Granular filtering material for adsorbing and removing heavy metals in water and preparation method thereof

A granular filter material and heavy metal technology, applied in the direction of adsorption of water/sewage treatment, chemical instruments and methods, water pollutants, etc., can solve secondary pollution and other problems, reduce the increase of structures, good economic and social benefits, and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

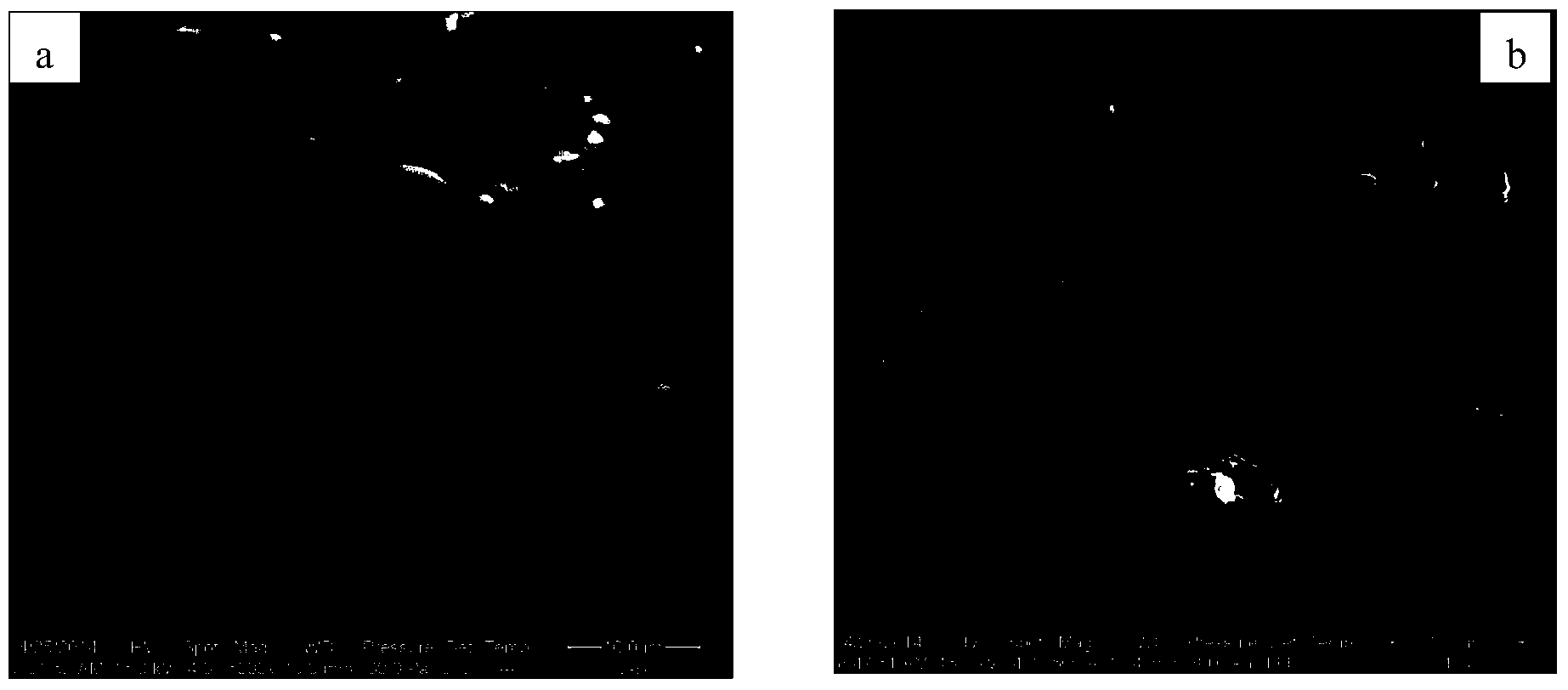

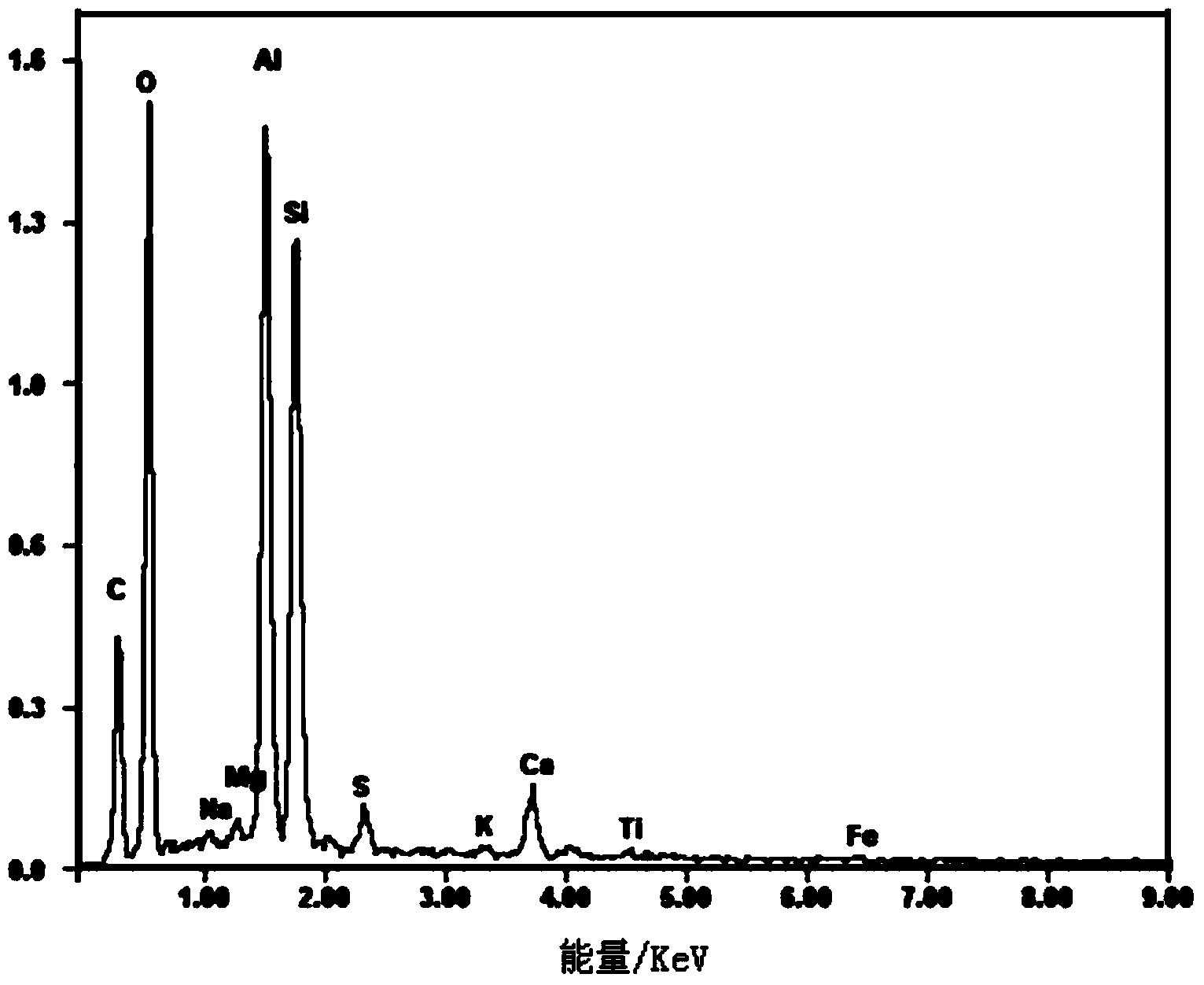

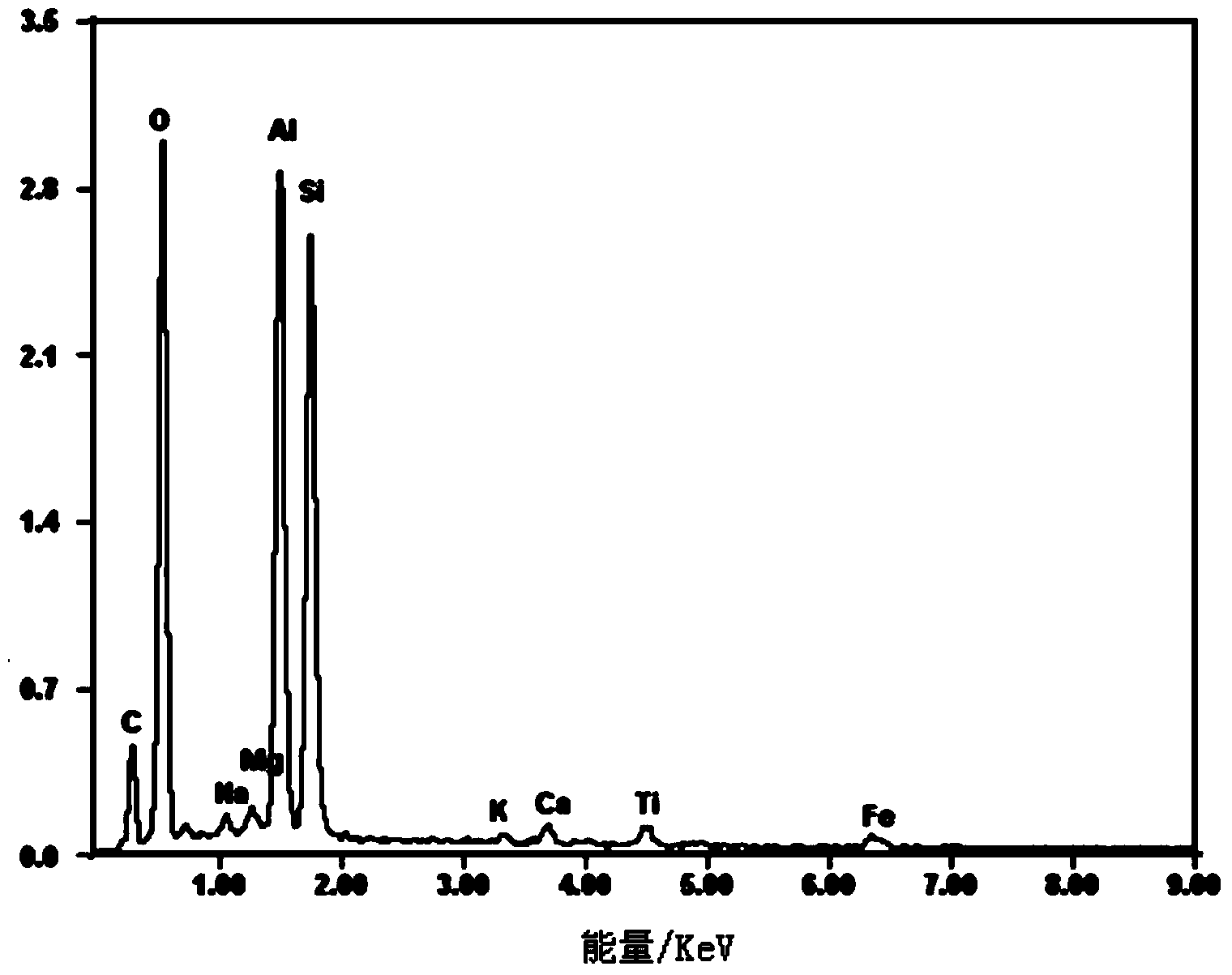

Image

Examples

Embodiment 1

[0030] Preparation of 1mol / L acid modified granular filter material and its adsorption performance test.

[0031]The fly ash and zeolite powder were soaked in 1mol / L hydrochloric acid for 24 hours respectively, then washed with deionized water until neutral, and then freeze-dried at -50°C and a vacuum of 20 Pa for 40 hours. Crush chitin to a particle size of less than 5 mm, add sulfonated coal and mix well, and then pyrolyze at 150°C for 2 hours under nitrogen, and then at 400°C for 2 hours. Weigh fly ash, zeolite powder, magnesium aluminum hydrotalcite, biochar, magnesium lignosulfonate and bentonite according to the mass ratio of 55:35:5.5:3:0.5:1 and mix them evenly. Add 2 % deionized water, stirred evenly, aged at 4°C for 36 hours to make spherical particles, and air-dried for 40 minutes. Spherical particles were dried at 90°C for 3 hours, then roasted in a muffle furnace at 500°C for 3 hours, and cooled to room temperature with the furnace to obtain a particle filter mat...

Embodiment 2

[0034] Preparation of 2mol / L acid-modified granular filter material and its adsorption performance test.

[0035] The fly ash and zeolite powder were soaked in 2mol / L hydrochloric acid for 36 hours respectively, then washed with deionized water until neutral, and then freeze-dried at -50°C and a vacuum of 20 Pa for 48 hours. Crush the cellulose to a particle size of less than 5mm, add sulfonated coal and mix evenly, and pyrolyze at 150°C for 2h under the condition of nitrogen gas, and then pyrolyze at 350°C for 2h. Weigh fly ash, zeolite powder, magnesium-aluminum hydrotalcite, biochar, magnesium lignosulfonate and bentonite according to the mass ratio of 60:30:5:6:0.7:2.5 and mix them evenly. Add 3 % deionized water, stirred evenly, aged at 3°C for 24 hours to make spherical particles, and air-dried naturally for 60 minutes. Spherical particles were dried at 110°C for 2 hours, then roasted in a muffle furnace at 600°C for 2 hours, and cooled to room temperature with the fu...

Embodiment 3

[0038] Preparation of 3mol / L acid-modified granular filter material and its adsorption performance test.

[0039] The fly ash and zeolite powder were soaked in 3mol / L hydrochloric acid for 30h, and then washed with deionized water until neutral, and then freeze-dried at -50°C and vacuum degree of 20Pa for 36h. Chitosan was crushed to a particle size below 5mm, sulfonated coal was added and mixed evenly, and pyrolyzed at 150°C for 2h under nitrogen, and then pyrolyzed at 500°C for 2h. Weigh fly ash, zeolite powder, magnesium aluminum hydrotalcite, biochar, magnesium lignosulfonate and bentonite according to the mass ratio of 65:40:7:3.5:0.5:1.5 and mix them evenly. Add 2 % deionized water, stirred evenly, aged at 2°C for 30 hours to make spherical particles, and air-dried for 30 minutes. Spherical particles were dried at 120°C for 1 hour, then roasted in a muffle furnace at 400°C for 4 hours, and cooled to room temperature with the furnace to obtain a particle filter material ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com