Pelletization processing technology for seeds

A processing technology and pelletization technology, which is applied in the field of seed pelletization processing technology, can solve the problems of poor granulation, poor adaptability, backward processing machinery and technology, etc., and achieve high granulation rate, uniform size, and pellets good quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

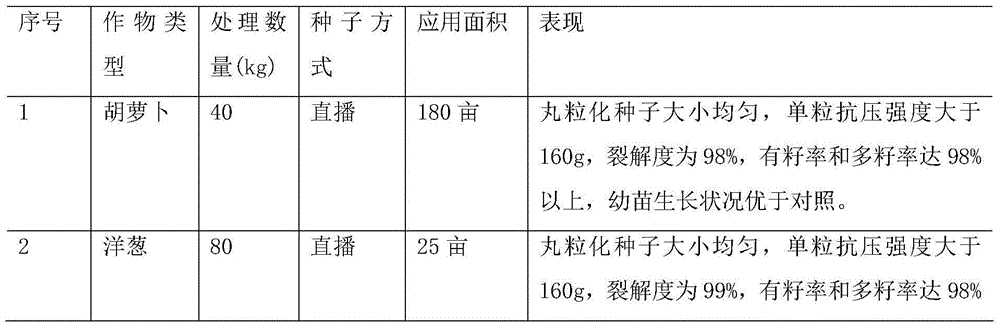

Examples

Embodiment 1

[0026] The pelletization of the seeds is done in the pelletizing machine. First formulate the formula of the carrot pelleting matrix, and after the pelleting matrix is ready, it can be implemented according to the following procedures:

[0027] (1) Selected seeds: The seeds to be pelleted have very strict requirements on cleanliness, and must not contain sand, stones or seeds of foreign crops. This is an important link to ensure the quality of pelleted seeds. Whether to re-select the material should be determined according to the clarity.

[0028] (2) Disinfection: In the pelletizing machine, the surface of the seeds is first contacted with thiram to play a disinfection role. Preferably, thiram is coated in a pellet colorant.

[0029] (3) Nucleation: Add additives (binders and fillers) to the sterilized seeds in a ratio of 1:1 by weight. The power of the continuously variable speed motor equipped with the pelletizing equipment system is set to 3kw, and the inclination angl...

Embodiment 2

[0036] The pelletization of the seeds is done in the pelletizing machine. First formulate the onion pelleting matrix formula, and after the pelleting matrix is ready, it can be implemented according to the following procedures:

[0037] (1) Selected seeds: The seeds to be pelleted have very strict requirements on cleanliness, and must not contain sand, stones or seeds of foreign crops. This is an important link to ensure the quality of pelleted seeds. Whether to re-select the material should be determined according to the clarity.

[0038] (2) Disinfection: In the pelletizing machine, the surface of the seeds is first contacted with thiram to play a disinfection role. Preferably, thiram is coated in a pellet colorant.

[0039] (3) Nucleation: Add additives (binders and fillers) to the sterilized seeds according to the proportion of the formula. The power of the continuously variable speed motor equipped with the pelletizing equipment system is set to 3kw, and the inclinati...

Embodiment 3

[0046] The pelletization of the seeds is done in the pelletizing machine. First formulate the formula of the burdock pelleting matrix, and after the pelleting matrix is ready, it can be implemented according to the following procedures:

[0047] (1) Selected seeds: The seeds to be pelleted have very strict requirements on cleanliness, and must not contain sand, stones or seeds of foreign crops. This is an important link to ensure the quality of pelleted seeds. Whether to re-select the material should be determined according to the clarity.

[0048] (2) Disinfection: In the pelletizing machine, the surface of the seeds is first contacted with thiram to play a disinfection role. Preferably, thiram is coated in a pellet colorant.

[0049] (3) Nucleation: Add additives (binders and fillers) to the sterilized seeds according to the proportion of the formula. The power of the continuously variable speed motor equipped with the pelletizing equipment system is set to 3kw, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com