Patents

Literature

110results about How to "No dissolution" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Granular filtering material for adsorbing and removing heavy metals in water and preparation method thereof

ActiveCN104289185AWide variety of sourcesRealize resource utilizationOther chemical processesWater contaminantsIndustrial waste waterSorbent

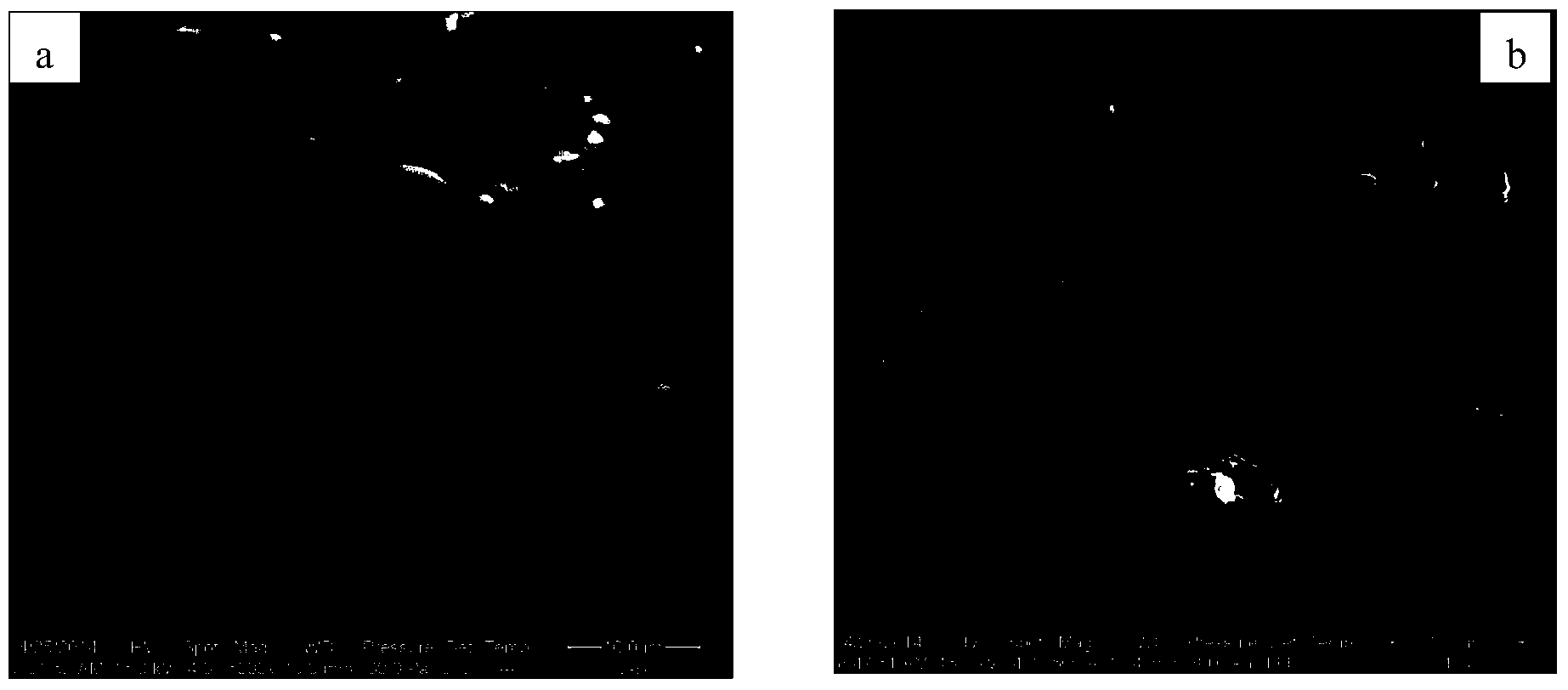

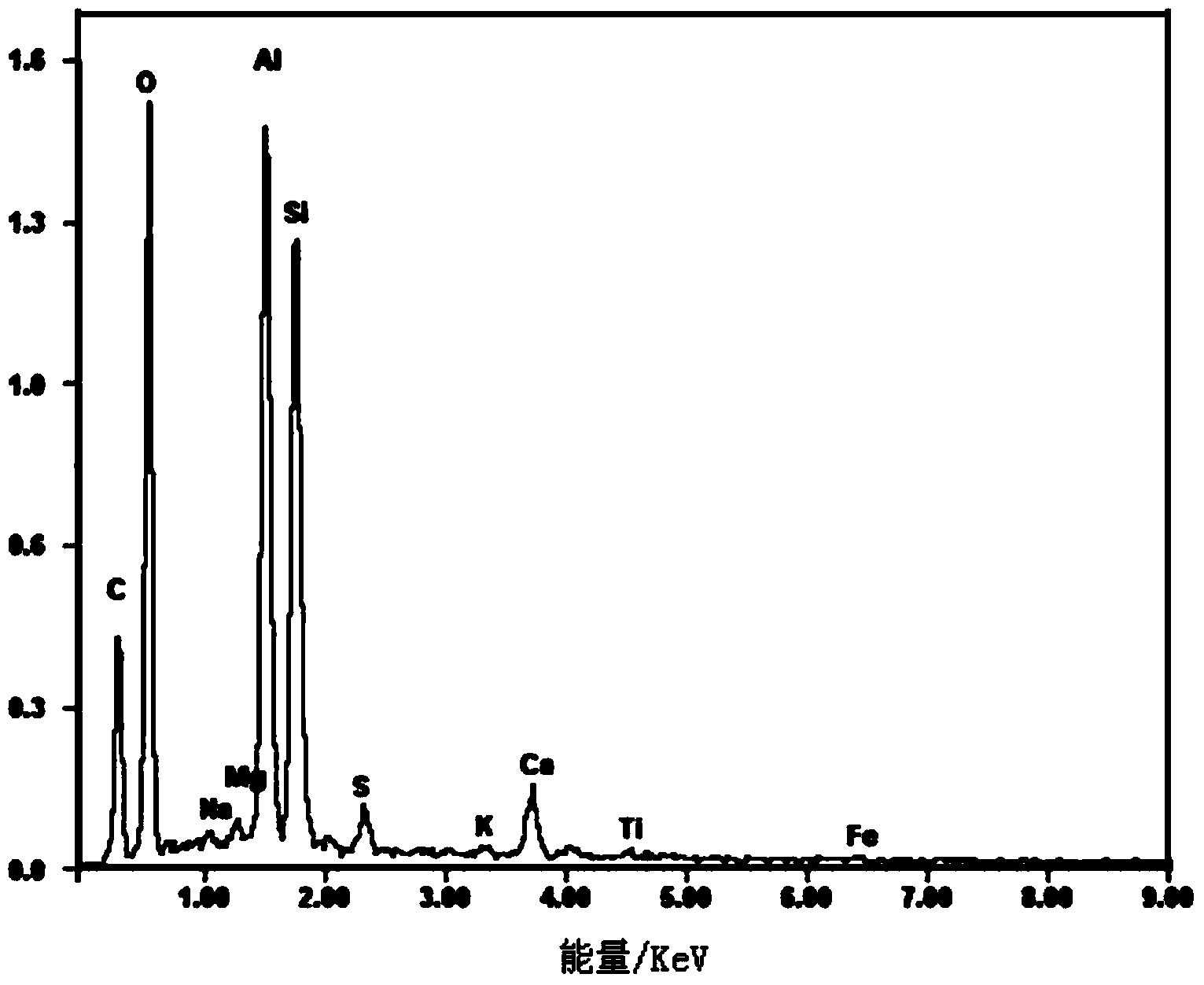

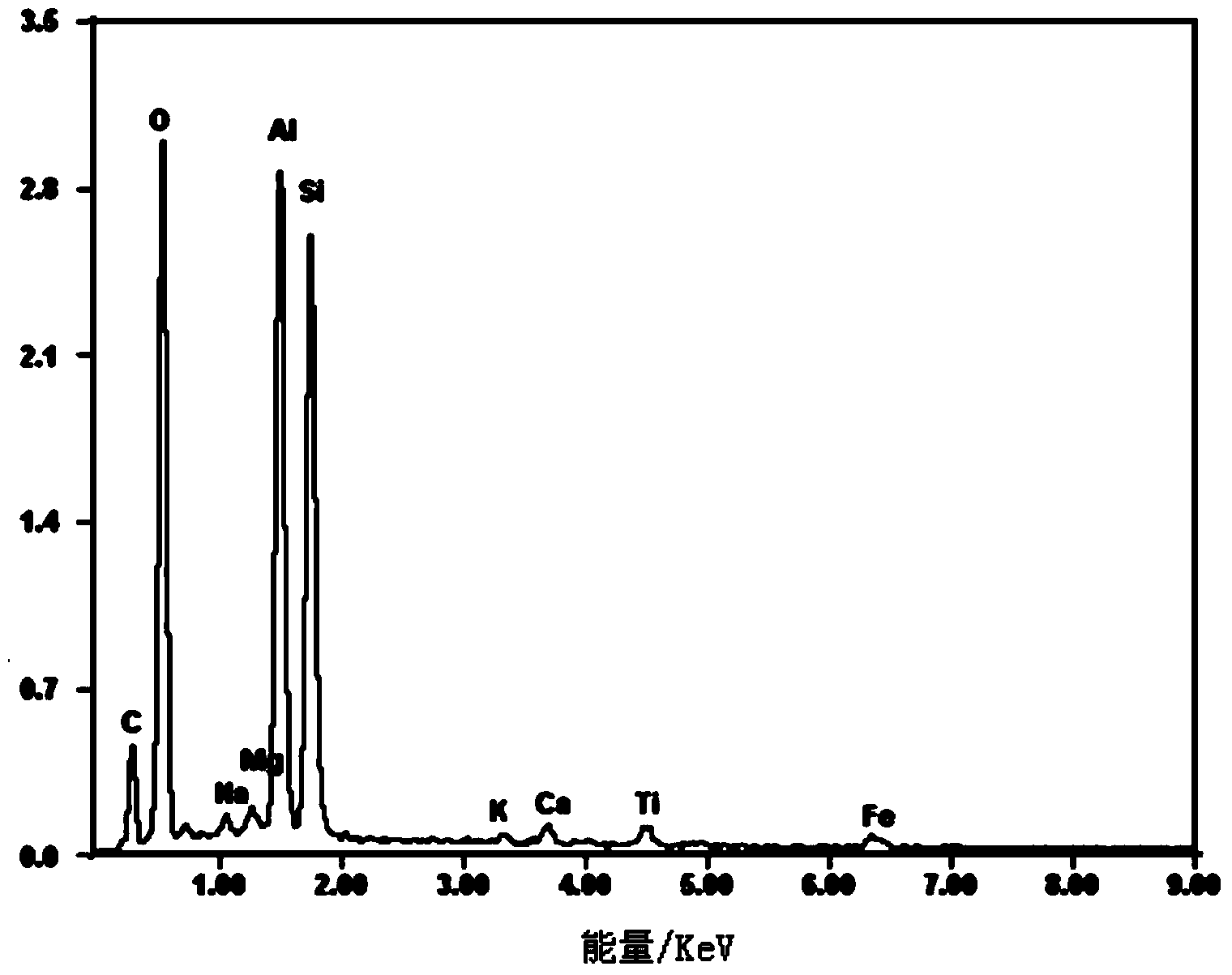

The invention discloses a granular filtering material for adsorbing and removing heavy metals in water and a preparation method thereof. The granular material consists of the following components in part by mass: 80-120 parts of an adsorbent, 7-14 pats of an additive and 0.5-3 parts of a binding agent, wherein the adsorbent consists of the following components in part by mass: 50-70 parts of coal ash and 30-50 parts of zeolite powder or sea-foam stone powder; the additive consists of the following components in part by mass: 5-7 parts of Mg-Al hydrotalcite, 2-6 parts of biochar and 0.5-1 part of magnesium Lignosulfonate; the binding agent is bentonite. The granular filtering material is prepared through the steps of adsorbent acid modification, biochar preparation, granulation and heat treatment process. According to the invention, the prepared granular filtering material is 3-6 mm in granule size, is large in adsorption capacity and excellent in adsorption effect and can effectively remove heavy metals in water, and no secondary pollutants are dissolved out, so that the granular filtering material can be applied to the treatment on heavy metal micro-polluted water and industrial waste water containing heavy metals, and has good economic and social benefits.

Owner:BEIJING FORESTRY UNIVERSITY

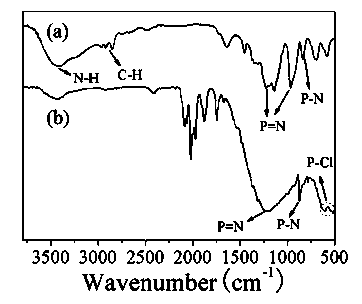

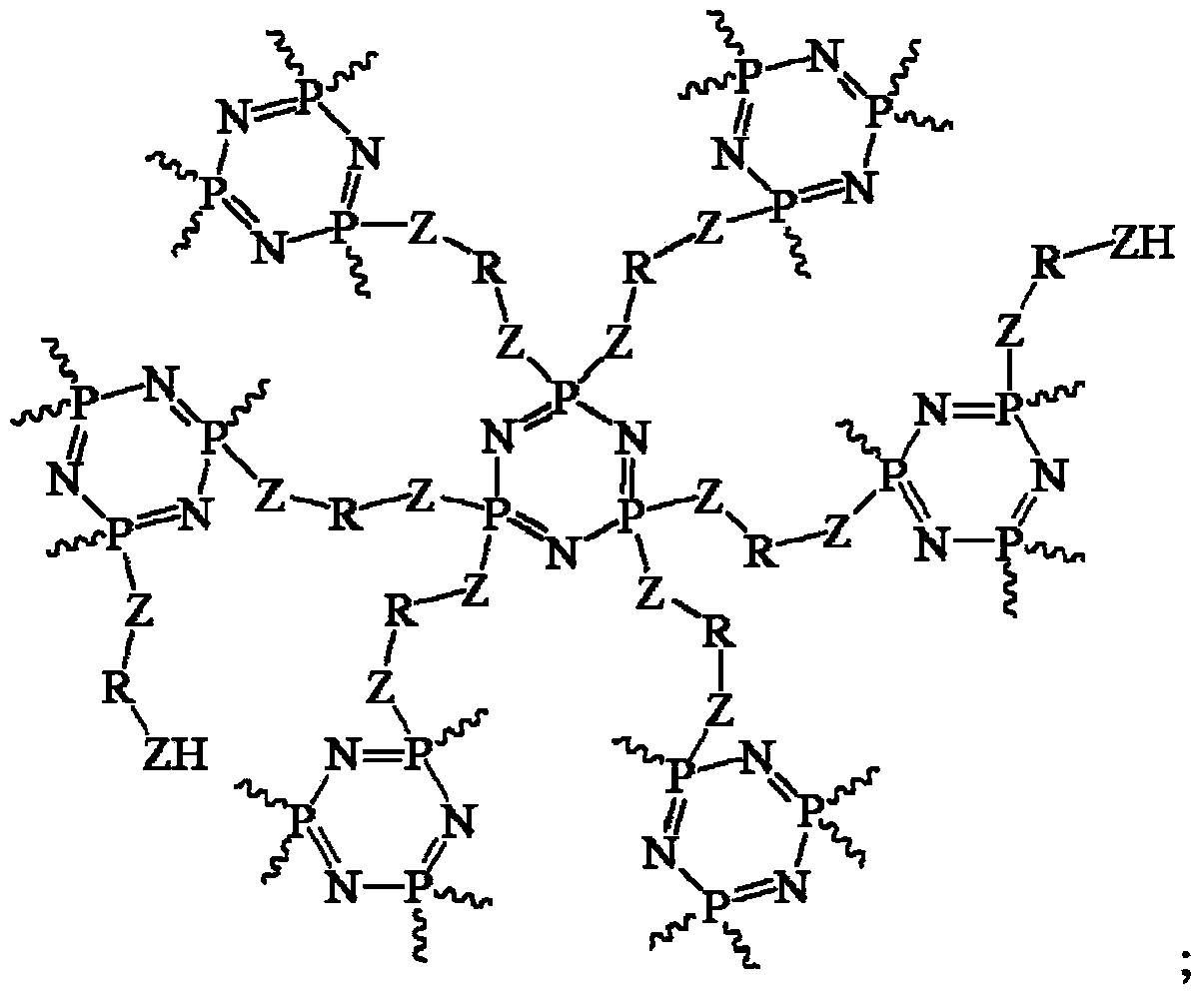

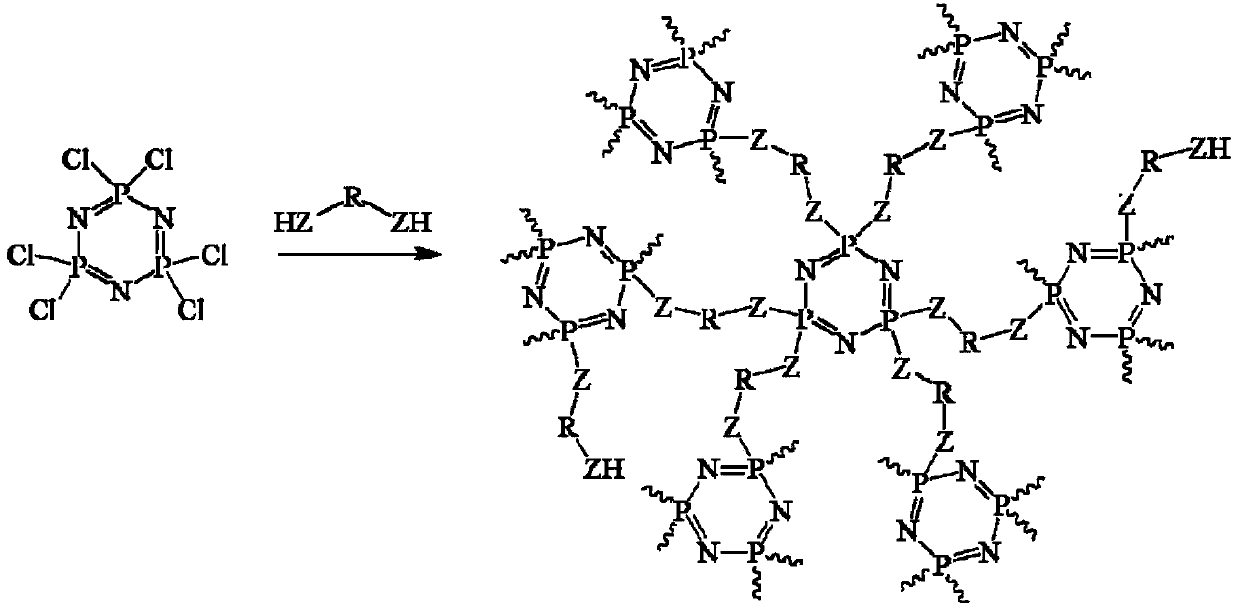

Hyperbranched polyphosphazene flame retardant charring agent and preparing method thereof

An efficient hyperbranched polyphosphazene flame retardant charring agent is prepared by reacting hexachlorocyclotriphosphazene with a binary compound containing two active groups. The charring agent has characteristics of good foaming charring performance, excellent flame retardant effects and good processing performance, and can be widely used in plastics, rubber, coating, adhesives, and other polymer materials. A preparing method adopts a one-pot method, and has characteristics of continuous reaction process, short reaction time and high production efficiency. By controlling the mole ratio of the hexachlorocyclotriphosphazene to the binary compound, no end-capping agent is added in the reaction process. When compared with the addition of end-capping agents in synthesis processes in triazine type charring agent patents, the synthetic process of the charring agent is simplified.

Owner:苏州安鸿泰新材料有限公司

Adsorbent for removing heavy metal from water and preparation method of adsorbent

InactiveCN102233259AImprove removal efficiencyLarge adsorption capacityOther chemical processesWater/sewage treatment by sorptionSorbentApplication areas

The invention discloses an adsorbent for removing heavy metal from water and a preparation method of the adsorbent, and belongs to the fields of water treatment technologies and application. The adsorbent for removing the heavy metal from the water comprises the following raw materials of a high polymer material, a metal oxide and a pore-forming agent. The prepared adsorbent has high heavy metal adsorption capacity and high adsorption speed and thoroughly removes the heavy metal from the water at high removal efficiency of over 95 percent.

Owner:BEIJING FORESTRY UNIVERSITY

Biological microcapsulation

A biological and micro-capsule technology to improve slow-release capability of micro-capsule which includes the following steps: add a strain of microorganism liquid seed into sodium alginate solution ,add the above solution into glutin-CaCl2 intermixture with certain pH value in 40-45DEG C temperature and 40-60 drops / min velocity, stabilize for3.5-5h to form micro-capsule rudiment, add CaCl2 solution to re-calcify for 10-15min, add chitosan solution with certain pH value for 2-3h for re-coacervation, immerse in steriled saline solution for 6-24h for proliferating. Micro-capsule made by this method shows uniform shape, well fastness and excellent slow-release capability.

Owner:SHENYANG INST OF APPL ECOLOGY CHINESE ACAD OF SCI

Lead-free cadmium-free ceramic pigment on glaze and preparation method thereof

The invention relates to a lead-free and cadmium-free porcelain pigment, composed by 70-92wt% solvent and 8-30wt% toner. The solvent is composed by SiO2 30-60wt%, B2O3 5-35 wt%, Al2O3 1.5-15 wt%, Na2O 1.5-10 wt%, K2O 1.5-10 wt%, Li2O 0-8 wt%, ZrO2 0-10 wt%, SnO2 0-10 wt%, TiO2 0-5 wt%, CoO 0-10 wt%, ZnO 0-15 wt%, BaO 0-5 wt%, CaO 0-5 wt%, La2O3 0-2 wt%, Nd2O3 0-2 wt%, prepared in the following orders: preparation of the solvent, ball milling of the solvent and the toner in mixture, re-burning, and fine milling to produce the pigment product. The product is characterized in high gloss, high thermal-stability and chemical-stability after glazing the ceramic pigment, and also pure and bright color, low cost, complete varieties of the pigments, free of lead and cadmium heavy metals in the components, no lead and cadmium dissolve-out, safety and credibility and capable of completely substituting the traditional lead and cadmium series pigments.

Owner:山东省淄博市博山长虹陶瓷装饰材料厂

Water-insoluble modified polyvinyl alcohol coating liquor and its preparation process

The invention discloses an insoluble modified polyvinyl alcohol coating liquid and preparing method and film through the coating liquid, which comprises the following parts: polyvinyl alcohol, modifier, inorganics, crosslinking agent, catalyst and water. The coating liquid improves levelling, adhering and even property greatly, which increases obstruct property for kinds of gas.

Owner:刘建林

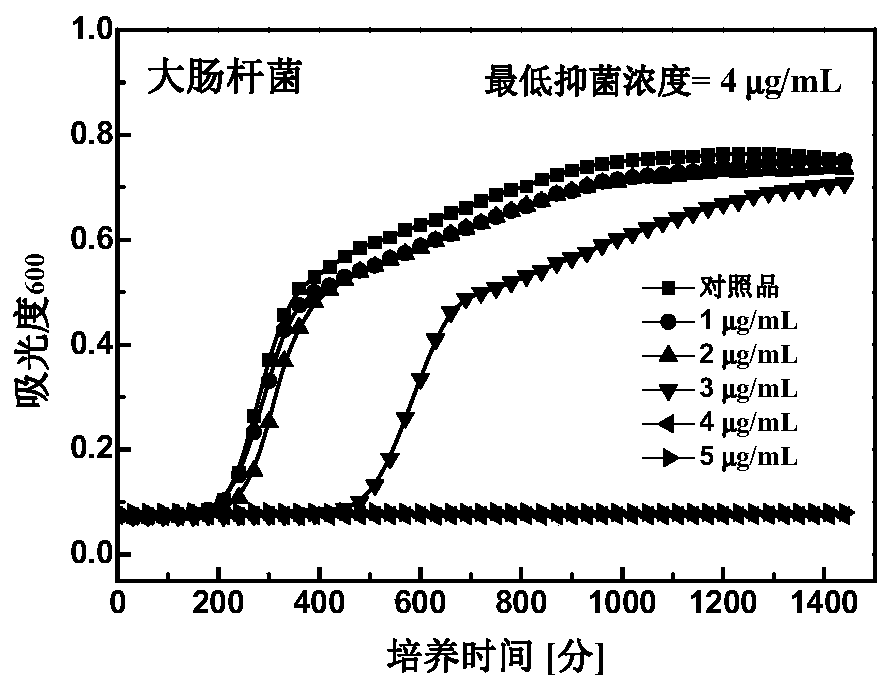

Antibacterial nanofibers or master batches

InactiveCN106884209AImprove water solubilityExpand the scope of useElectro-spinningConjugated synthetic polymer artificial filamentsElectrospinningAntimicrobial polymer

The invention discloses antibacterial nanofibers or master batches and a preparation method thereof, including components of an antibacterial polymer resin solution and the preparation method of the antibacterial nanofibers or master batches. The antibacterial nanofibers or master batches are characterized by being formed through electrostatic spinning, melt-blowing, fibrillation and two-component compound methods on antibacterial polymer resin solution. Photosensitive molecules in the antibacterial nanofibers or the antibacterial master batches are antibacterial, do not generate a dissolution phenomenon, and are high in efficiency, wide in spectrum and antibacterial; the high temperature resistance of an organic antibacterial agent material is effectively provided; and the application range of an antibacterial agent is further expanded.

Owner:SUNDYNAMIC TECH

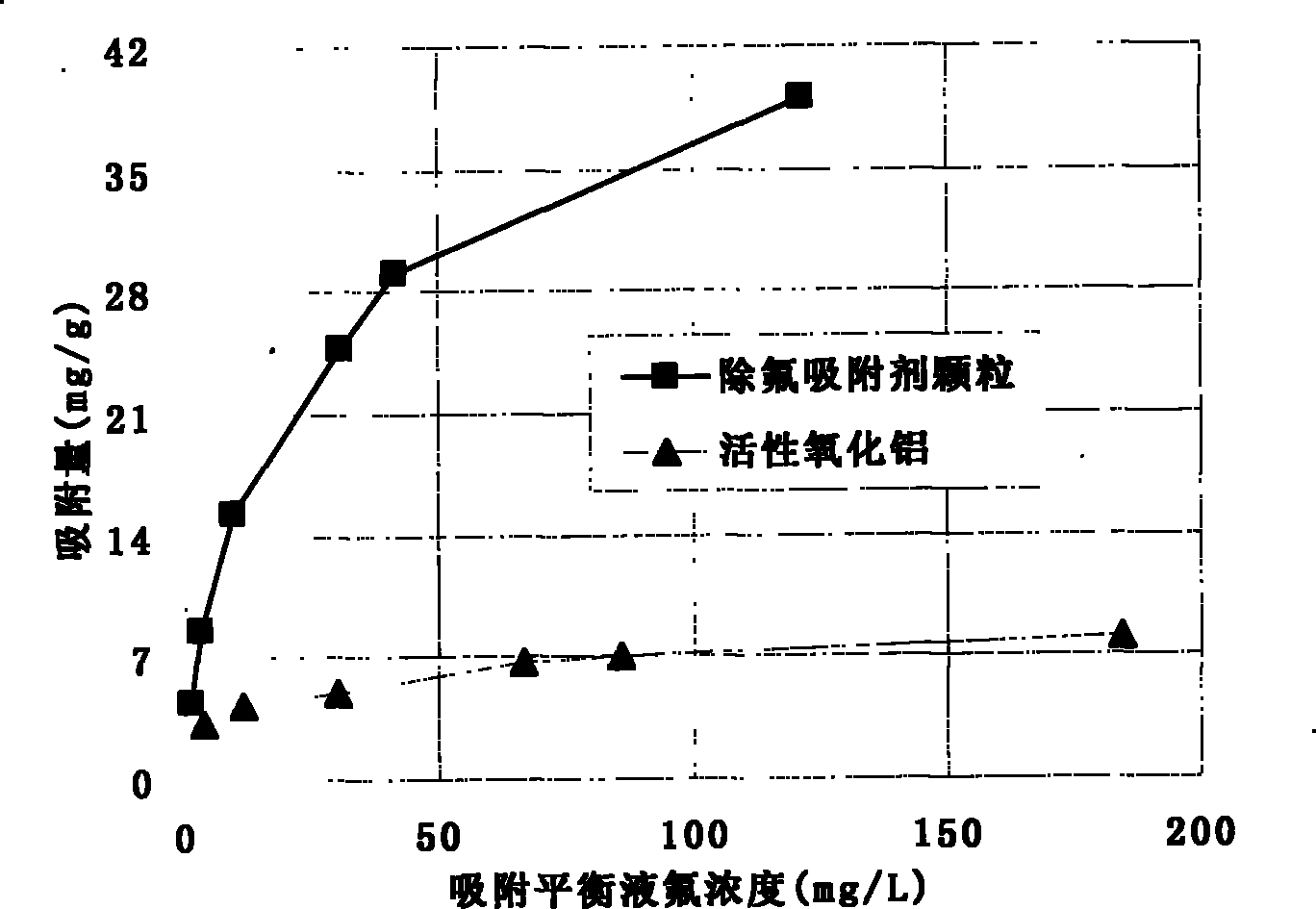

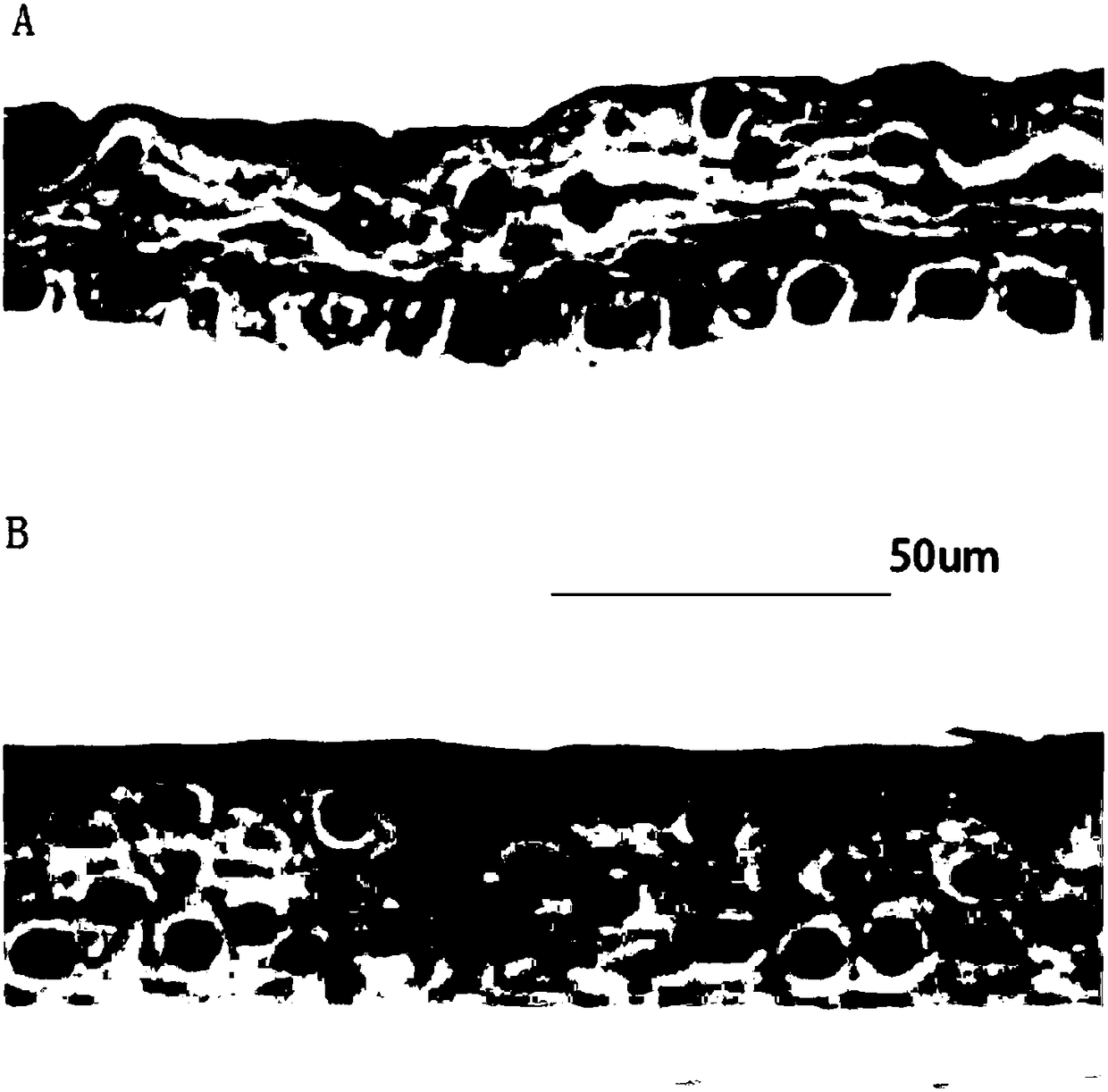

Defluorinating adsorbent and preparation method thereof

The invention provides a defluorinating adsorbent for drinking water, which is a composite metal oxide defluorinating adsorbent and a high polymer material playing a role of adhering absorbent particles. Absorbent powder and a high polymer binder are mixed, extruded, cut and dried to prepare into particles. The defluorinating adsorbent has the characteristics of good ion selectivity, high adsorption capacity, better strength in both dry and wet states, and no crushing or dissolving after being used for a long time.

Owner:北京国中科创环境科技有限责任公司

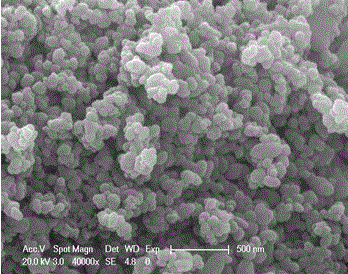

Compound arsenic-removing adsorbent and preparation method thereof

ActiveCN102114403AHigh ion selectivityGood choiceOther chemical processesGranulation by material expressionSorbentWater flow

The invention provides an arsenic-removing adsorbent for drinking water and a preparation method thereof. The adsorbent contains composite metal oxide and a polymer material binder. The arsenic-removing adsorbent has high adsorption property, high adsorption selectivity on arsenic in the drinking water, and high adsorption capacity; adsorbent particles have high strength in a dry state or in a moist state, and the adsorbent has low breakage rate of the particles and cannot be dissolved out during use; and the adsorbent is used under the conditions of long time and larger change of waterflow pressure.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

Arsenic removal adsorbent and preparation method thereof

The invention provides an arsenic removal adsorbent and a preparation method thereof. The adsorbent contains sulfate akaganeite and high-molecular material agglomerant. In the invention, the particles of the arsenic removal adsorbent have high adsorption property to have high adsorption selectivity to arsenic in drinking water, the adsorption capacity is high, the adsorbed particles have large strength under a drying state or a moisture state, the particle crushing rate is low during use, no adsorbent is dissolved out, and the arsenic removal adsorbent is suitable for being used for a long time and under the condition of larger water flow pressure change.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

Sensing film for potassium ion-selective electrode, production method and application thereof

InactiveCN102558724AImprove performanceStable and accurate testMaterial analysis by electric/magnetic meansPolyvinyl chlorideTetrahydrofuran

The invention provides a sensing film for a potassium ion-selective electrode, a production method and the application technical field thereof. Solute is evenly mixed with more or more solvents, and the film is formed after the solute is volatilized; the solute comprises 20 to 40 percents of polymers, 50 to 80 percent of plasticizers, 2 to 10 percent of ion-selective carriers and 0.1 to 2 percent liposoluble salt according to the weight percentage occupying the total weight of the solute; the total content of the solute is 150 to 400mg / ml; the polymers comprise one or more from carboxyl polyvinyl chloride, high molecular weight polyvinyl chloride and polyurethane; the plasticizers comprise di-(2-ethylhexyl) decanedi; the ion-selective carriers comprise valinomycin; the liposoluble salt is potassium tetra (4-chlorphenyl) boric acid; and the solvents comprise tetrahydrofuran or a mixture of the tetrahydrofuran and acetone.

Owner:上海中科润达医学检验实验室有限公司

Cell preservation liquid

ActiveCN104041484AMorphological integrityNo dissolutionDead animal preservationEthylene diamineAcetic acid

The invention provides a cell preservation liquid which is composed of sodium chloride, ethylene diamine tetraacetic acid disodium, PEG10000, Proclin300, methanol, and an acetic acid-sodium acetate buffer solution. The cell preservation liquid reduces the use cost, really effectively protects the integrity and stationarity of cells, prevents cell dissolution and expansion, is easy to popularize and strong in compatibility, and saves the sample preparation time.

Owner:ZHENGZHOU KODIA BIOTECHNOLOGY CO LTD

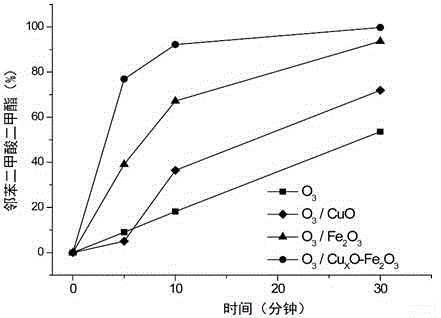

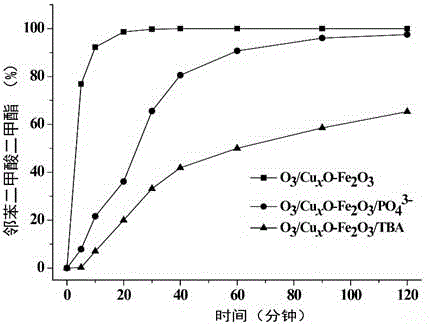

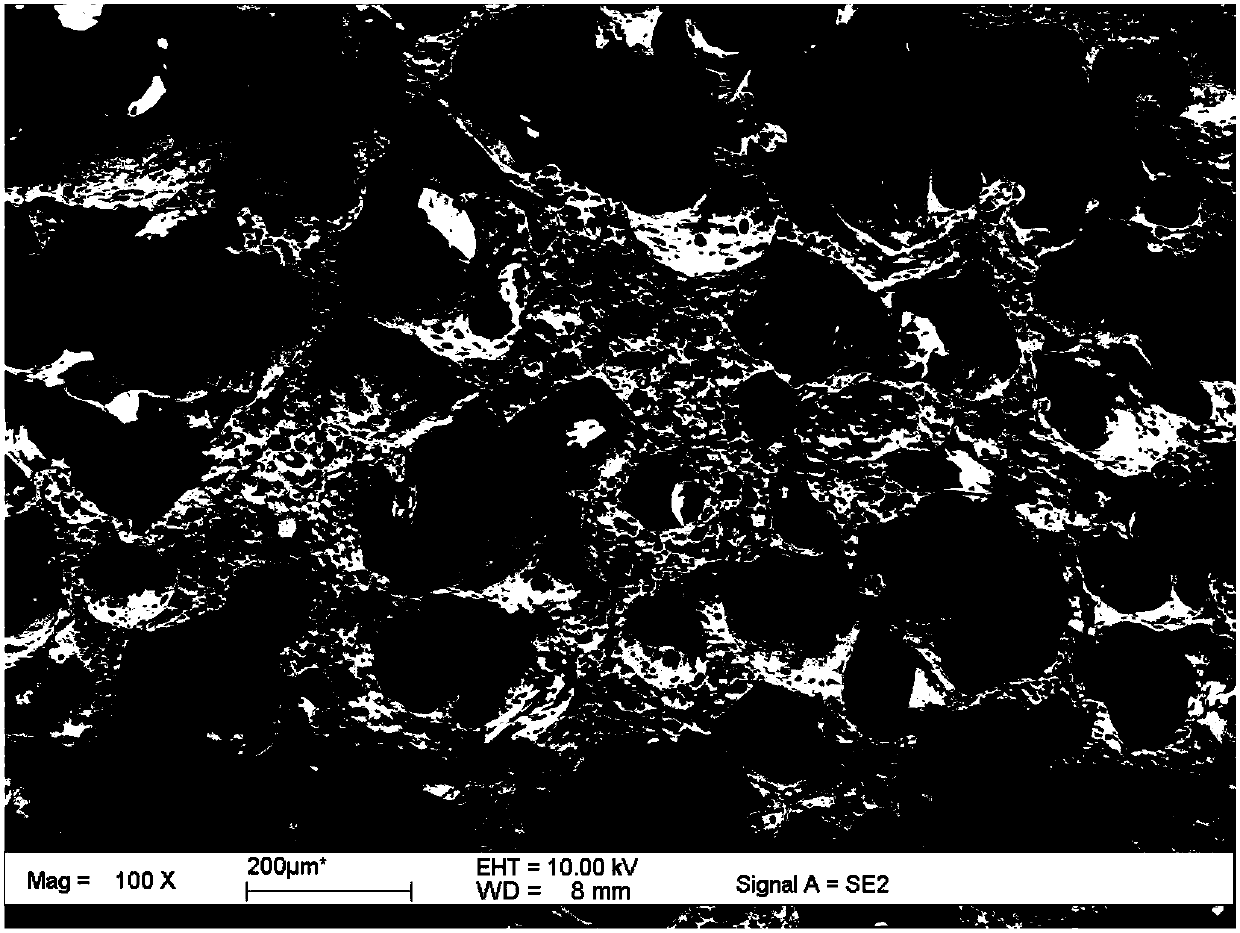

Preparation method and application of magnetic CuxO-Fe2O3 nano ozone catalyst

ActiveCN105797728AOvercoming repetitivenessOvercoming pollutionWater contaminantsMetal/metal-oxides/metal-hydroxide catalystsDispersityCatalytic effect

The invention relates to a preparation method and application of a CuxO-Fe2O3 nano material, and belongs to the technical field of advanced waste water treatment and environmental catalysis.The CuxO-Fe2O3 nano material is prepared through an impregnation method, the CuxO-Fe2O3 nano material serves as a catalyst and is added into organic waste water which is difficult to degrade to catalyze an ozone reaction, degradation of organic contaminants is promoted, and the mineralization rate of organic matter is greatly increased; the CuxO-Fe2O3 nano material is small in size and good in dispersity in a nano material system, CuxO-Fe2O3 has magnetism, the catalyst subjected to the reaction can be effectively separated from water and recycled by means of an external magnetic field, the catalyst is good in stability, and the high catalytic activity can still be maintained after the catalyst is repeatedly used three times.The added CuxO-Fe2O3 catalyst can obviously improve the the removal efficiency of ozone to the contaminants, a good catalytic effect can be achieved on the condition that the pH ranges from 3 to 11, and the catalyst is small in dosage and stable in repeatedly used performance and has a wide prospect in water treatment.

Owner:TONGJI UNIV

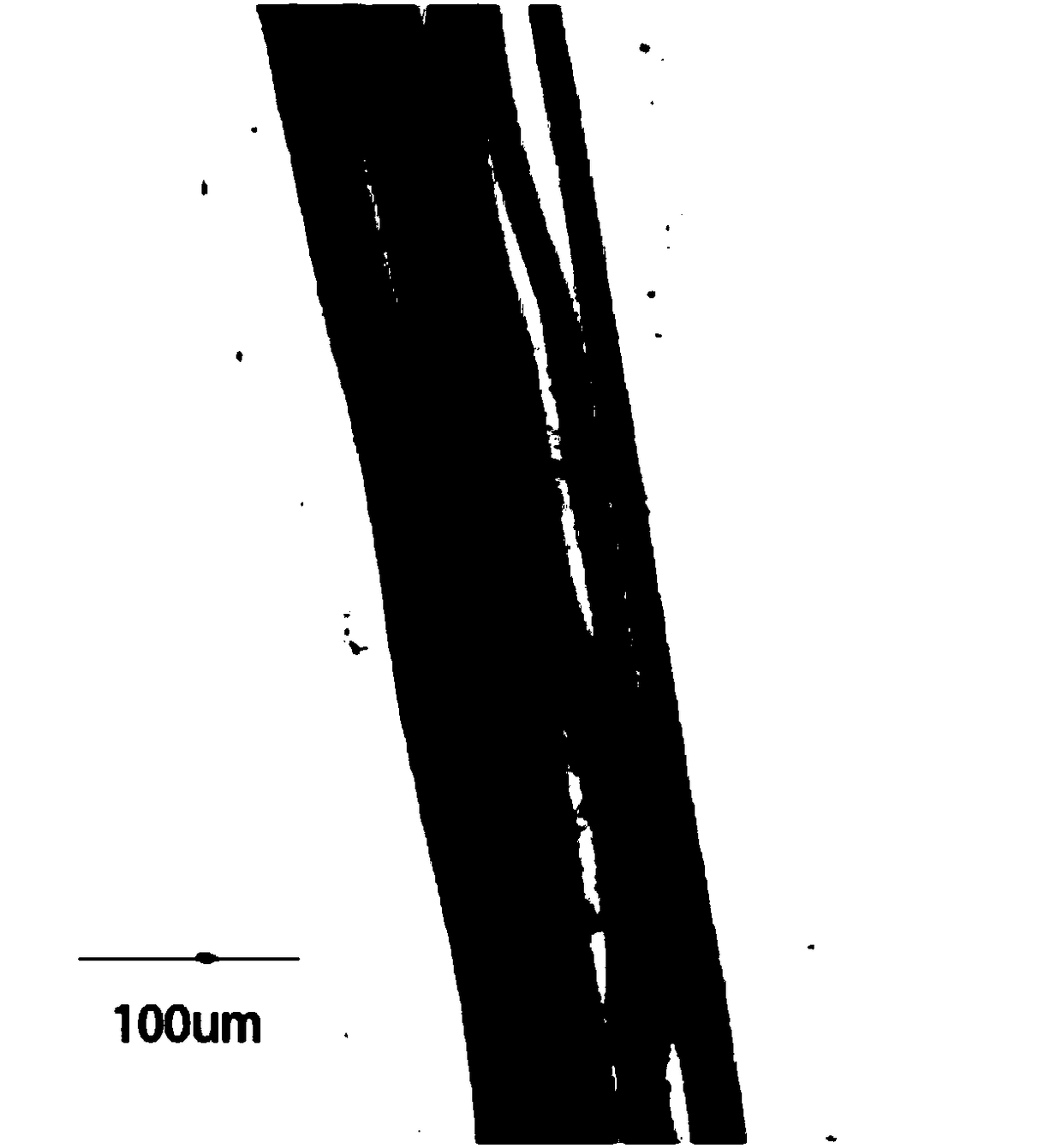

Preparation method of fluoride removal electro adsorption electrode for drinking water and fluoride removal electro adsorption electrode

InactiveCN102234145AHigh ion selectivityGood choiceWater contaminantsWater/sewage treatment by ion-exchangeElectricitySorbent

The invention provides a preparation method of a fluoride removal electro adsorption electrode for drinking water and a fluoride removal electro adsorption electrode. The method comprises the following steps: (1) mixing a conductive material and an adsorbent to obtain a conductive mixture, wherein a weight ratio of the conductive material and the adsorbent is 3-55: 45-97; (2) adding hot melt adhesive into the mixture obtained in the above step to stir uniformly and obtaining an electro adsorption mixture, wherein a weight ratio of the hot melt adhesive and the conductive mixture is 5-50: 50-95; (3) adding the electro adsorption mixture into a mould, and followed by hot pressing moulding to obtain the fluoride removal electro adsorption electrode. Combined electrode prepared with the method in the invention has the advantages of strong fluoride removal and adsorption capability, high strength, no fragmentation in long-term use, small mass loss, no digestion, free of secondary pollution, safety and reliability, and is suitable for long-term usage under a condition of big change of water flow pressure.

Owner:BEIJING FORESTRY UNIVERSITY

Preparation method of fluoride removal electric adsorption lanthanum-loaded electrode for drinking water and fluoride removal electrode

InactiveCN103641201AHigh ion selectivityGood choiceWater contaminantsWater/sewage treatment by ion-exchangeComposite electrodeWater flow

The invention provides a preparation method of a fluoride removal electric adsorption lanthanum-loaded electrode for drinking water and a fluoride removal electric adsorption electrode prepared by the method. The method comprises the steps of (1) loading lanthanum into a carbon aerogel material to prepare a conductive adsorbent, wherein the weight part ratio of lanthanum to the carbon aerogel material is (5-60):(40-95); (2) adding a hot melt adhesive into the lanthanum-loaded carbon aerogel material prepared in the step (1), and mixing uniformly to prepare an electric adsorption mixture, wherein the weight part ratio of the hot melt adhesive to the lanthanum-loaded carbon aerogel material is (10-40):(60-90); (3) putting the electric adsorption mixture into a mold, and performing hot press molding. The composite electrode prepared by the method provided by the invention is strong in fluoride removal adsorptivity and high in strength, can not be broken after long-term use, is small in mass loss without dissolution and the problem of secondary pollution, is safe and reliable, and is suitable for long-term use under the condition with large water flow pressure changes.

Owner:BEIJING FORESTRY UNIVERSITY

Polyvinyl formal sponge fabric, preparation method therefor and application of polyvinyl formal sponge fabric

InactiveCN107652464ARelieve painNo dropPharmaceutical delivery mechanismMembrane filtersPorosityFiber

The invention discloses a polyvinyl formal sponge fabric, a preparation method therefor and an application of the polyvinyl formal sponge fabric. The sponge fabric is polyvinyl formal sponge and is prepared from the following raw material ingredients in parts by mass: 80-150 parts of polyvinyl alcohol, 300-1,800 parts of water, 10-150 parts of formaldehyde or hexamethylene tetramine, 10-300 partsof hydrochloric acid or sulfuric acid and 0.01-3 parts of surfactant. According to the sponge, both porosity and pore rate are not lower than 85%, the average pore size is between 10 microns and 2mm,the degree of acetalization is 30% to 70%, and the sponge has the thickness of 0.5mm to 10cm and has the dry density of 0.05 to 0.12. According to the polyvinyl formal sponge fabric, the preparation method therefor and the application of the polyvinyl formal sponge fabric, the process is short in cycle, low in emission, low in energy consumption and high in product uniformity and can be used for carrying out continuous production; the obtained sponge fabric is integrated sponge with a three-dimensional open-pore structure, is air-permeable, fluffy, soft and comfortable, is free of fiber falling and has excellent liquid sucking characteristics; and the materials can be applied to filtering industry instead of the traditional filter media such as non-woven fabrics, Kraft paper and glass fibers.

Owner:克林纳奇(荆州)高分子科技有限公司

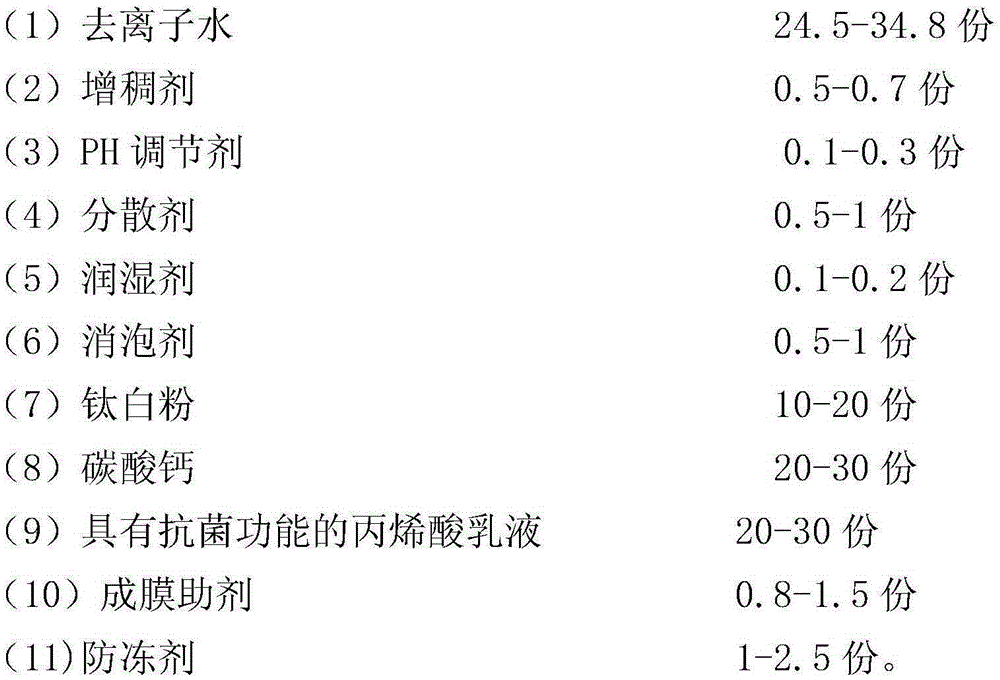

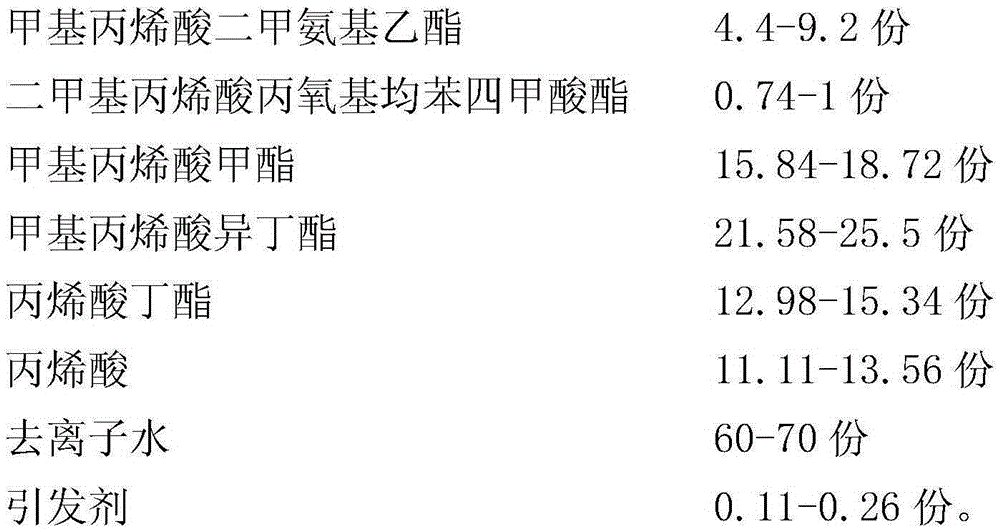

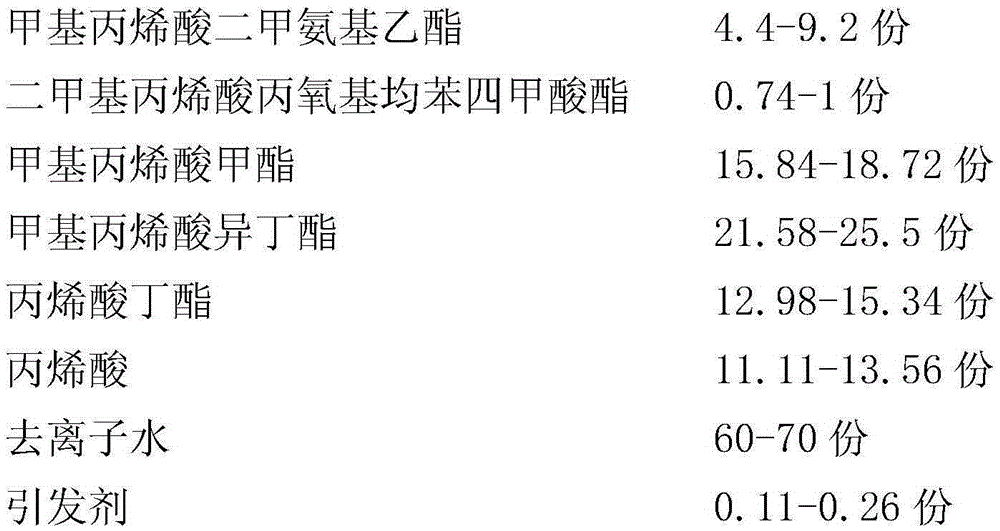

Antibacterial coating and preparation method thereof

ActiveCN105348972AIncrease contentLow toxicityAntifouling/underwater paintsPaints with biocidesEmulsionTitanium dioxide

The invention relates to an antibacterial coating, wherein the antibacterial coating is prepared from the following components: deionized water, a thickening agent, a pH regulator, a dispersant, a wetting agent, a defoamer, titanium dioxide, calcium carbonate, an acrylic emulsion having an antibacterial function, a film-forming auxiliary agent, and an antifreezing agent. The coating has good antibacterial mouldproof stability, and a coating film is good in patience and high in hardness.

Owner:SKSHU PAINT

A kind of firing process of reinforced enamel bone china

The invention belongs to the technical field of firing ceramics, in particular to a firing process for strengthening enamel bone china. Its characteristics are: after the blank is formed, it is polished smooth after biscuit firing at 780-800°C, then glazed, and then the glaze on the edge and bottom edge is removed; when loading the blank, the edge of the product with the glaze removed In the groove of the shaped pad cake, put the billets into the kiln together, and use the reduction flame for the first firing, and the firing temperature is 1330-1350°C. The shaped pad cake is made of the same mud as the product. A groove pad cake made of mud that completely matches the edge of the finished product; after firing and cooling, the porcelain is selected and graded, and the colored flowers in the glaze are pasted. Secondary firing in a weak reducing atmosphere, that is, firing the in-glaze color at the same time as the second mouth glaze firing. The strengthened enamel bone china of the invention has the characteristics of good whiteness, good translucency, good heat stability, high glaze hardness, no lead cadmium dissolution and the like.

Owner:尧忠义

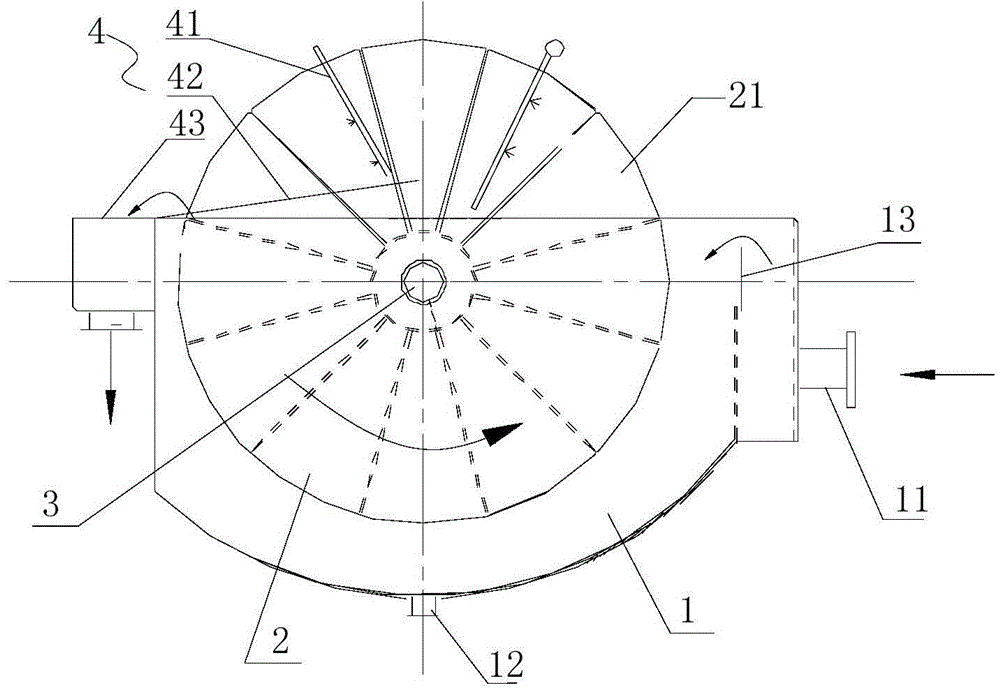

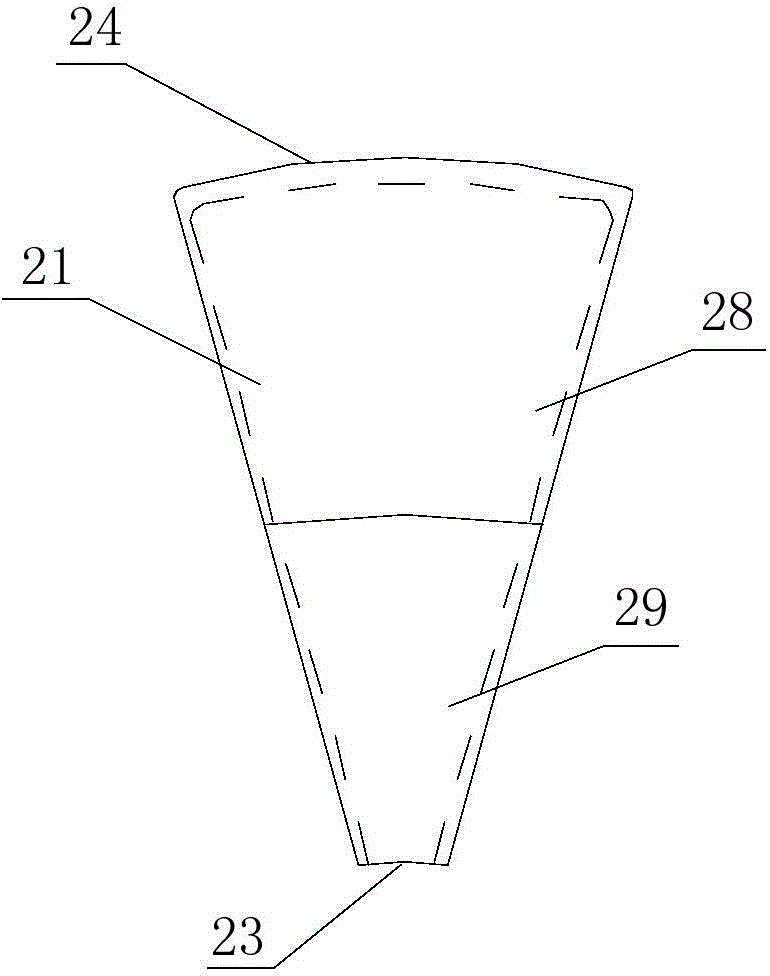

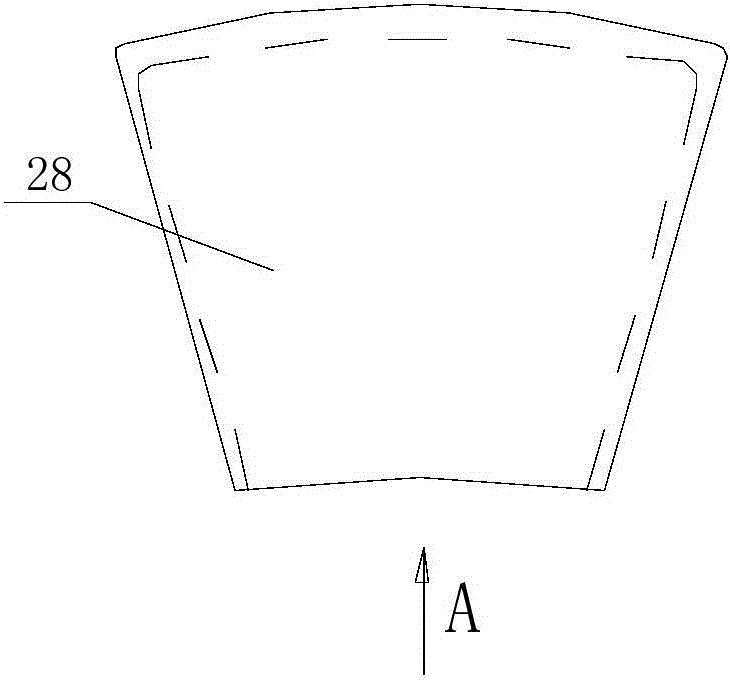

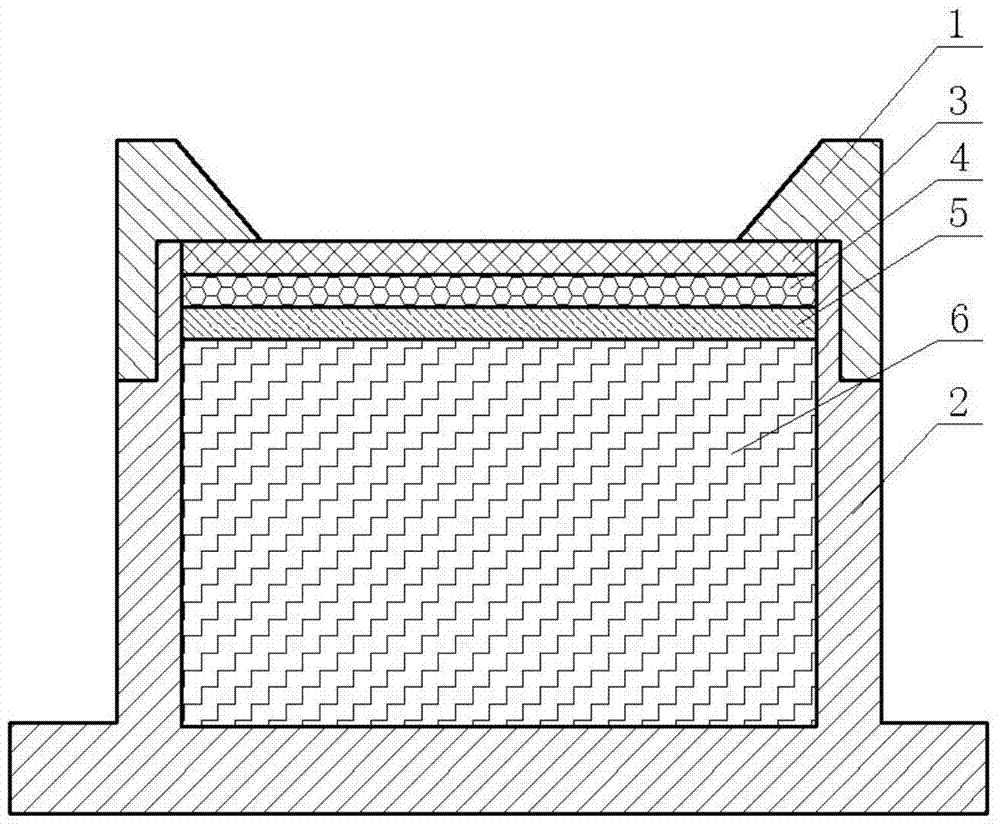

Ceramic disc type filtering machine

ActiveCN103638733BCorrosion resistanceHigh temperature resistantMachine wet endMoving filtering element filtersMetallurgyWhite water

The invention provides a ceramic disc type filtering machine. The ceramic disc type filtering machine comprises a white water groove, a ceramic filtering disc, a hollow collecting pipe and a driving device, wherein a part of the ceramic filtering disc is immersed into the white water groove; the ceramic filtering disc is formed by a plurality of sector-shaped ceramic filtering units which are distributed along the circumferential direction; each ceramic filtering disc is hollow; a plurality of micro-filtering holes are distributed in each ceramic filtering unit; the hollow collecting pipe is arranged on the center axis of the ceramic filtering disc in a penetrating manner; a hollow chamber of the ceramic filtering disc is communicated with an inner cavity of the hollow collecting pipe; the driving device is connected with the ceramic filtering disc and drives the ceramic filtering disc to rotate around the axial direction. The ceramic disc type filtering machine provided by the invention has the advantages of good filtering effect, reasonable configuration, stable operation and low cost.

Owner:MCC CAPITAL ENGINEERING & RESEARCH +2

Induction film used for calcium ion-selective electrode, production method and application thereof

InactiveCN102735736AImprove performanceStable and accurate testMaterial analysis by electric/magnetic meansPolyvinyl chlorideEthyl group

The invention relates to the technical field of an induction film used for a calcium ion-selective electrode, a production method and application thereof. The method comprises the following steps: taking polymer, plasticizer, ion selective carrier and fat soluble salt as solute, and uniformly mixing the solute with solvent and stirring for 12 hours at normal temperature, wherein the total content of the solute is 150-400mg / ml; and then volatilizing for 72 hours to prepare the induction film with thickness of about 0.5mm, wherein the polymer is one or more of carboxyl polyvinyl chloride, polyvinyl chloride with high molecular weight or polyurethane, the plasticizer is one or two of bis(2-ethylhexyl) sebacate and o-nitrophenyl octyl ether, the ion selective carrier is laurate, the fat soluble salt is potassium tetra-(4-chlorphenyl) boric acid, and the solvent is tetrahydrofuran or a mixture of the tetrahydrofuran and acetone.

Owner:上海中科润达医学检验实验室有限公司

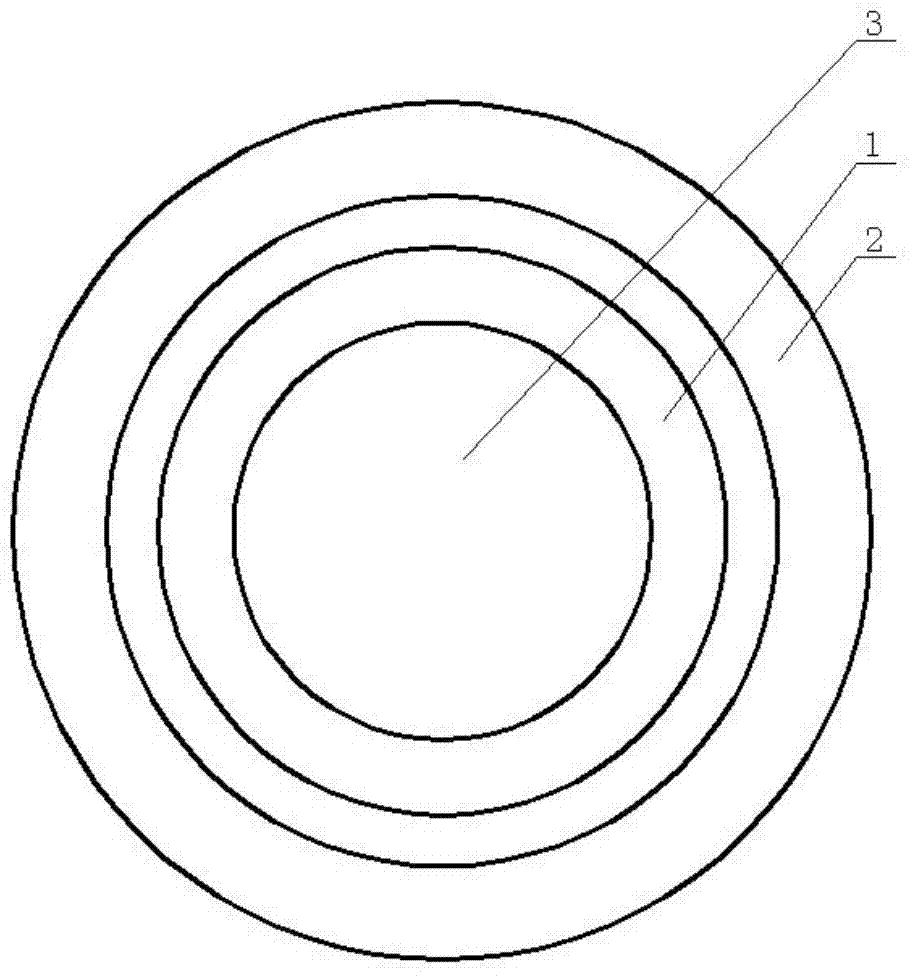

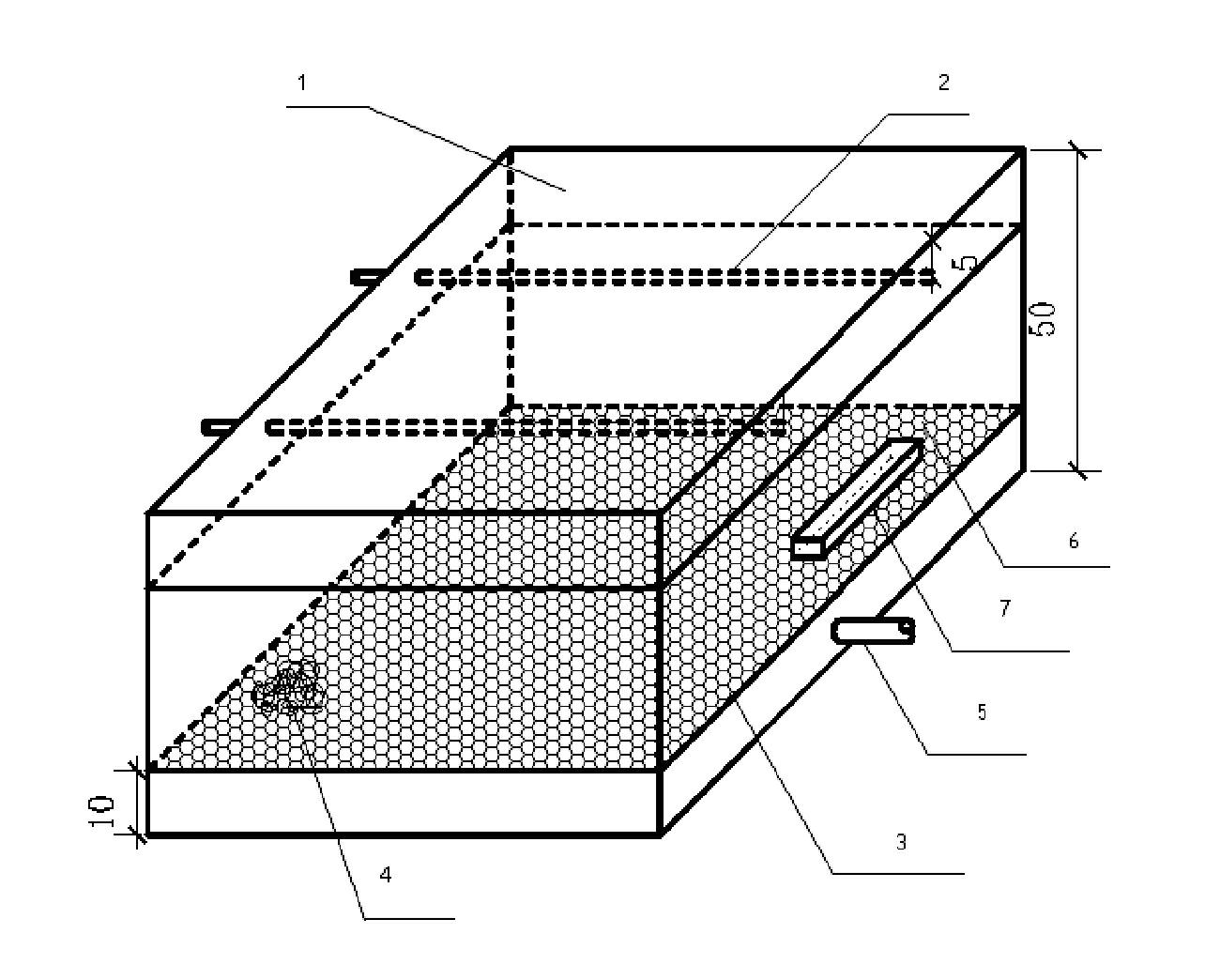

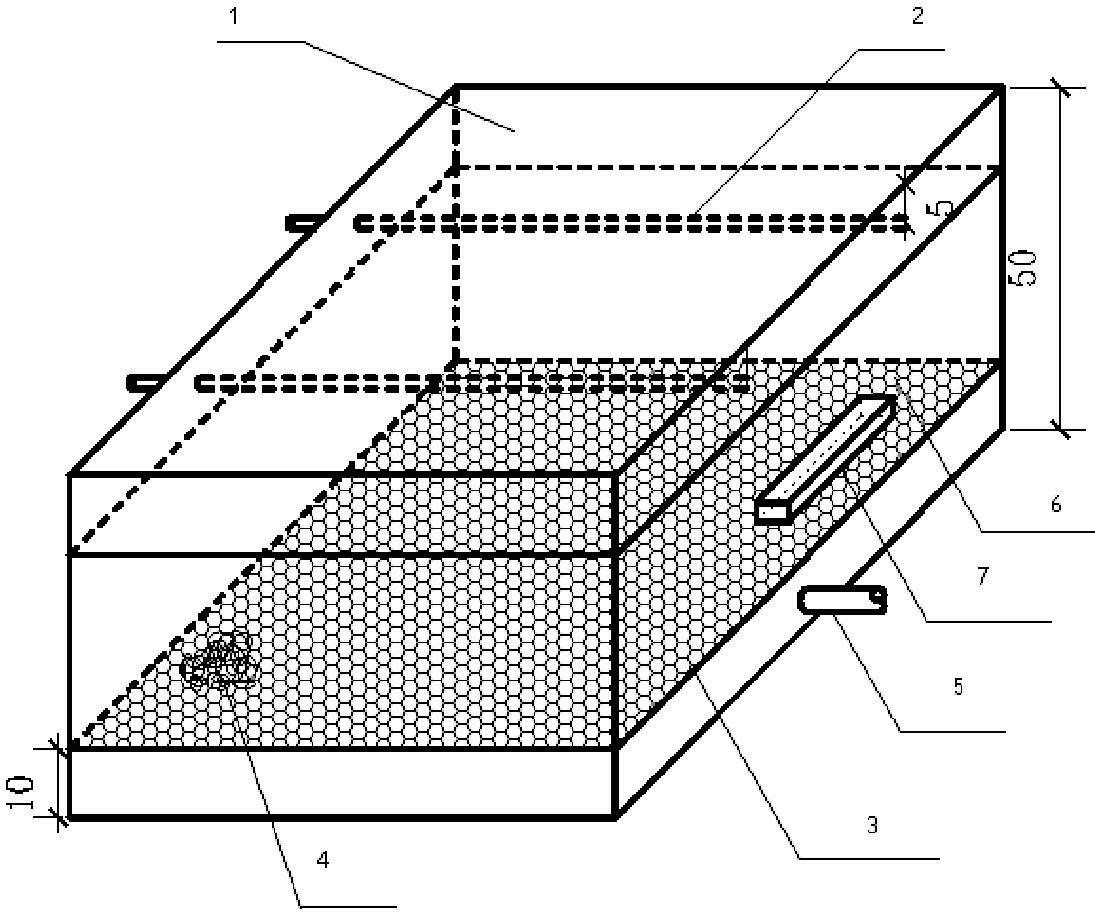

Absorbent material for water body purification and biological carbon brick

ActiveCN103752285ASolve problems that are not suitable for direct use in wastewater treatmentContribute to exposureOther chemical processesAlkali metal oxides/hydroxidesBrickAbsorbent material

The invention relates to an absorbent material for water body purification and a biological carbon brick; the absorbent material disclosed by the invention is composed of biological carbon and sodium polyacrylate (PAAS); the concentration of the PAAS solution is 0.1-50g / L; 10-200 g of biological carbon is added into 500-1000 mL of PAAS solution; the biological carbon brick comprises a hollow base; an annular top cover is installed on the top end of the base; the absorbent material is filled in the base; two layers of protective filter films cover the upper surface of the absorbent material; and a diffusion film interlayer is arranged between the two layers of filter films. According to the invention, due to the added diffusion film, PAAS and biological carbon can be effectively prevented from being dissolved; pollutants having high activity and low molecular weight are allowed to freely diffuse to enter the biological carbon brick, and therefore, the absorbent material for water body purification and the biological carbon brick disclosed by the invention have the capability of selectively eliminating hazard pollutants in a water body.

Owner:上海孚祥生态环保科技股份有限公司

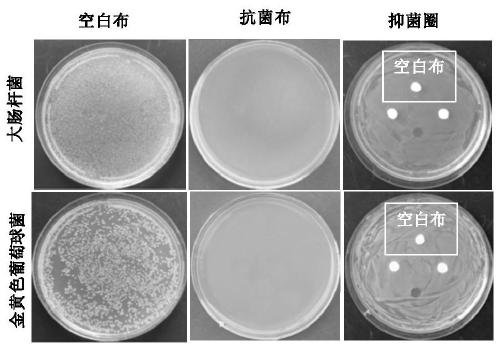

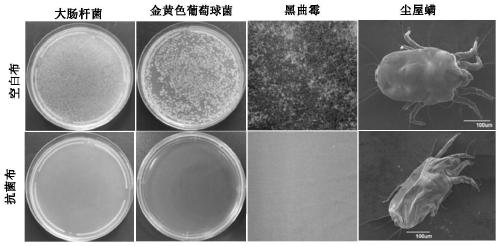

Compound, antibacterial finishing liquid, and preparation method and application of compound

ActiveCN109879823AGood flexibilityImprove antistatic performanceBiocideGroup 5/15 element organic compoundsCelluloseQuaternary ammonium cation

The invention provides a compound, antibacterial finishing liquid, and a preparation method and application of the compound. The general formula of the compound is shown in the description. The R1 ishalogen; the R2 is halogen, hydrogen, nitryl or heteroatom substituted or unsubstituted C1-8 hydrocarbyl; X is NH, O, S and heteroatom substituted or unsubstituted C1-18 hydrocarbyl; R3 contains at least of a quaternary ammonium salt group and a phosphonium salt group. -OH and -NH2 groups on the surfaces of high molecular material surfaces of cellulose, starch, chitosan, protein, polyvinyl alcohol(PVA) and poly(hydroxyethyl acrylate) can take chemical reaction in a chemical bonding mode to be firmly combined onto the surface of the material, so that the durable antibacterial mildewproof anti-mite performance can be given to the surface of materials of fabrics; the physical performance such as the mechanical performance, the moisture and air permeability, the color and luster and the colordifference of the material per se is hardly changed.

Owner:HAISI MEIYU SHENZHEN TECH CO LTD

Efficient electric promoting absorptive fluorine removal adsorbent and preparation method thereof

InactiveCN102335590AImprove adsorption capacityLarge adsorption capacityOther chemical processesWater contaminantsHydration reactionSorbent

The invention relates to the field of fluorine removal, in particular to an efficient electric promoting absorptive fluorine removal adsorbent and a preparation method thereof. The composite efficient electric promoting absorptive fluorine removal adsorbent provided by the invention comprises an active metal oxide, a conductive material and a dispersant. The fluorine removal adsorbent provided bythe invention is a composite absorption system containing a hydrous metal oxide and carbon material, promotes to absorb fluorine by using the non-characteristic adsorption and characteristic adsorption of double electrode layers in the reaction process and an exchange reaction between a fluorine removal material and a fluorinion, and has large absorption capability and a wide application range.

Owner:BEIJING FORESTRY UNIVERSITY

Forming method of efficient composite type electrical fluoride removing adsorbent

InactiveCN102371146ALow biological toxicityMild conditionsOther chemical processesWater contaminantsWater bathsSorbent

The present invention relates to the field of adsorbent preparation, specifically to a forming method of an efficient composite type electrical fluoride removing adsorbent. The method comprises the following steps: 1) adding polyvinyl alcohol to water under stirring at a room temperature, swelling, and heating until the polyvinyl alcohol is completely dissolved; 2) cooling the resulting polyvinylalcohol aqueous solution from the step 1), adding a carboxylic acid solution under stirring; carrying out esterification and crosslinking in water bath with a temperature of 40-100 DEG C to obtain anesterification product solution, cooling the solution to the room temperature; 3) adding an active metal oxide, a conductive material and a dispersing agent to the resulting esterification product solution from the step 2), extruding the resulting mixture under pressure of 0.5-10 Mpa into strips, then cutting into sections to obtain wet particles with the required size; carrying out a post-crosslinking treatment and drying. The method of the present invention has the following advantages that: the polyvinyl alcohol and the carboxylic acid are selected as the binders, the biological toxicity is low, and the reaction conditions are mild; the formed adsorbent has high strength, high toughness, less adsorption capacity loss, small swelling, no metal or toxic organic compound dissolving, and the water quality is safe after treating.

Owner:BEIJING FORESTRY UNIVERSITY

Whole eye cornea bioengineering cultivation method

InactiveCN108277204AAvoid rejectionAvoid finitenessNervous system cellsCell culture supports/coatingBiocompatibility TestingCornea layer

The invention relates to the field of cell culture and particularly relates to a whole eye cornea bioengineering cultivation method. The various layers of the cornea are respectively cultivated, and the advantage is that only a cornea layer needed by a patient is cultivated when the patient does not need the transplantation of the whole cornea. According to the provided preparation method of the whole cornea, a seed cell between the cornea epidermal layer and a mesenchymal layer is an autologous cell, a corneal endothelial cell is from a donator, a large quantity of endothelial cells are obtained through cultivation, and the limit of the source of the donator is avoided. A collagen culture medium is taken as a gluing medium between the epidermal layer and the mesenchymal layer, and the intraneural growth of the human bioengineering cornea is promoted. The provided whole cornea and partial cornea both have an excellent optical property, the patients all recovers the eyesight after the operation, the cornea has a stable biochemical characteristic, the dissolution of the cornea in the later period does not exist, the biocompatibility is excellent, and no rejection reaction is caused.

Owner:山东麦德克斯生物科技有限公司

Sulfide composite solid-state electrolyte, method for preparing same and solid-state battery

InactiveCN109361015AImprove ionic conductivityNo dissolutionSolid electrolytesFinal product manufactureSolid-state batterySolvent

The invention relates to a sulfide composite solid-state electrolyte, a method for preparing the same and a solid-state battery. The sulfide composite solid-state electrolyte is prepared from polycarbonate alkenyl ester and raw materials for preparing sulfide solid-state electrolyte matrixes or is prepared from the polycarbonate alkenyl ester and the sulfide solid-state electrolyte matrixes. The method includes steps of S1, weighing the raw materials for preparing the sulfide solid-state electrolyte matrixes or the sulfide solid-state electrolyte matrixes according to certain weights, mixing the raw materials or the sulfide solid-state electrolyte matrixes with the polycarbonate alkenyl ester with a certain weight to obtain mixtures, then placing the mixtures into centrifugal tanks, addingsolvents into the centrifugal tanks, further adding grinding balls into the centrifugal tanks and sealing the centrifugal tanks; S2, driving the sealed centrifugal tanks to rotate and carrying out centrifugal crushing to obtain slurry; S3, scraping the slurry on platy articles and carrying out drying to obtain sulfide composite solid-state electrolyte membranes. The sulfide composite solid-stateelectrolyte, the method and the solid-state battery have the advantages that the polycarbonate alkenyl ester is used as a composite material for the sulfide composite solid-state electrolyte, and accordingly the ionic conductivity of the sulfide composite solid-state electrolyte can be improved.

Owner:桑德新能源技术开发有限公司 +1

Roof rainwater forced circulatory filtering, recycling and utilizing device and method

ActiveCN102515300ASimple operation and managementSmall footprintWater/sewage treatment by sorptionActivated carbonRainwater harvesting

The invention belongs to the technical field of roof rainwater filtering, recycling and utilization and in particular relates to a roof rainwater forced circulatory filtering, recycling and utilizing device and method. According to the invention, in the roof rainwater forced circulatory filtering, recycling and utilizing device, active carbon is used as filter material; a uniform water distribution pipe and a filter material drawer as well as an interior porous bearing layer are also arranged in the device; the filter material drawer can be pulled out; the collected roof rainwater is uniformly distributed on the active carbon layer with a certain thickness by using a perforated pipe; the bottom outlet water of the box body is lifted back to a roof rainwater collecting device by using a pump to be redistributed and is filtered by using the active carbon layer in circulation; and COD and chrominance which is hard to be removed in the roof rainwater can be removed by using the adsorbing and filtering property of the active carbon.

Owner:BEJING SUNSHINE LANDSCAPE CO LTD

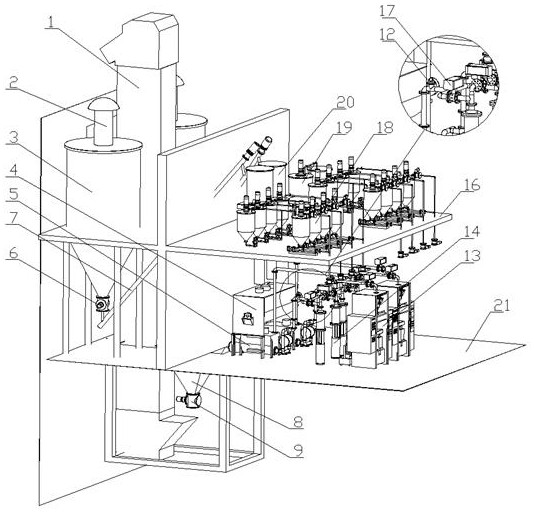

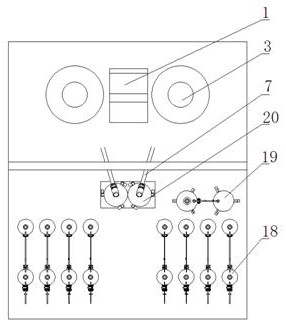

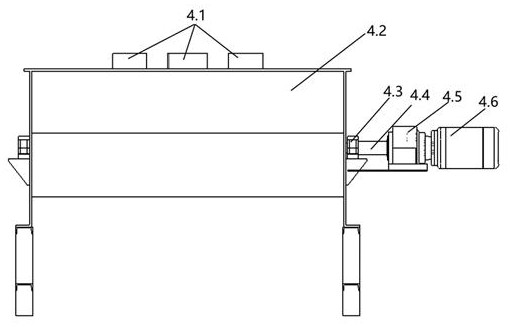

Unmanned production equipment for anchoring agent for anchor net supporting

PendingCN113859602AThe overall structure is simpleCompact layoutMixer accessoriesLiquid materialProcess engineeringPotential energy

The invention belongs to the field of anchoring agent production, and particularly relates to unmanned production equipment for an anchoring agent for anchor net supporting. The unmanned production equipment comprises a stock bin, a stock bin feeding system, a resin stirring system, a curing agent stirring system, a plaster cylinder, a weighing stock bin, a stirring system and a machine head control cabinet, wherein the resin stirring system, the curing agent stirring system, the plaster cylinder, the weighing stock bin, the stirring system and the machine head control cabinet are connected according to the working procedures and arranged in a layered mode in the material flow direction. The stock bin supplies anchoring agent raw materials to the weighing stock bin, the weighing stock bin quantitatively feeds materials to the stirring system, the stirring system uniformly mixes the anchoring agent raw materials and resin to prepare plaster, and the plaster enters the plaster cylinder and then is pushed into the machine head control cabinet. The curing agent stirring system is connected with the machine head control cabinet, a curing agent is conveyed to the machine head control cabinet, and the plaster and the curing agent are quantitatively canned through the machine head control cabinet. The whole production line is arranged in a layered mode, the gravitational potential energy of the raw materials is fully utilized, the system integration is high, and a large number of conveying pipelines and connectors are saved. Compared with existing anchoring agent production equipment in China, the scheme has the advantages that the plant space is reasonably utilized, the occupied space is reduced, and the arrangement is more compact.

Owner:TAIYUAN UNIV OF TECH

Water insoluble modified polyvinyl alcohol coating liquid and its producing process

The water insoluble modified polyvinyl alcohol coating liquid consists of polyvinyl alcohol, regulator, inorganic matter, crosslinking agent, catalyst and water. The water insoluble modified polyvinyl alcohol coating liquid includes two components, the component A is prepared through mixing all the material except catalyst and heating at certain temperature, and the component B is catalyst. When used, the two components, A and B, are mixed through stirring, and the mixture forms water insoluble film. The foamed film has excellent processibility, high reflectivity to ultraviolet light and infrared light, high wear resistance, low transmissibility and high adhesion to substrate, and is used in product package.

Owner:刘建林

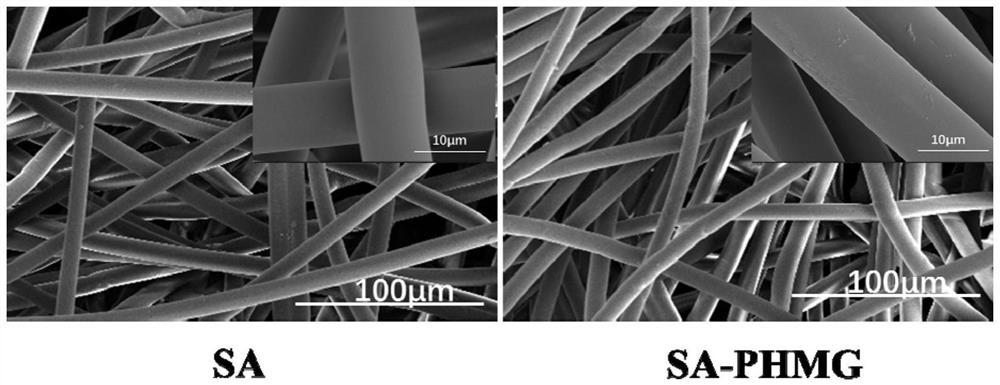

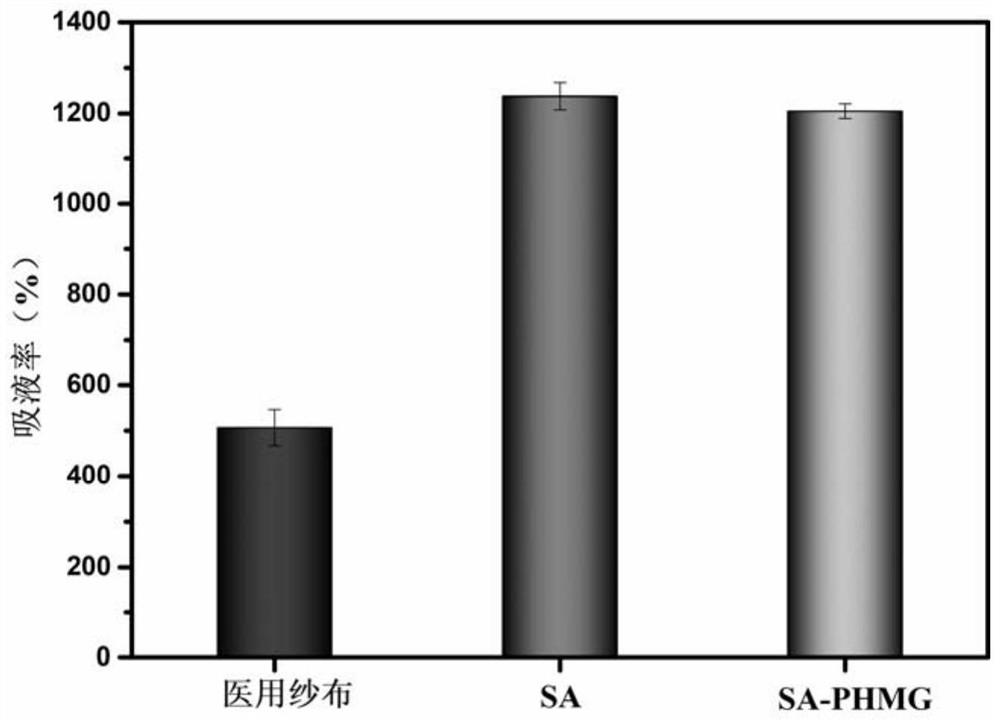

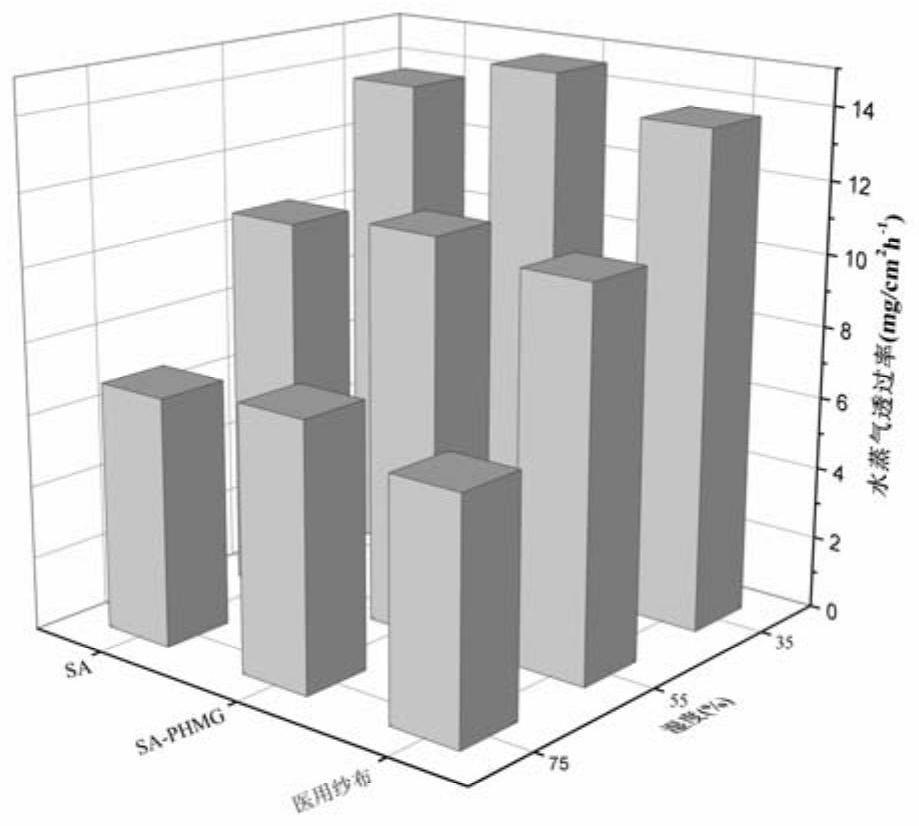

Antibacterial alginate dressing as well as preparation method and application thereof

PendingCN113975447AGood antibacterial propertiesGood hemostatic propertiesBiochemical fibre treatmentAbsorbent padsAlginate dressingChemistry

The invention discloses an alginate fiber dressing. Polymer guanidine and / or salt thereof are / is attached to the alginate fiber dressing through electrostatic interaction. The dressing disclosed by the invention not only has excellent antibacterial performance, but also has good hemostatic performance, is free of dissolution and long in acting time, ensures the safety to human bodies and environments, has excellent washable performance (washable for at least 50 times) and can be repeatedly used, and tests prove that the dressing can be continuously antibacterial for at least 10 cycles. The dressing disclosed by the invention can also be used for products such as face towels, facial masks and the like. The preparation method of the dressing is simple in process, low in production cost and suitable for industrial mass production.

Owner:SICHUAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com