Sludge mixing granulation device and method

A granulation device, mixing and granulation technology, applied in the direction of combination devices, separation methods, chemical instruments and methods, etc., can solve the problems of long transportation time, polluting the environment, and not having the function of purifying odor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

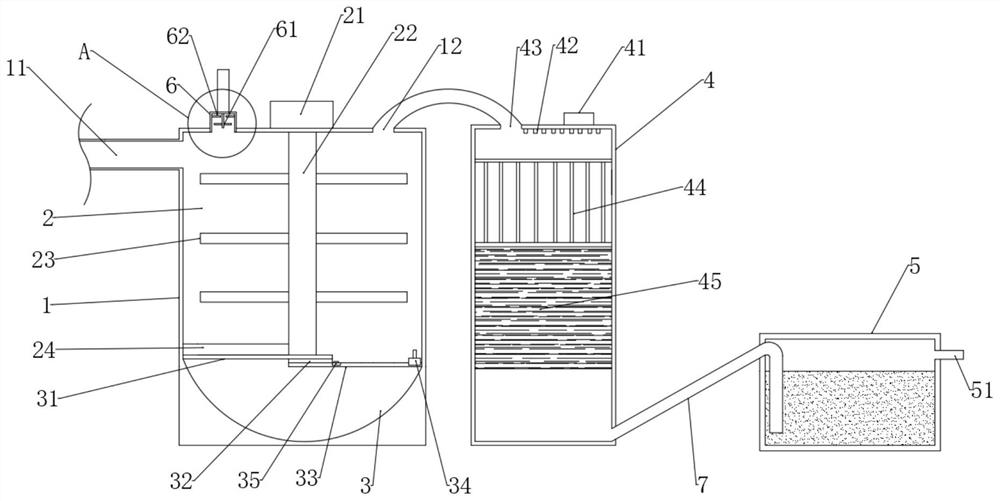

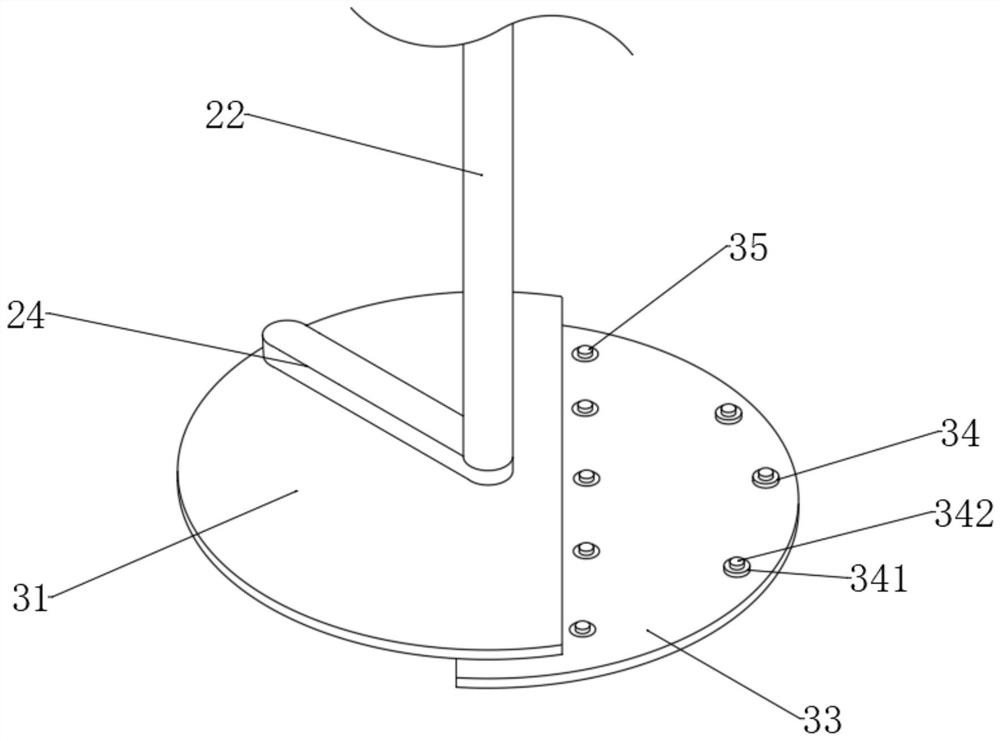

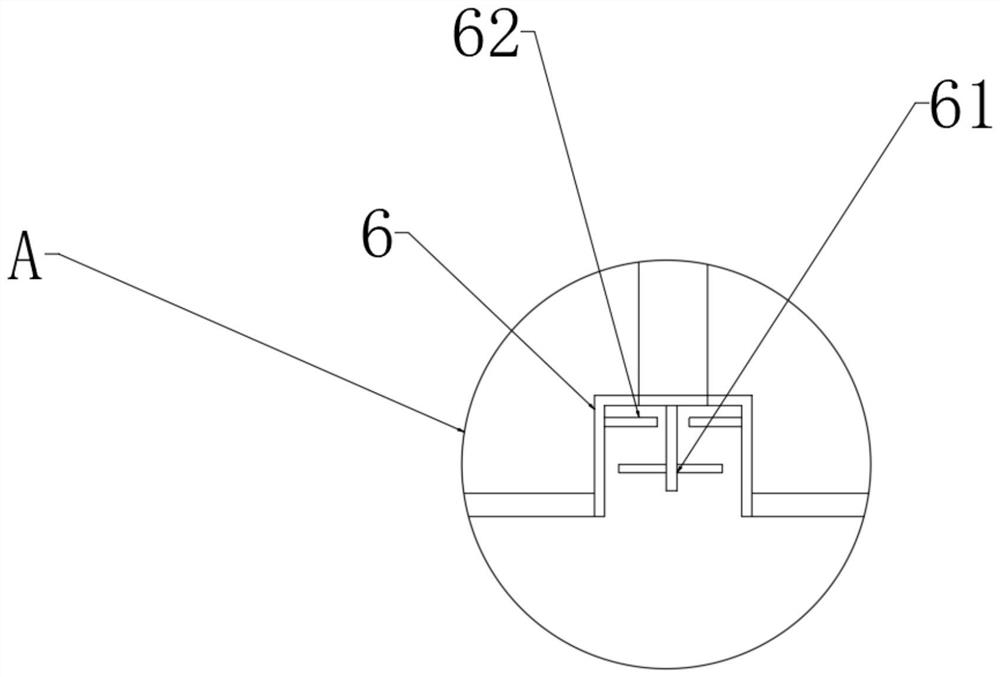

[0021] A sludge mixing and granulating device and a granulating method. In order to solve the problem that the existing sludge mixing and granulating device has no function of purifying odor and polluting the environment, and the existing sludge mixing and granulating device has complicated procedures and long transportation time, There is no problem of preheating the sludge particles in advance, as a preferred embodiment, such as figure 1 , figure 2 and image 3 As shown, it includes a granulation device body 1, a purification device 4 and a pool 5. The granulation device body 1 is a cylindrical hollow structure. The upper part of the granulation device body 1 is provided with a mixing device 2. Feed pipe 11, motor 21 is welded and fixed on the top of mixing and stirring device 2, and stirring rod 22 is welded on the output end of motor 21. The lower part of the device body 1 is provided with a granulation device 3, and a baffle 31 is welded and fixed between the granulati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com