Patents

Literature

65 results about "Ammonium chloroplatinate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ammonium hexachloroplatinate, also known as ammonium chloroplatinate, is the inorganic compound with the formula (NH 4) 2 [PtCl 6]. It is a rare example of a soluble platinum(IV) salt that is not hygroscopic. It forms intensely yellow solutions in water.

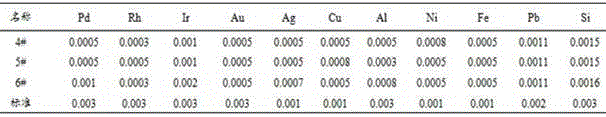

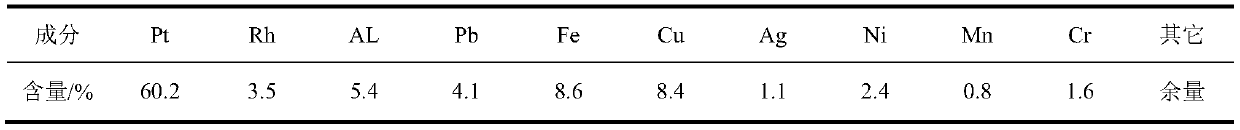

Method for recovering valuable metals from waste printed circuit board

ActiveCN101787547ASolve pollutionReduce energy consumptionPhotography auxillary processesProcess efficiency improvementElectrolysisFiltration

The invention discloses a method for recovering valuable metals from a waste printed circuit board. The method comprises the following steps: sorting and crushing the printed circuit board, evenly mixing powder containing multiple metal parts with a fluxing agent, and smelting at low temperature for 1-3.5h; adding hot water into smelting products for leaching; evaporating and concentrating filtrate after filtration, and then returning evaporation mother liquor to the water leaching process step; using solution after leaching for swirl electrodeposition of metal silver, and adding 5-25% of HNO3 into filter residue for leaching; filtering the solution after electrodeposition, and adding 1-5 times of the weight of aqua regia into the filter residue for leaching; using the solution after leaching by the aqua regia for the swirl electrodeposition of gold, adding saturated NH4Cl into the solution after the electrodeposition for reaction, then filtering, using ammonium chloroplatinate for refining the filter residue, obtaining sponge platinum, adding methanoic acid into the solution after precipitation, and carrying out reaction for obtaining crude palladium powder. The method can extract copper, nickel, silver, gold, platinum, palladium and other main products and other by-products, realize the maximization of reutilization of value metal resources in the waste printed circuit board and solve the environmental pollution problem; and the adoption of the swirl electrolysis technology can realize low energy consumption, low reagent consumption, short process flow and simple operation.

Owner:HUNAN JIANG YE MECHANICAL & ELECTRICAL TECH CO LTD

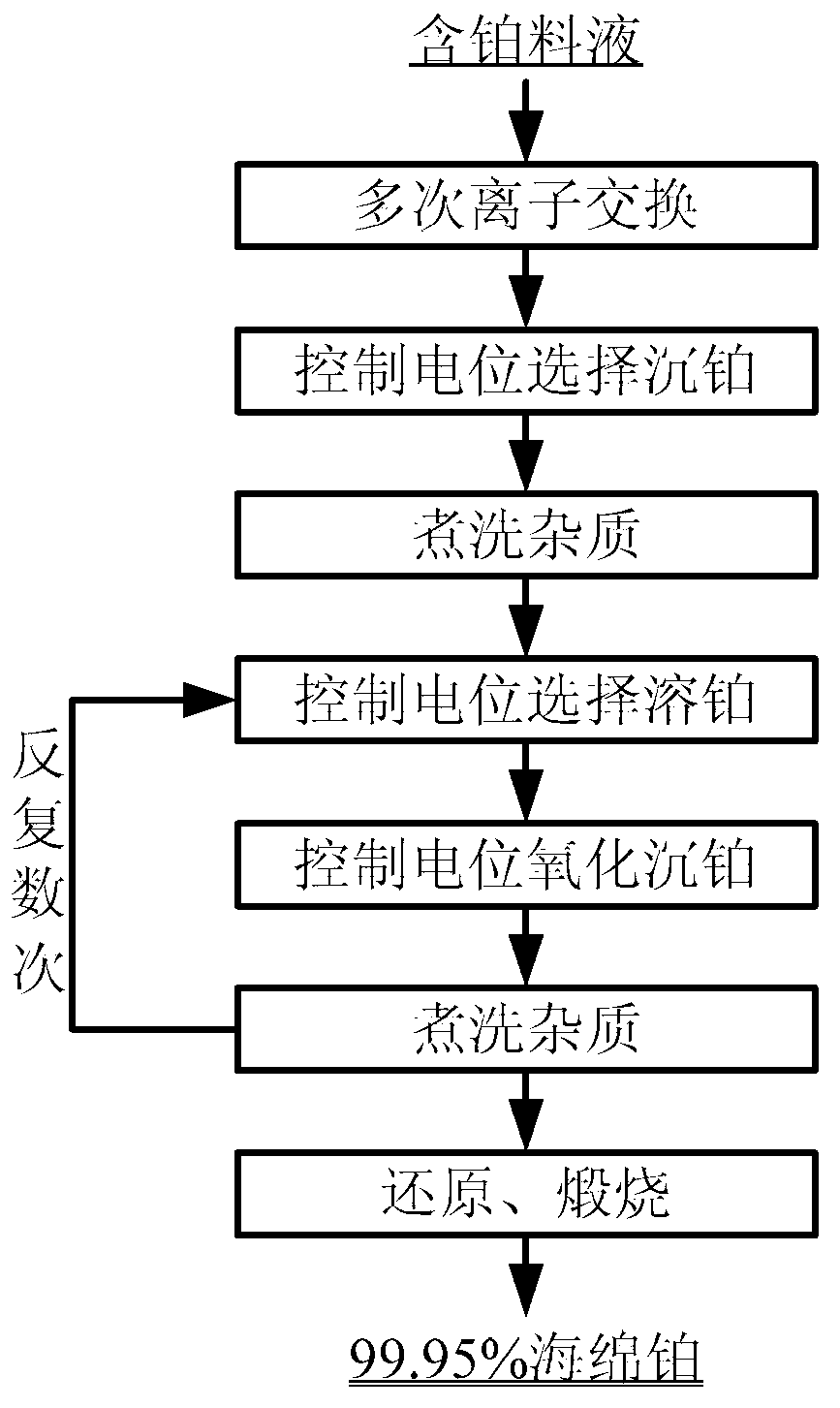

Method for separating and purifying platinum by adopting holding potential

ActiveCN102797018AHigh purityHigh recovery ratePhotography auxillary processesProcess efficiency improvementIon exchangeCalcination

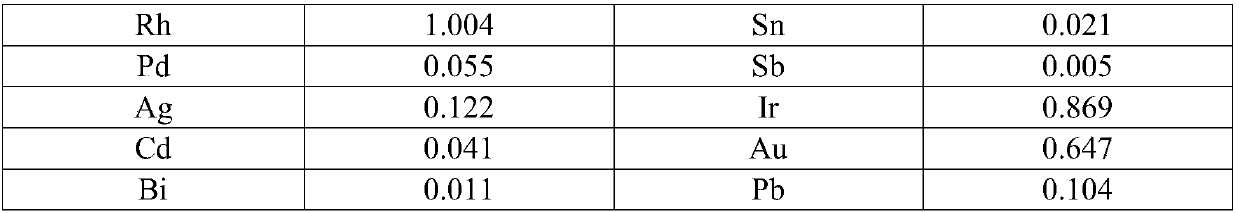

The invention mainly relates to a novel method for separating and purifying platinum from complex platinum family metal solution. Base metal impurities in the solution are removed through ion exchange, pure platinum family metal solution can be obtained, ammonium chloride precipitate platinum is added under a certain oxidation-reduction potential, the electric potential is adjusted, precipitate containing platinum is reduced by a specific reducing agent, the platinum deposit is enabled to be resolved, then the oxidation-reduction potential is adjusted again, the platinum is oxidized to be high valence state again, the ammonium chloride is added so as to enable the platinum to be deposited again, the process of precipitation and resolution are repeated in such a way according to the complexity of raw materials until the ammonium chloroplatinate deposit with purity meeting the requirements can be obtained, and high-purity spongy platinum is obtained from the qualified ammonium chloroplatinate through the processes of reduction, washing, calcination and the like. The method has the advantages of short process, simplicity in operation, and high platinum recovery.

Owner:GUIYAN RESOURCE YIMEN

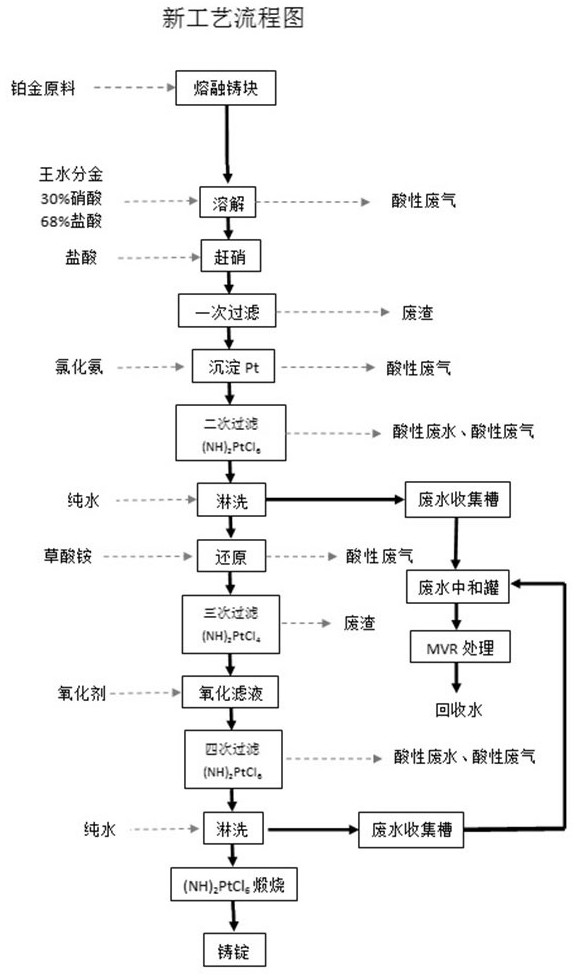

Refined platinum producing process

The present invention relates to wet noble metal smelting process. The process includes dissolution of coarse ammonium chloroplatinate with sodium hydroxide solution, reduction by adding hydrazine hydrate and filtering to obtain platinum black, hydrogen peroxide and hydrochloric acid dissolution to obtain platinum black, adidng ammonium chloride for fractional deposition of platinum in the form of ammonium chloroplainate, and conventional calcinatino to obtain spongy platinum. The present invention has short technological process, low productino cost, low power consumption, and good operationcondition, and it is possible to produce various products in different grade.

Owner:JINCHUAN GROUP LIMITED

Platinum refining technology

A platinum refining technology comprises the steps of platinum family metal contained concentrate (slag, secondary resources and the like) chlorination dissolving, dissolved solution acidity adjustment, organic reducing agent ammonium oxalate precipitation, and precious metal filtering separation. The technology has the characteristics of wide material adaptability and simple operation, allows ammonium chloroplatinate of a platinum family metal contained material containing ammonium chloroplatinate to be efficiently and rapidly dissolved and precipitated, and allows the dissolving efficiency, the precipitation rate and the refining recovery efficiency to reach 95-99%, 99% and 90-95% respectively in the whole refining process; and compared with a traditional ammonium chloride repeated-precipitation method, the technology effectively solves a problem that nitrogen oxide cannot be discharged in a standard reaching mode, and eliminates the problems of large labor intensity of a aqua regia dissolved solution nitrate removing process and low production efficiency. The reducing agent ammonium oxalate is an organic reagent, and reacts to generate a pollution-free gas which can be directly discharged in the reaction process, so a solution system is not changed, thereby no influences on subsequent platinum precipitation by ammonium chloride are caused, and the yield and the quality of platinum family metal products are substantially improved.

Owner:JINCHUAN GROUP LIMITED

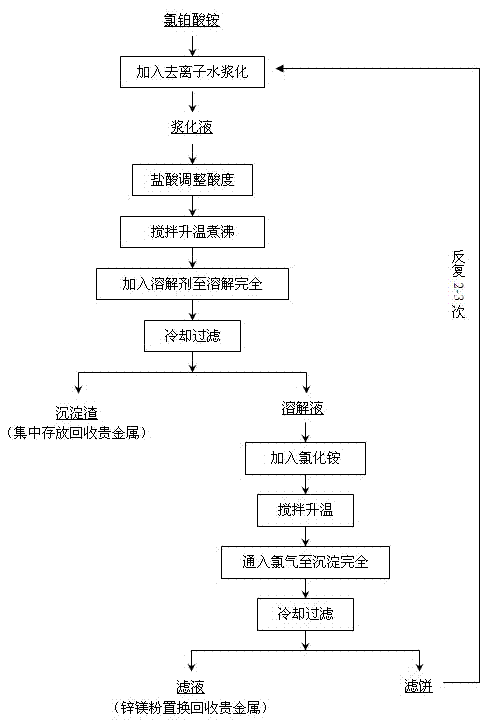

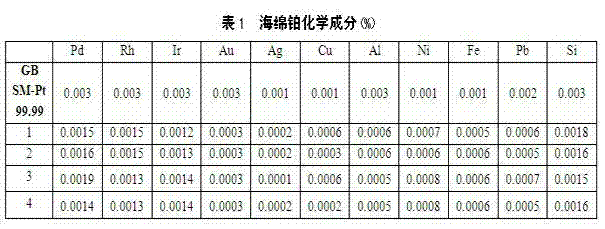

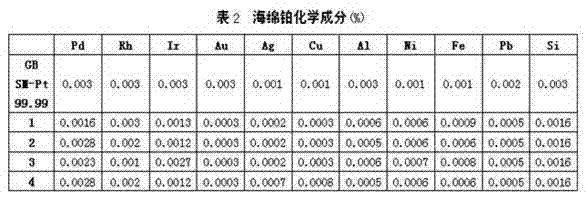

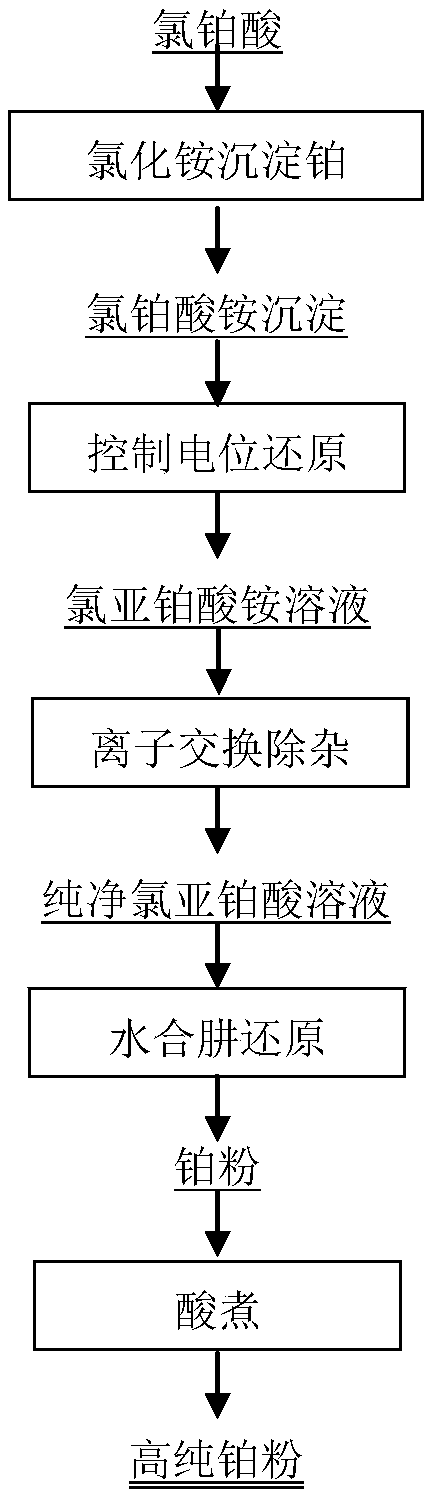

Preparation method of high-purity platinum powder

The invention discloses a preparation method of ultra-pure platinum powder. The preparation method comprises the steps of (1) precipitating platinum with ammonium chloride; (2) controlling potential for reduction: precipitating ammonium chloroplatinate with deionized water to prepare suspension liquid, adding reductant, and controlling the potential of a solution for reduction, so that an ammoniumchloroplatinite solution is obtained; (3) performing ion exchange to remove impurities: putting the ammonium chloroplatinite solution to a cation exchange column, and removing cation impurities, so that a pure chloroplatinous acid solution is obtained; (4) deeply reducing chloroplatinous acid: adding hydrazine hydrate to the chloroplatinous acid solution for deep reduction, so that platinum is reduced to powder; and (5) boiling with acid to remove impurities: boiling and washing the obtained platinum powder with a nitric acid and hydrofluoric acid mixed solution, fully washing with deionizedwater, and drying, so that high-purity platinum powder is obtained. The preparation method has the advantages of low energy consumption, low cost, simple process and the like, a conventional hydrometallurgical technique is adopted in the whole process, a high-temperature calcining process is not involved, and the purity is greater than 99.999%.

Owner:SINO PLATINUM METALS CO LTD

A kind of preparation method of high-purity platinum

The invention relates to a method for preparing high-purity platinum. The steps are as follows: (1) dissolving 100 grams of metallic platinum in aqua regia, and reacting with ammonium chloride to form ammonium chloroplatinate precipitation, and then draining to obtain platinum chloride (2) ion-exchange purification of ammonium chloroplatinate, (3) preparation of high-purity platinum, the ammonium chloroplatinate obtained in step (2) is packed into a quartz boat, put into a muffle furnace and calcined to obtain high-purity platinum pure platinum. In the present invention, metallic platinum and aqua regia are dissolved to generate ammonium chloroplatinate, and then the ammonium chloroplatinate is removed by ion exchange resin to generate chloroplatinic acid, and ammonium chloride is added to generate ammonium chloroplatinate, which is obtained by burning after drying. High purity platinum.

Owner:TIANJIN CHEM REAGENT RES INST

Preparation method of ammonium chloroplatinate

ActiveCN103288147AAffect purityHigh purityRuthenium/rhodium/palladium/osmium/iridium/platinum compoundsPtru catalystAmmonium chloroplatinate

The invention relates to a preparation method of ammonium chloroplatinate, and the preparation method comprises the following steps of: (1) adding dilute acid to platinum, carrying out cooking washing for 10-60 minutes, and then filtering and washing to obtain refined platinum; (2) adding a hydrochloric acid and perchloric acid solution to the refined platinum, introducing chlorine, and heating the platinum to be completely dissolved to obtain a mixed solution; (3) slowly evaporating the mixed solution into a viscous state, adding hydrochloric acid and oxydol to the mixed solution, continuously slowly evaporating to dryness, and then adding distilled water to obtain a chloroplatinic acid solution; (4) adding the distilled water to ammonium chloride, and heating and dissolving to obtain an ammonium chloride solution; and (5) slowly adding a thermal ammonium chloride solution to the chloroplatinic acid solution to obtain deposits, and filtering, washing and drying the deposits to obtain ammonium chloroplatinate. The prepared ammonium chloroplatinate is mainly used for industrially preparing the noble metal catalyst, the noble metal electroplated layer and the platinized asbestos and can also be used for analytical chemistry.

Owner:陕西煤业化工技术开发中心有限责任公司

Platinum recovery refining process

The invention discloses a platinum recovery refining process. The platinum recovery refining process is characterized by comprising the following process steps: a. carbonizing a platinum-containing material for 1.5-2.5 hours at 750-850 DEG C; b. cooling to a room temperature and then adding aqua regia to dissolve the material at 65 to 75 DEG C until the material is completely dissolved; c. adding ammonium chloride and precipitating for 0.5-1.5 hours; after the precipitation is finished, filtering and washing ammonium chloroplatinate; d. adding sodium hydroxide till dissolving in 20-40 minutes to form dissolution solution; e. heating the dissolution solution obtained in the step d to 45-55 DEG C and then adding hydrazine hydrate for reducing, and reacting for 0.5-1.5 hours to finish platinum recovery; f. drying the reduced platinum powder. The recovery process disclosed by the invention has the beneficial effects of greatly shortened process time, reduced production cost, good operability, low energy consumption, and capability of greatly improving the yield and the quality of platinum metal products.

Owner:KUNSHAN HONGFUTAI ENVIRONMENTAL PROTECTION TECH

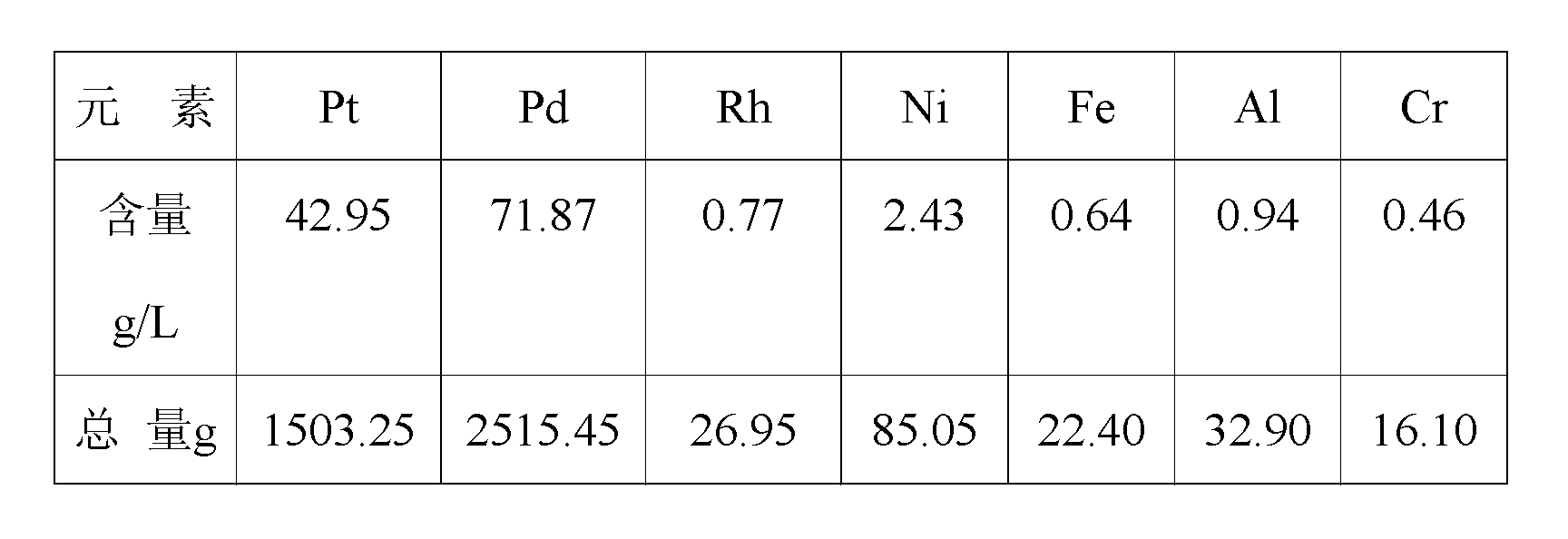

Method for separating and extracting platinum group metals

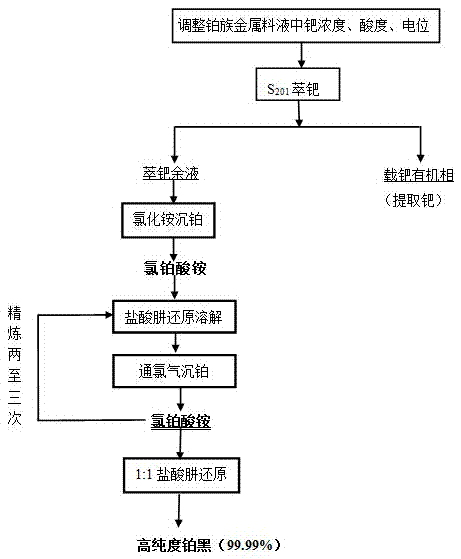

The invention provides a method for separating and extracting platinum group metals. The method comprises the steps that the palladium concentration of feed liquid containing the platinum group metals is controlled to be 1.5-5.5g / L, the electric potential of the feed liquid is controlled to be 850-950mv, palladium is extracted by means of S201 organic phases, and palladium is extracted from the palladium-loaded organic phases through the following process. Ammonium chloride is added into palladium extraction raffinate to deposit platinum, obtained ammonium chloroplatinate is subjected to reduction and dissolution by being added with hydrazine dihydrochloride solution and is heated to 90-95 DEG C, and chlorine gas is introduced; after the obtained ammonium chloroplatinate is repeatedly subjected to the hydrazine dihydrochloride reduction process for 2-3 times, and high-purity platinum black can be obtained by reducing the ammonium chloroplatinate through the hydrazine dihydrochloride according to the mass ratio of 1:1. Compared with the prior art, the method has the advantages that the process is simple, the precious metal separation efficiency is high, generation of a larger amount of ammonia-contained waste gas is avoided in the process of reducing ammonium chloroplatinate through hydrazine hydrate, and no nitrogen oxide pollution is produced.

Owner:JINCHUAN GROUP LIMITED

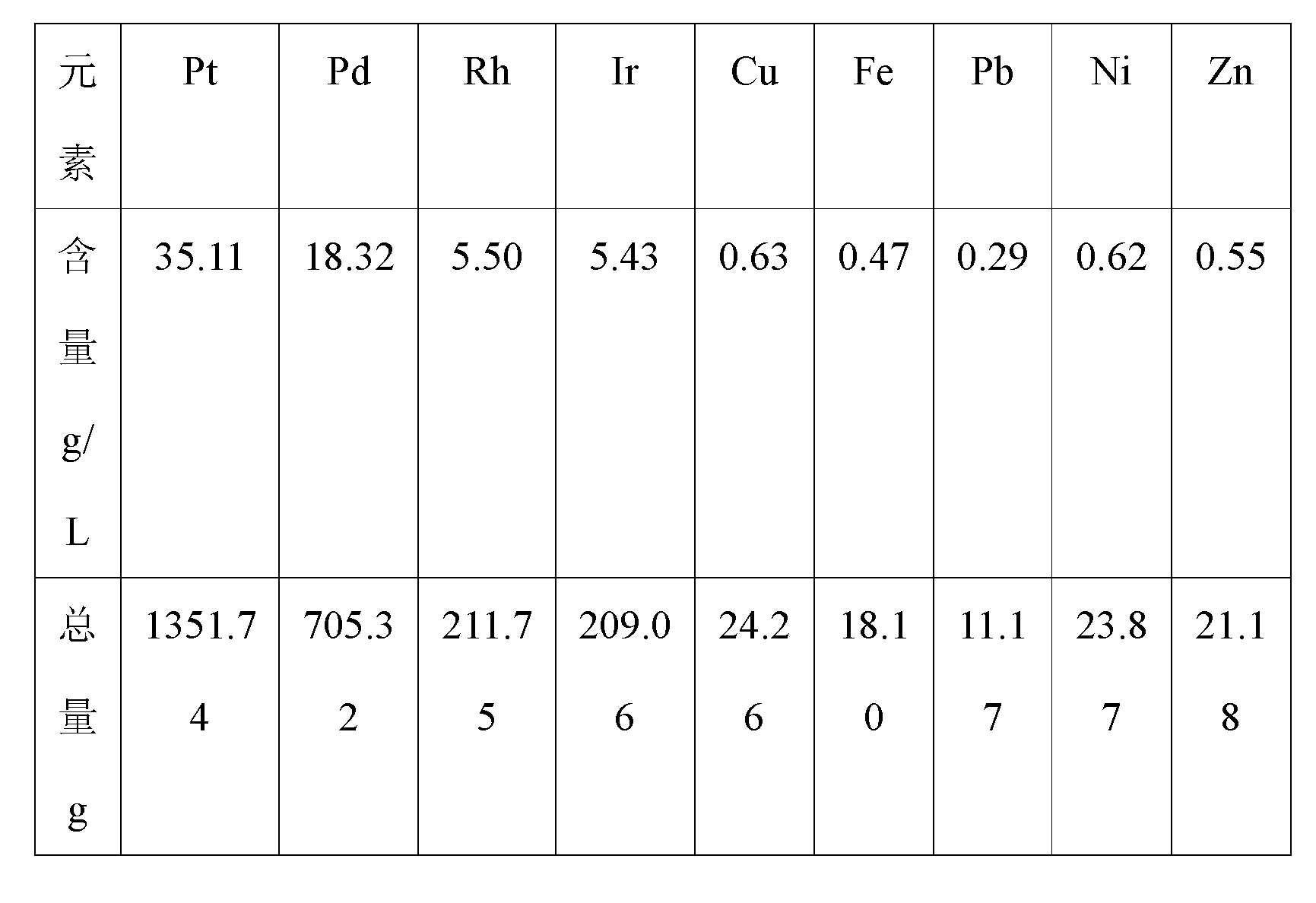

Platinum refining method

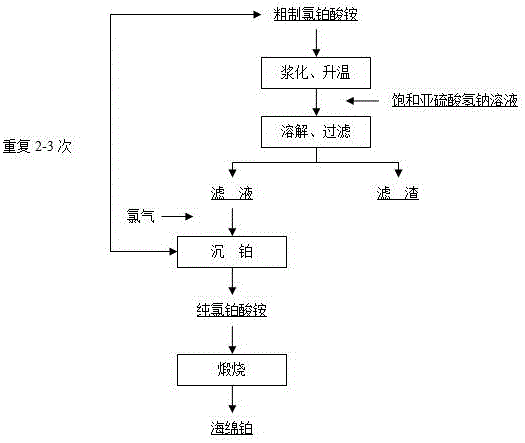

InactiveCN108929953AOvercome a series of problems such as palladium exceeding the standardHigh purityProcess efficiency improvementSulfite saltSlurry

The invention discloses a platinum refining method. The method comprises the following steps: adding water to crude ammonium chloroplatinate, slurrying the crude ammonium chloroplatinate and water toobtain a slurry, heating the slurry to 90-95 DEG C, and adding sodium sulfite or sodium pyrosulfite while stirring until the crude ammonium chloroplatinate is completely dissolved; cooling the obtained solution, filtering the cooled solution, heating the obtained filtrate to 90-95 DEG C, adding hydrochloric acid and sodium chlorate with stirring, and stopping the addition of the hydrochloric acidand sodium chlorate when no ammonium chloroplatinate crystals are precipitated from the solution; cooling the obtained solution to room temperature, adding ammonium chloride, performing stirring to dissolve the ammonium chloride, and filtering the obtained solution to obtain a solid that is pure ammonium chloroplatinate; washing the obtained pure ammonium chloroplatinate with a hydrochloric acid and ammonium chloride mixed solution; and repeating above steps to obtain pure ammonium chloroplatinate, and finally carrying out high-temperature calcination on the pure ammonium chloroplatinate to obtain spongy platinum. The method avoids ammonium chloroplatinate calcination, aqua regia dissolution and the like, overcomes excessive palladium in the spongy platinum and other problems caused by insufficient nitrate removal of the platinum in the sponge platinum, and obtains the spongy platinum with a purity reaching up to 99.99%.

Owner:DAYE NONFERROUS METALS

Platinum refining process based on two-stage sedimentation method

ActiveCN103555937ASimple processEasy to operateProcess efficiency improvementPlatinum saltsSodium chlorate

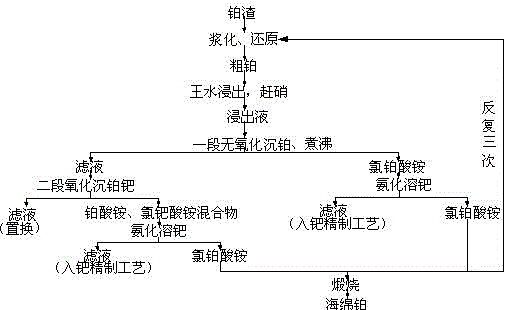

The invention discloses a platinum refining process based on a two-stage sedimentation method. The platinum refining process comprises the following steps: (1), hydrazine hydrate reduction, wherein platinum concentrate is added with water for pulpifying and heating up to 50 DEG C+ / -5 DEG C, and hydrazine hydrate is added for reducing ammonium chloroplatinate into crude platinum; (2), aqua regia dissolving, wherein the filtered-out crude platinum is placed into a glass cup and added with water for pulpifying, and the aqua regia is added for dissolving until the platinum is completely dissolved; (3), first-stage non-oxidation platinum depositing-boiling to dissolve palladium, wherein liquor is controlled to contain 50g / l platinum, heated up to 60 DEG C, added with NH4C1 to deposit platinum, heated and boiled after the reaction is ended, and filtered and washed after being cooled; (4), second-stage oxidization platinum-palladium depositing, wherein the first-stage palladium-depositing filtrate is heated up to 60 DEG C, added with ammonium chloride and sodium chlorate in a ratio f 10:1 to deposit platinum and palladium, cooled, filtered and washed after the reaction is ended; (5), ammonifying and palladium dissolving, wherein the first-stage platinum salt and the second-stage platinum salt obtained by filtering are respectively pulpified by using pure water; (6), roasting, wherein the platinum salt placed in a porcelain crucible is heated and roasted in a muffle furnace, and taken out for being washed and dried after being slowly cooled.

Owner:铜陵有色金属集团股份有限公司

Method for purifying platinum through reduction

ActiveCN106319241AEasy to handleEasy to recycle and replaceProcess efficiency improvementThermal stateHydrogen

A new method for purifying platinum through reduction relates to a process for purifying platinum from crude ammonium chloroplatinate through reduction. The method comprises the steps of: pulpifying the crude ammonium chloroplatinate and then heating, adding a saturated sodium hydrogen sulfite solution into the pulp under a thermal state to reduce and dissolve the crude ammonium chloroplatinate, and introducing chlorine after filtering to precipitate again. The purifying effect is achieved through repeated operation and spongy platinum which accords with the natural first-class standard is produced. The method provided by the invention has the advantages that the process is simple in flow and cost is low; less waste gas is discharged and is easy to treat; and waste liquid is low in acidity and is easy to recycle. By adoption of the process provided by the invention, the direct recovery rate of the platinum is 93% to 97%. By the method, the problems that the platinum settling efficiency is low, the waste gas amount is large, waste water is difficult to treat, the reduction efficiency is low and the reduction process is difficult to control in the traditional process of purifying the platinum through reduction are avoided; and environmental friendliness, high efficiency, simplicity and convenience of the process of purifying the platinum through reduction are realized.

Owner:JINCHUAN GROUP LIMITED

Platinum refining process

Owner:JINCHUAN GROUP LIMITED

Preparation method for tetraammineplatinum (II) acetate

The invention discloses a preparation method for tetraammineplatinum (II) acetate. The preparation method comprises the following steps: reacting ammonium chloroplatinate (IV) with oxalic acid, ammonia water and calcium acetate respectively in three steps to form a tetraammineplatinum (II) acetate solution; then subjecting the tetraammineplatinum (II) acetate solution to concentration and separation through solvent-out crystallization so as to obtain a tetraammineplatinum (II) acetate crystal; and performing vacuum drying so as to obtain tetraammineplatinum (II) acetate with a purity of no less than 99.95%. According to the invention, the starting material, i.e., the ammonium chloroplatinate (IV) is a conventional compound of platinum and is easy to obtain and high in yield, and the otherauxiliary materials consisting of oxalic acid, concentrated ammonia water and calcium acetate are cheap, so production cost is greatly lowered; in addition, the method avoids residues of chloride ionsand nitrate ions and lowers residual silver ions in the produced tetraammineplatinum (II) acetate. The preparation method of the invention is carried out under normal temperature and normal pressure,is simple to operation and easy to control, has high reaction yield (more than 92%) and high product purity (no less than 99.95%), and is applicable to batch and industrial production of tetraammineplatinum (II) acetate.

Owner:HOOTECH

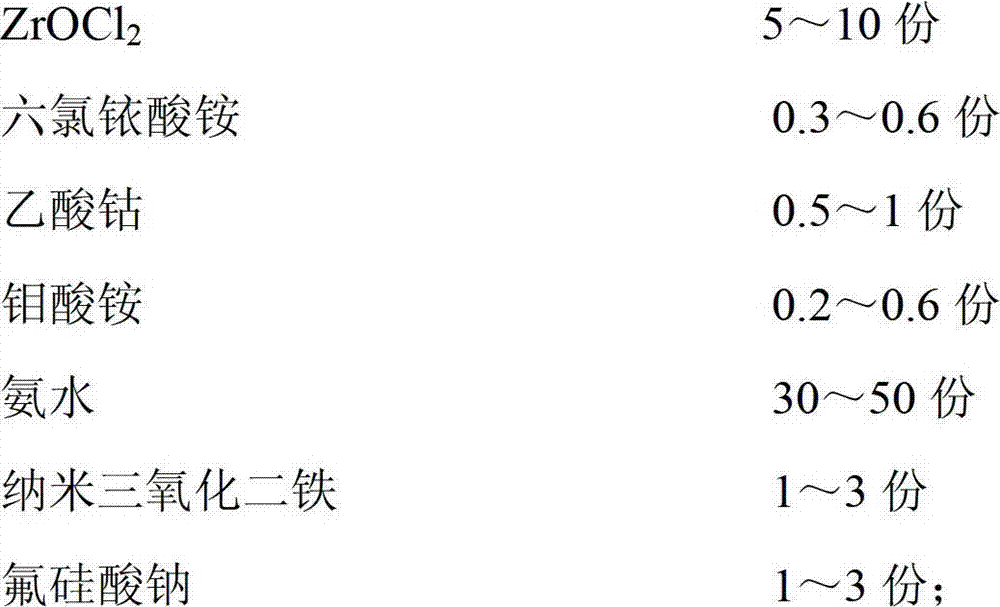

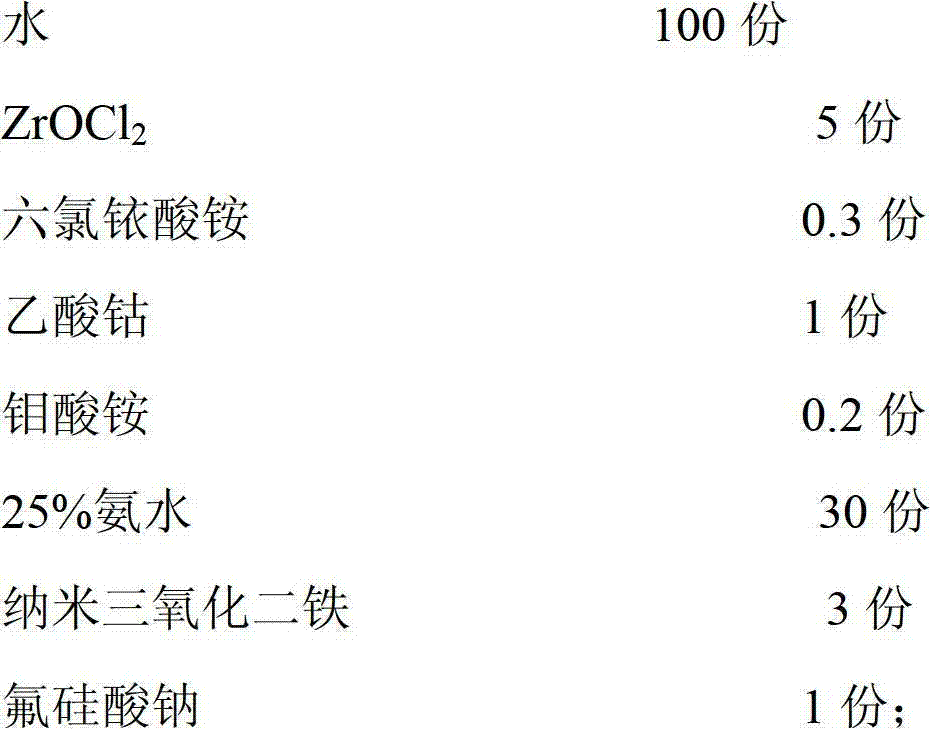

SO4<2->/ZrO2-Fe2O3-SiO2 doped mixed-crystal solid acid and preparation method thereof

The invention discloses a SO4<2-> / ZrO2-Fe2O3-SiO2 doped mixed-crystal solid acid and a preparation method thereof. The preparation method comprises the following steps: (1) dropwisely adding ammonia in an aqueous solution of ZrOCl2, ammonium hexachloroiridate, cobaltous acetate and ammonium molybdate, then adding nano ferric oxide, dispersing, after a spacing interval of 1 hour, adding sodium fluosilicate, preserving the heat, standing, filtering, collecting precipitates, washing the precipitates and drying; and (2) dipping the product obtained by the step (1) in an ammonium chloroplatinate solution, then roasting, dipping the roasted article in a sulfuric acid solution, and then roasting again to obtain the SO4<2-> / ZrO2-Fe2O3-SiO2 doped mixed-crystal solid acid. According to the invention, the strength of the acid can be significantly raised, the acid site amount is stabilized and increased, the reuse effect is good, and the solid acid disclosed herein is an ideal acid catalyst for high-molecular polymerization, addition reaction, cracking reaction, esterification reaction, etherification reaction, etc.

Owner:润桐(苏州)技术服务有限公司

Novel colored and fragrant firecracker

The invention discloses a novel colored and fragrant firecracker which is prepared from the following components in parts by weight: 50-70 parts of potassium perchlorate, 1-3 parts of acetylene black, 5-9 parts of ammonium chloroplatinate, 8-15 parts of magnesium powder, 7-15 parts of aluminum powder, 5-10 parts of titanium white, 6-10 parts of iron powder, 5-15 parts of aged folium artemisiae argyi powder, 6-25 parts of Artemisia santonica powder, 8-16 parts of strontium carbonate, 2-6 parts of phenol formaldehyde resin, 2-6 parts of polyvinyl chloride, 4-12 parts of strontium nitrate, 9-30 parts of sulfur, 1-6 parts of shellac, 10-50 parts of barium nitrate, 10-50 parts of calcium nitrate, 2-5 parts of sodium nitrate, 0.5-1 part of rosin, 2-25 parts of antimony sulfide, 1-3 parts of vegetable oil and 15-35 parts of hard charcoal powder. The invention has the advantages of reasonable product formula, high safety performance and favorable explosion effect, and integrates fireworks and crackers; after the firecracker is ignited, the firecracker can generate dual effects of fireworks and crackers, has beautiful colors and fragrant smell, and can last for a long time.

Owner:李辉

ZnO modified all-silicon zeolite molecular sieve supported Pt catalyst, preparation method and application

ActiveCN108816271AIncrease acidityStrong sulfur resistanceHydrocarbon by isomerisationMolecular sieve catalystsIsomerizationDehydrogenation

The invention discloses a preparation method of a ZnO modified Silicalite-1 zeolite molecular sieve supported Pt catalyst. The preparation method comprises the following steps: immersing a Silicalite-1 Zeolite molecular sieve in a zinc salt aqueous solution, and performing drying and roasting to obtain a ZnO / Silicalite-1 support; immersing the ZnO / Silicalite-1 support in a chloroplatinic acid or ammonium chloroplatinate aqueous solution, and performing drying and roasting to obtain the ZnO modified Silicalite-1zeolite molecular sieve supported Pt catalyst. The reforming catalyst prepared withthe method has an acid center and a metal active center required for aromatization of paraffins, and paraffin can be subjected to dehydrogenation, isomerization, cyclization and other processes for generation of arene under dual-function synergistic action of metal and acid. Pt particles have better sulfur resistance due to strong interaction between the Pt particles and ZnO clusters.

Owner:DALIAN UNIV OF TECH

Platinum refining process

InactiveCN109234528AOvercome calcinationOvercome solubilityProcess efficiency improvementSodium chlorateSodium metabisulfite

The invention relates to a platinum refining process, which comprises the following steps that deionized water is added into crude ammonium chloroplatinate; pulpifying is performed to obtain pulpifiedliquid; after the pulpified liquid is heated, sodium metabisulfite is added into the pulpified liquid in a stirring state; continuous stirring is performed; heat insulation reaction is performed until the ammonium chloroplatinate is completely dissolved; first reaction liquid obtained through reaction is cooled and filtered; filtering liquid obtained through filtering is heated; then, hydrochloric acid and sodium chlorate are sequentially added under the stirring state; continuous stirring is performed; heat insulation reaction is performed until the ammonium chloroplatinate is completely separated out; second reaction liquid obtained through reaction is cooled; ammonium chloride is added; stirring is performed until the ammonium chloride is dissolved; then, filtering is performed; filterslag obtained through filtering is washed by a hydrochloric acid-ammonium chloride solution; then, the first to third steps are repeated for 2 to 3 times; pure ammonium chloroplatinate is obtained; calcination is performed; spongy platinum can be obtained. The sodium pyrosulfite is used for reduction; the ammonium chloroplatinate is dissolved; a series of problems of ammonium chloroplatinate calcination, royal water dissolution and denitration processes in the prior art can be solved.

Owner:JINGCHU UNIV OF TECH

Method for recovering and refining platinum from crude ammonium chloroplatinate

InactiveCN110964920ANo wasteShort processing cycleProcess efficiency improvementFractional PrecipitationSodium chlorate

The invention discloses a method for recovering and refining platinum from crude ammonium chloroplatinate. The crude ammonium chloroplatinate is slurried, hydrochloric acid and sodium chlorate are added, and a mixed solution is obtained; the mixed solution is boiled and kept for a fixed time, ammonium chloride is added, the mixed solution is cooled and filtered, and high-purity ammonium chloroplatinate is obtained; the high-purity ammonium chloroplatinate is slurried, the pH value is adjusted to 8-9 and heating is carried out, hydrazine hydrate is added for reduction, and a platinum element isobtained; the platinum element is dissolved with hydrochloric acid and hydrogen peroxide to obtain a dissolving solution; the dissolving solution is precipitated by adopting an ammonium chloride fractional precipitation method to obtain ammonium chloroplatinate, and the ammonium chloroplatinate obtained in the first step is calcined to obtain sponge platinum; and the sponge platinum is subjectedto deoxygenation treatment, washing and drying to obtain a sponge platinum product. According to the method, impurity elements in the crude ammonium chloroplatinate are removed by adopting an aqueoussolution chlorination method, the ammonium chloroplatinate is refined by reduction of hydrazine hydrate, dissolution of hydrogen peroxide and hydrogen peroxide and fractional precipitation of ammoniumchloride to obtain sponge platinum, and the whole process period is short.

Owner:JINGMEN GEM NEW MATERIAL

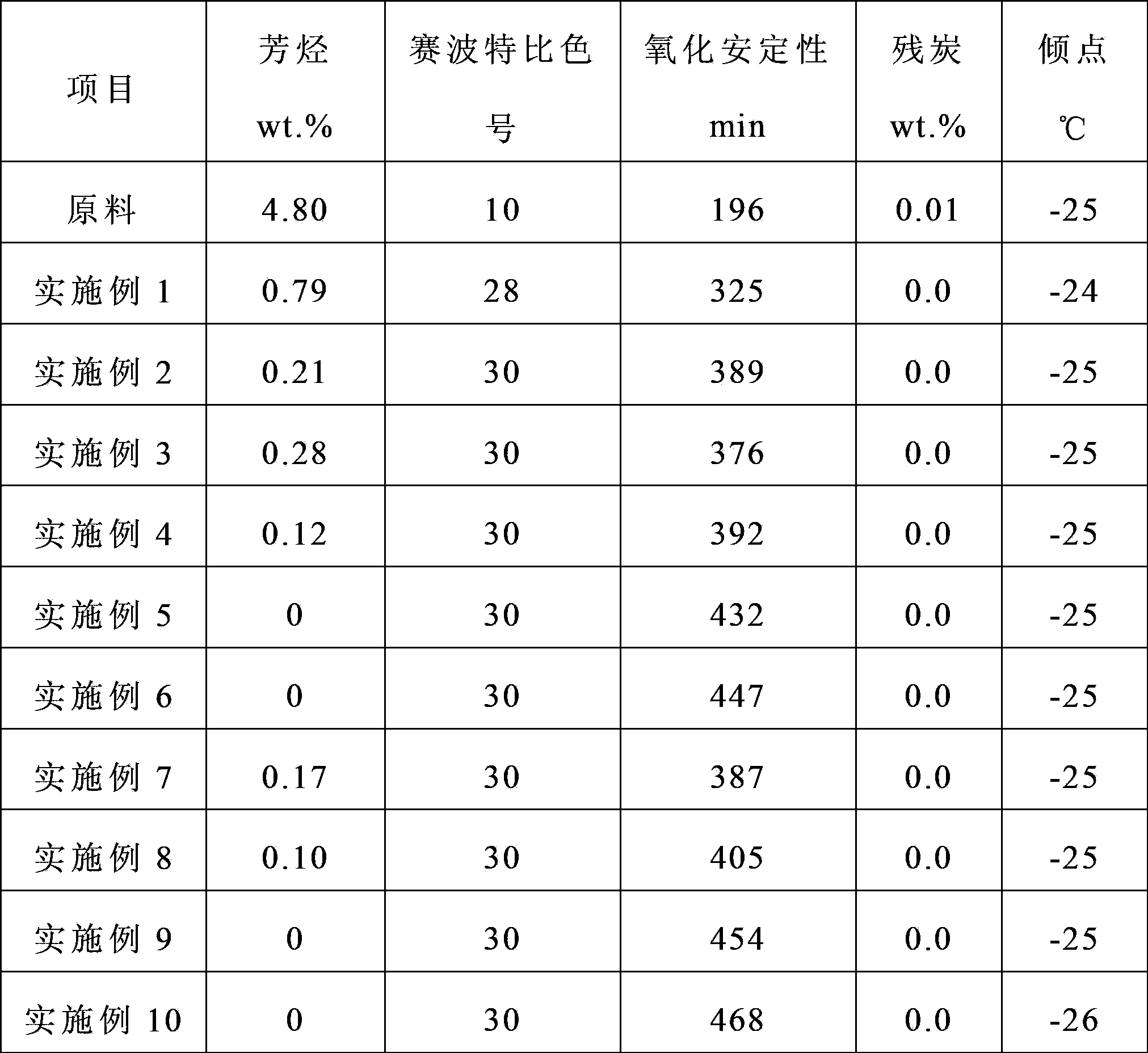

Method for deep hydrofinishing of lubricant base oil

ActiveCN103897728AGood aromatic saturationImprove performanceMolecular sieve catalystsMetal/metal-oxides/metal-hydroxide catalystsPotassiumSilicon oxide

The invention relates to a method for deep hydrofinishing of lubricant base oil. Based on the base oil produced by adopting a hydrogenation process, or using the base oil isodewaxed by hydrogenation as a raw material, the lubricant base oil with light and heat stability is produced. A catalyst comprises the following components in percent by weight: 40.0-99.9 percent of aluminum oxide, 0.0-60.0 percent of silicon oxide, and 0.1-1.0 percent of platinum and / or palladium; the aluminum oxide is selected from modified gamma-aluminum oxide and modified amorphous silica and alumina, the silicon oxide is selected from amorphous silica and alumina, platinum is selected from one or more of chloroplatinic acid, potassium chloroplatinate, ammonium chloroplatinate and sodium chloroplatinate, and palladium is selected from one or more of palladium chloride, palladium sulfate, ammonium tetrachloropalladate and potassium chloropalladite. According to the method, through deep hydrofinishing of the base oil produced by using a hydrogenation process, or aromatic hydrocarbon and olefin in the lubricant base oil isodewaxed by hydrogenation, the oxidation stability and light stability of a product are improved, the color of an oil product is improved, and the pour point of the product is not increased.

Owner:PETROCHINA CO LTD +1

Method for recovering refined platinum from crude ammonium chloroplatinate

The invention discloses a method for recovering refined platinum from crude ammonium chloroplatinate. The method is carried out according to the following steps of slurrying the crude ammonium chloroplatinate, carrying out heating and adding hydrochloric acid and sodium chlorate to obtain a mixed solution; boiling the mixed solution, adding ammonium chloride, and carrying out filtering after the mixed solution is cooled to obtain the high-purity ammonium chloroplatinate; slurrying the ammonium chloroplatinate, adjusting the pH value to 8-9, and adding hydrazine hydrate to obtain platinum elements; dissolving the platinum elements by using the hydrochloric acid and hydrogen peroxide to obtain a dissolving solution containing the platinum elements; precipitating the dissolving solution by adopting an ammonium chloride fractional precipitation method to obtain the ammonium chloroplatinate, and calcining the ammonium chloroplatinate to obtain sponge platinum; and finally, introducing oxygen into the sponge platinum, then introducing chlorine, carrying out the heating reaction, and heating and decomposing the product under an inert atmosphere, then introducing reducing gas under the inert atmosphere, and keeping constant temperature until the reaction is complete to obtain the metal platinum. According to the method, the ammonium chloroplatinate is refined to obtain the sponge platinum by adopting the hydrazine hydrate reduction-hydrochloric acid and hydrogen peroxide dissolving-ammonium chloride fractional precipitation method, and the whole process period is short.

Owner:JINGMEN GEM NEW MATERIAL

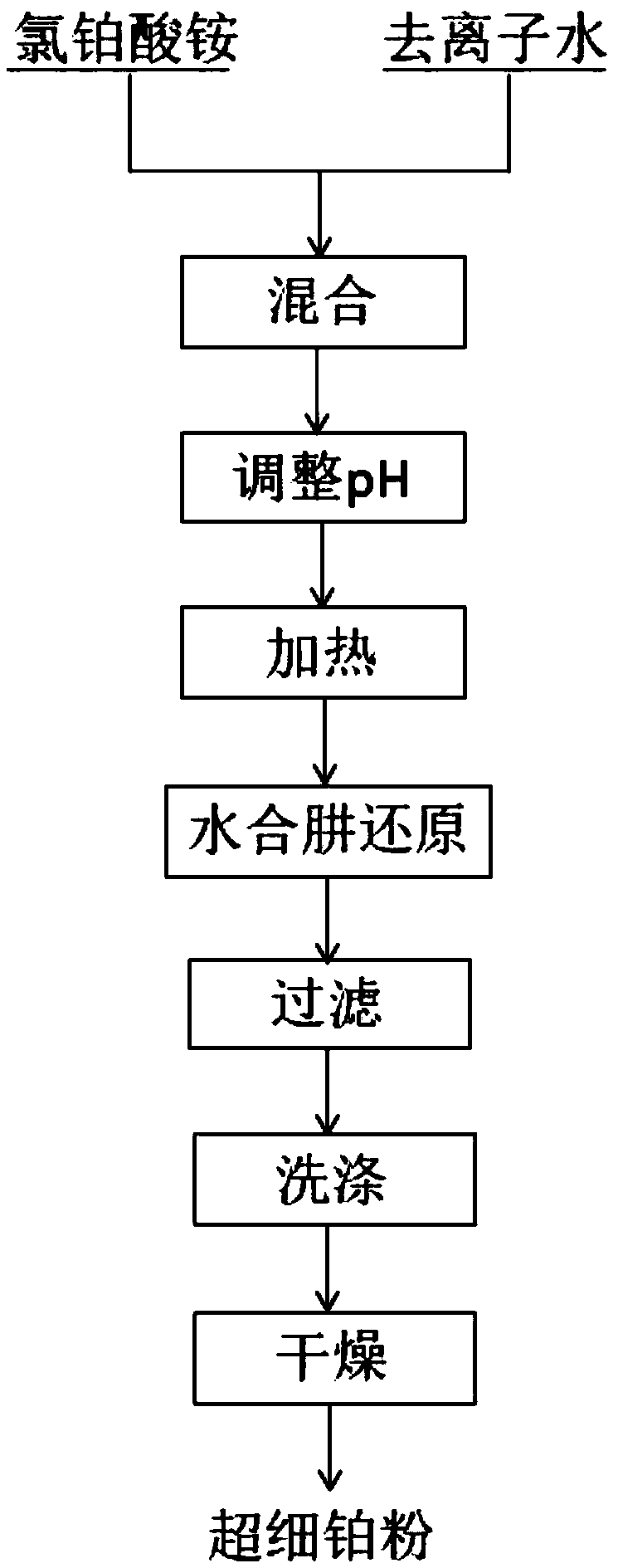

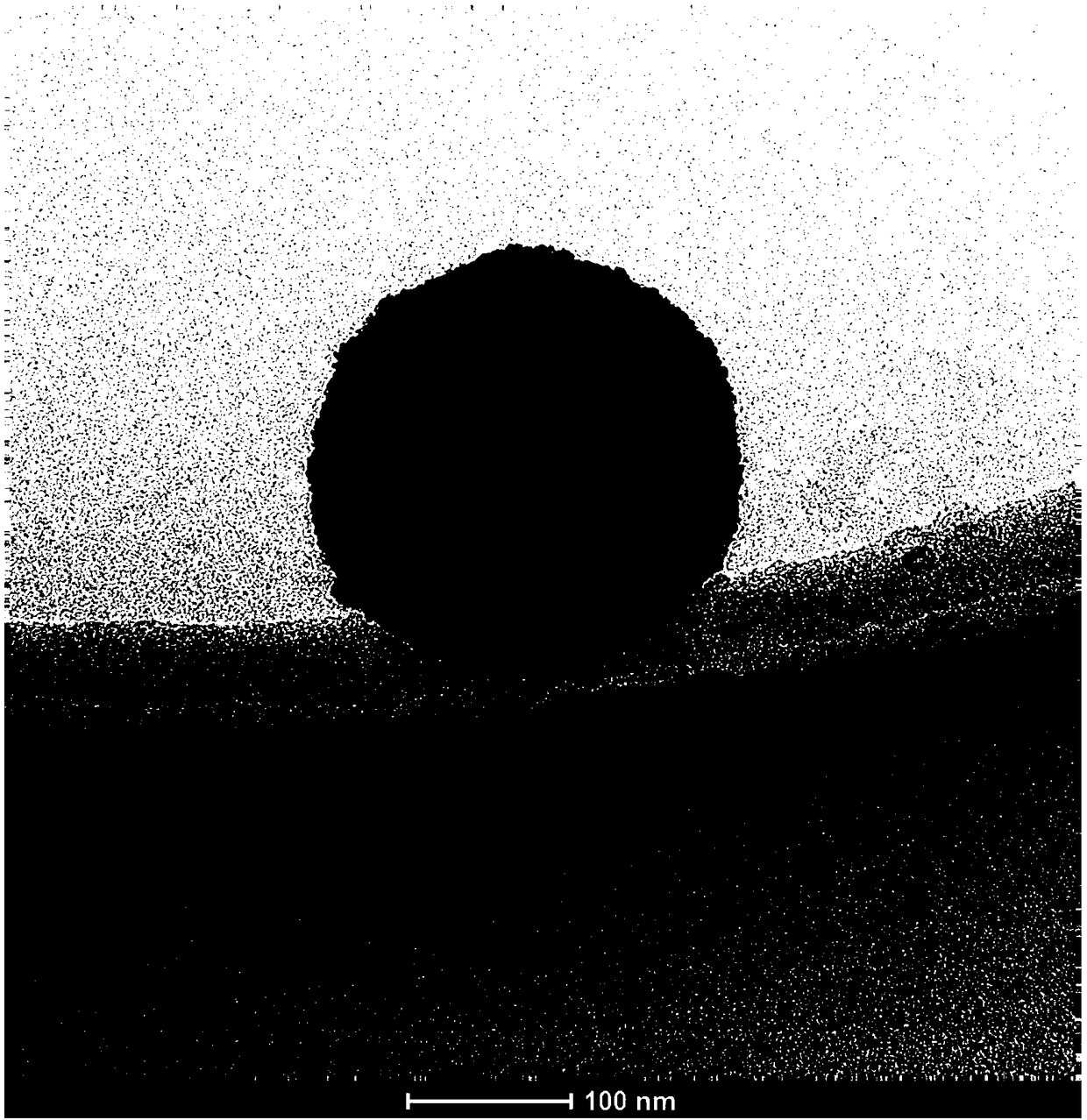

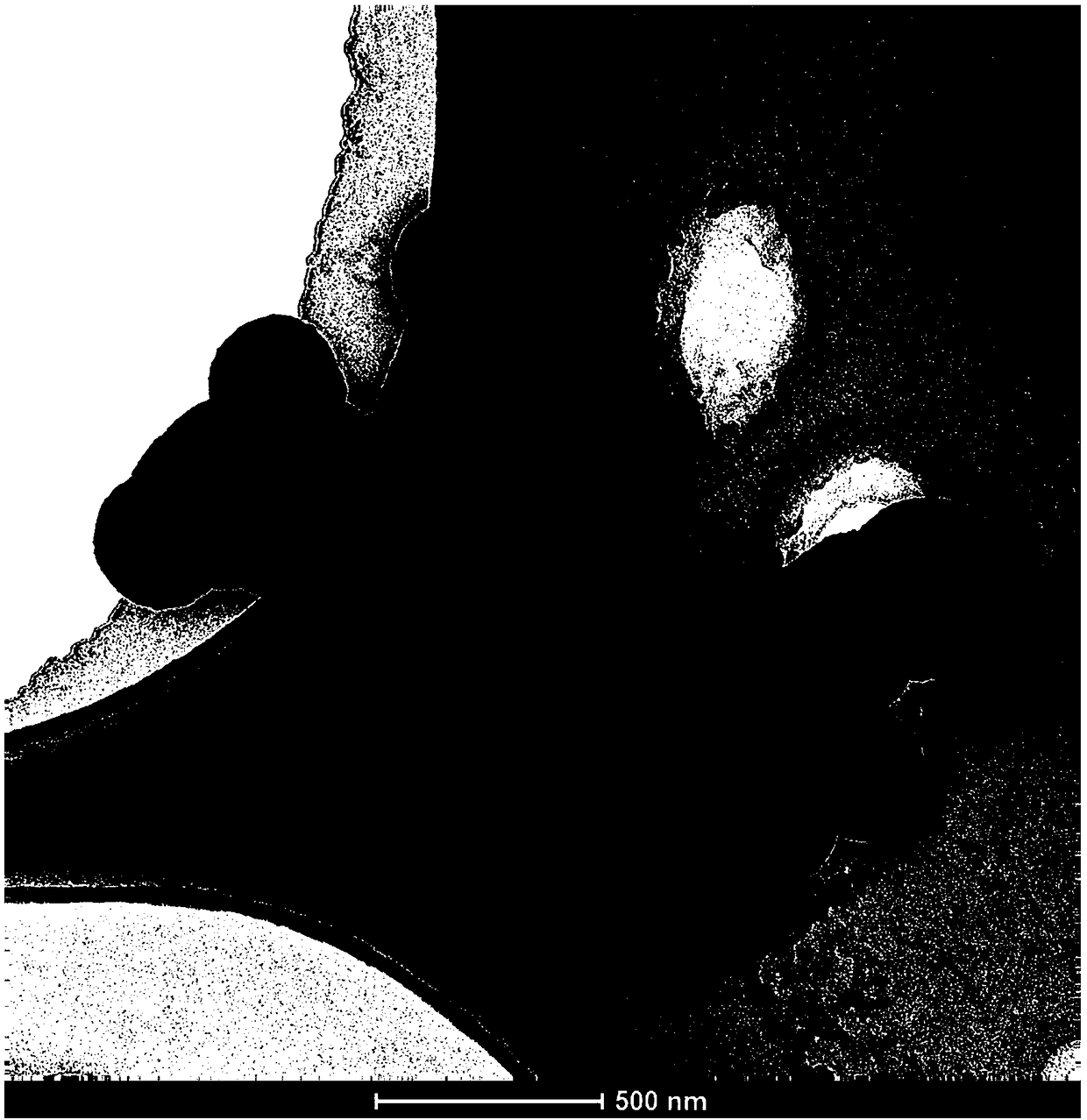

Method for short process preparation of superfine platinum powder

The invention discloses a method for short process preparation of superfine platinum powder. Specifically, a certain amount of ammonium chloroplatinate solid is weighed, deionized water is added, andthe specific value of the volume of the deionized water to the mass of the ammonium chloroplatinate solid is (10-20):1 (ml / g); aqueous alkali is used for adjusting the aqueous phase pH to be 4-8; a hydrazine hydrate solution with the mass fraction being 40% is weighed, attenuation is carried out to enable the mass fraction to be 20%, and the solution obtained after attenuation is used as a reducing agent for standby application, and the using amount of the hydrazine hydrate is 2-4 times the theoretical using amount of reducing platinum; heating is carried out, and the system temperance is maintained to be 40-50 DEG C; under the stirring condition, a reducing agent is dropwise added into a platinum containing water phase slowly, the aqueous alkali is used for adjusting the aqueous phase pHin the phase, and the pH value is maintained to be 4-8; after the reducing agent is completely added, stirring is carried out for 0.5-1 h; and the superfine platinum powder is obtained after filtering, washing and drying. According to the method, a solid phase reduction method is adopted, the ammonium chloroplatinate solid is restored directly, meanwhile, the superfine platinum powder with the small prepared size can be prepared under the condition that a dispersing agent is not added, the technology is simple, and the flow is short.

Owner:XUZHOU GUOMAO VALUABLE & RARE METAL COMPREHENSIVE UTILIZATION INST +1

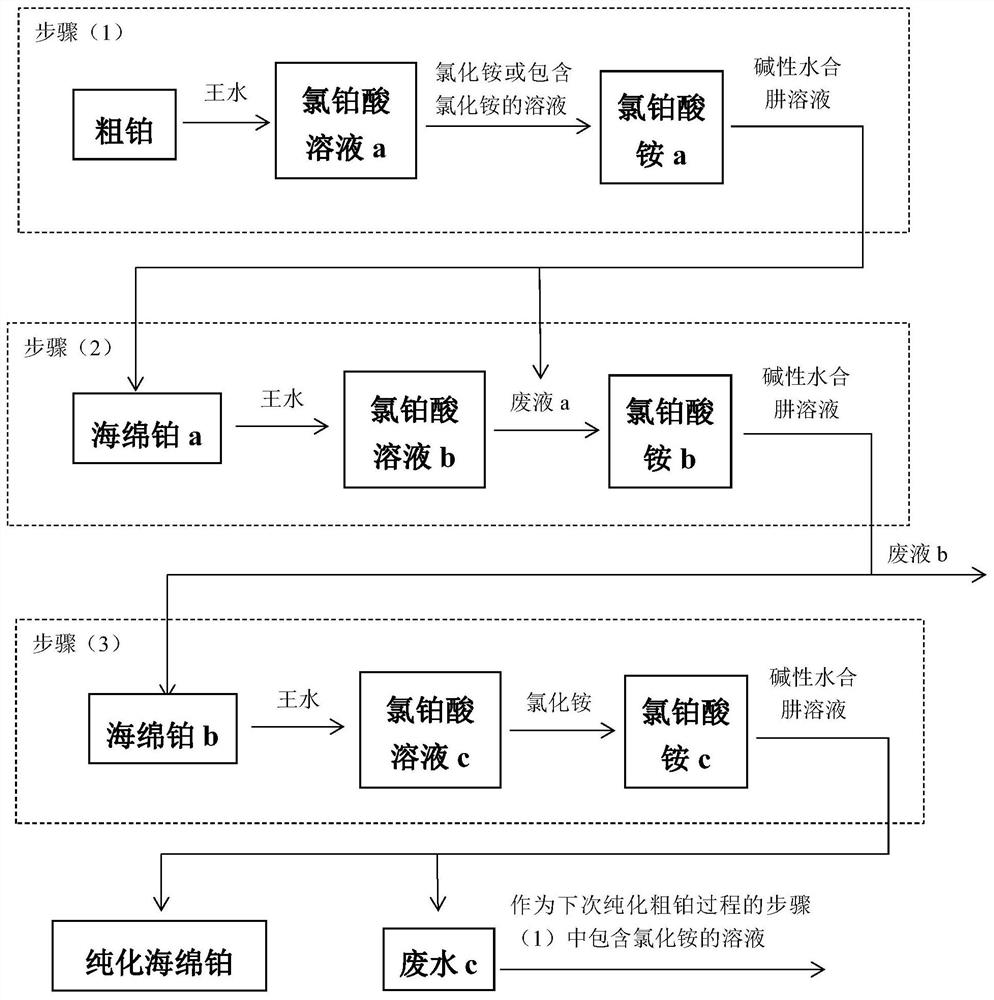

Recycling method of ammonium chloroplatinate reduction waste liquid

InactiveCN113061743AReduce purification costsReduce processing costsProcess efficiency improvementAlkaline waterEnvironmental engineering

The invention relates to the technical field of platinum metal purification, and particularly discloses a recycling method of ammonium chloroplatinate reduction waste liquid. The recycling method sequentially comprises the following steps that (1) crude platinum is dissolved with aqua regia to obtain a chloroplatinic acid solution a, precipitating is carried out with ammonium chloride or a solution containing ammonium chloride to obtain ammonium chloroplatinate a, and then reducing is carried out with an alkaline hydrazine hydrate solution to obtain sponge platinum a and wastewater a; (2) sponge platinum a is dissolved with aqua regia to obtain a chloroplatinic acid solution b, precipitating is carried out with wastewater a to obtain ammonium chloroplatinate b, and reducing is carried out with an alkaline hydrazine hydrate solution to obtain sponge platinum b and wastewater b; and (3) the sponge platinum b is dissolved with aqua regia to obtain a chloroplatinic acid solution c, ammonium chloride is used for precipitation to obtain ammonium chloroplatinate c, then an alkaline hydrazine hydrate solution is used for reduction to obtain purified sponge platinum and waste water c, wherein the waste water c can be used as the solution containing ammonium chloride in the step (1) of a next crude platinum purification process. According to the method, a large amount of ammonium chloride contained in the reduction waste liquid is fully utilized, and the wastewater treatment cost is saved.

Owner:深圳市金正龙科技有限公司

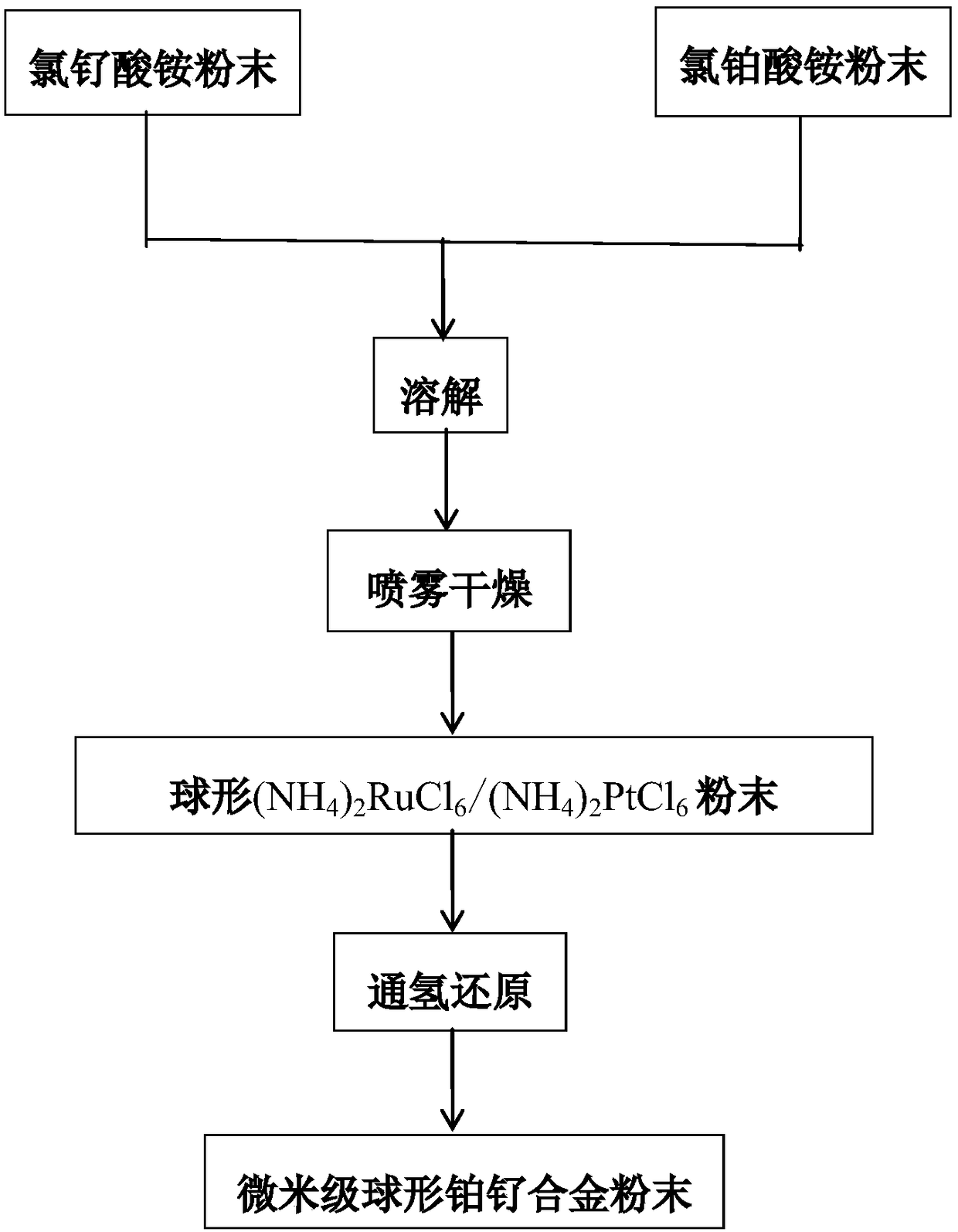

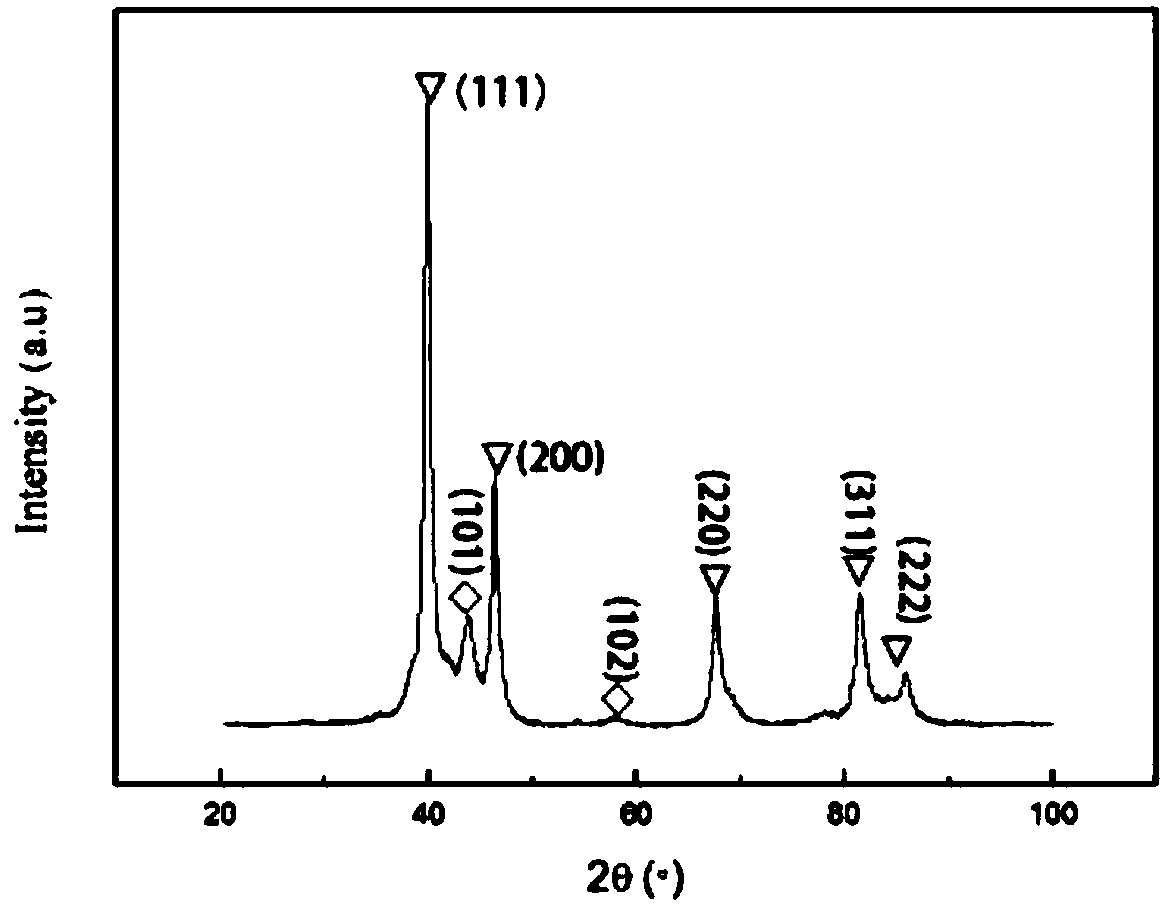

Preparation method of micron-grade spherical Pt-Ru alloy powder

The invention discloses a preparation method of micron-grade spherical Pt-Ru alloy powder. The particle size range of the prepared micron-grade Pt-Ru alloy powder is 1-4 [mu]m, the average size of particles is 2.5 [mu]m, and the specific surface range of the Pt-Ru alloy powder is 0.1-42 m<2> / g. Ammonium chloroplatinate [(NH4)2PtCl6] and diammonium hexachlororuthenate [(NH4)2RuCl6] are adopted as precursors of the platinum and ruthenium alloy powder, through combining of spray drying and hydrogen-leading reduction, the micron-grade Pt-Ru alloy powder is prepared. Through spray drying and hydrogen-leading reduction, the Pt-Ru alloy powder with the average size being about 2.5 [mu]m is prepared, the preparation process is simple in technology and high in operability, and meanwhile leading-inof impurities is also avoided.

Owner:SINO PLATINUM METALS CO LTD

Method for preparing high-purity platinum on basis of microbial adsorption

InactiveCN111321308ASimple preparation processEasy to implementProcess efficiency improvementIon exchangeMicrobiology

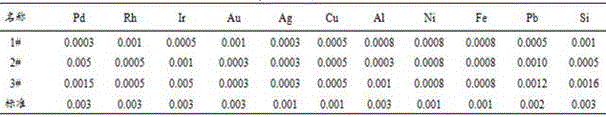

The invention discloses a method for preparing high-purity platinum on basis of microbial adsorption, and belongs to the technical field of preparation of high-purity precious metals. According to themethod, the high-purity platinum is prepared with the technology combining impurity removal methods of microbial selective adsorption, hydrochloric acid desorption, ion exchange, ammonium chloroplatinate precipitation and the like with calcined hydrogen reduction. The method includes the following steps of (1) microbial selective adsorption, (2) desorption separation of platinum, (3) ammonium chloride precipitation of the platinum, (4) calcination and (5) acid cooking for removal of impurities. According to the method, the preparation technological process is simple, the method is easy to implement, a microbial adsorption agent can be recycled, the preparation process is clean, environment-friendly and pollution-free, preparation conditions are mild, the cost is low, and the obtained high-purity platinum has the purity being 99.999% or above, has the impurity content lower than 10 ppm and is applicable in the fields of electronic industries, high-purity precious metal materials and the like.

Owner:SINO PLATINUM METALS CO LTD

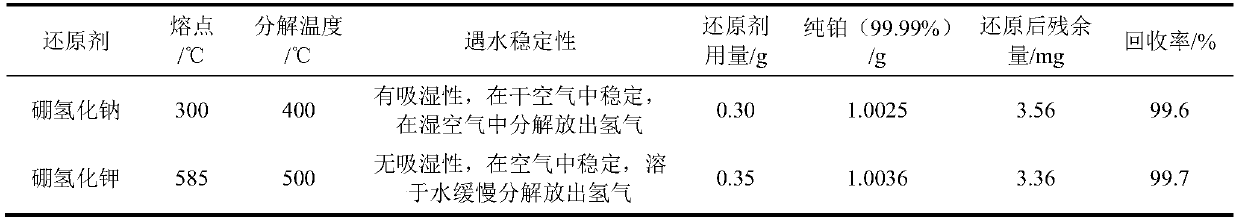

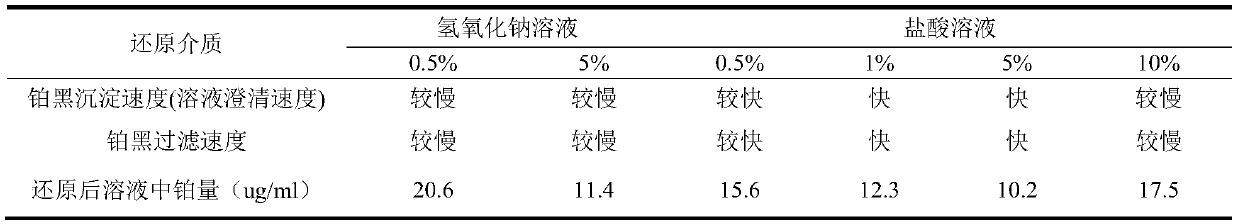

Method for recovering platinum from laboratory waste noble metal material through potassium borohydride-ammonium chloride reduction

ActiveCN111455184AAvoid wastingAvoid lostProcess efficiency improvementPotassium borohydrideNitric oxide

The invention discloses a method for recovering platinum from a laboratory waste noble metal material through potassium borohydride-ammonium chloride reduction. The method for recovering the platinumthrough a potassium borohydride reduction-ammonium chloride precipitation method by taking a laboratory platinum-containing waste consumable as a raw material is researched and established. Nitric acid is adopted to separate impurity elements, the platinum is dissolved in aqua regia, nitric oxide is repeatedly expelled with hydrochloric acid, and the platinum is fully converted into chloroplatinicacid. The method comprises the following steps of reducing the chloroplatinic acid into platinum black by using potassium borohydride in a 40 DEG C and 5% (V / V) hydrochloric acid medium, then dissolving the platinum black by using the aqua regia, completely converting the platinum black into chloroplatinic acid, forming yellow ammonium chloroplatinate precipitate by using the chloroplatinic acidand excessive ammonium chloride, and performing aging and overnighting; and performing drying by using a segmented slow heating firing method, and decomposing the ammonium chloroplatinate to obtain pure loose platinum powder or dense metal platinum. The method is low in cost and easy and convenient to operate, and residual platinum ions in the two precipitation solutions are smaller than 20 ug / mL,the purity of the recovered platinum is not less than 99.5%, and the recovery rate is greater than 99%.

Owner:河南省岩石矿物测试中心

Purification method for crude ammonium chloroplatinate

The invention discloses a purification method for crude ammonium chloroplatinate. The purification method comprises the specific steps of S1, pulpifying crude ammonium chloroplatinate, heating the crude ammonium chloroplatinate, adding hydrochloric acid and sodium chlorate, and stirring the mixture to obtain a mixed solution; S2, boiling the mixed solution and keeping the temperature for a fixed time, adding ammonium chloride, and filtering the solution after the mixed solution is cooled to obtain high purity ammonium chloroplatinate and a filtrate; and S3, adjusting the pH value of the filtrate to 8-9 and heating the filtrate, and adding hydrazine hydrate to reduce the filtrate to recover gold, palladium and tellurium. Impurity elements such as gold, palladium and tellurium in the crude ammonium chloroplatinate are removed by adopting a water solution chlorination process, and the process is simple and feasible.

Owner:JINGMEN GEM NEW MATERIAL

Novel process for purifying high-purity platinum

PendingCN114317997ASimple processHigh purityProcess efficiency improvementSulfite saltMaterials science

The invention provides a novel process for purifying high-purity platinum. The novel process comprises the following steps: 1, dissolving metal platinum to prepare a solution; 2, preparing the platinum solution into a precipitate: adding solid ammonium chloride to obtain an ammonium chloroplatinate precipitate; 3, dissolving the precipitate: adding water into the ammonium chloroplatinate precipitate for slurrying, and adding ammonium oxalate to obtain filtrate; 4, re-precipitating: adjusting the acidity of the filtrate with hydrochloric acid, and adding hydrogen peroxide to obtain ammonium chloroplatinate precipitate; 5, calcining: calcining the ammonium chloroplatinate to obtain metal platinum; and 6, ingot casting: heating and melting the metal platinum, and pouring into a cooling tank for ingot casting. According to the method, potassium sulfite or sodium sulfite in the original process is replaced with ammonium oxalate and ammonium chloride, ammonium is separated from metal platinum in the form of ammonia gas after calcination, the purity is improved, the process is simplified, time and cost are saved, and efficiency is improved.

Owner:深圳市博远贵金属科技有限公司

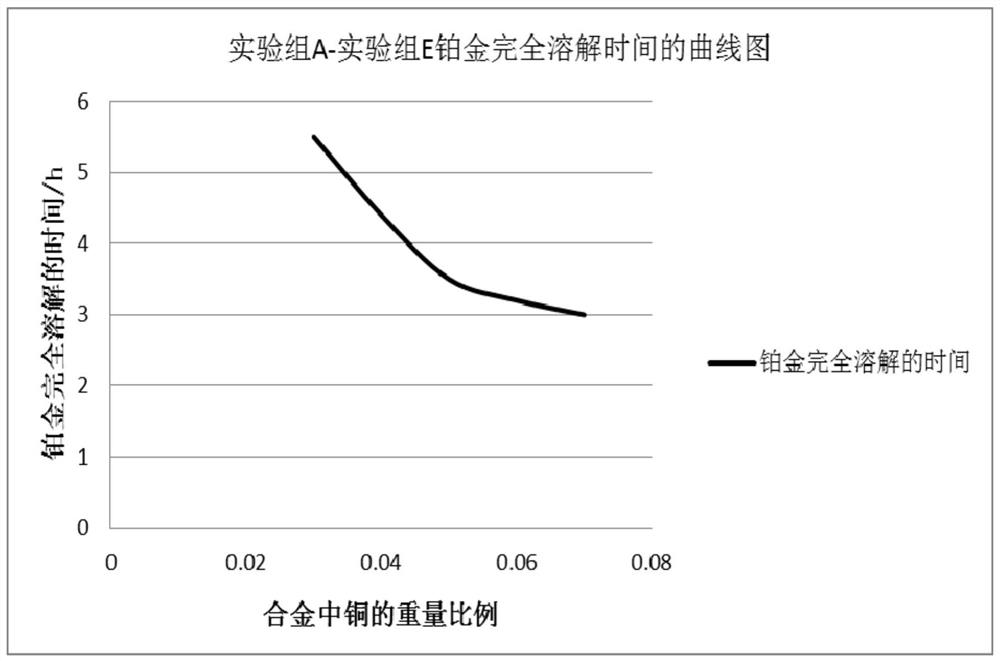

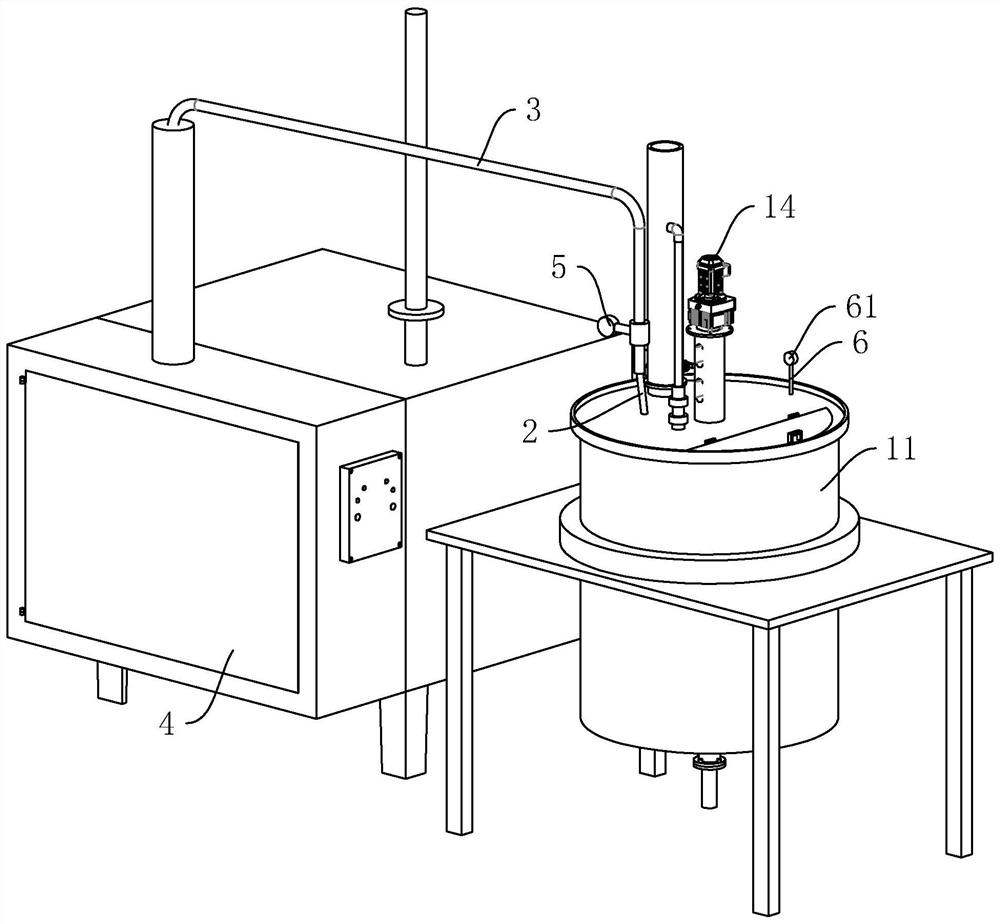

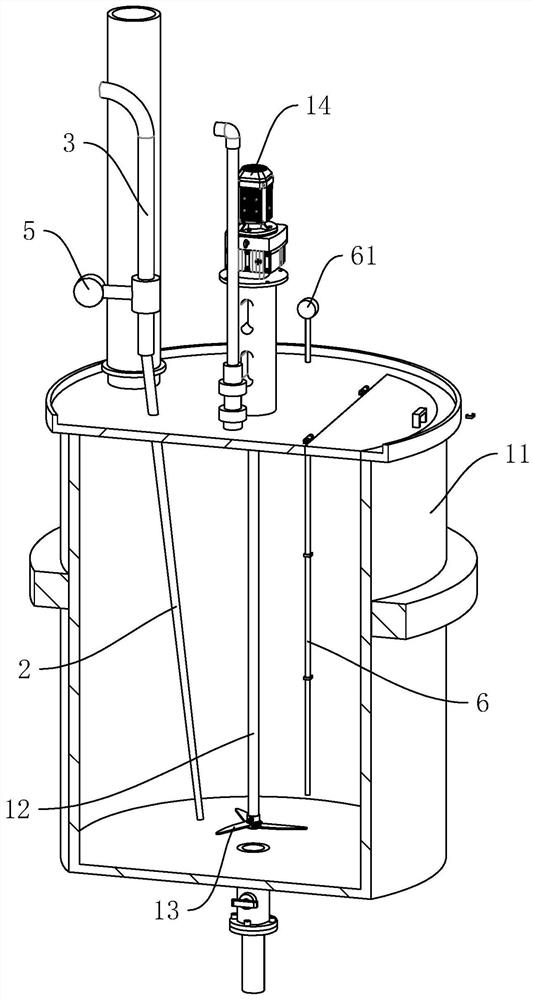

Platinum purification method and reaction kettle

InactiveCN111690819ALarge specific surface areaHigh purityChemical/physical/physico-chemical stationary reactorsDissolution reactionAqua regia

The invention relates to a platinum purification method and a reaction kettle. The problem that in an existing platinum purification technology, the recovery rate of platinum and the purity of spongyplatinum are not easily balanced is solved. The platinum purification method comprises the following steps that a platinum ingot and base metal are mixed together, molten to form liquid gold and processed to form gold grains; the gold grains and aqua regia are added to a dissolution reaction kettle, stirred and heated to enable the gold grains to be dissolved, and dissolved platinum liquid is obtained; the dissolved platinum liquid is added to a separation reaction kettle, ammonium chloride is added, and stirring operation and heating operation are conducted so that platinum ions in a solutioncan be deposited to form ammonium chloroplatinate; residual liquid in the separation reaction kettle is filtered away, the deposited ammonium chloroplatinate is washed and filtered by an ammonium chloride solution; and a reducing agent and the washed deposited ammonium chloroplatinate are added to the separation reaction kettle, ammonium chloroplatinate is reduced, and the pure spongy platinum isobtained, specifically, the weight ratio of the content of platinum in the platinum ingot to ammonium chloride is 1:(1-1.7). The platinum purification method has the advantages of saving the cost andbeing high in platinum primary recovery rate and high in purity of the spongy platinum.

Owner:广东金正龙科技有限公司

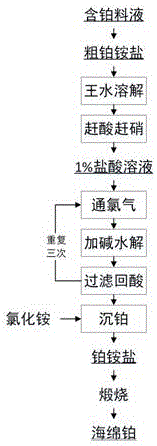

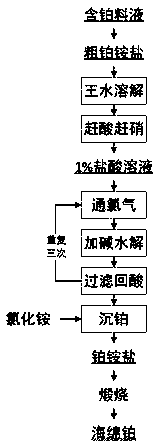

A platinum refining process

The invention relates to a platinum refining process. The platinum refining process comprises the following steps: (1) dissolving various platinum containing feed liquids and a coarse platinum ammonium salt, and performing filtration after brushing away acids and denitrating; (2) throwing the filtrate into a reaction kettle, introducing chlorine for hydrolyzing while raising the temperature, and stopping introducing chlorine when the potential is increased to over 1000mV; (3) adding a caustic soda liquid while stirring to adjust the pH value, and directly cooling and filtering the mixture when the pH=8-9 is stabilized for more than 5min, wherein the filtrate is orange; (4) returning acid from the filtrate, repeating the steps 2 and 3 three times, finally returning acid from post-hydrolyzed liquids obtained in three times to control the acidity of the feed liquids, adding a saturated ammonium chloride solution after boiling to precipitate platinum, and then cooling and filtering the mixture after boiling; and (5) calcining ammonium chloroplatinate obtained at 680 DEG C to obtain sponge platinum. The platinum refining process provided by the invention has the beneficial effects that 1, the production period is shortened by more than 40%; 2, denitrating is reduced by at least one time, so that the capacity is favorably enhanced and the environment is favorably improved; and 3, the direct yield of platinum is improved by 1.94%.

Owner:JINCHUAN GROUP LIMITED

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com