Sewage processing process using microbial carrier

A technology for microbial carrier and sewage treatment, which is applied in granular microbial carrier treatment, biological water/sewage treatment, special compound water treatment, etc. The difficulty of solidification treatment and the effect of solving sludge bulking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0067] The invention discloses a sewage treatment process using a microbial carrier, which comprises the following process steps:

[0068] S1: Sewage flows into the primary sedimentation tank for primary sedimentation to obtain primary sedimentation sewage.

[0069] S2: The sewage after the initial precipitation in step S1 is filtered through the grid and then flows into the granulated sludge tank for treatment. The granulated sludge tank is added with granulated sludge.

[0070] S3: The sludge treated in the granulated sludge tank in step S2 is discharged into the secondary sedimentation tank for secondary sedimentation.

[0071] The middle layer sludge in the secondary sedimentation tank enters the front end of the granulated sludge tank, and is mixed with the sewage that has undergone primary sedimentation in step S1 to obtain a mixed solution, which then flows into the granulated sludge tank for secondary sewage treatment.

[0072] The sludge in the lower layer of the sec...

Embodiment 18

[0102] The difference between Example 18 and Example 1 is that the microbial agent includes Bacillus coagulans, Bacillus natto, Bacillus subtilis, Bacillus cereus, Bacillus pumilus, Lactobacillus acidophilus, Lactobacillus plantarum, cloth Lactobacillus subtilis, Nitrosomonas, Nitrosospirillum, Bacillus licheniformis, Bacillus lateralis, Deinococcus aquaticus, Bacillus megaterium, Staphylococcus aureus, Bacillus highlander, Bacillus jelly-like, and the above-mentioned bacteria Accounting for 50% of the total weight of the bacterial agent.

Embodiment 19

[0103]The difference between Example 19 and Example 1 is that the microbial agent includes Bacillus coagulans, Bacillus natto, Bacillus subtilis, Bacillus cereus, Bacillus pumilus, Lactobacillus acidophilus, Nitrospirulina, Nitrosococcus, Nitrosococcus, Nitrospinus, Nitrococcus, Bacillus licheniformis, Bacillus lateralis, Deinococcus aquaticus, Bacillus megaterium, Staphylococcus aureus, Bacillus highlander, and the above-mentioned bacteria account for the total weight of the bacterial agent 50% of.

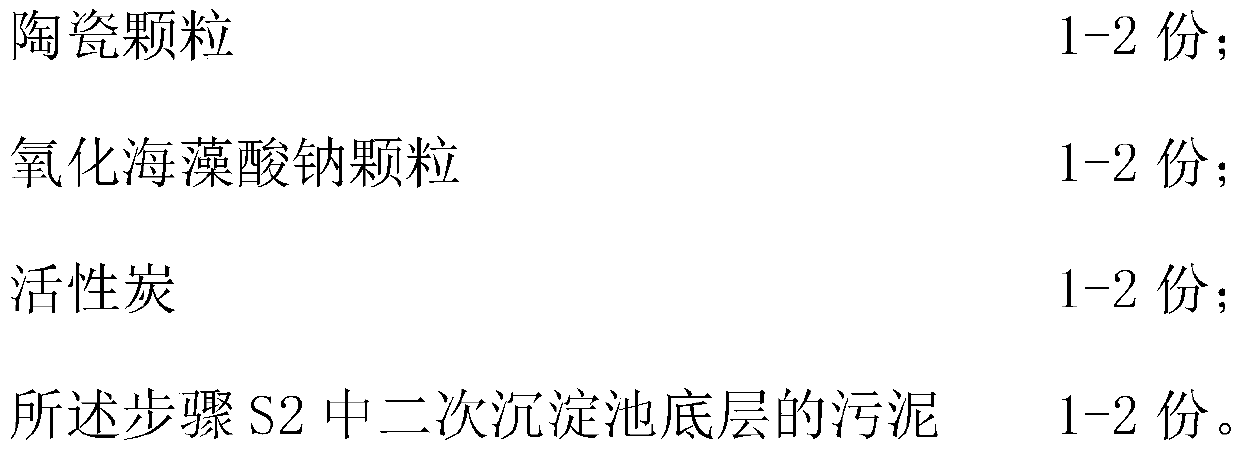

[0104] The difference between Embodiment 20-23 and Embodiment 1 is that the parts by weight of each component of the nutrient are calculated as the following table:

[0105]

[0106]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com