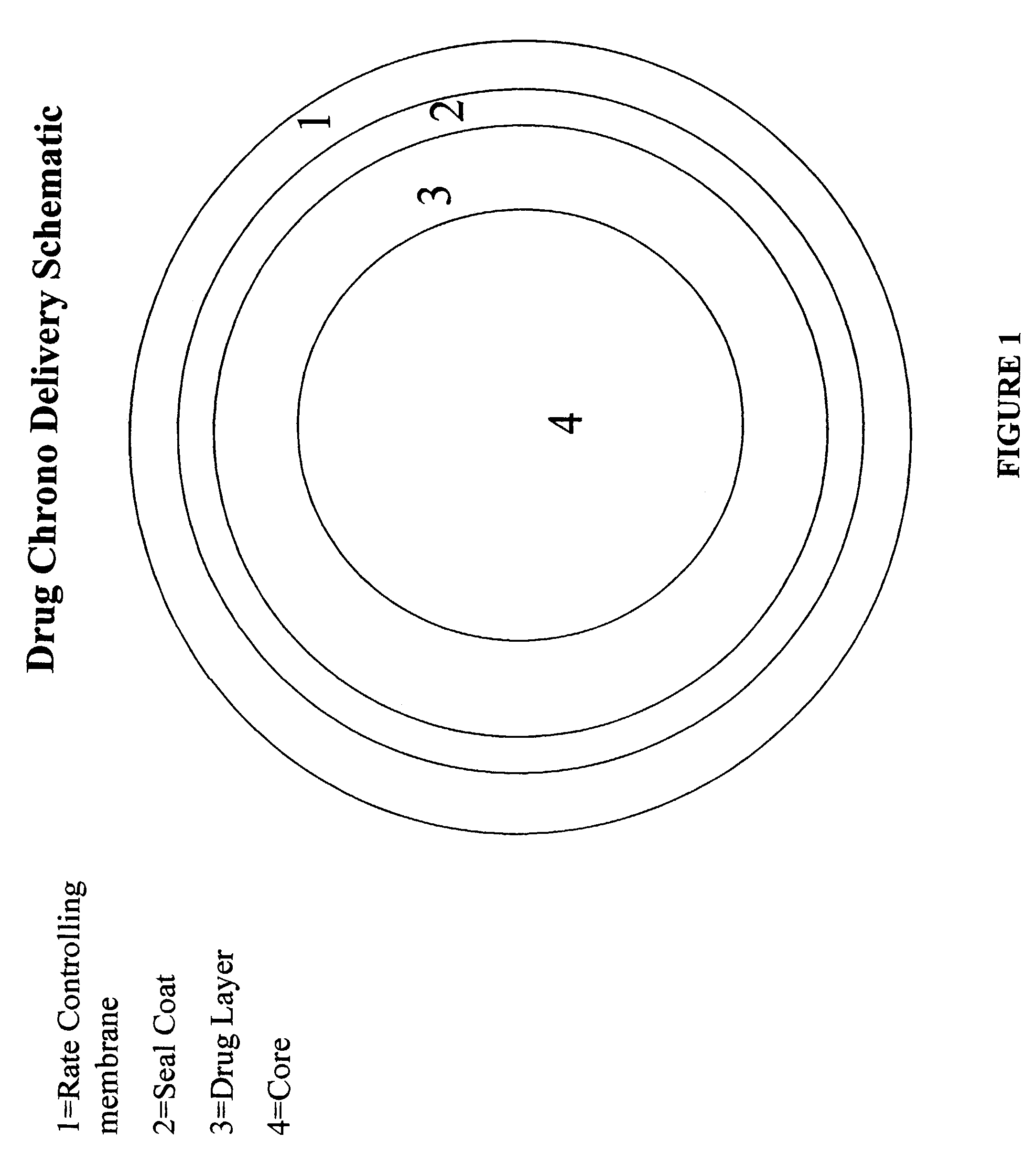

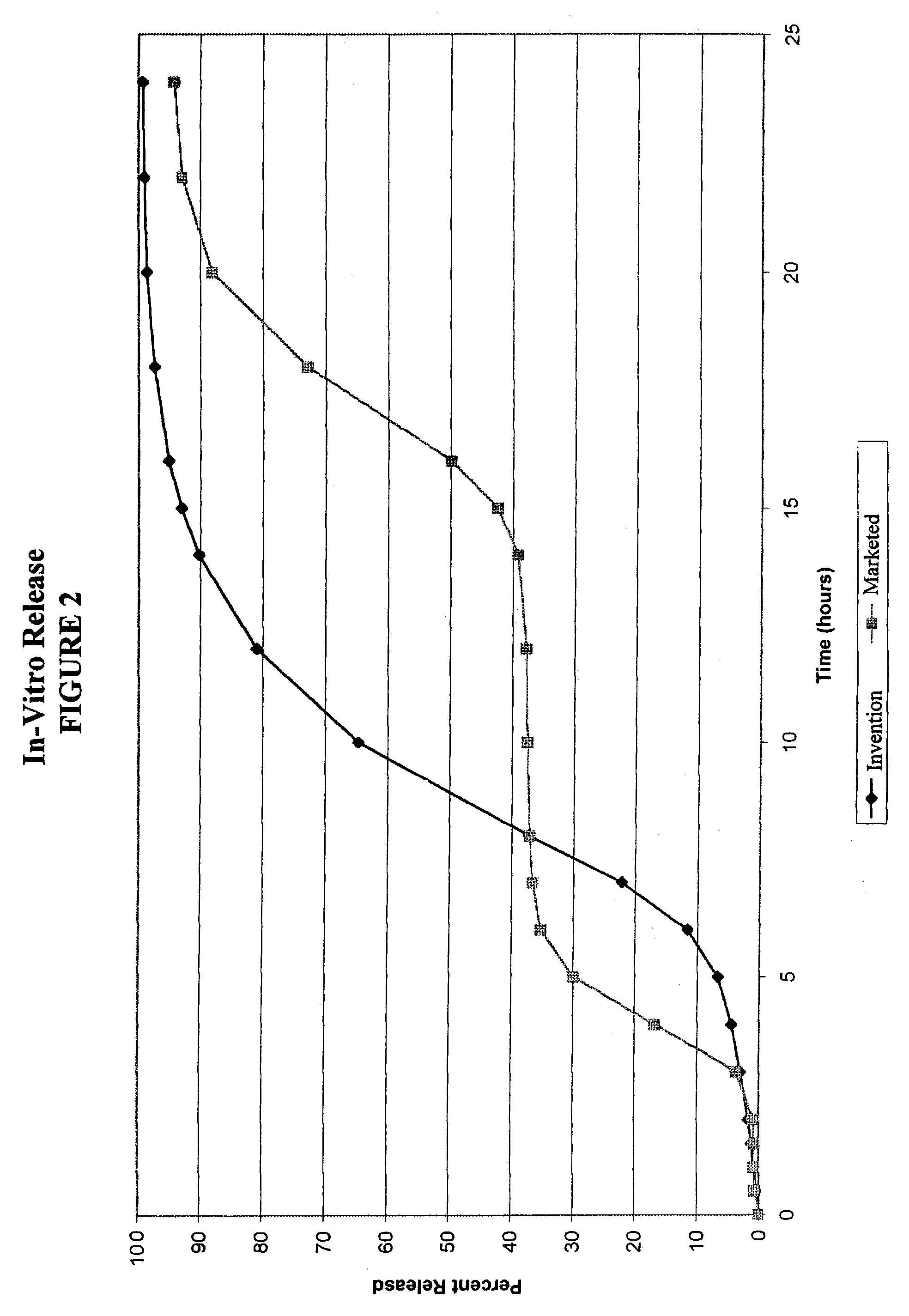

Chrono delivery formulations and method of use thereof

A dosage formulation for once daily administration prior to sleeping is described that provides an initial delay in pharmaceutical release followed by controlled release of the pharmaceutical. There is also provided a method for preparing a time specific delayed, controlled release formulation of dosage, which method includes coating a single pellet with at least one dosage layer, which is coated by at least one seal coat and at least one outer rate controlling layer of a water soluble polymer coat. The dosage formulation of this invention provides substantially a drug free interval of about 0 to 5 hours followed by a drug delivery interval at a rate permitting bioavailability thereof for up to about 24 hours following oral administration. A method of using the formulations of the present invention for the treatment of early morning pathologies is also described.

Owner:ELITE LAB

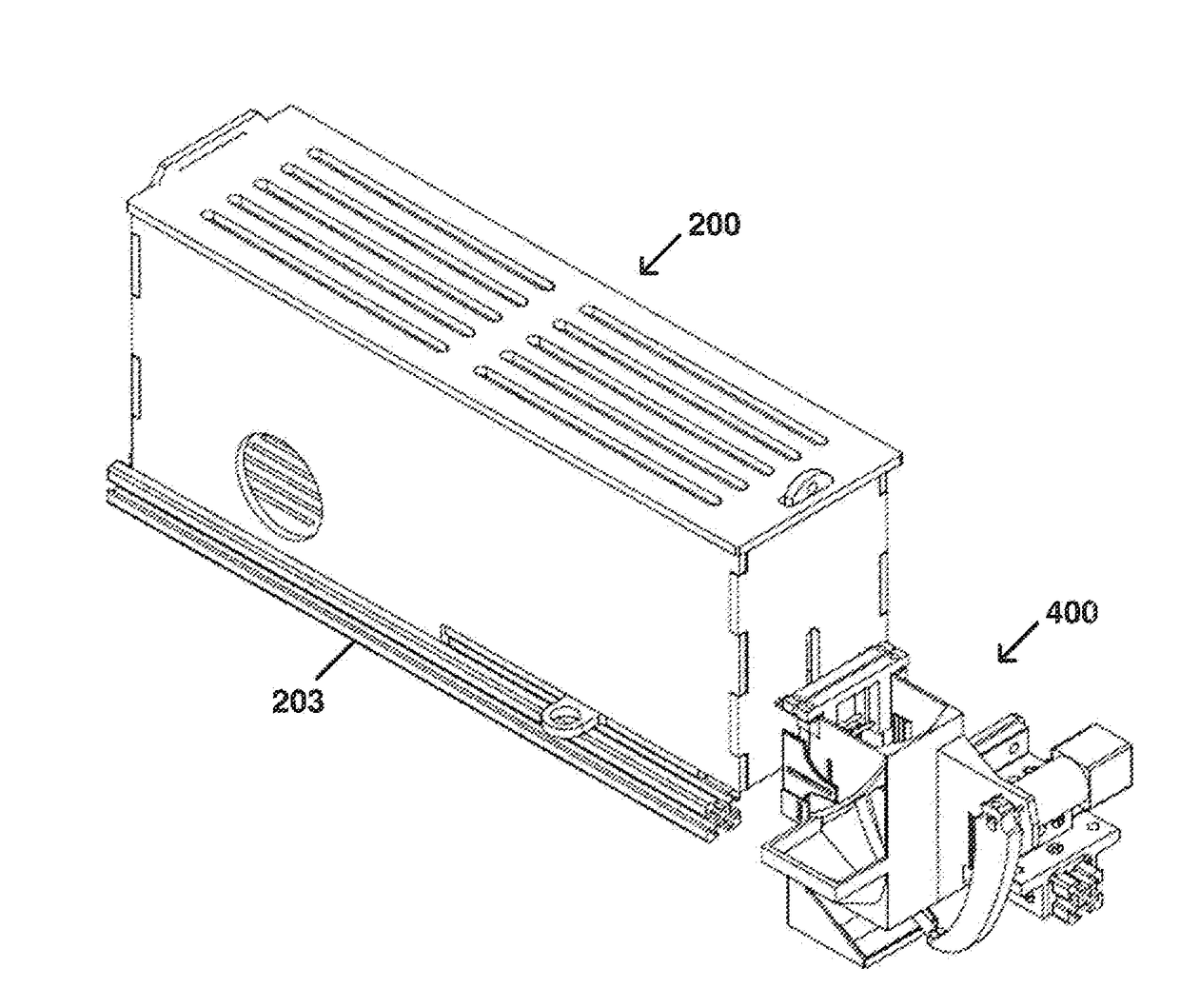

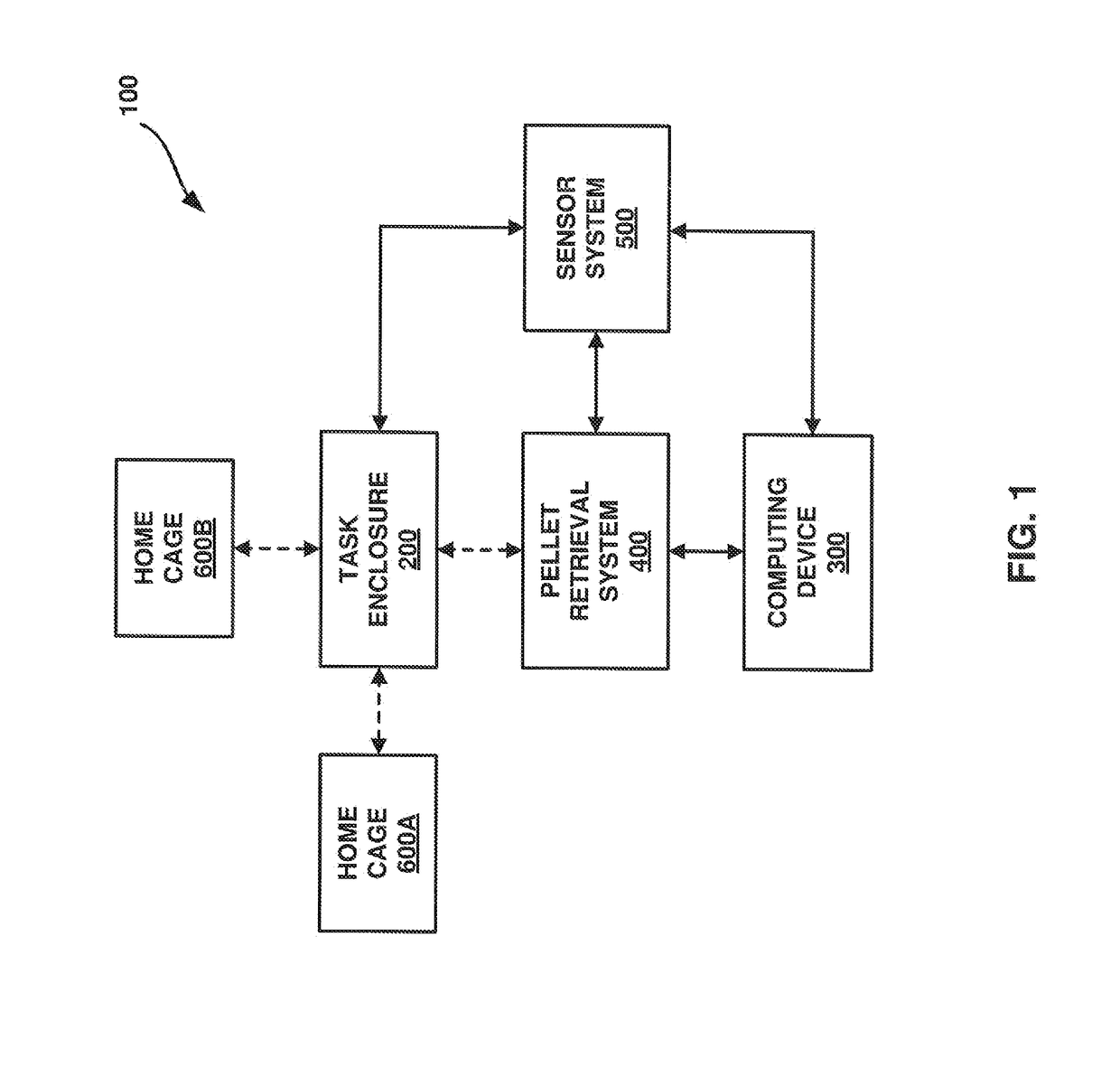

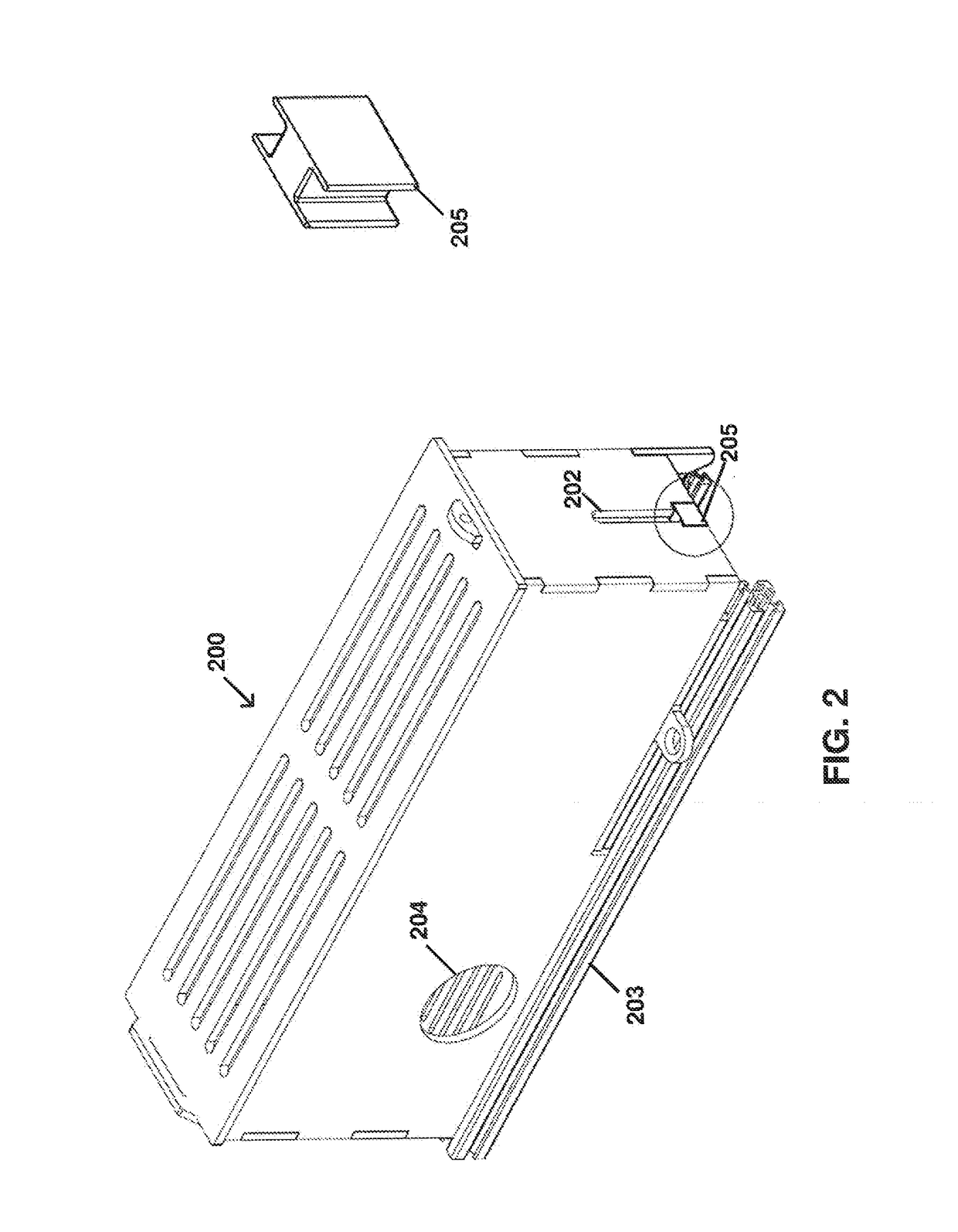

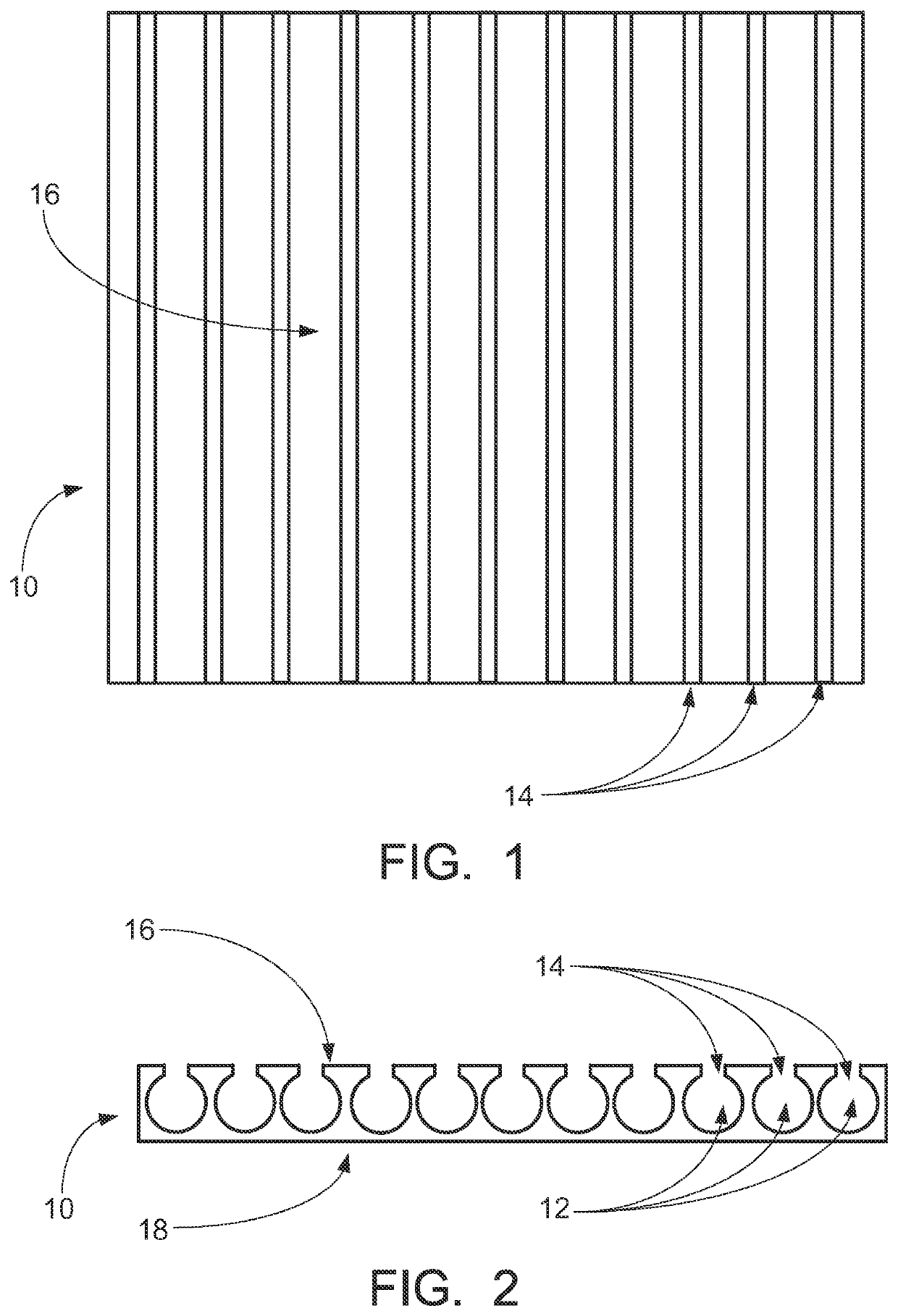

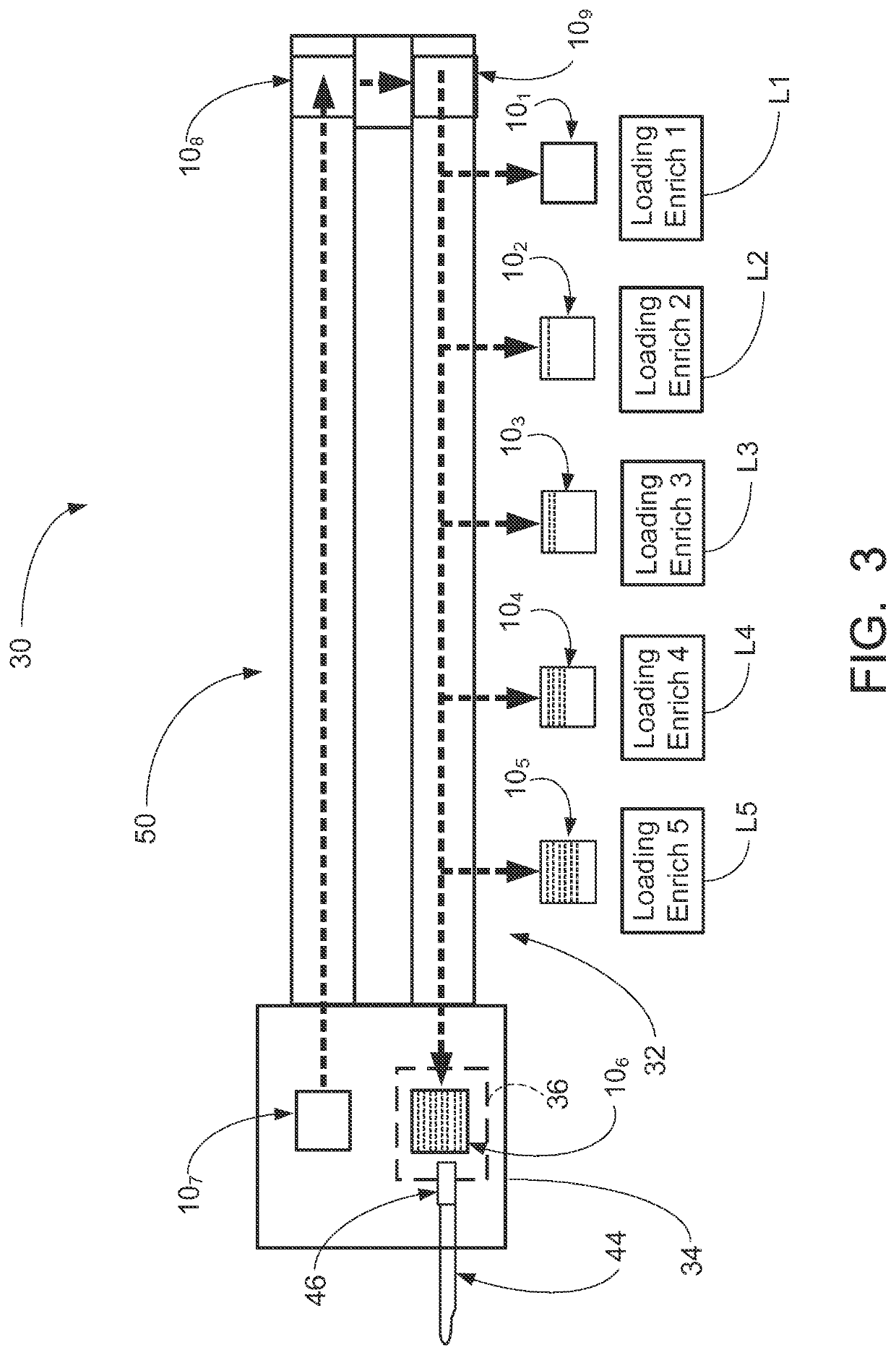

Systems and methods for behavioral and task training of laboratory animals

Systems and techniques for task training laboratory animals are described. The systems and techniques may be particularly useful for training laboratory rodents to perform a single pellet grasping (SPG) task. A system for training animals may include a task enclosure having a slit at one end. A system may include an automated pellet retrieval system. A system may include a sensor system. A system may include a computing device configured to receive data from a sensor system and cause pellet retrieval system to present a pellet to an animal. Further computing device may be configured to evaluate each task attempt.

Owner:THE GOVERNORS OF THE UNIV OF ALBERTA

Recycling process for low-frequency (LF) furnace refining slag

ActiveCN102899483AReduce manufacturing costRecycling and recovery technologiesProcess efficiency improvementSingle pelletSlag

The invention discloses a recycling process for low-frequency (LF) furnace refining slag. The process is characterized in that the process comprises the following steps of: mixing LF furnace slag with the weight percentage of 10-30 percent with iron-containing waste materials with the weight percentage of 70-90 percent; controlling moisture content of the mixed material to be 13-18 percent; putting the mixed material into a mixing mill for mixing and milling according to the proportion for 20-30 minutes to uniformly mix; compacting and forming the mixture by a cold press forming machine; and naturally placing for 25-30 days to form metallurgy cold-pressed pellets. The process has the effects that for the pellets prepared by the method, the compression strength of a single pellet can reach over 2500N, a one-meter free drop test can be performed more than twenty times to completely meet a requirement of the strength of the metallurgy cold-pressed pellets, and the pellets can be applied to blast furnaces or converters. The process provides a new path for recycling LF furnace refining slag. A binder is not needed to add, the LF furnace refining slag is used, and the high-strength pellets are compressed, so that a direction for the recycling metallurgy iron-containing waste materials is provided, and the production cost of the cold-pressed pellets is reduced.

Owner:ANGANG STEEL CO LTD

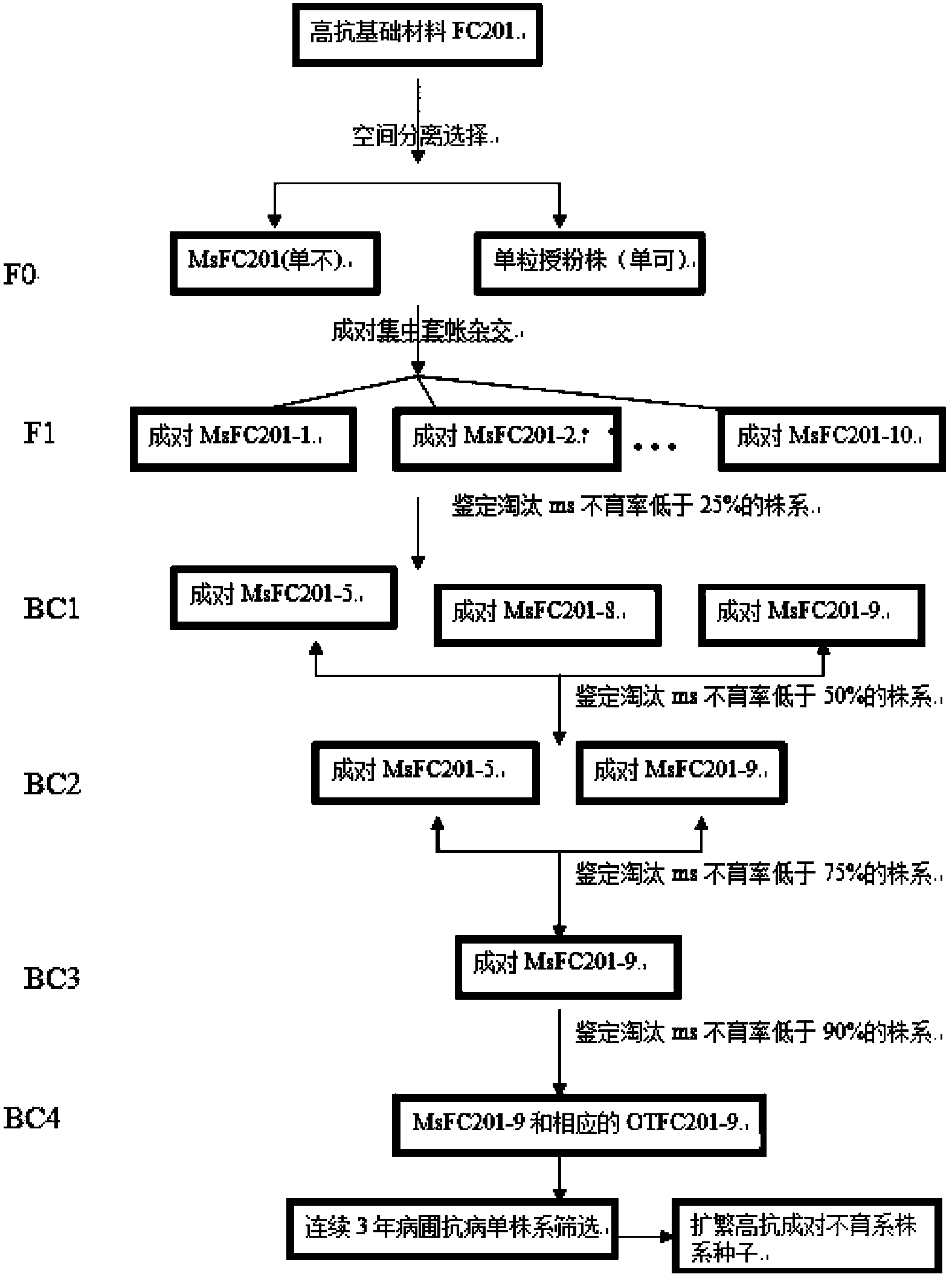

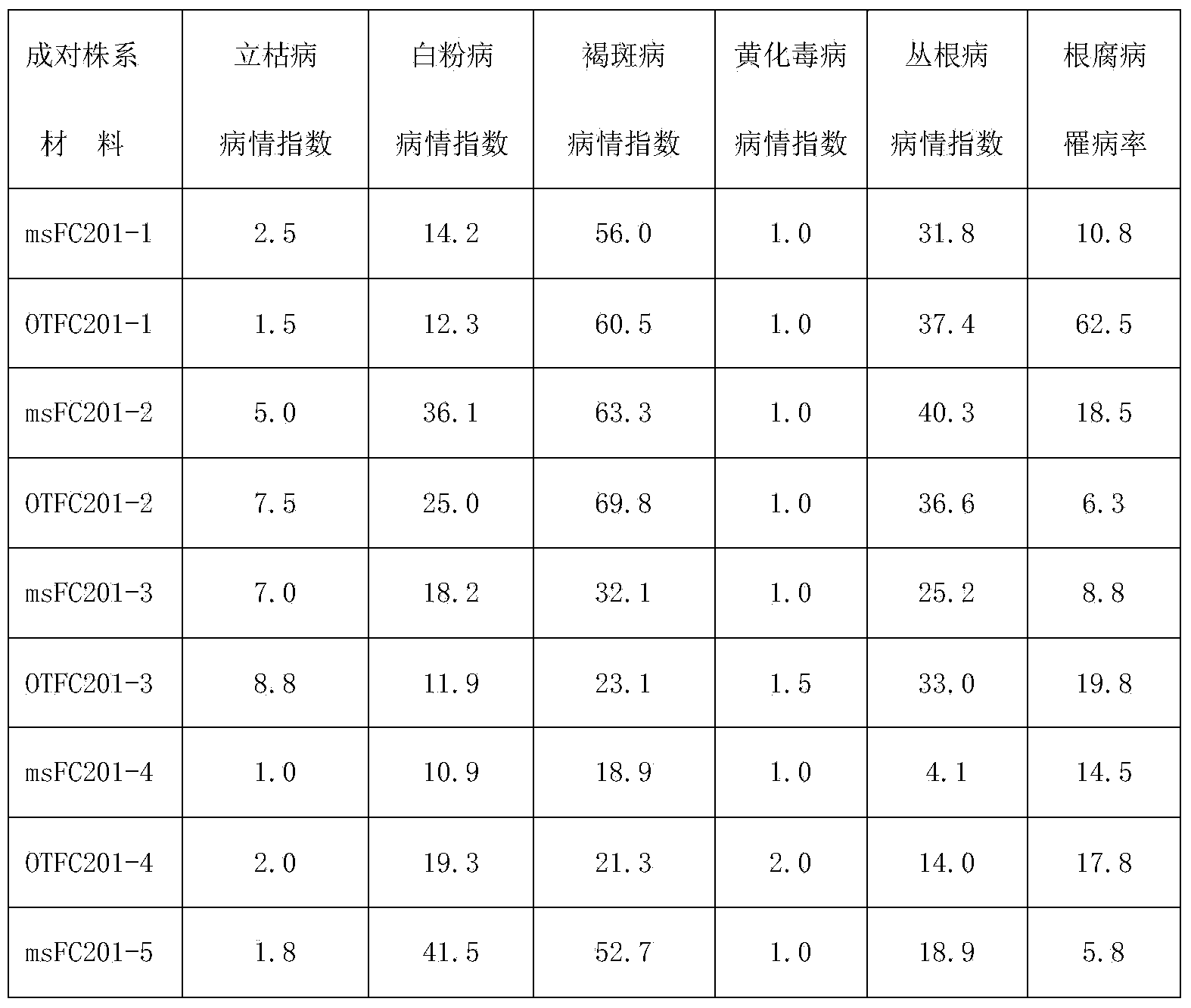

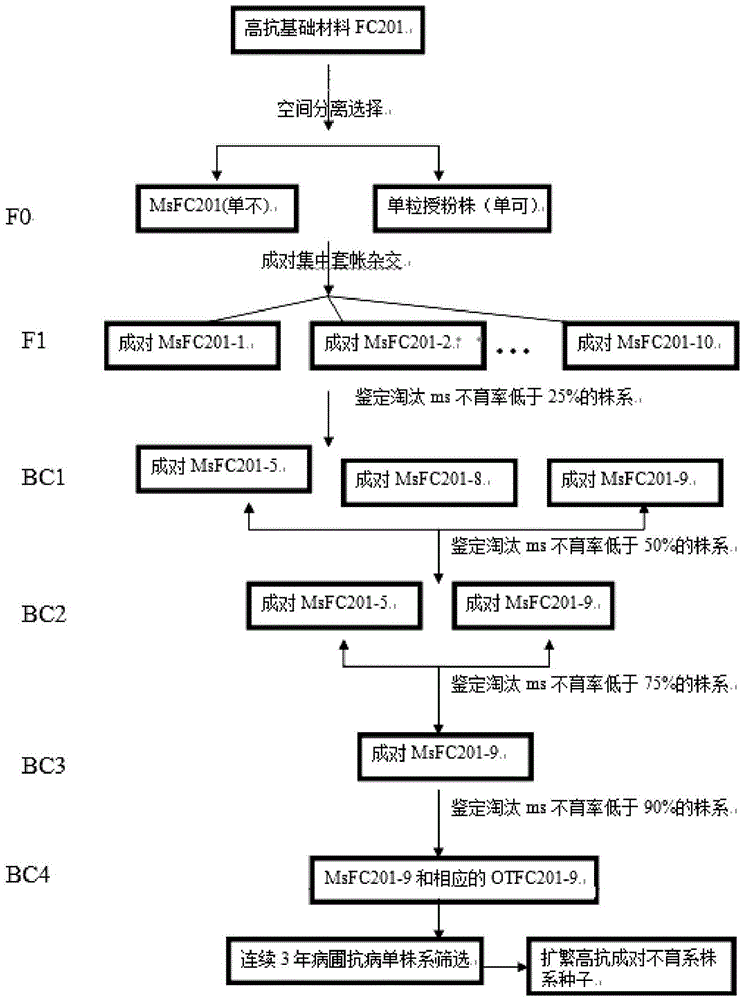

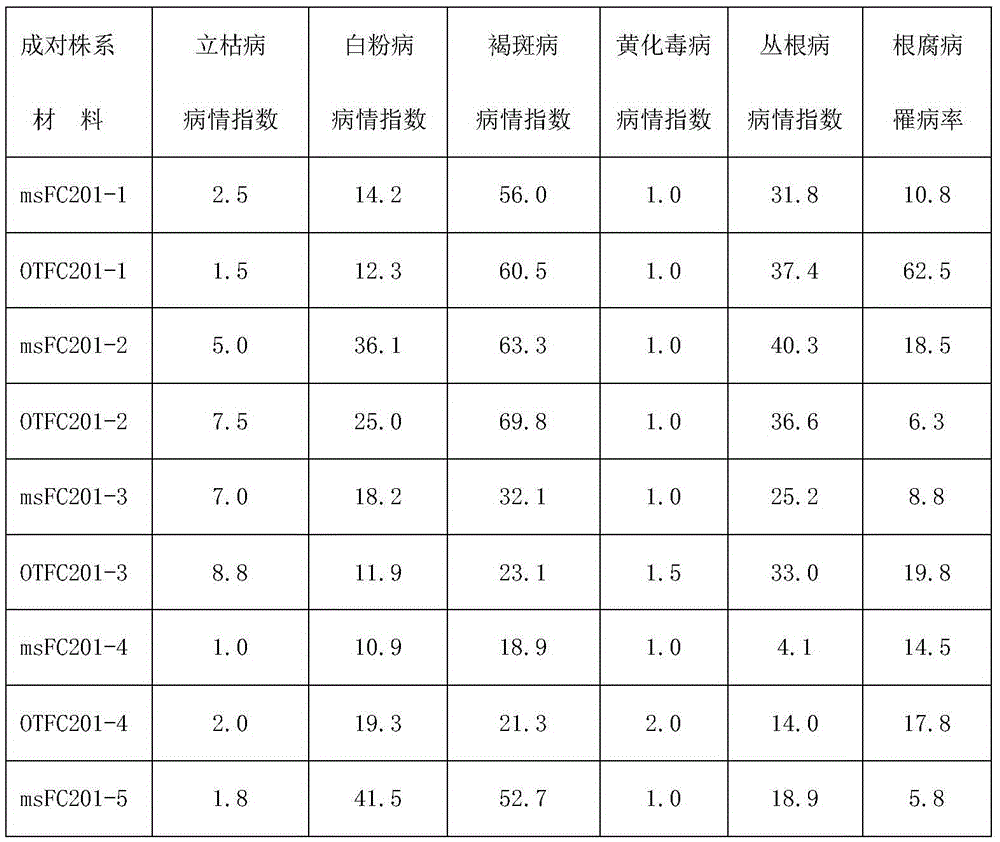

Breeding method of single-grain beet high-resistance pairing sterile line

The invention discloses a breeding method of a single-grain beet high-resistance pairing sterile line. The method comprises the steps of selecting high-resistance and single-grain beet base material, and carrying out summer seeding to cultivate a mother root; carrying out spatial isolation planting, inspecting the grain fertility of all single plants, separating single-grain sterile plants from single-grain fertile plants, and respectively listing to obtain seeds of the sterile plants and corresponding seeds of the fertile plants; carrying out centralized isolated hybridization on plant pairs, and harvesting to obtain first-filial generation F1 strain seeds; carrying out backcross selection by a backcross transformation method, and selecting the strain material with the single fertility rate higher than 95% in the sterile line; indentifying and selecting the cultivated single-grain paired male sterile material on a beet spring sowing disease garden land or a beet seed collecting disease garden land; carrying out disease resistance screening, selecting and remaining the plants with resistance, and harvesting the seeds in pairs. Compared with the prior art, the breeding method has the beneficial effects that the single-grain sterile line with high purity can be cultivated, the single grain rate reaches 99%, and the sterility rate reaches 95%. After being indentified, selected and cultivated on the disease garden land for a plurality of years, the single-grain beet pairing sterile line is high in resistance.

Owner:石河子农业科学研究院

Binder for metallurgical cold-pressed pellets and using method thereof

The invention relates to the field of metallurgical cold-pressed pellets, in particular to a binder for the metallurgical cold-pressed pellets. The binder consists of the following components in percentage by weight: 71.4 to 91 percent of MgO and 9 to 28.6 percent of MgCl2.6H2O, wherein the particle size of the MgO and the MgCl2.6H2O is 50 to 200 meshes, and the water content is less than 1 percent. A using method of the binder comprises the following steps of: uniformly mixing and milling 79 to 94.5 percent of iron-containing dust mud and 5.5 to 21 percent of binder in a mixing mill, and performing cold pressing forming by using a cold pressing forming machine with the pressure of 1,000 to 3,000N when the temperature of the materials is between 38 and 45 DEG C. The invention has the advantages that: the binder meets the production requirement of the metallurgical cold-pressed pellets on strength, the compression strength of a single pellet reaches 1,800N after a 2m free drop test is performed for more than six times, and the production cost of the metallurgical cold-pressed pellets is reduced.

Owner:鞍钢实业集团有限公司

Automatic pellet loader of pneumatic air gun

ActiveUS20180073831A1Easy to carryAvoid error introductionAmmunition loadingCompressed gas gunsSingle pelletEngineering

An automatic pellet loader of a pneumatic air gun, including a pellet clip seat, a pellet clip lid, a pellet clip closure, and a magnetic shaft. The pellet clip seat and the pellet clip lid are connected to form a magazine case that includes a pellet inlet. The pellet clip closure is rotatably connected to the magazine case for opening or closing the pellet inlet. The bottom side wall of the pellet clip seat is provided with a loading sleeve that extends to the pellet clip lid. A center hole of the loading sleeve perpendicularly penetrates through the pellet clip seat. The pellet clip lid includes a loading channel allowing the pull-bolt thimble to pass through. The loading sleeve includes an opening close to an exit side of the loading channel through which a single pellet can slip autonomously into the loading channel.

Owner:ZHONG SHAN NEW SWAN TECH CO LTD

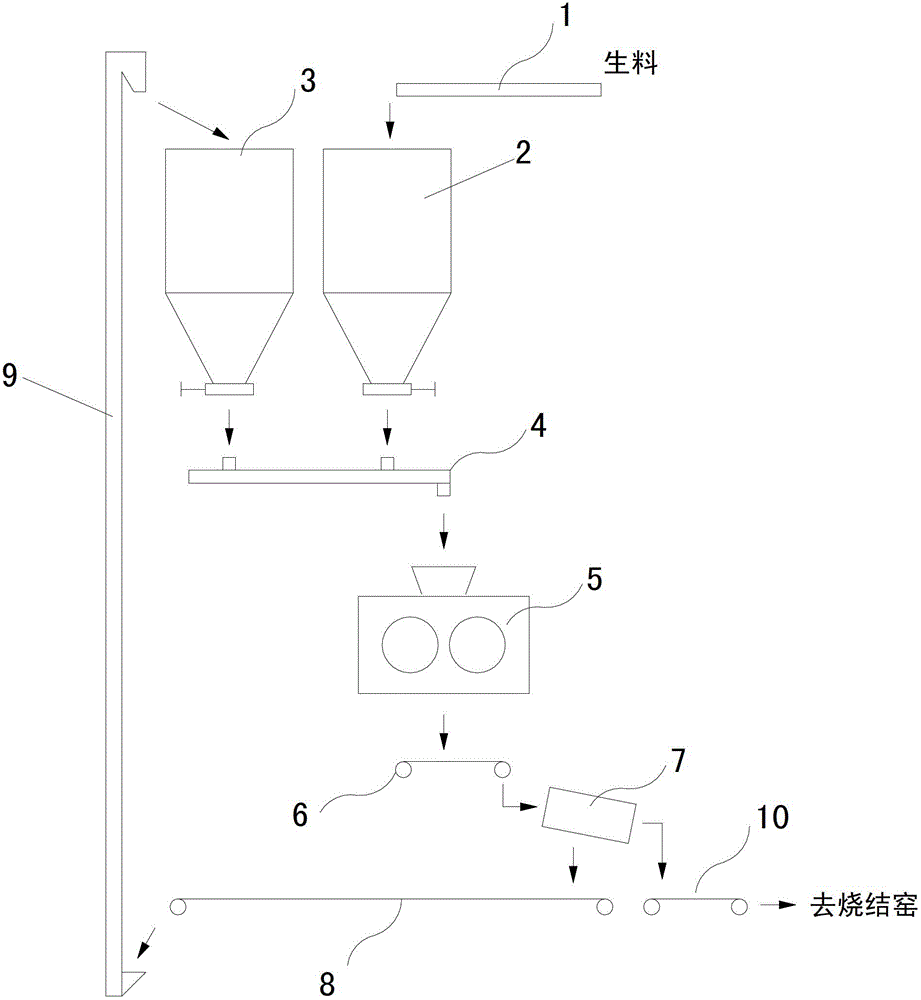

Fly ash raw material pellet production method

ActiveCN103848447AMeet production requirementsRealize energy saving and consumption reductionAluminium oxides/hydroxidesSingle pelletAdhesive

The present invention discloses a fly ash raw material pellet production method, which comprises: 1) a mixing step, wherein coal powder coal and ammonium sulfate are mixed according to a predetermined ratio to obtain a raw material; 2) a pellet pressing step, wherein the raw material is pressed into a raw material pellet; 3) a screening step, wherein the complete pellet is conveyed into a sintering kiln system through screening, and the broken pellet is conveyed to the step 1); and 4) a re-pressing step, wherein the conveyed broken pellet and the raw material are mixed and are re-pressed into the pellet. According to the present invention, the raw material obtained by mixing the fly ash and the ammonium sulfate can be prepared into the raw material pellet, and the raw material pellet does not contain water and any other adhesives so as to effectively achieve energy saving and consumption reduction; and the physical performances of the raw material pellet produced by adopting the process can achieve the following parameters, wherein the single pellet density is 1.3-1.6 g / mm<3>, the pellet bulk density is 800-1000 kg / m<3>, the pellet initial strength is 400-650 N, and the pellet strength after heating is 1200-1500 N, such that the performances can completely meet production requirements of the sintering kiln.

Owner:SHENYANG ALUMINIUM MAGNESIUM INSTITUTE

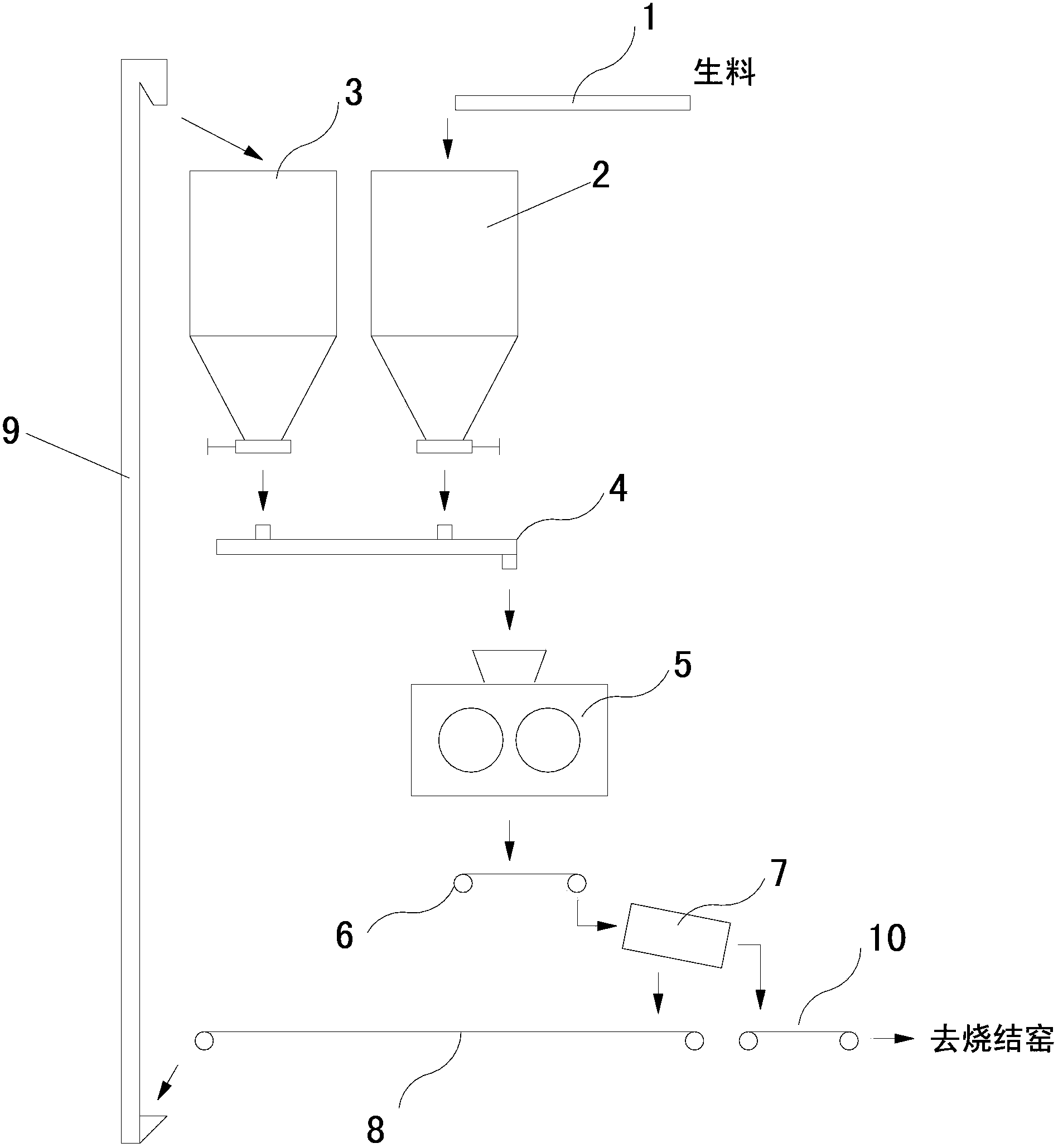

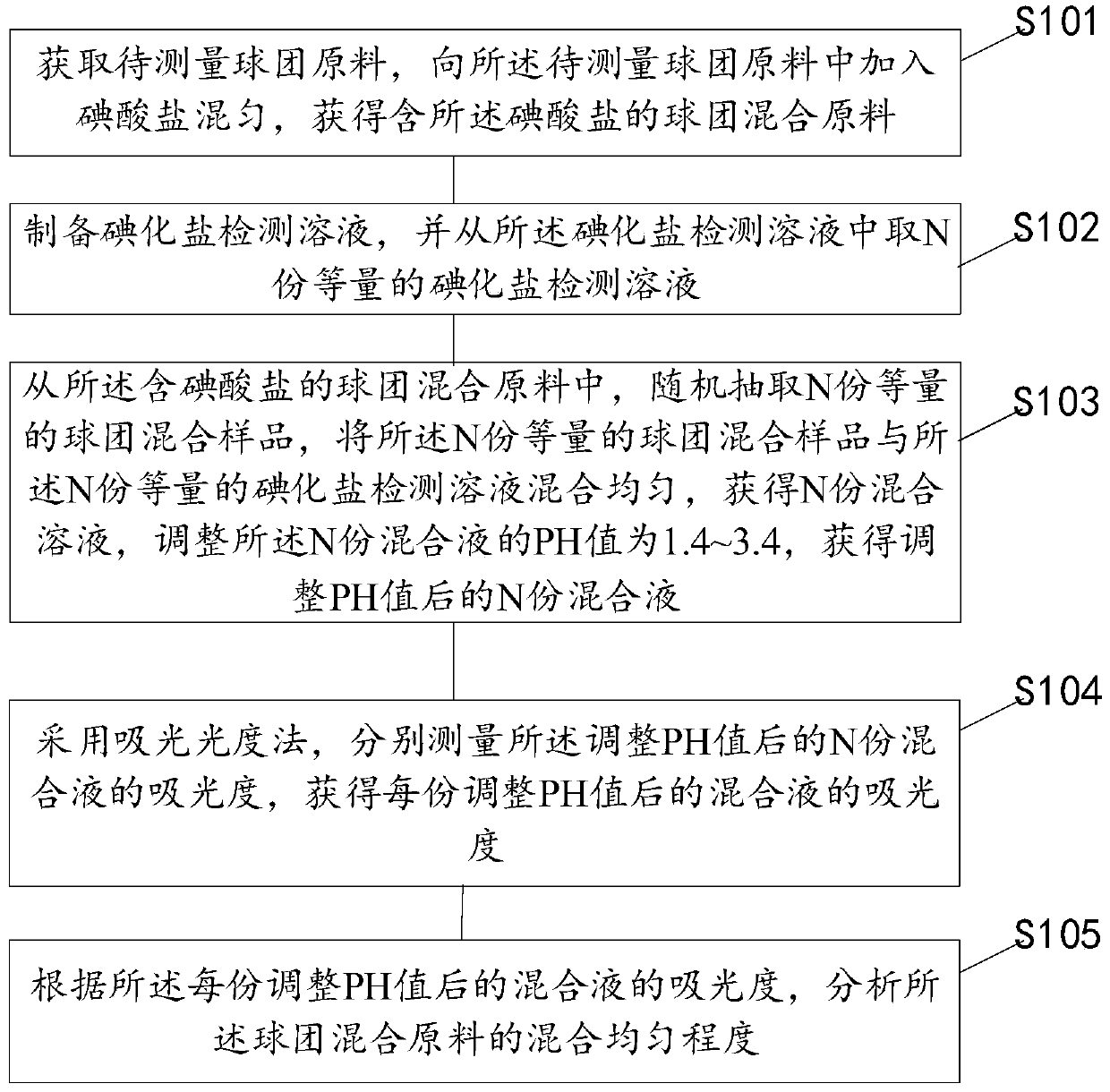

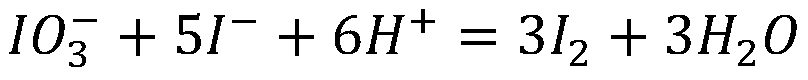

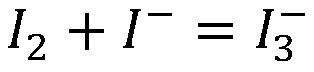

Method for measuring the mixing uniformity degree of pellet raw material

ActiveCN111239070ASensitive light absorptionCharacterize the degree of mixing uniformityPreparing sample for investigationColor/spectral properties measurementsSingle pelletPhysical chemistry

The invention discloses a method for measuring the mixing uniformity degree of a pellet raw material, which comprises the following steps: adding iodate into a pellet raw material to be measured, andperforming uniform mixing to obtain a pellet mixed raw material; preparing an iodide salt detection solution, and taking N parts of the same amount of iodide salt detection solution from the iodide salt detection solution; randomly extracting N parts of pellet mixed samples with the same amount, uniformly mixing the N parts of pellet mixed samples with the same amount with N parts of an iodide salt detection solution to obtain N parts of a mixed solution, and adjusting the pH value of the N parts of the mixed solution to 1.4-3.4 to obtain N parts of the mixed solution with the adjusted pH value, wherein the mass ratio of iodate in a single pellet mixed sample to iodate in a single iodate detection solution is less than 1:6; respectively measuring the absorbance of the N parts of mixed liquid after the PH value is adjusted by adopting an absorbance spectrophotometric method to obtain the absorbance of each part of mixed liquid after the PH value is adjusted; and analyzing the mixing uniformity degree of the pellet mixed raw materials according to the absorbance of each part of the mixed solution after the pH value is adjusted.

Owner:SHOUGANG CORPORATION

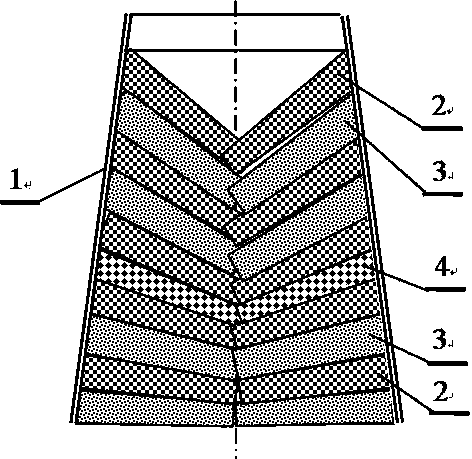

Material layer structure of blast furnace

The invention relates to a material layer structure in an iron-making blast furnace and particularly relates to a single pellet layer included material layer structure of a blast furnace. The material layer structure comprises mineral aggregates and cokes filled in the upper part of a blast furnace body, wherein the mineral aggregates and the cokes are respectively and independently filled to form mixing mineral layers and coke layers; the mixing mineral layers and the coke layers are arranged at intervals and are circularly overlaid; the thickness of each layer in the material layers of the blast furnace is the thickness of the material layer, which is lower than the material layer on the periphery of the round cavity, at the central position of a round cavity in the blast furnace; the material level is of a funnel shape with a downward cone angle; the pellet layers are also arranged between the coke layers and the mixing mineral layers and can be added into an overall material layer structure as a material layer constituent part of the overall material layer structure. By using the material layer structure with the 'single pellet layers', sticking substances in the furnace can be washed in time and the blast furnace can stably run for a long period of time in low cost.

Owner:JIGANG GRP

Fe3O4 ceramsite, preparation method and applications thereof

ActiveCN110776332AImprove energy efficiencyImprove sterilization effectOther chemical processesFiltration separationSingle pelletMetallurgy

The invention discloses Fe3O4 ceramsite, a preparation method and applications thereof. The preparation method comprises: 1, weighing Fe3O4 powder and bentonite according to a mass ratio of (7-9):2, adding NaHCO3 accounting for 0.4-0.6% of the total mass of the Fe3O4 powder and the bentonite, completely mixing, adding water, and uniformly blending; 2, preparing a single pellet with a diameter of 5-10 mm from the mixture obtained in the step 1 by using a pelletizer; 3, drying the pellet prepared in the step 2 for 20-40 min at a temperature of 120-180 DEG C; and 4, sealing the dried pellet, roasting the pellets at 150-250 DEG C for 20-40 min, and naturally cooling to a room temperature of 20-30 DEG C to obtain the Fe3O4 ceramsite. According to the invention, the Fe3O4 ceramsite can be used as a wave-absorbing material so as to be used for microwave radiation inactivation of biological aerosols.

Owner:TIANJIN UNIV

Single conductive pellets of long glass fiber reinforced thermoplastic resin and manufacturing method thereof

ActiveUS20100327235A1Improve mechanical propertiesConductive materialNon-conductive material with dispersed conductive materialGlass fiberSingle pellet

Single pellets of a thermoplastic resin containing long glass fibers and a conductive filler are set forth that enable molded articles made from these pellets to exhibit conductivity and, at the same time, high mechanical properties. These pellets have mechanical properties that are substantially equivalent to non-conductive pellets of a thermoplastic resin containing same loading of long glass and provide conductivity that is substantially equivalent to articles obtained by blending two kinds of pellets, one pellet having a conductive filler and the other pellet one containing long glass fibers. The pellets include a thermoplastic resin, a long fiber reinforcing filler and a conductive additive dispersed in the pellet.

Owner:SHPP GLOBAL TECH BV

Single conductive pellets of long glass fiber reinforced thermoplastic resin and manufacturing method thereof

ActiveUS8524120B2Conductive materialNon-conductive material with dispersed conductive materialSingle pelletGlass fiber

Single pellets of a thermoplastic resin containing long glass fibers and a conductive filler are set forth that enable molded articles made from these pellets to exhibit conductivity and, at the same time, high mechanical properties. These pellets have mechanical properties that are substantially equivalent to non-conductive pellets of a thermoplastic resin containing same loading of long glass and provide conductivity that is substantially equivalent to articles obtained by blending two kinds of pellets, one pellet having a conductive filler and the other pellet one containing long glass fibers. The pellets include a thermoplastic resin, a long fiber reinforcing filler and a conductive additive dispersed in the pellet.

Owner:SHPP GLOBAL TECH BV

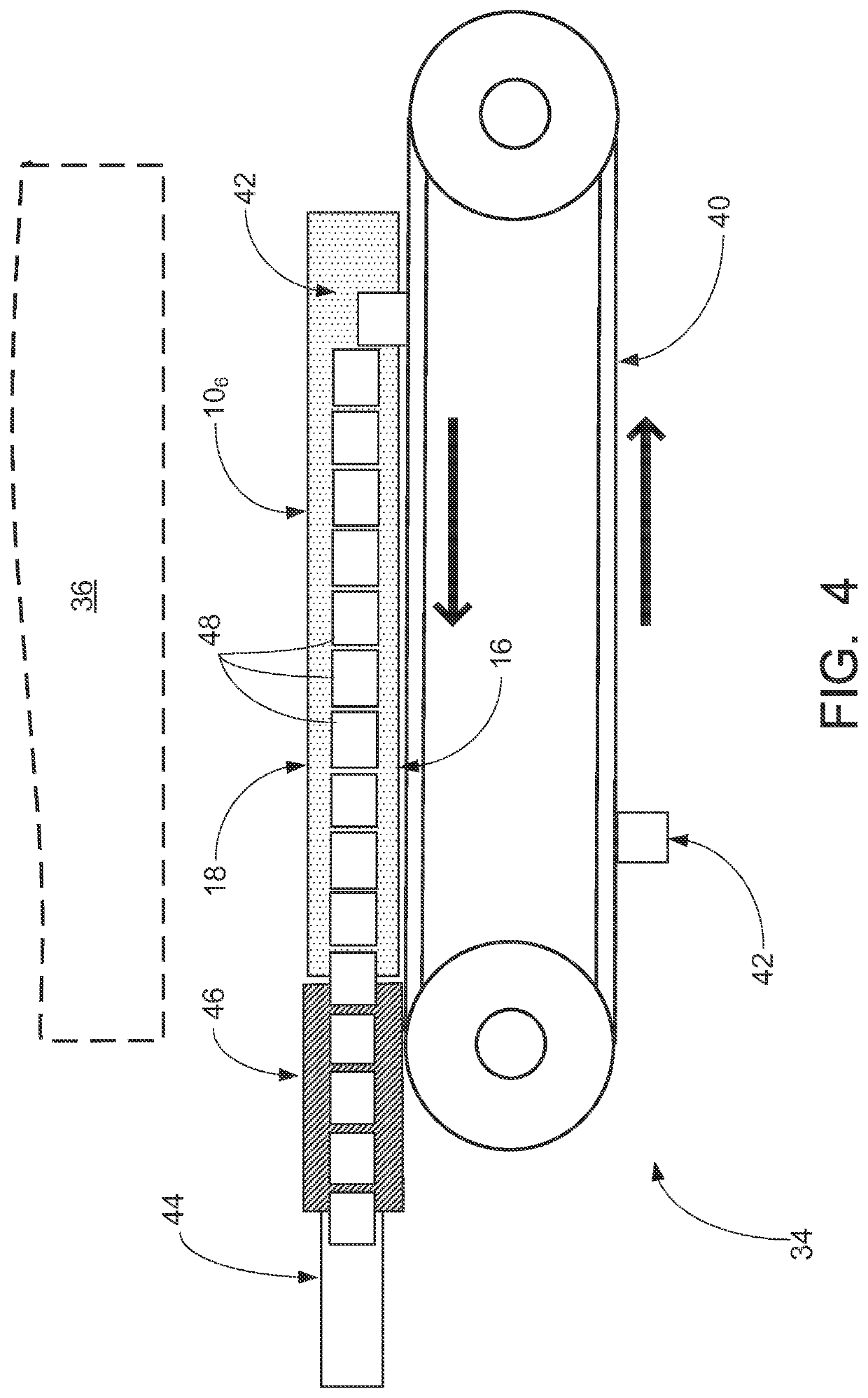

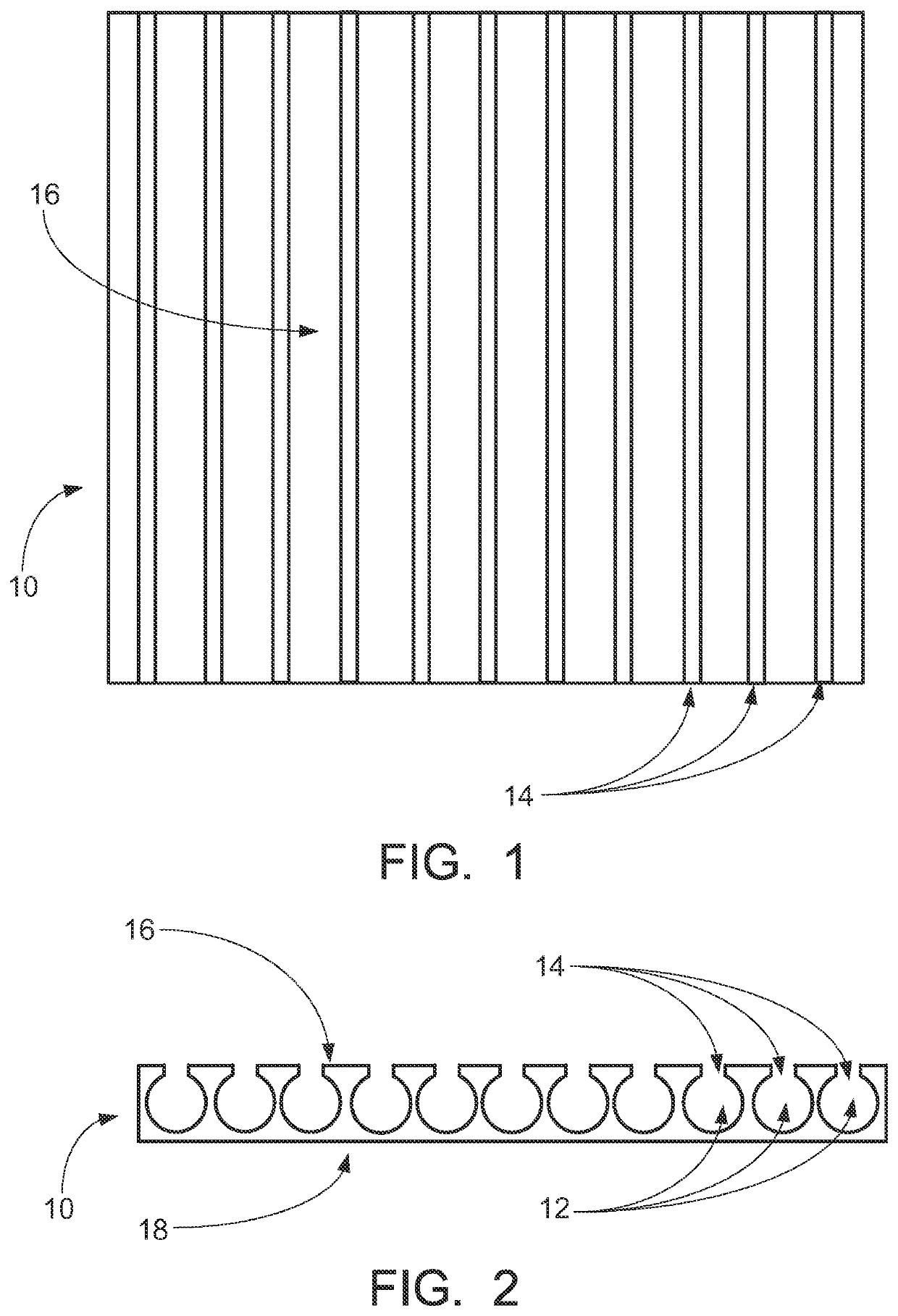

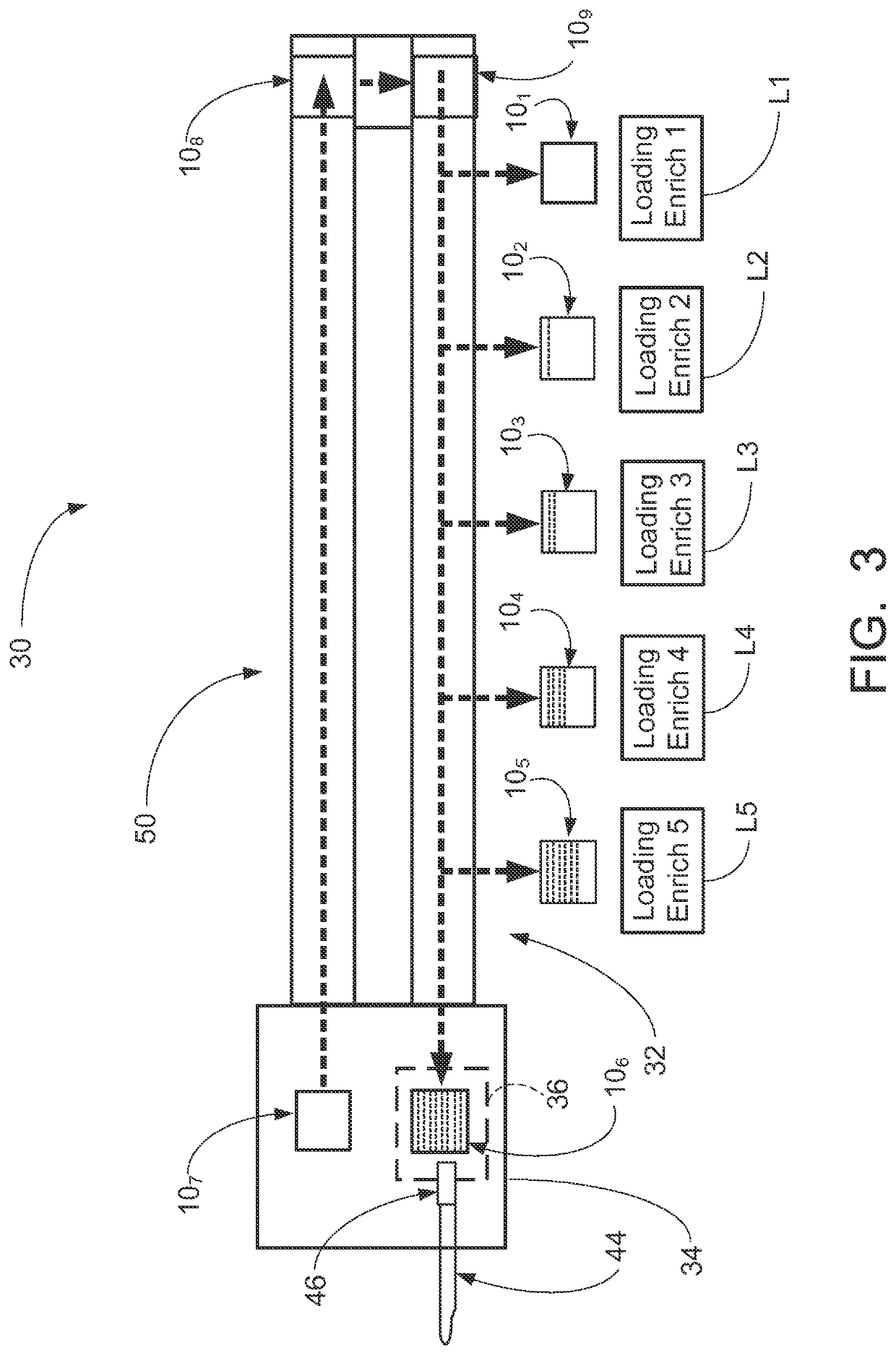

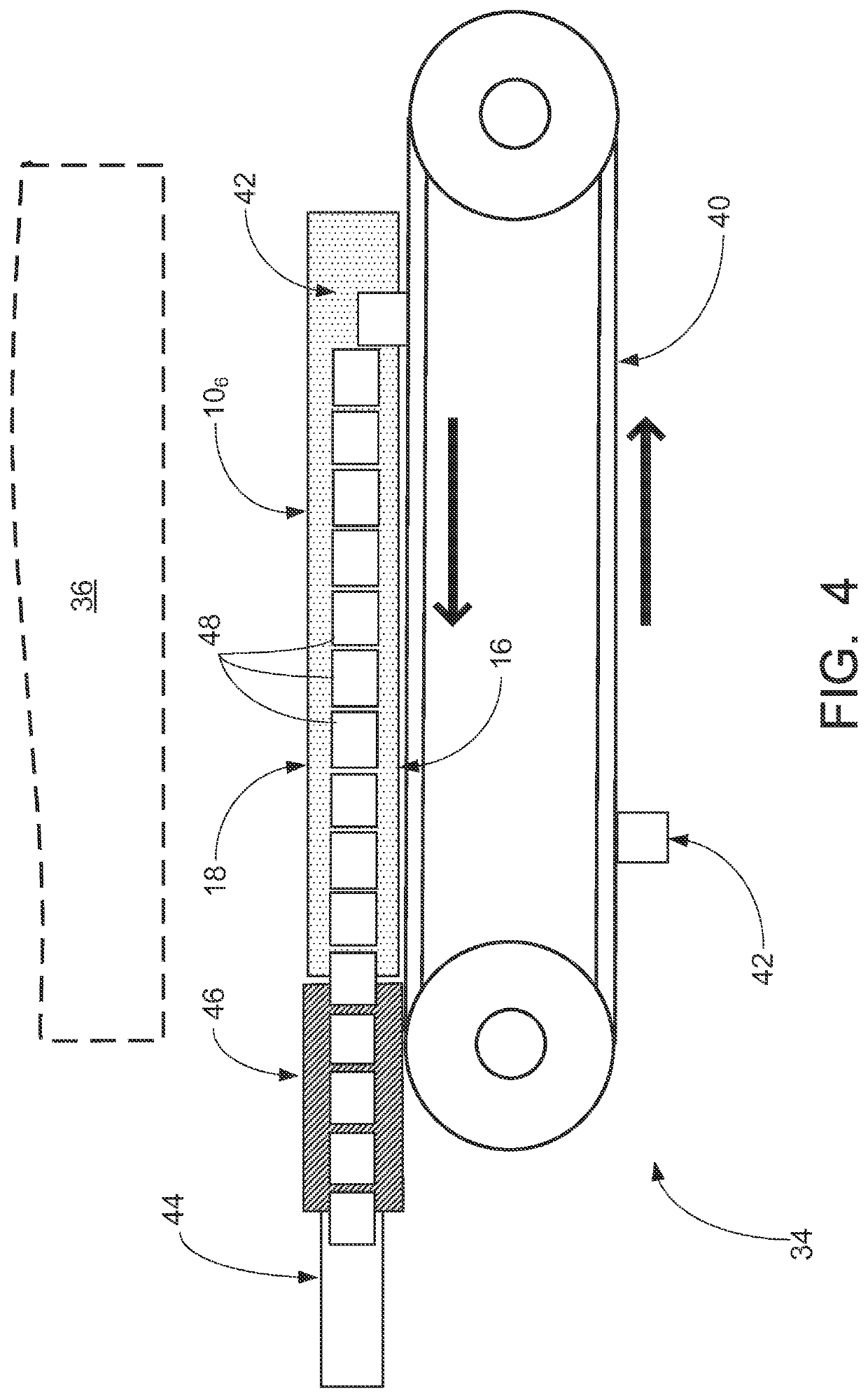

Pellet handling apparatus and fuel rod loading method

A pellet magazine includes a plurality of pellet bores sized to receive pellets for loading into a fuel rod. A fuel rod loading system includes a plurality of pellet loading stations each designated to load a single pellet type into one or more pellet bores of the pellet magazine, a rod loading station configured to unload pellets from the pellet bores of the pellet magazine into a fuel rod, and a conveyance system configured to transport the pellet magazine to the loading stations and then to the rod loading station in a defined sequence.

Owner:BWXT MPOWER INC

Beet seed pelleting formula and processing method

PendingCN111084181AHigh granulation rateGranulation speedBiocidePlant growth regulatorsGibberellic acidCellulose

The invention discloses a beet seed pelleting formula and a processing method, and relates to the field of beet seed pelleting treatment. The pelleting formula comprises a powder material A, a powdermaterial B, a powder material C and a liquid material D, wherein the powder material A comprises an inert filling material, an adhesive and a granulating agent; the powder material B is an additive formed by mixing thiram, zinc sulfate, manganese sulfate, borax, gibberellic acid and brassinolide; the powder material C is formed by mixing the powder material A and the powder material B according toa weight ratio of 15: 1; and the liquid material D comprises a colorant, namely a pure acrylic emulsion, carboxymethyl cellulose, warning color, pearl powder and water. According to the invention, byadoption of the granulating agent, the granulation rate of beet coating seeds can be improved; the granulation speed of the beet coating seeds is reinforced; high granulation strength is achieved; and the growth of plants can be promoted. By adoption of the adhesive, the compressive strength of a single pellet seed can be improved; and the single pellet seed is not easy to be broken. By adoptionof various additives coated around the seeds to be slowly released, a micro-element fertilizer required by plant growth is provided; the stress resistance is enhanced; and the emergence rate of beet pelletized seeds is increased.

Owner:石河子农业科学研究院

Pellet handling apparatus and fuel rod loading method

A pellet magazine includes a plurality of pellet bores sized to receive pellets for loading into a fuel rod. A fuel rod loading system includes a plurality of pellet loading stations each designated to load a single pellet type into one or more pellet bores of the pellet magazine, a rod loading station configured to unload pellets from the pellet bores of the pellet magazine into a fuel rod, and a conveyance system configured to transport the pellet magazine to the loading stations and then to the rod loading station in a defined sequence.

Owner:BWXT MPOWER INC

A kind of breeding method of sweet beetroot high-resistance paired sterile line

The invention discloses a breeding method of a single-grain beet high-resistance pairing sterile line. The method comprises the steps of selecting high-resistance and single-grain beet base material, and carrying out summer seeding to cultivate a mother root; carrying out spatial isolation planting, inspecting the grain fertility of all single plants, separating single-grain sterile plants from single-grain fertile plants, and respectively listing to obtain seeds of the sterile plants and corresponding seeds of the fertile plants; carrying out centralized isolated hybridization on plant pairs, and harvesting to obtain first-filial generation F1 strain seeds; carrying out backcross selection by a backcross transformation method, and selecting the strain material with the single fertility rate higher than 95% in the sterile line; indentifying and selecting the cultivated single-grain paired male sterile material on a beet spring sowing disease garden land or a beet seed collecting disease garden land; carrying out disease resistance screening, selecting and remaining the plants with resistance, and harvesting the seeds in pairs. Compared with the prior art, the breeding method has the beneficial effects that the single-grain sterile line with high purity can be cultivated, the single grain rate reaches 99%, and the sterility rate reaches 95%. After being indentified, selected and cultivated on the disease garden land for a plurality of years, the single-grain beet pairing sterile line is high in resistance.

Owner:石河子农业科学研究院

A kind of preparation method of fly ash raw meal pellet

ActiveCN103848447BMeet production requirementsRealize energy saving and consumption reductionAluminium oxides/hydroxidesAdhesiveCoal

The present invention discloses a fly ash raw material pellet production method, which comprises: 1) a mixing step, wherein coal powder coal and ammonium sulfate are mixed according to a predetermined ratio to obtain a raw material; 2) a pellet pressing step, wherein the raw material is pressed into a raw material pellet; 3) a screening step, wherein the complete pellet is conveyed into a sintering kiln system through screening, and the broken pellet is conveyed to the step 1); and 4) a re-pressing step, wherein the conveyed broken pellet and the raw material are mixed and are re-pressed into the pellet. According to the present invention, the raw material obtained by mixing the fly ash and the ammonium sulfate can be prepared into the raw material pellet, and the raw material pellet does not contain water and any other adhesives so as to effectively achieve energy saving and consumption reduction; and the physical performances of the raw material pellet produced by adopting the process can achieve the following parameters, wherein the single pellet density is 1.3-1.6 g / mm<3>, the pellet bulk density is 800-1000 kg / m<3>, the pellet initial strength is 400-650 N, and the pellet strength after heating is 1200-1500 N, such that the performances can completely meet production requirements of the sintering kiln.

Owner:SHENYANG ALUMINIUM MAGNESIUM INSTITUTE

A kind of ferroferric oxide ceramsite and its preparation method and application

ActiveCN110776332BImprove energy efficiencyImprove sterilization effectOther chemical processesFiltration separationSingle pelletPhysical chemistry

The invention discloses a ferroferric oxide ceramsite and its preparation method and application. The preparation method of the ferroferric oxide ceramsite includes the following steps: step 1, weighing four Ferric oxide powder and bentonite, then add 0.4-0.6% NaHCO of the total mass of the two 3 , mix well, add water and mix thoroughly; step 2, use the pelletizing machine to make the mixture obtained in step 1 into a single pellet with a diameter of 5-10mm; step 3, dry the pellet prepared in step 2 at 120-180°C 20-40 minutes; step 4, seal the dried pellets, bake at 150-250°C for 20-40 minutes, then cool naturally to room temperature 20-30°C to obtain ferric oxide ceramsite. The ferroferric oxide ceramsite can be used as a microwave-absorbing material to inactivate biological aerosols by microwave radiation.

Owner:TIANJIN UNIV

Chrono delivery formulations and method of treating atrial fibrillation

A dosage formulation for once daily administration prior to sleeping is described that provides an initial delay in pharmaceutical release followed by controlled release of the pharmaceutical. There is also provided a method for preparing a time specific delayed, controlled release formulation of dosage, which method includes coating a single pellet with at least one dosage layer, which is coated by at least one seal coat and at least one outer rate controlling layer of a water soluble polymer coat. The dosage formulation of this invention provides a substantially drug free interval of about 0 to 5 hours followed by a drug delivery interval at a rate permitting bioavailability thereof for up to about 24 hours following oral administration. A method of using the formulations of the present invention for the treatment of early morning pathologies, including atrial fibrillation, is also described.

Owner:ELITE LAB

Cigarette blasting bead sterile single-particle release pen

ActiveCN113208166AAvoid affecting useTobacco devicesContainers preventing decaySingle pelletMechanical engineering

The invention belongs to the technical field of cigarette blasting beads, and particularly relates to a cigarette blasting bead sterile single-particle release pen which comprises a shell, a conical discharging head, a driving device, a discharging device and a protection device, the inner surface of the upper end of the conical discharging head is in threaded connection with the outer surface of the lower end of the shell, and the driving device is arranged at the upper end of the shell; the discharging device is arranged on the inner wall of the lower end of the shell, the driving device is fixedly connected with the discharging device through a bolt and drives the discharging device to discharge blasting beads, discharging is conducted through the conical discharging head, and the protection device is arranged on the inner wall of the middle of the shell. According to the sterile single-particle release pen for the cigarette blasting beads, discharging spoons slide in a discharging track, the cigarette blasting beads are discharged out of the discharging track while sliding, the discharging spoons with different sizes can be replaced according to the cigarette blasting beads with different sizes, and the inner wall of the discharging track is controlled to be expanded and shrunk through a limiting plate according to the sizes of the discharging spoons.

Owner:安徽一丸生物科技有限公司

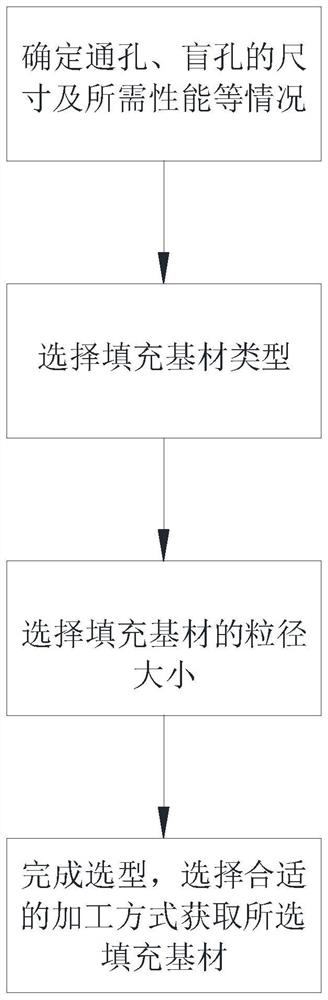

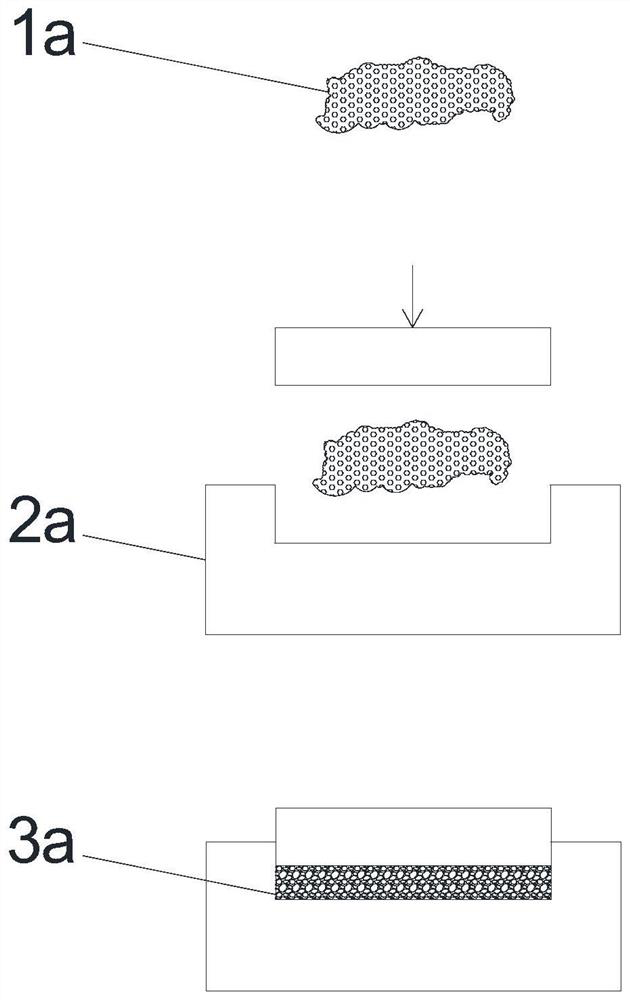

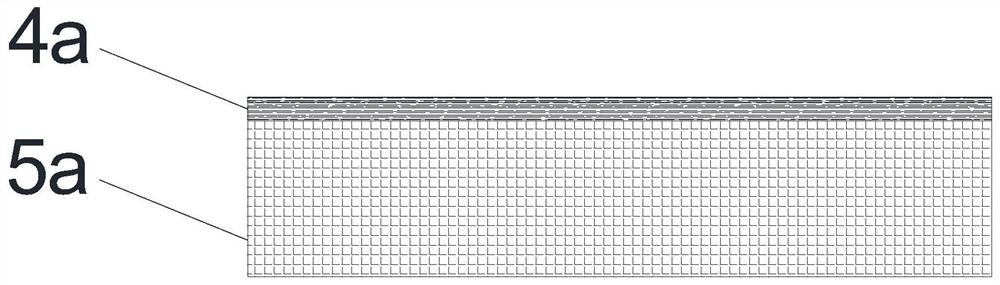

Filling base material type selection method of support plate hole filling process and support plate hole filling process

ActiveCN113543527ARefinement of hole filling processPrecision hole filling processPrinted element electric connection formationSingle pelletMaterial type

The invention discloses a filling base material type selection method of a support plate hole filling process and the support plate hole filling process. The filling base material type selection method comprises the following steps: (1) determining the size and the required performance condition of a through hole or a blind hole in a carrier plate; (2) selecting a proper filling base material type; (3) selecting the particle size of the filling base material, wherein the particle size of the filling base material is selected as follows: (a) small particle filling, D = 0.001-0.2 d, (b) string type filling, D = 0.5-2d, (c) single particle integral filling, D = 0.5(1.5d2h)0.5-2(1.5 d2h)0.5; the D is the diameter of the filler, d is the diameter of the through hole or the blind hole in the carrier plate, and h is the depth of the through hole or the blind hole in the carrier plate. According to the filling base material type selection method, a filling base material type selection scheme is provided for a support plate hole filling technology. According to the method, the hole filling process of the support plate is more perfect, the proper filling base material can be selected according to the required performance of the through holes and the blind holes of the support plate, and the circuit structure performance of the support plate can be improved.

Owner:GUANGDONG UNIV OF TECH

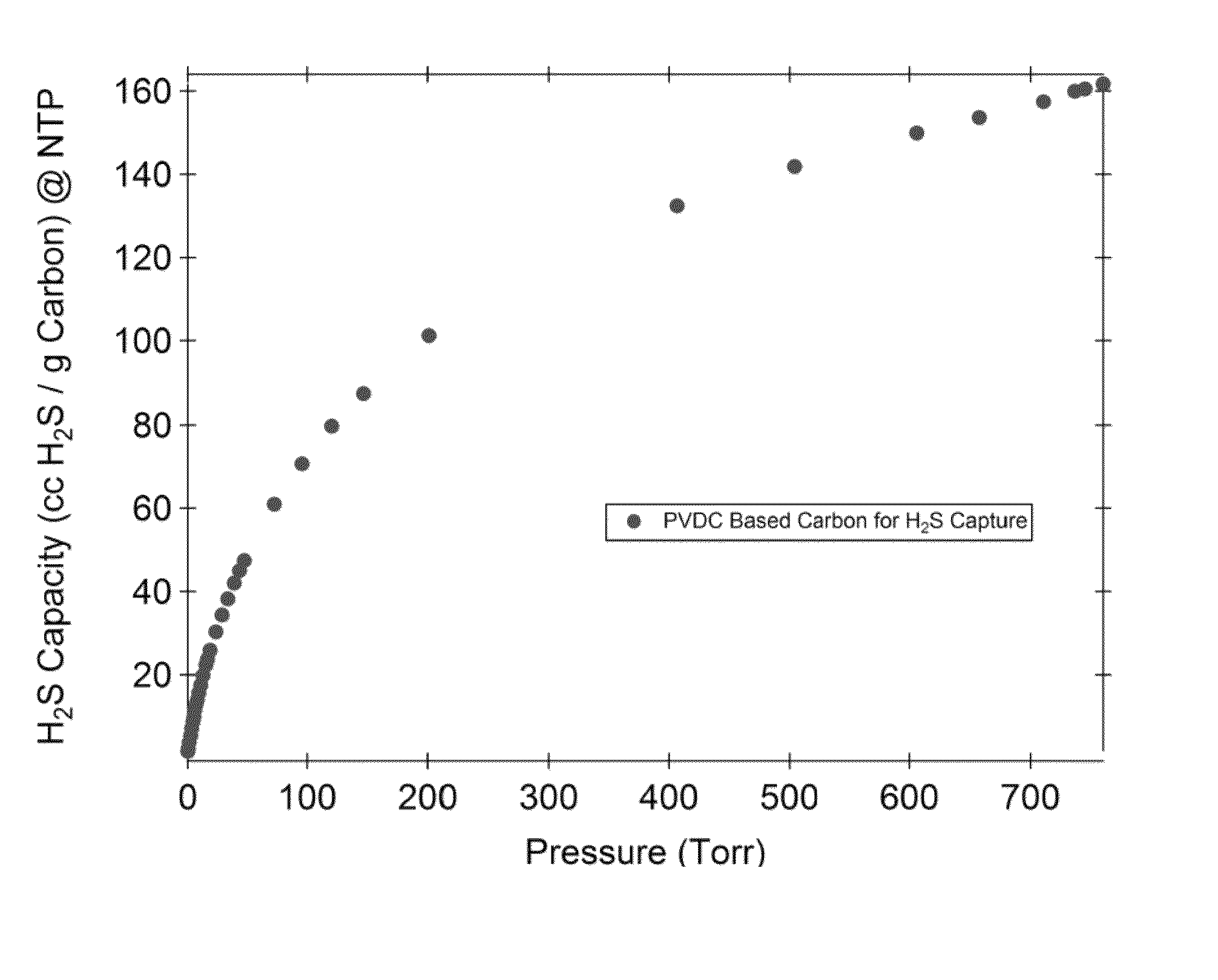

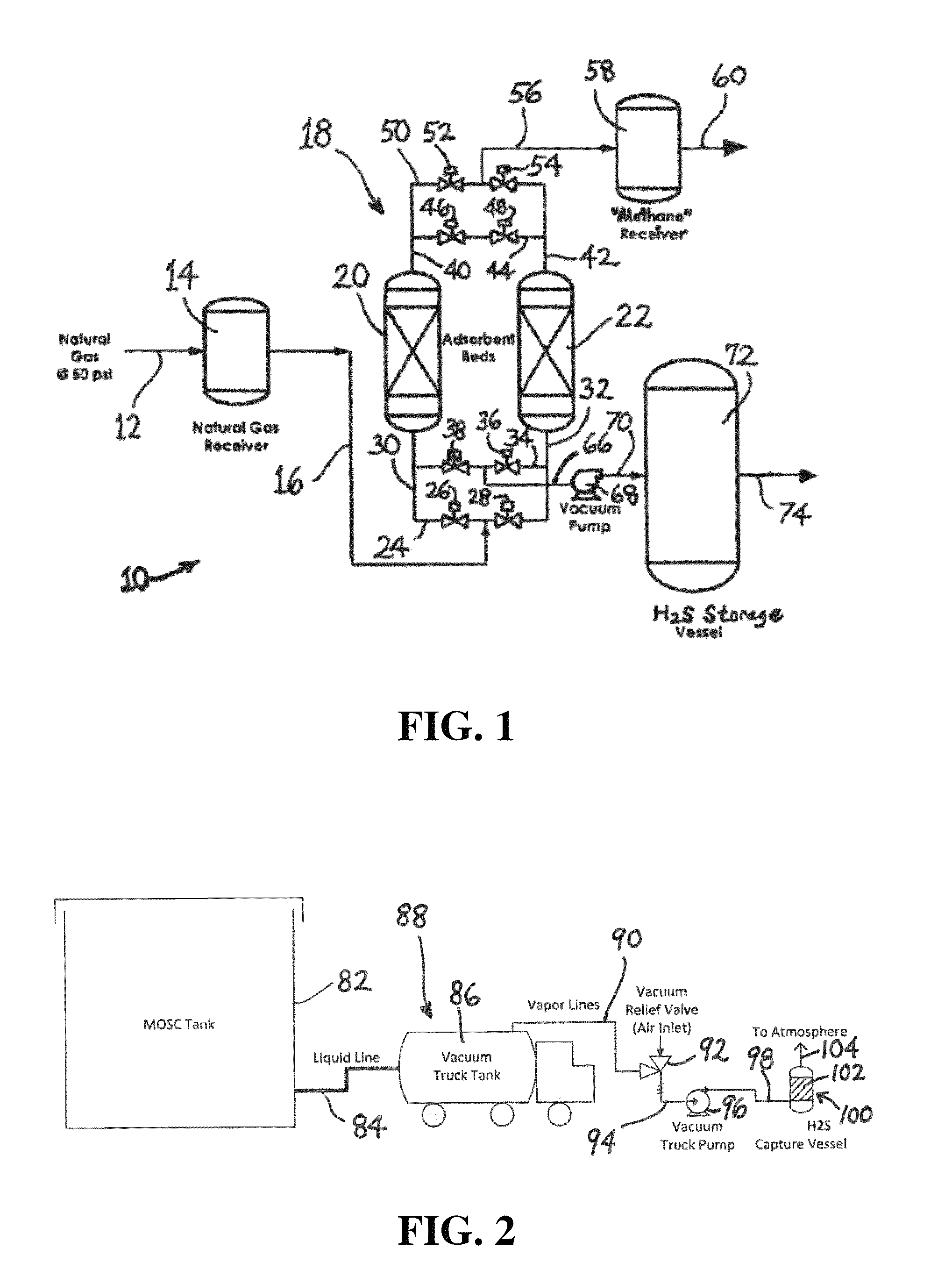

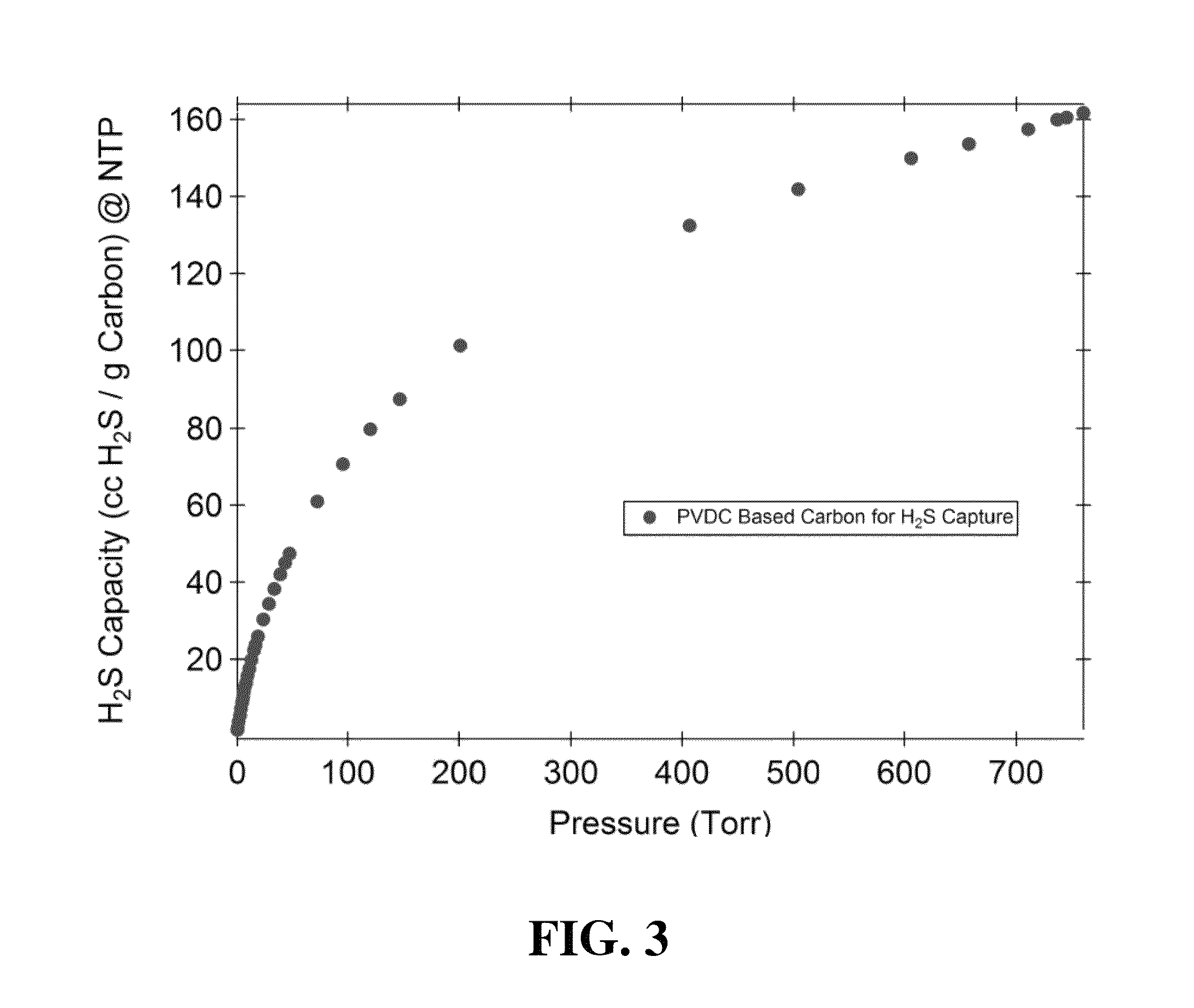

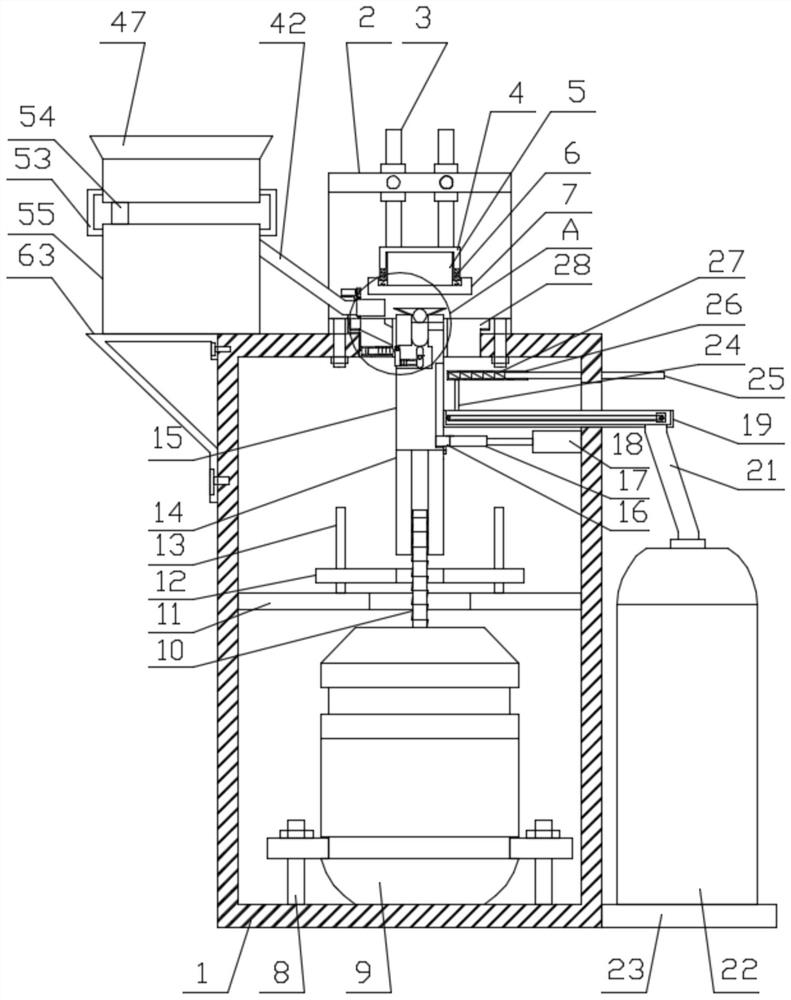

Carbon adsorbent for hydrogen sulfide removal from gases containing same, and regeneration of adsorbent

InactiveUS9126139B2Bioreactor/fermenter combinationsBiological substance pretreatmentsSorbentVolumetric Mass Density

A durable carbon pyrolyzate adsorbent having reversible sorptive affinity for hydrogen sulfide, and including the following characteristics: (a) a bulk density as measured by ASTM D2854 in a range of from 0.55 g / cc adsorbent to 1.25 g / cc adsorbent; (b) an H2S capacity in a range of from 140 cc H2S / g adsorbent to 250 cc H2S / g adsorbent, at normal conditions (1 atm, 293.15° K); (c) an H2S capacity in a range of from 1.0 cc H2S / g adsorbent to 15.0 cc H2S / g adsorbent, at partial pressure of 0.76 torr (101.3 Pa) (1000 ppm) of H2S at 293.15° K; and (d) a single pellet radial crush strength in a range of from 7 kilopond (kP) to 40 kilopond (kP) as measured by ASTM D4179. Such adsorbent is usefully employed for capture of hydrogen sulfide from gases containing same, such as H2S-containing gas associated with flowable hydrocarbonaceous material in refining operations, biogas produced by biomass digesters, gas mixtures produced by fluid catalytic cracking (FCC) units, and effluents from power plants gasifying sulfur-containing coal in an integrated gasification combined cycle (IGCC) process.

Owner:ENTEGRIS INC

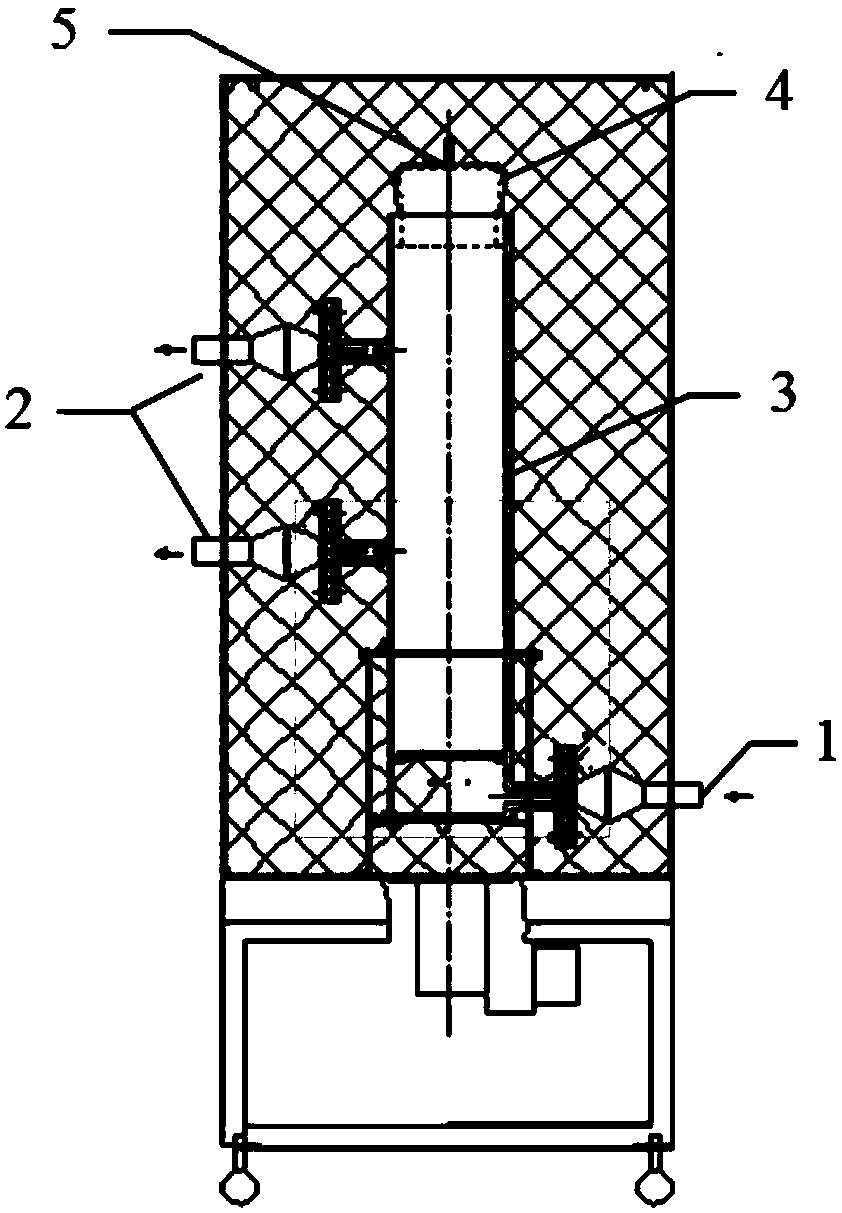

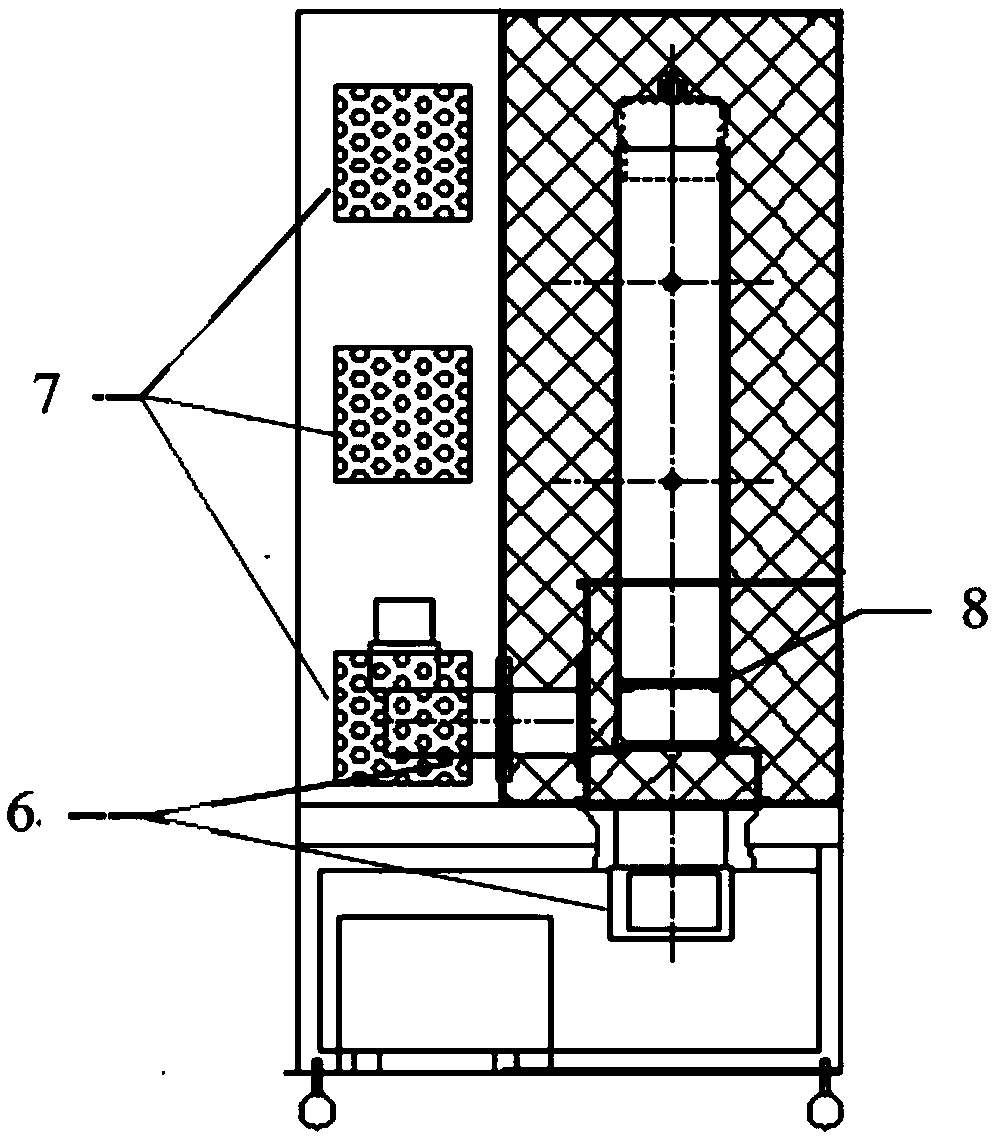

Pellet compressive strength detection device

PendingCN114323921AGuaranteed automatic feedingGuaranteed pressingConveyorsMaterial strength using tensile/compressive forcesSingle pelletSlag

The pellet compressive strength detection device comprises a device table, a pressure mechanism and a material conveying mechanism are installed on the device table, and an automatic lifting material pressing mechanism and a slag clearing and conveying mechanism are installed in the device table. By arranging the conveying mechanism, single pellets can be guided and conveyed to the automatic lifting pressing mechanism in sequence for automatic pressing, so that automatic guiding and pressing can be guaranteed, manual operation is avoided, the automation degree is high, and the influence of human factors is small; by arranging the slag clearing and conveying mechanism, the crushed green pellets on the automatic lifting and pressing mechanism can be directionally guided and collected in a centralized manner, so that the crushed pellets do not need to be manually cleared each time, and the operation efficiency is high.

Owner:江西联达金砂湾冶金有限公司

A kind of recycling technology of lf furnace refining slag

ActiveCN102899483BReduce manufacturing costMetal recyclingProcess efficiency improvementSingle pelletSlag

The invention discloses a recycling process for low-frequency (LF) furnace refining slag. The process is characterized in that the process comprises the following steps of: mixing LF furnace slag with the weight percentage of 10-30 percent with iron-containing waste materials with the weight percentage of 70-90 percent; controlling moisture content of the mixed material to be 13-18 percent; putting the mixed material into a mixing mill for mixing and milling according to the proportion for 20-30 minutes to uniformly mix; compacting and forming the mixture by a cold press forming machine; and naturally placing for 25-30 days to form metallurgy cold-pressed pellets. The process has the effects that for the pellets prepared by the method, the compression strength of a single pellet can reach over 2500N, a one-meter free drop test can be performed more than twenty times to completely meet a requirement of the strength of the metallurgy cold-pressed pellets, and the pellets can be applied to blast furnaces or converters. The process provides a new path for recycling LF furnace refining slag. A binder is not needed to add, the LF furnace refining slag is used, and the high-strength pellets are compressed, so that a direction for the recycling metallurgy iron-containing waste materials is provided, and the production cost of the cold-pressed pellets is reduced.

Owner:ANGANG STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com