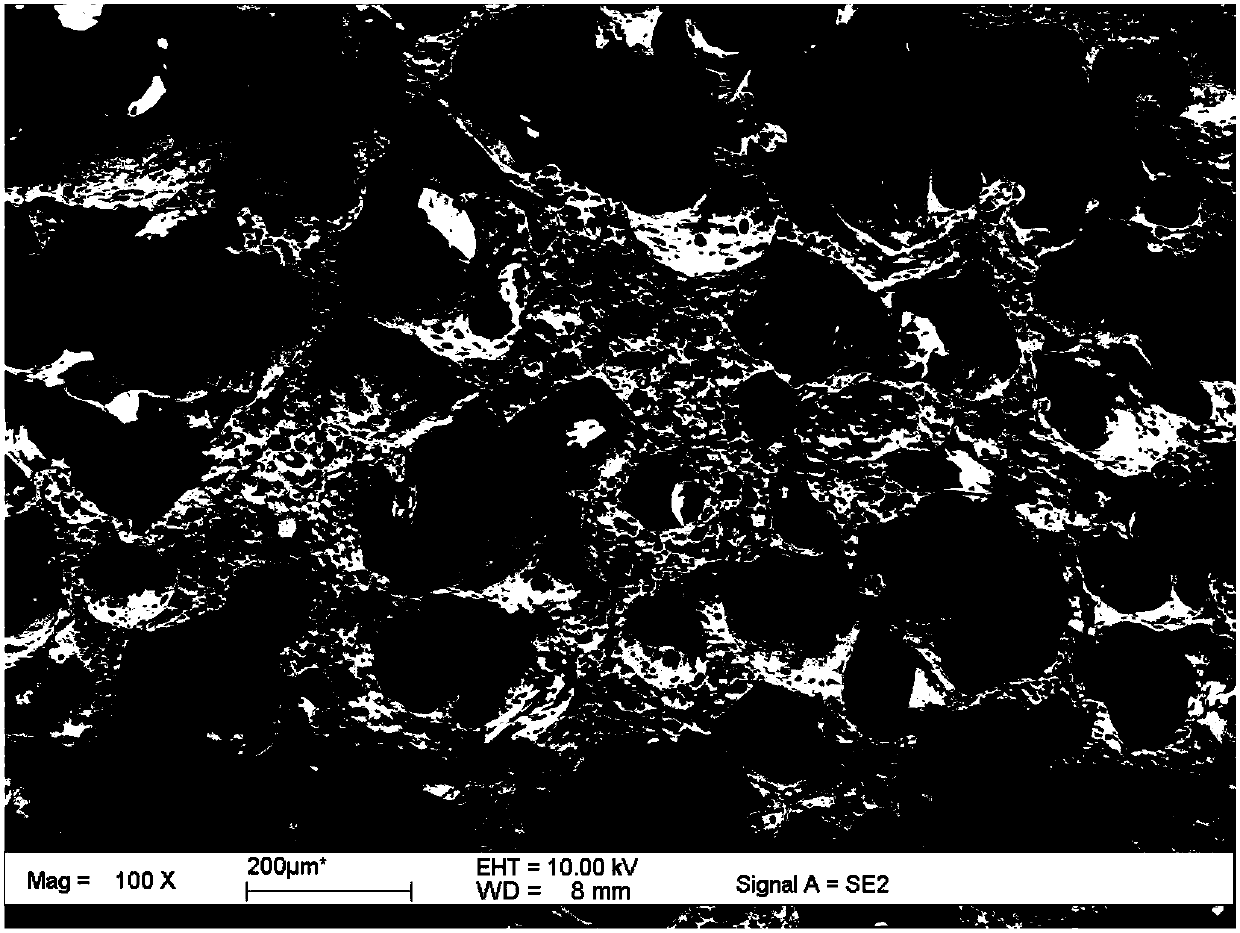

Polyvinyl formal sponge fabric, preparation method therefor and application of polyvinyl formal sponge fabric

A technology of polyvinyl formal and polyvinyl acetal, applied in the field of polyvinyl formal sponge cloth and its preparation, can solve the problem of reducing product absorption rate and magnification, unsatisfactory drainage effect, and management of seepage Limited capacity and other issues, to achieve high product uniformity, clean surgical field of view, and obvious blood-absorbing/hemostasis effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028]Dissolve 80 parts of polyvinyl alcohol with an alcoholysis degree of 99% in 800 parts of water, add 24 parts of hexamethylenetetramine and 160 parts of hydrochloric acid after cooling, and put it into a closed autoclave for vacuum degassing. 0.09MPa, then stir and add 0.4 parts of cetyltrimethylammonium chloride, while filling clean carbon dioxide gas and maintaining a pressure of 0.01-0.8MPa. Open the discharge valve, maintain a constant pressure, and evenly coat the obtained mixture on the conveyor belt with a coating thickness of 2.5mm, and then transport it to the channel with radiation heating function through the conveyor belt, and cross-link and cure at 90 degrees for 3 minutes. Finally, it is pulled into a cooling tank filled with saturated calcium hydroxide solution to remove residual acid and formaldehyde. Next, it is sprayed and pad-washed by three sets of pad-washing rollers arranged side by side, and the water is squeezed by the fourth set of pad-washing rol...

Embodiment 2

[0030] Dissolve 10 parts of polyvinyl alcohol with an alcoholysis degree of 99% in 80 parts of water, add 3 parts of hexamethylenetetramine and 20 parts of hydrochloric acid after cooling, put it in a closed autoclave for vacuum degassing, and then stir Add 0.05 parts of cetyl ammonium chloride, while filling with clean nitrogen and maintaining a pressure of 0.2-1.2MPa. Open the discharge valve, maintain a constant pressure, and evenly coat the obtained mixture on the conveyor belt with a coating thickness of 3.0mm, and then transport it to the channel with radiation heating function through the conveyor belt, and cross-link and mature at 90 degrees for 3 minutes. Finally, it is pulled into the cooling tank to remove the residual acid and formaldehyde. Next, it is sprayed and pad-washed by three sets of pad-washing rollers arranged side by side, and the water is squeezed by the fourth set of pad-washing rolls before winding to obtain a polyvinyl formal sponge. The sponge body...

Embodiment 3

[0032] Dissolve 10 parts of polyvinyl alcohol with an alcoholysis degree of 99% in 60 parts of water, add 15 parts of formaldehyde and 10 parts of hydrochloric acid after cooling, stir and add 0.1 part of fatty alcohol polyoxyethylene ether, 0.1 part of higher fatty alcohol, Then put it into a closed autoclave to vacuumize and defoam, fill it with butane until the pressure is between 0.4-0.7MPa, open the discharge valve and spread the obtained mixture evenly on the conveyor belt, the coating thickness is 3.5mm, and then pass The conveyor belt is transported into the channel with radiant heating function, and the cross-linking is cured at 90 degrees for 5 minutes. Finally, it is pulled into the cooling tank to remove the residual acid and formaldehyde. Next, it is sprayed and pad-washed by three sets of pad-washing rollers arranged side by side, and the water is squeezed by the fourth set of pad-washing rolls before winding to obtain a polyvinyl formal sponge. Said can be appl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com