Antibacterial coating and preparation method thereof

An antibacterial coating, acrylic emulsion technology, applied in antifouling/underwater coatings, coatings, latex paints, etc., can solve the problems of promotion resistance, high price, and blackening of sterilization delayed products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] 2. Preparation of antibacterial coating

[0042]

[0043] The preparation method of described antibacterial coating is characterized in that: comprises the steps:

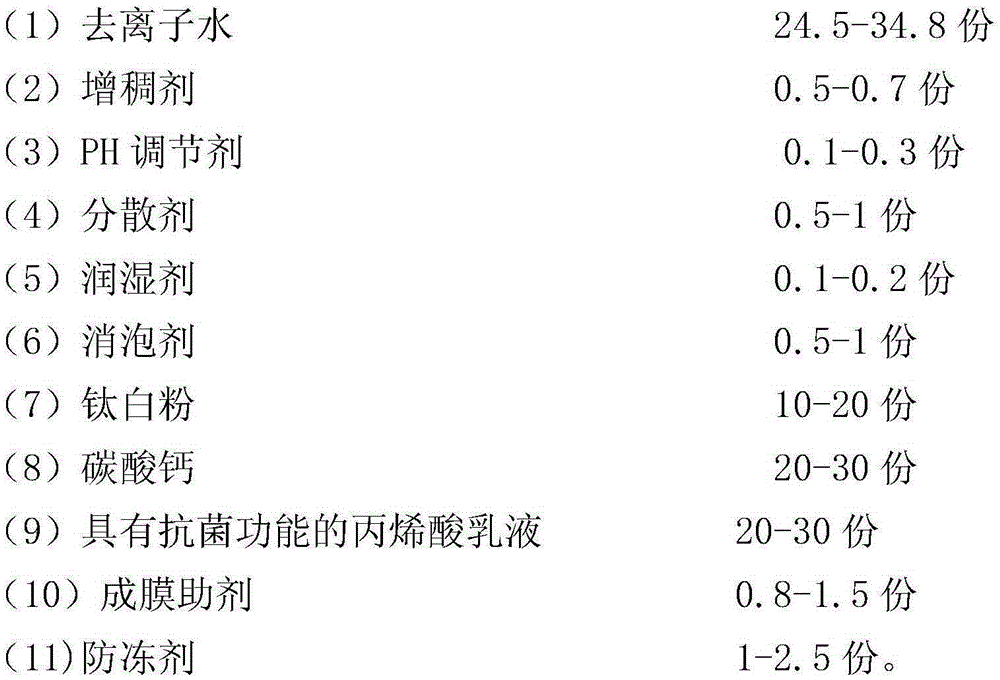

[0044] (1) Control the stirring rate to 300-500rmp, add 24.5-34.8 parts of deionized water, 0.5-0.7 parts of thickener and 0.1-0.3 parts of PH regulator to the mixer in sequence, and stir for 5-10 minutes;

[0045] (2) Then increase the speed to 800-1000r / min, add 0.1-0.2 parts of wetting agent, 0.5-1 part of dispersant, 0.5-1 part of defoamer, 10-20 parts of titanium dioxide and 20-30 parts of carbonic acid Calcium, then increase the speed to 1800-2000r / min, stir for 15-20min;

[0046] (3) Finally, reduce the speed to 1000-1200r / min, add 20-30 parts of emulsion, 0.8-1.5 parts of film-forming aid and 1-2.5 parts of antifreeze in turn, stir for 10-15 minutes and sieve with 200-300 mesh , to obtain the product of the present invention.

[0047] (two) embodiment:

Embodiment 1

[0049] 1. Preparation of antibacterial emulsion

[0050]

[0051]

[0052]The described acrylic emulsion with antibacterial function is formulated according to the following steps:

[0053] 1) Preparation of quaternary ammonium antibacterial monomer:

[0054] In a three-neck flask equipped with a stirrer and a constant pressure funnel, add 100% propoxypyromellitic acid ester dimethacrylate at a speed of 200rmp, slowly add dimethylaminoethyl methacrylate dropwise at room temperature, 0.5 After the addition of h is completed, react at room temperature for 1.5 h, stop stirring, and obtain the quaternary ammonium salt antibacterial monomer.

[0055] 2) Preparation of acrylic emulsion with antibacterial function:

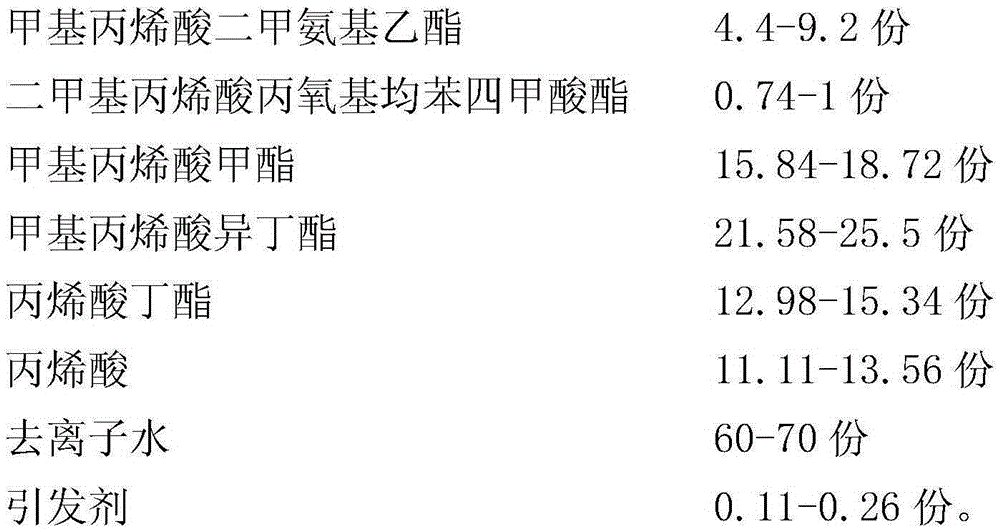

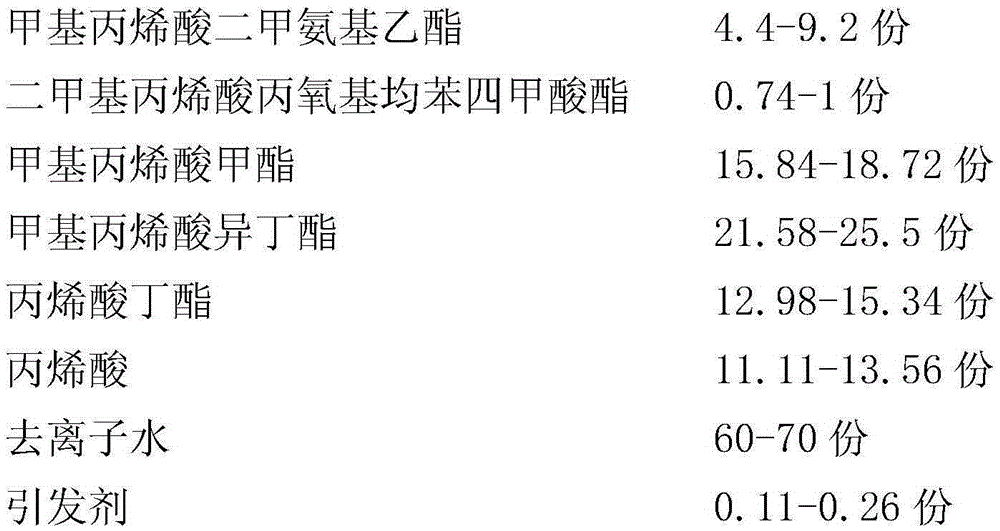

[0056] With stirrer, N 2 Add quaternary ammonium salt antibacterial monomer, methyl methacrylate, isobutyl methacrylate, butyl acrylate, acrylic acid, deionized water in the five-necked flask of conduit, constant pressure funnel and thermometer, stir 15min under...

Embodiment 2

[0064] 1. Preparation of antibacterial emulsion

[0065]

[0066] The described acrylic emulsion with antibacterial function is formulated according to the following steps:

[0067] 1) Preparation of quaternary ammonium antibacterial monomer:

[0068] In a three-necked flask equipped with a stirrer and a constant pressure funnel, add 1 portion of propoxypyromellitic acid dimethacrylate, the rotation speed is 300rmp, and slowly add dimethylaminoethyl methacrylate dropwise at room temperature, 0.8 After the addition of h is completed, react at room temperature for 1.8 h, stop stirring, and obtain a quaternary ammonium salt antibacterial monomer.

[0069] 2) Preparation of acrylic emulsion with antibacterial function:

[0070] With stirrer, N 2 Add quaternary ammonium salt antibacterial monomer, methyl methacrylate, isobutyl methacrylate, butyl acrylate, acrylic acid, deionized water in the five-necked flask of conduit, constant pressure funnel and thermometer, stir 25min u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com