Method for measuring the mixing uniformity degree of pellet raw material

A technology for uniform mixing and mixing of raw materials, which is applied in the preparation of test samples and measurement of color/spectral characteristics, etc., and can solve the problem of not being able to accurately know the degree of uniformity of raw materials in the pellet mixer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

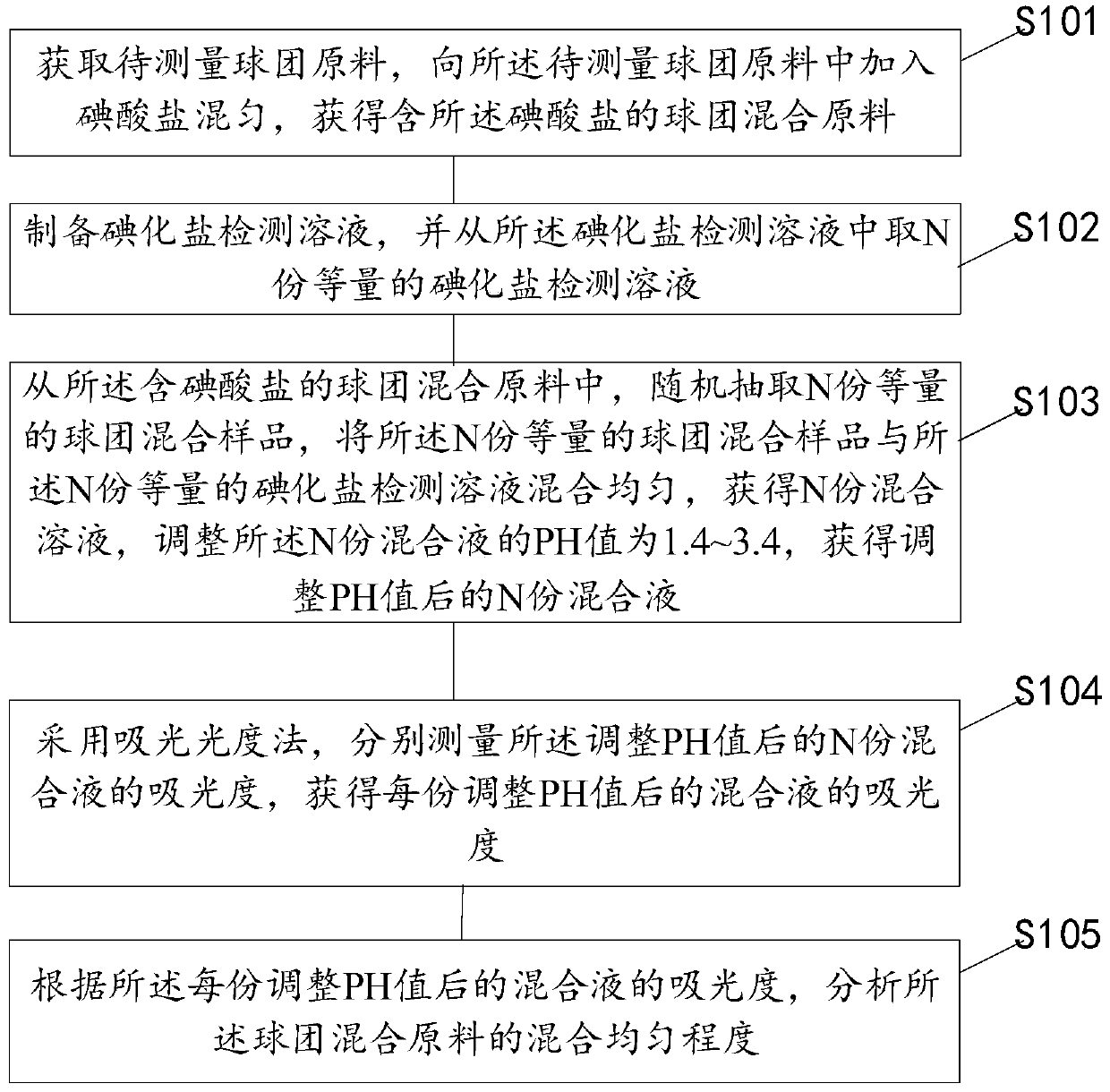

[0028] This embodiment provides a method for measuring the uniformity of pellet raw material mixing, including:

[0029] S101: Obtain the pellet raw material to be measured, add iodate to the pellet raw material to be measured and mix evenly, to obtain a pellet mixed raw material containing iodate.

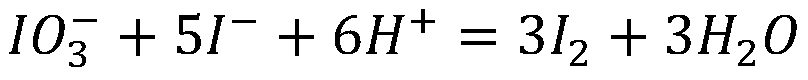

[0030] In the actual production process of pellets, in order to detect the degree of uniformity of the pelletizing mineral powder (the pellet raw material to be measured) mixed in the mixer, this program mainly uses iodate as a tracer when the raw materials are mixed. Then sample the mixed raw materials and tracers, and test the content of each tracer to reflect the mixing uniformity of raw materials.

[0031] The iodate used as a tracer, firstly, does not exist in the pelletizing mineral powder; secondly, the iodate does not chemically react with the pelletizing mineral powder, that is, the iodate is There will be no change in mass and concentration before and after mixing. The...

Embodiment 2

[0082] (1) Preparation of pellet mixed raw materials:

[0083] After adding the pellets with mineral powder (10kg in total) into the mixer, add potassium iodate solid (3g) into the mixer, and mix well.

[0084] (2) Preparation of detection solution:

[0085] Prepare 1.2g / L potassium iodide KI solution: weigh 0.6g KI, dissolve it in 200ml water, and dilute to 500ml.

[0086] Prepare 0.1mol / L dilute hydrochloric acid: dilute concentrated hydrochloric acid to make 0.1mol / L.

[0087] (3) Determination of absorbance of pellet mixed raw materials:

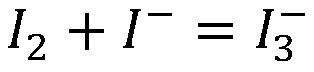

[0088] Prepare the solution to be tested: randomly select the mixed samples of pellets in different positions, take five times, each time 100g of the sample is put into a 500ml beaker, add 200ml of distilled water to the 500ml beaker, stir well, react for 20min, then filter and use the filtrate 500ml or 1000ml volumetric flask to volume.

[0089] Prepare the sample solution: take out 25ml of the solution to be tested from the volumet...

Embodiment 3

[0099] (1) Preparation of pellet mixed raw materials:

[0100] After adding the pellets with mineral powder (10kg in total) into the mixer, add potassium iodate solid (2g) into the mixer and mix well.

[0101] (2) Preparation of detection solution:

[0102] Prepare 2g / L KI solution: weigh 1.0g KI, dissolve it in 200ml water, and dilute to 500ml.

[0103] Prepare 0.1mol / L dilute hydrochloric acid: dilute concentrated hydrochloric acid to make 0.1mol / L.

[0104] (3) Determination of absorbance of pellet mixed raw materials:

[0105] Prepare the solution to be tested: randomly select the mixed samples of pellets in different positions, take five times, each time 100g, put them into a 500ml beaker, add 150ml of distilled water to the 500ml beaker, stir well, react for 30min, then filter and use the filtrate 500ml volumetric flask to volume.

[0106] Prepare the sample solution: take out 25ml of the solution to be tested from the volumetric flask with a pipette, and transfer it...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| absorbance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com