Preparation method of high-purity platinum powder

A platinum powder and high-purity technology is applied in the field of preparation of high-purity platinum powder, and achieves the effects of simple preparation method, low energy consumption and good removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

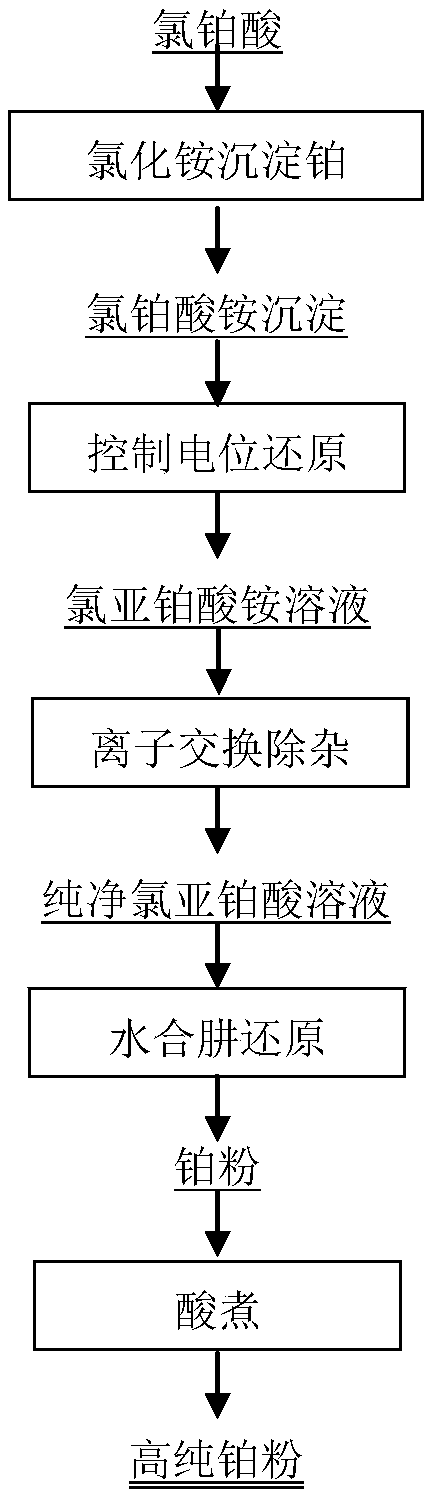

[0015] Embodiment 1, see attached figure 1 , Ammonium chloride is added to the chloroplatinic acid solution to generate ammonium chloroplatinate precipitate, which is filtered and washed; the generated ammonium chloroplatinate precipitate is made into a suspension with deionized water, and then sulfurous acid is slowly added, wherein sulfurous acid and chlorine The molar ratio of ammonium platinate is 1.2, and the solution potential is controlled at 0.68±0.2V throughout the process, so that the ammonium chloroplatinate is reduced to soluble ammonium chloroplatinite, and the insoluble matter is filtered out, and the ammonium chloroplatinate solution is passed through a three-stage 001×7 ion exchange resin column to remove impurity ions; to obtain pure chloroplatinous acid solution, add superior grade pure hydrazine hydrate to this solution, wherein the molar ratio of hydrazine hydrate to chloroplatinous acid is 3, fully reduce, Platinum powder is obtained, and the platinum powd...

Embodiment 2

[0016] Embodiment 2, see attached figure 1 , Ammonium chloride is added to the chloroplatinic acid solution to generate ammonium chloroplatinate precipitate, which is filtered and washed; the ammonium chloroplatinate precipitate is made into a suspension with deionized water, and then sulfurous acid is slowly added, wherein sulfurous acid and chloroplatinic acid The molar ratio of ammonium is 1.2, and the solution potential is controlled at 0.65±0.2V throughout the process to reduce ammonium chloroplatinate to soluble ammonium chloroplatinite, filter out insoluble matter, and pass the ammonium chloroplatinite solution through a three-stage 001×7 ion Exchange resin column to remove impurity ions; obtain pure chloroplatinous acid solution, add superior grade pure hydrazine hydrate to this solution, wherein the mol ratio of hydrazine hydrate to chloroplatinous acid is 4, fully reduce, and obtain platinum powder, The platinum powder was boiled and washed with a mixed dilute soluti...

Embodiment 3

[0017] Embodiment 3, see attached figure 1 , ammonium chloride is added to the chloroplatinic acid solution to generate ammonium chloroplatinate precipitate, which is filtered and washed with saturated ammonium chloride solution; the ammonium chloroplatinate precipitate is made into a suspension with deionized water, and then slowly added oxalic acid, wherein The molar ratio of oxalic acid to ammonium chloroplatinate is 1.2, and the potential of the solution is controlled at 0.70±0.2V throughout the process to reduce the ammonium chloroplatinate to soluble ammonium chloroplatinate, filter out the insoluble matter, and pass the ammonium chloroplatinate solution through three Grade 001×7 ion exchange resin column to remove impurity ions; to obtain pure chloroplatinous acid solution, add superior grade pure hydrazine hydrate to this solution, wherein the molar ratio of hydrazine hydrate to chloroplatinous acid is 5, fully reduce , to obtain platinum powder, the platinum powder wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com