Filling base material type selection method of support plate hole filling process and support plate hole filling process

A carrier plate and substrate technology, which is applied to the filling substrate selection method and the hole filling process field of the carrier plate hole filling process, can solve the problems of affecting the filling efficiency, failure, low efficiency, etc., and achieves improved filling effect and high speed. , the effect of high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

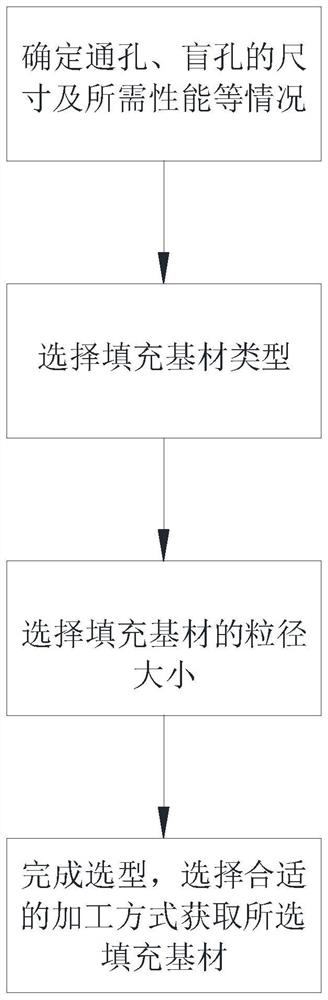

[0048] see Figure 1-Figure 3 , this embodiment discloses a filling substrate type selection method for a carrier plate hole filling process, comprising the following steps:

[0049] (1) Determine the size and required performance of the through hole or blind hole on the carrier board 1 .

[0050] (2) Select the appropriate type of filling substrate 5, including nano-metal sintered body, metal block, etc.

[0051] (3) Select the particle size of filling base material 5; Wherein, the particle size of filling base material 5 is selected as follows:

[0052] (a) Small grain filling, D=0.001~0.2d

[0053] (b) String filling, D=0.5d~2d

[0054] (c) Single-grain overall filling, D=0.5(1.5d 2 h) 0.5 ~2(1.5d 2 h) 0.5

[0055] Wherein, in the above formula, D is the particle diameter of the filling substrate 5, d is the diameter of the through hole or blind hole on the carrier plate 1, and h is the depth of the through hole or blind hole on the carrier plate 1.

[0056]When th...

Embodiment 2

[0067] This embodiment discloses a specific example of the type selection method for the filling base material 5 in Embodiment 1. specifically,

[0068] (1) The size of the through hole to be filled on the carrier plate 1: the diameter d is 300 nm, and the depth h is 800 nm.

[0069] (2) A nano-silver sintered body is selected as the filling base material 5 .

[0070] (3) Select string filling, that is, D=0.5d~2d; the selected particle size is 150nm~600nm.

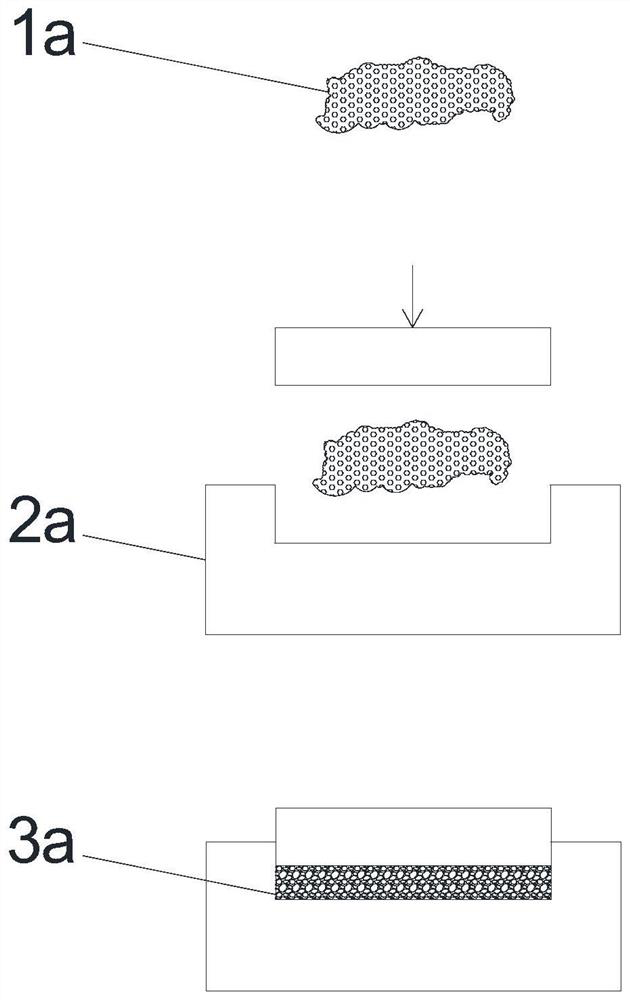

[0071] see figure 1 , for the filling base material 5 selected above, the processing method is as follows: the nano-silver particles 1a are pressurized and sintered into a block in a mold 2a with a cross-sectional area of 10×10mm under the temperature of 350°C and a pressure of 20MPa to form The metal silver block 3a is used as the filling base material 5 for the hole-filling embossing of the carrier plate 1 .

Embodiment 3

[0073] This embodiment discloses a specific example of the type selection method for the filling base material 5 in Embodiment 1. specifically,

[0074] (1) The size of the through hole to be filled on the carrier plate 1: the diameter d is 20 μm, and the depth h is 100 μm.

[0075] (2) A metal block is selected as the filling base material 5 .

[0076] (3) Choose small grains to fill, that is, D=0.001~0.2d; the selected particle size is 0.02μm~4μm.

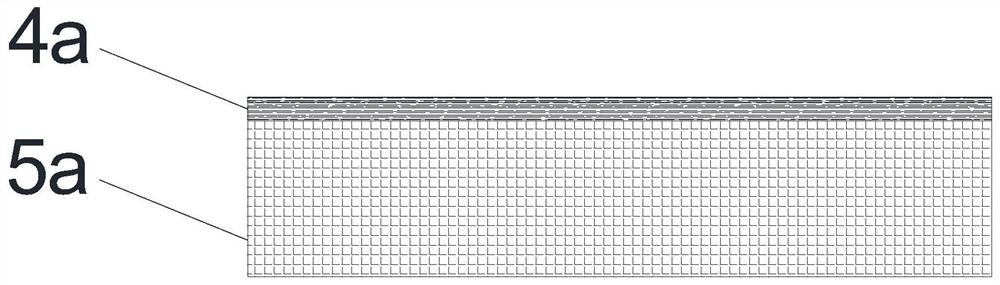

[0077] For the filling base material 5 selected above, the processing method is as follows: a copper block with a shape of 10×10×2 mm is passed through a high-frequency current of 30 MHz 5 A to heat the surface of the copper block. Conduct ultrasonic vibration on the copper block, and control the ultrasonic frequency to 2.26×10 under the condition that the surface wave sound velocity of the copper block is 2260m / s 8 Hz, so that the average grain size on the surface reaches 5 μm, thereby making a filling base material 5 of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com