Biomass straw smashing and forming all-in-one machine

A technology of biomass straw and integrated machine, which is applied in the direction of material forming presses, presses, grain processing, etc., which can solve the problems of long operation cycle, high power consumption, and high logistics cost, and achieve high crushing efficiency and granulation speed Fast and reduce the cost of transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

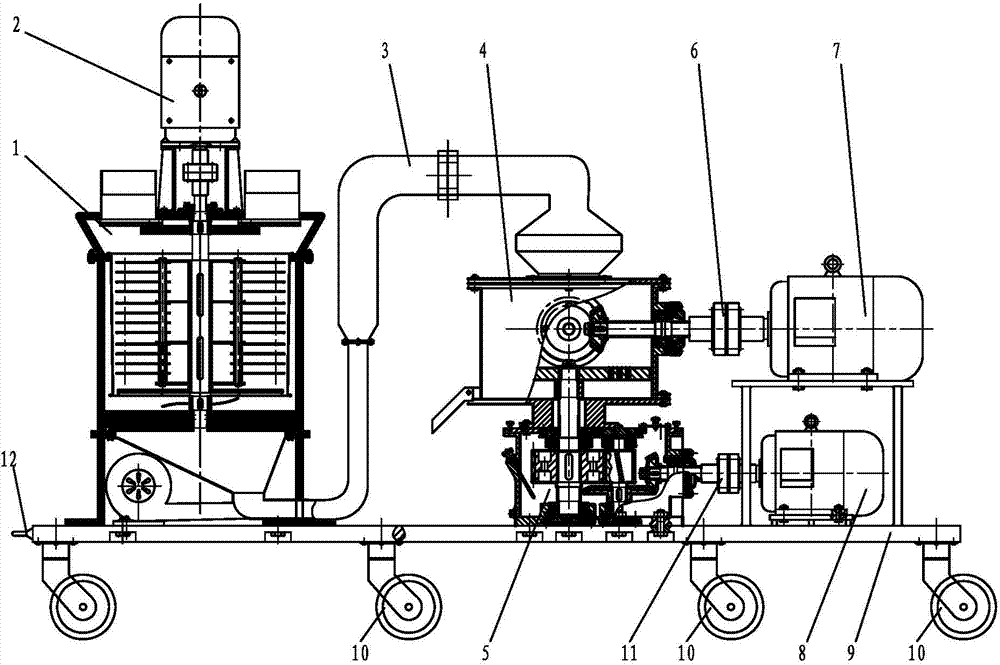

[0037] Specific implementation mode one: see Figure 1 to Figure 3 , the integrated biomass straw crushing and molding machine in this embodiment includes a vertical crushing device 1 and an extrusion molding device, the outlet of the vertical crushing device 1 is connected to the inlet of the extrusion molding device through an air duct 3,

[0038]The vertical crushing device 1 and the extruding device are arranged side by side on the traveling disc 9 from front to back, and a plurality of traveling wheels 10 are installed under the traveling disc 9, and the reducer 5 and the third motor 8 are installed on the traveling disc 9;

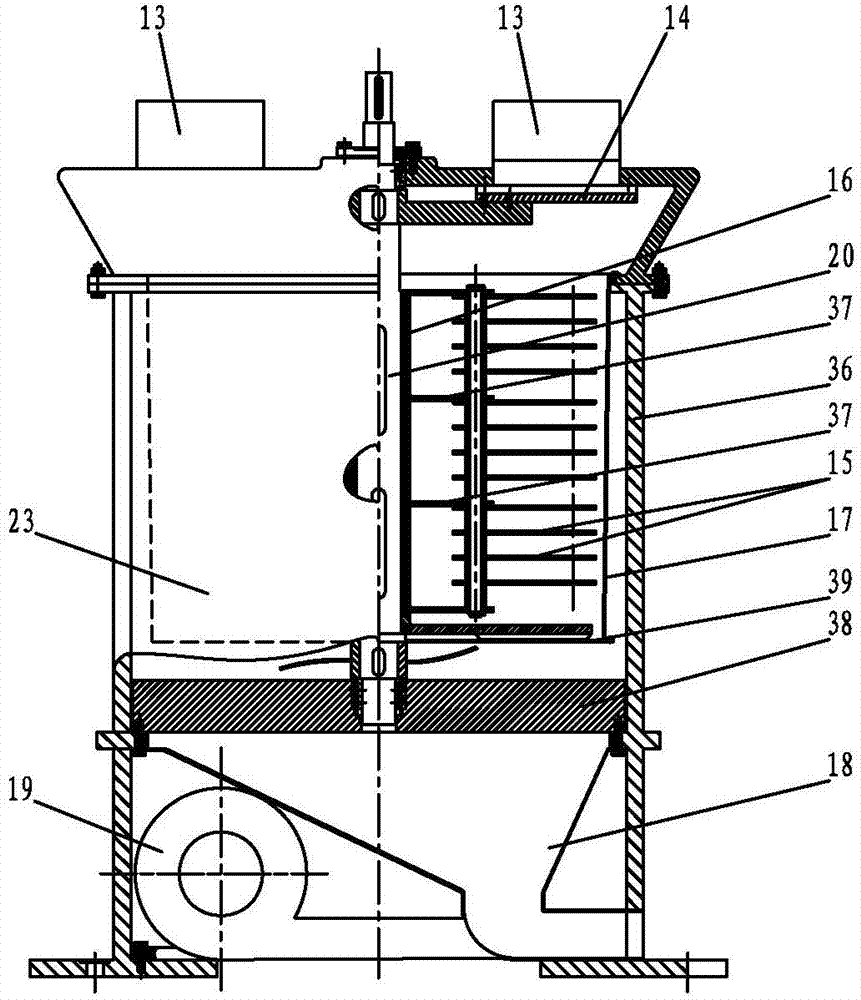

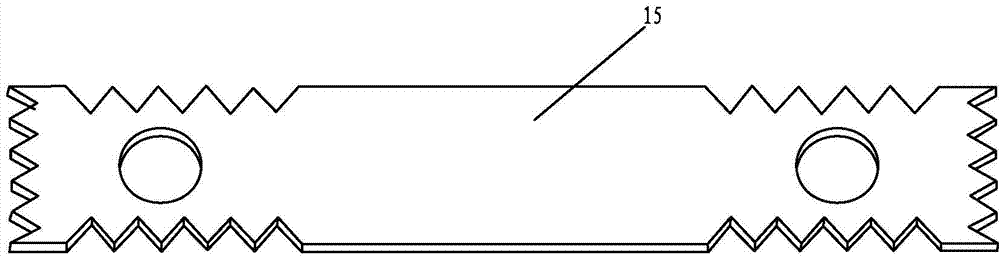

[0039] The vertical crushing device 1 comprises a first motor 2, a casing 36, a feed port 13, a blade 14, forty-eight hammer blades 15, a sleeve 16, a storage hopper 18, four hammer frame plates 37, a bearing frame 38 and Blower 19, casing 36 is provided with feed inlet 13, and the bottom of feed inlet 13 is equipped with blade 14, and described pulv...

specific Embodiment approach 2

[0043] Specific implementation mode two: see Figure 4 to Figure 10 The difference between this embodiment and the first embodiment is that the extrusion molding device of this embodiment includes an extrusion molding working chamber 4, a speed reducer 5, a first coupling 6, a second motor 7, and a third motor 8 , the second coupling 11, the driving bevel gear 21, the input shaft 22 of the molding studio, the flat die disc spindle 26, the flat die disc 27, a plurality of die hole sleeves 35, the feeder 28, two pressure rollers 30, two Roller main shaft 32 and two driven bevel gears 40;

[0044] The input end of the flat die disc spindle 26 of the extrusion molding studio 4 is connected with the reducer 5, the output end of the flat die disc spindle 26 is connected with the flat die disc 27 in the extrusion molding studio 4, and the input end of the reducer 5 Connect with the third motor 8 through the second coupling 11, one end of the input shaft 22 of the molding chamber of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com