Functional sustained or controlled release fertilizer core based on bio-based adhesive and preparation method thereof

A technology of slow and controlled release fertilizers and binders, applied in nitrogen fertilizers, potassium fertilizers, phosphate fertilizers, etc., can solve the problems of unsustainable development, poor cohesiveness, environmental pollution, etc., and achieve improved fluidization performance, strong cohesiveness, and particle size strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

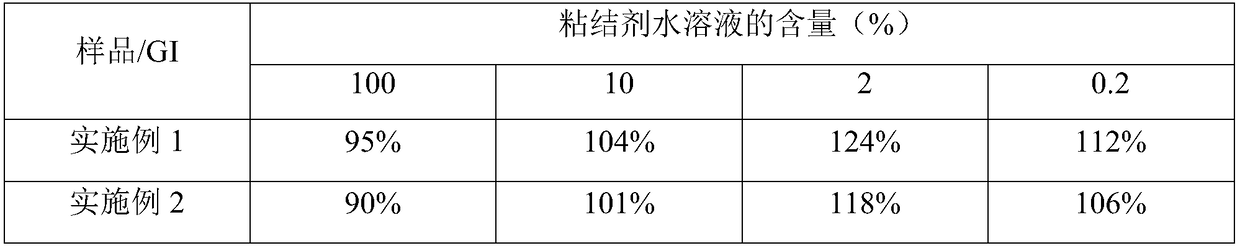

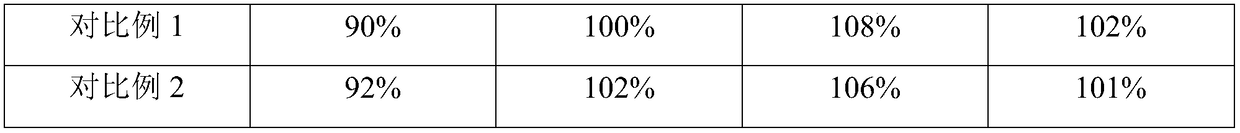

Examples

Embodiment 1

[0048] Embodiment 1: the preparation of bio-based binder

[0049] Weigh 70g of lignin, 25g of phenol and 4.6g of transition metal coordination complex catalyst and mix them evenly, then put them into the reactor, set the temperature of the reactor at 150°C, and react for 2h to obtain the lignin bio-based polyol; take 45g The obtained lignin bio-based polyol was reacted with 0.2g of bisphenol A glyceryl diacrylate, 0.2g of 3-aminopropyltrimethoxysilane, and 50g of vinyltriamine at 60°C for 1h to prepare a bio-based binder .

Embodiment 2

[0050] Embodiment 2: the preparation of bio-based binder

[0051] Weigh 70g of tannin, 25g of ethylene glycol and 4.6g of sulfuric acid catalyst and mix them evenly and put them into the reactor; set the temperature of the reactor to 150°C and react for 2h to obtain tannin bio-based polyol; take 45g of the obtained tannin bio base polyol with 0.1 g 3,5 dimethylthio-2,4-diaminotoluene (DMTDA), 0.1 g carboxy-functionalized castor oil (CCE) and 0.1 g hexamethoxymethylcyanuric acid (HMMM) , 0.1g of trimethylolethane, and 50g of vinyltriamine were mixed, and reacted at 100°C for 0.5h to prepare a bio-based binder.

Embodiment 3

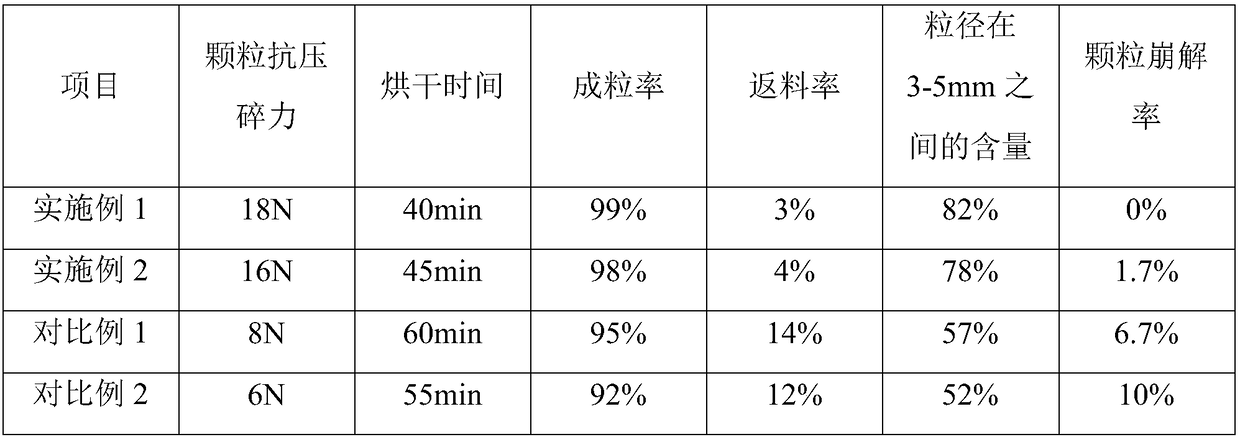

[0052] Example 3: Preparation of functional slow-release fertilizer core

[0053] Sieve powdered urea, monoammonium phosphate, potassium chloride and fulvic acid, the fineness of the sieve is 60 mesh, weigh 1.8kg powdered urea, 1.6kg monoammonium phosphate, 1.6kg potassium chloride and 25g Mix the fulvic acid evenly, add it to the heat preservation disc granulator preheated to 50°C; spray 100g of the bio-based binder prepared in Example 1 on the mixed fertilizer under positive pressure, granulate, and sieve the granules 3-5mm diameter granules; dry the sieved 3-5mm granules to obtain a functional slow-release fertilizer core.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com