Method for preparing smelting cast-in-site synthetic alpha-Al2O3 granule reinforced copper base composite material

A copper-based composite material and particle-reinforced technology, which is applied in the field of melting and casting-in-situ synthesis of α-Al2O3 particle-reinforced copper-based composite materials, can solve problems such as poor wettability, difficulty in controlling the number of reinforcements, and deterioration of material properties. , to achieve the effect of reducing preparation cost, high utilization rate and improving comprehensive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

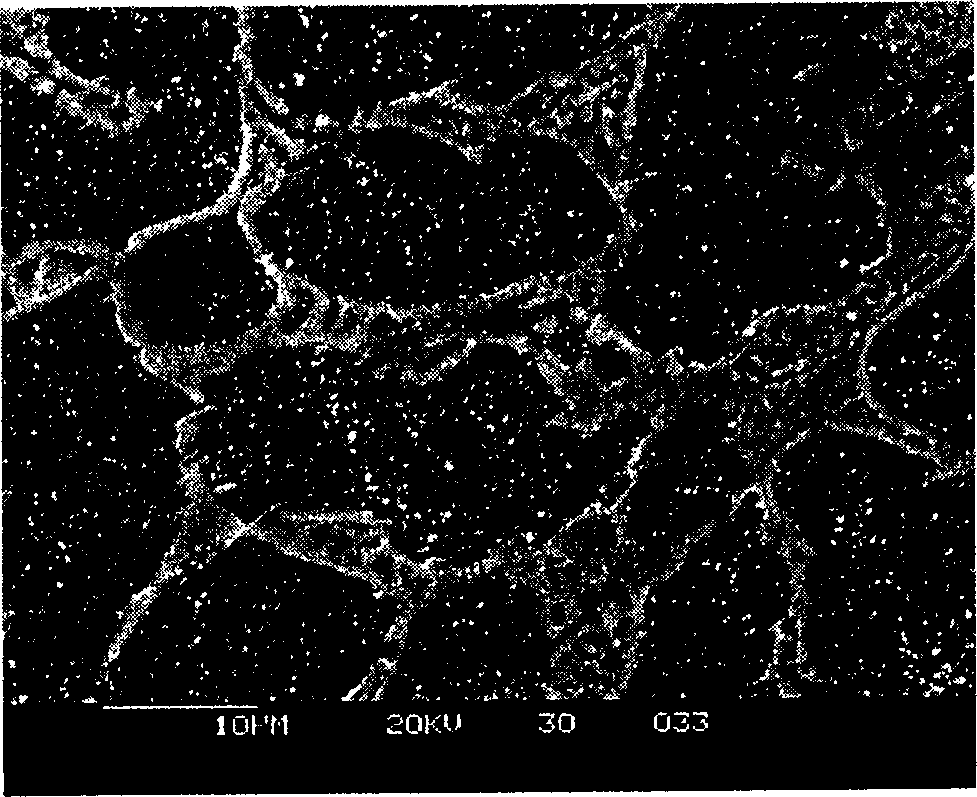

Embodiment 1

[0023] Preparation of 3 wt% Al 2 o 3 / copper composite. According to the ratio of Al:CuO=9:35 (weight%), Al powder and CuO powder with purity of 96% and 98% and particle size of 75 μm were weighed and mixed uniformly. A cylindrical prefabricated block of Φ20×30 mm is pressed on a press, and the pressing pressure is 26 MPa. Put 2kg of pure copper into a medium frequency induction furnace to melt and heat to 1160°C. Press a 0.16 kg prefabricated block into the copper liquid with a graphite bell jar and keep it warm for 15 minutes. When the melt temperature is 1150°C, it is poured into the metal mold to obtain about 3 wt% Al 2 o 3 / copper composite.

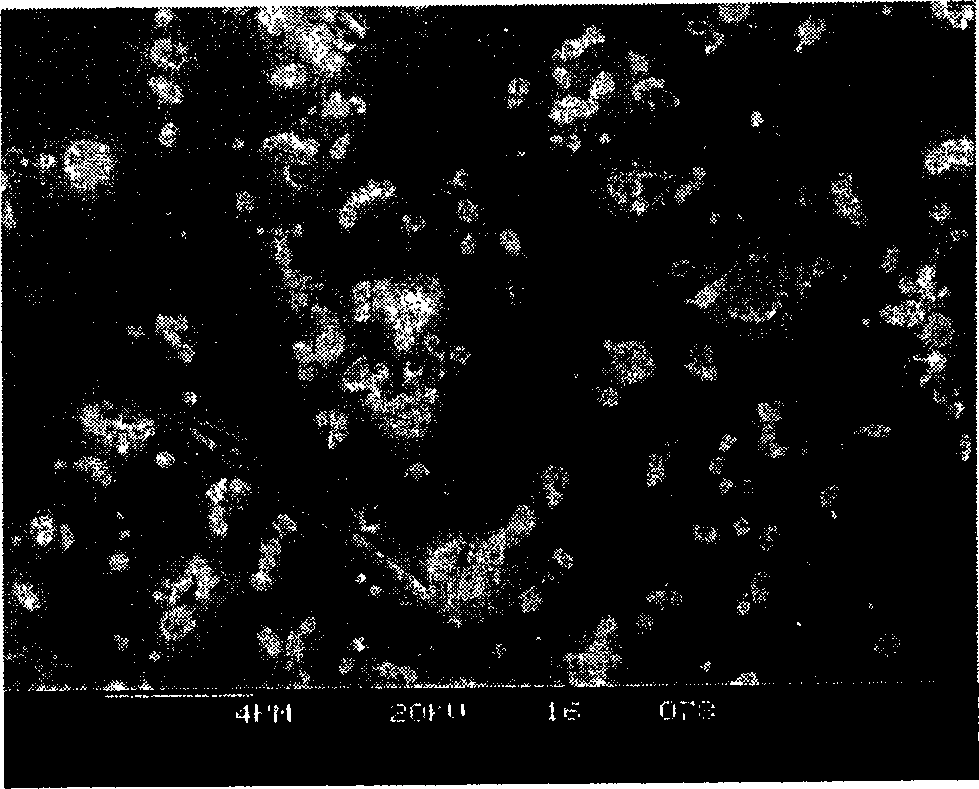

Embodiment 2

[0025] Preparation of 6 wt% Al 2 o 3 / copper composite. According to the ratio of Al:CuO=9:39 (weight%), Al powder and CuO powder with a purity of 96% and 98% and a particle size of 75 μm were weighed and mixed uniformly. A cylindrical prefabricated block of Φ20×30 mm is pressed on a press, and the pressing pressure is 33 MPa. Put 2kg of pure copper into a medium frequency induction furnace to melt and heat to 1170°C. Press a 0.32 kg prefabricated block into the copper liquid with a graphite bell jar and keep it warm for 20 minutes. When the melt temperature is 1160°C, it is poured into the metal mold to obtain about 6 wt% Al 2 o 3 / copper composite.

Embodiment 3

[0027] Preparation of 9 wt% Al 2 o 3 / copper composite. According to the ratio of Al:CuO=9:37 (weight%), Al powder and CuO powder with a purity of 96% and 98% and a particle size of 75 μm were weighed and mixed uniformly. A cylindrical prefabricated block of Φ20×30 mm is pressed on a press, and the pressing pressure is 37 MPa. Put 2kg of pure copper into a medium frequency induction furnace to melt and heat to 1200°C. Press a 0.48 kg prefabricated block into the copper liquid with a graphite bell jar and keep it warm for 25 minutes. When the melt temperature is 1170°C, it is poured into the sand mold to obtain about 9 wt% Al 2 o 3 / copper composite.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com