A kind of ferroferric oxide ceramsite and its preparation method and application

A technology of ferroferric oxide and ceramsite, which is applied in the direction of chemical instruments and methods, applications, ceramic products, etc., can solve the problem of degrading airborne endotoxin without microwave radiation, achieve good application prospects, easy preparation, and high reflection loss Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

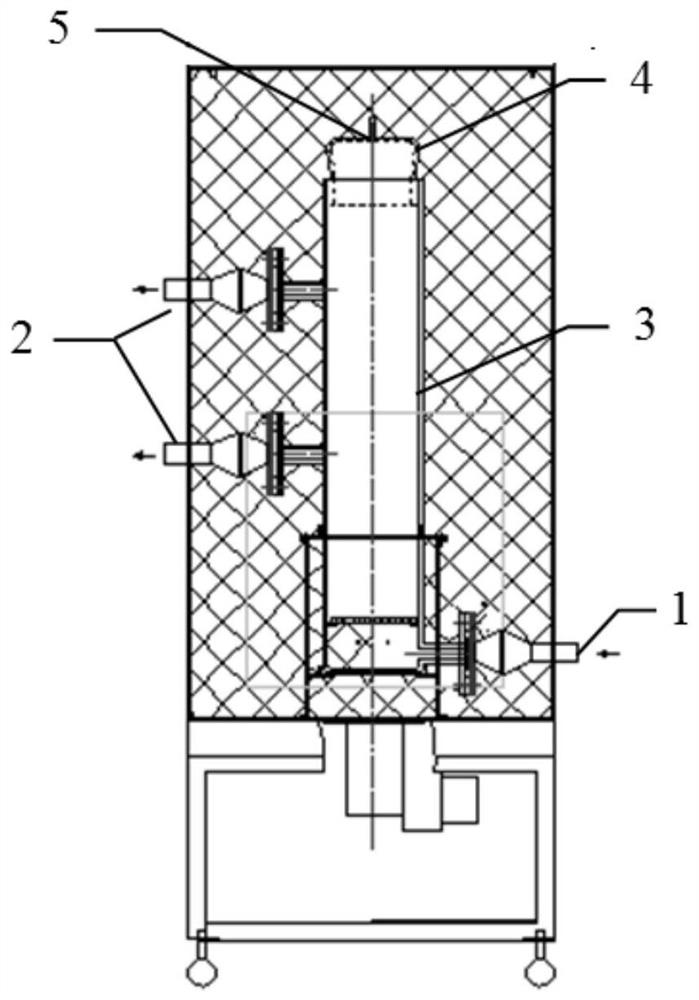

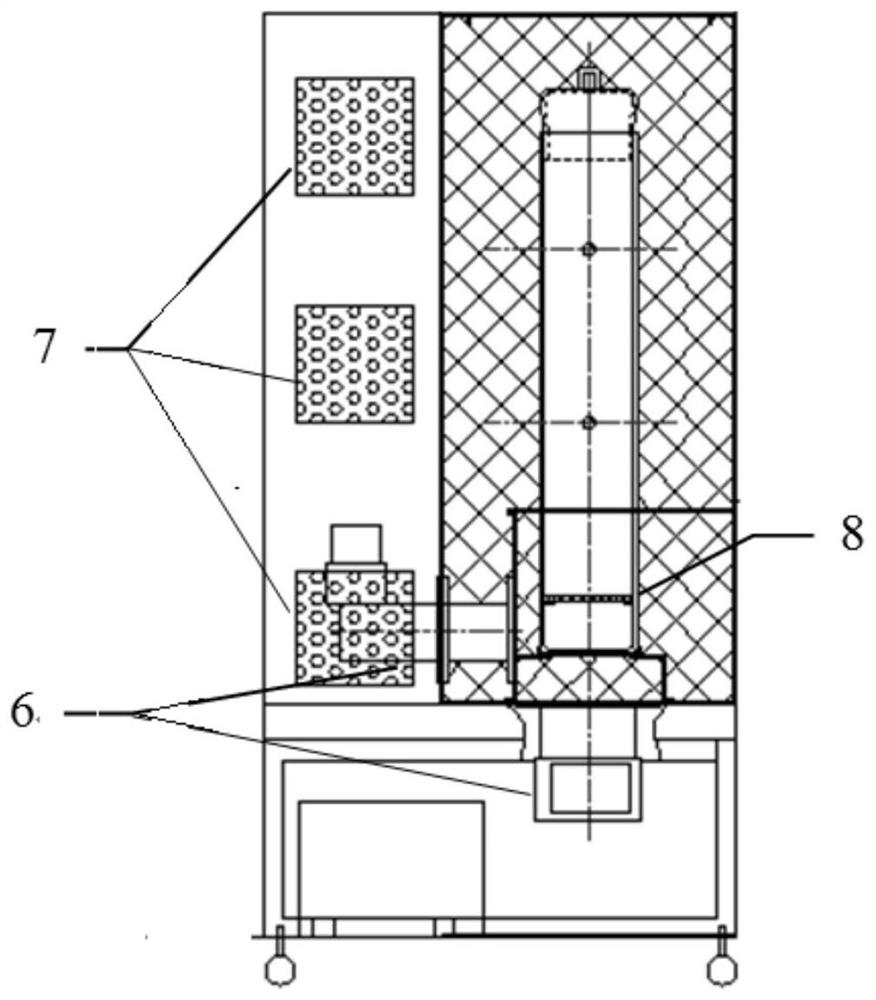

[0037] A microwave reaction device for removing bioaerosols, comprising a shell, a quartz tube 3 fixedly arranged in the shell, and quartz wool filled between the quartz tube 3 and the shell, the top of the quartz tube 3 is fixed with The infrared temperature measurement module 5 is fixed with a magnetron 6 for generating microwaves at the bottom, and a porous sieve plate 8 is arranged inside the quartz tube 3 to divide the quartz tube 3 into an upper chamber and a lower chamber. The side wall of the chamber is provided with an air inlet 1 communicating with it, the upper chamber is used for filling wave-absorbing filler and at least one air outlet 2 communicating with it is provided on the side wall, and the housing is provided with There is an observation port 7 for observing the wave-absorbing filler.

[0038] As a preferred manner, the number of the gas outlets 2 is two, which are respectively located at different heights of the quartz tube 3 .

[0039] As a preferred met...

Embodiment 2

[0045] Weigh 40g of ferric oxide powder, 10g of bentonite, NaHCO 3 0.25g, mix thoroughly and add water and mix thoroughly. Use the above-mentioned mixed materials to make a single pellet with a diameter of 5-10mm, put it in an oven at 150°C for 30 minutes, then put it into a muffle furnace, bake it at 200°C for 30 minutes, and naturally cool to room temperature to obtain tetraoxide Tri-iron ceramsite with a porosity of 4.7%.

[0046] The above-mentioned ferroferric oxide ceramsite is packed into the reaction device of embodiment 1 as a microwave filler, the total power of the magnetron 6 with a set frequency of 2.45GHz is 700W, and the initial concentration of treatment is 10 5.8 CFU / m 3About Escherichia coli bioaerosol (Escherichia coli CMCC1.3373), when described Escherichia coli bioaerosol is under the condition of 20 seconds residence time in the reaction device of embodiment 1, the Escherichia coli biogas of export Sol concentration is 10 1.7 CFU / m 3 About, inactivat...

Embodiment 3

[0048] Weigh 80g of ferric oxide powder, 20g of bentonite, NaHCO 3 0.5g, mix thoroughly and add water and mix thoroughly. Use the above-mentioned mixed materials to make a single pellet with a diameter of 5-10mm, put it in an oven at 150°C for 30 minutes, then put it into a muffle furnace, bake it at 200°C for 30 minutes, and naturally cool to room temperature to obtain tetraoxide Tri-iron ceramsite with a porosity of 4.7%.

[0049] The above-mentioned ferroferric oxide ceramsite is packed into the reaction device of embodiment 1 as a microwave filler, the total power of the magnetron 6 with a set frequency of 2.45GHz is 700W, and the initial concentration of treatment is 10 6.1 CFU / m 3 About Bacillus subtilis bioaerosol (Bacillus subtilis CMCC1.4255), when described Bacillus subtilis bioaerosol residence time is under the condition of 20 seconds in the reaction device of embodiment 1, the Bacillus subtilis organism of export Aerosol concentration is 10 2.9 CFU / m 3 About,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com