Microfluidic one-step synthesis method of chitosan microspheres for heavy metal wastewater treatment

A technology of chitosan microspheres and wastewater treatment, which is applied in water/sewage treatment, adsorption water/sewage treatment, water/sludge/sewage treatment, etc. It can solve the problems of time-consuming, high cost, and slow granulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

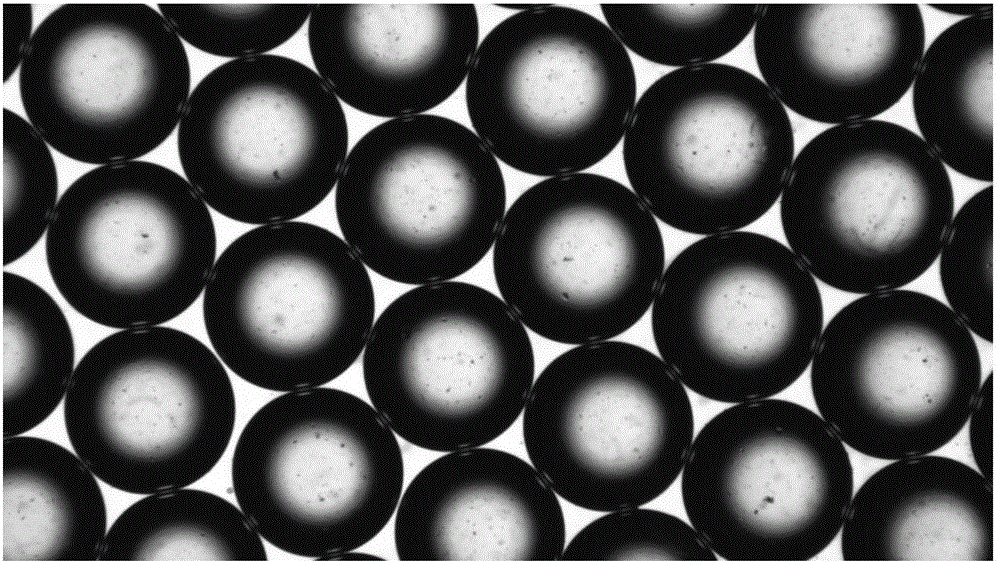

[0059] Preparation of chitosan microspheres:

[0060] Prepare chitosan microspheres according to the method of the present invention, step is as follows:

[0061] a. prepare aqueous solution of chitosan as dispersed phase, wherein, by weight of said aqueous solution of chitosan, the proportion of chitosan (purchased from Shanghai Shifeng Technology Co., Ltd.) is 2%, and the proportion of acetic acid is 2%. %;

[0062] b. prepare n-octane, Span and glutaraldehyde mixed solution as the continuous phase, wherein, by weight of the oil phase, the proportion of Span (purchased from Sinopharm Chemical Reagent Co., Ltd.) is 2%. The proportion of dialdehyde is 0.5%;

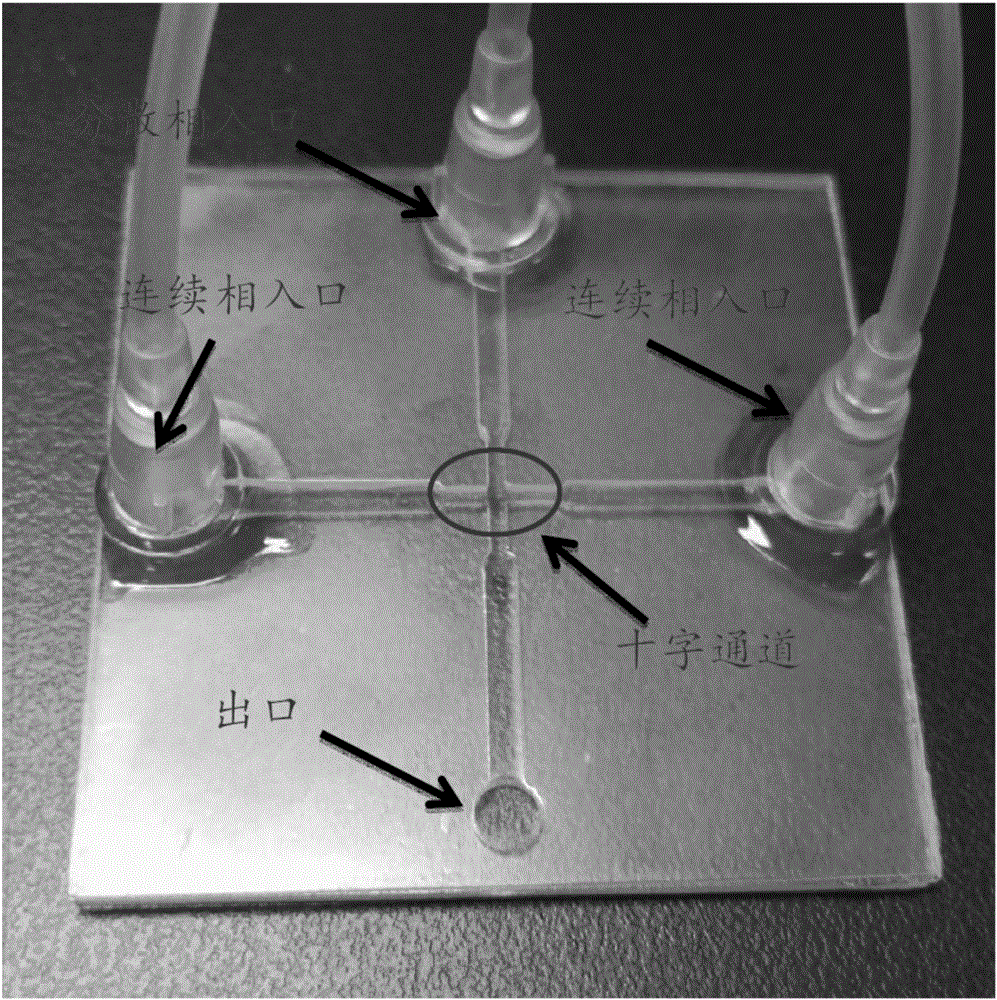

[0063] c. Pass the obtained continuous phase and dispersed phase into the microfluidic chip for shearing to form chitosan droplets, and cross-link and solidify, wherein the material of the microfluidic chip is polymethyl methacrylate, and the dispersed phase and the continuous phase The flow rate ratio is 1:5, and the ...

Embodiment 2

[0070] Preparation of chitosan microspheres:

[0071] Prepare chitosan microspheres according to the method of the present invention, step is as follows:

[0072] a. prepare aqueous solution of chitosan as dispersed phase, wherein, by weight of said aqueous solution of chitosan, the proportion of chitosan (purchased from Shanghai Shifeng Technology Co., Ltd.) is 4%, and the proportion of acetic acid is 2% %;

[0073] b. prepare n-octane, Span and glutaraldehyde mixed solution as the continuous phase, wherein, by weight of the oil phase, the proportion of Span (purchased from Sinopharm Chemical Reagent Co., Ltd.) is 4%. The proportion of dialdehyde is 0.5%;

[0074] c. Pass the obtained continuous phase and dispersed phase into the microfluidic chip for shearing to form chitosan droplets, and cross-link and solidify, wherein the material of the microfluidic chip is polymethyl methacrylate, and the dispersed phase and the continuous phase The flow rate ratio is 1:5, and the w...

Embodiment 3

[0081] Preparation of chitosan microspheres:

[0082] Prepare chitosan microspheres according to the method of the present invention, step is as follows:

[0083] a. prepare aqueous solution of chitosan as dispersed phase, wherein, by weight of said aqueous solution of chitosan, the proportion of chitosan (purchased from Shanghai Shifeng Technology Co., Ltd.) is 4%, and the proportion of acetic acid is 2% %;

[0084]b. prepare n-octane, Span and glutaraldehyde mixed solution as the continuous phase, wherein, by weight of the oil phase, the proportion of Span (purchased from Sinopharm Chemical Reagent Co., Ltd.) is 4%. The proportion of dialdehyde is 1%;

[0085] c. Pass the obtained continuous phase and dispersed phase into the microfluidic chip for shearing to form chitosan droplets, and cross-link and solidify, wherein the material of the microfluidic chip is polymethyl methacrylate, and the dispersed phase and the continuous phase The flow rate ratio is 1:7, and the wate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com