Beet seed pelleting formula and processing method

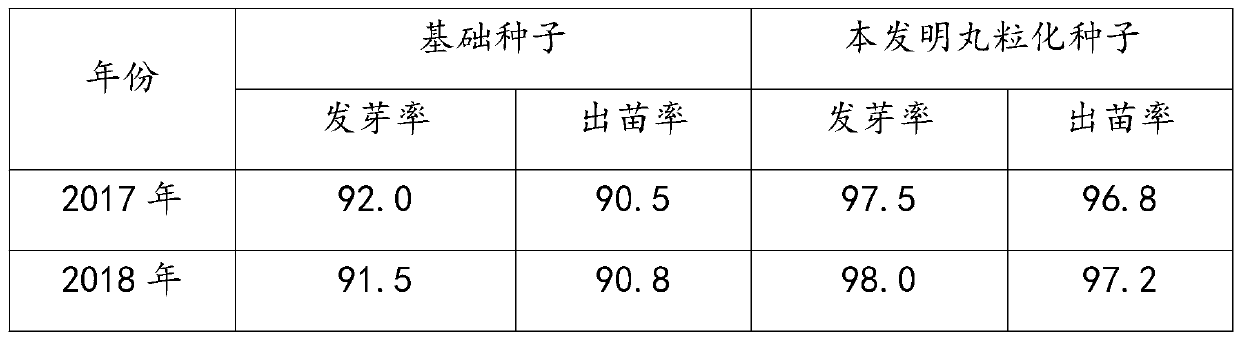

A pelletizing and seed technology, applied in the field of beet seed pelleting formulation, can solve the problems of poor cracking degree, low compressive strength, low field emergence rate, etc., achieves no dampening, high granulation strength, and promotes plant growth. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A beet seed pelleting formula, comprising powder A, powder B, powder C and liquid material D, in parts by weight, said powder A is 57 parts of pure poplar wood powder of 120 mesh inert filling materials, viscose Mixture polymer composite material ZJY-2 2 parts, granulating agent is 20 parts of quartz stone and attapulgite 20 parts, described powder B is 0.15 part of thiram, 0.28 part of zinc sulfate, 0.28 part of manganese sulfate, 0.28 part of borax part, 0.0002 part of gibberellic acid, and 0.0098 part of brassinolide, the powder C is powder A mixed with powder B in a weight ratio of 15:1, and the liquid material D is a coloring agent 6 parts of pure acrylic emulsion, 0.3 parts of carboxymethyl cellulose, 7 parts of warning color, 6 parts of pearl powder, and 80.7 parts of water.

[0035] The method of pelletizing sugar beet seeds using the above sugar beet seed pelletization formula is: select the beet seeds with full grains as the basic seeds, first perform polishin...

Embodiment 2

[0037] The sugar beet seed pelletization formula of the present embodiment is the same as that of Embodiment 1.

[0038]The method for pelletizing sugar beet seeds using the formula for pelletizing sugar beet seeds is as follows: select sugar beet seeds with full grains as the basic seeds, first carry out polishing treatment, and then carry out winnowing and specific gravity selection, so that the kernel splitting rate reaches 98% % or more; get 2g 0.15% brassinolide EC and 50g 0.006% S-induced antibiotic solution mixed with 20kg of water to make trigger liquid, immerse selected sugar beet seeds in prepared trigger liquid , the drug species ratio of the initiation treatment is 5:1, the treatment temperature is 18° C., and the constant temperature treatment time is 6 hours. Overheating is avoided during the treatment process, and stirring is carried out every 3 hours. After the treatment, the sugar beet seeds floating on the water surface are taken out and left Dry the beet see...

Embodiment 3

[0040] The sugar beet seed pelletization formula of the present embodiment is the same as that of Embodiment 1.

[0041] The method for pelletizing sugar beet seeds using the formula for pelletizing sugar beet seeds is as follows: select sugar beet seeds with full grains as the basic seeds, first carry out polishing treatment, and then carry out winnowing and specific gravity selection, so that the kernel splitting rate reaches 98% % or more; get 2g 0.15% brassinolide EC and 50g 0.006% S-induced antibiotic solution mixed with 20kg of water to make trigger liquid, immerse selected sugar beet seeds in prepared trigger liquid , the drug species ratio of the initiation treatment is 5:1, the treatment temperature is 18° C., and the constant temperature treatment time is 6 hours. Overheating is avoided during the treatment process, and stirring is performed every 3 hours. After the treatment, the sugar beet seeds floating on the water surface are taken out and left Dry the beet seed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com