ZnO modified all-silicon zeolite molecular sieve supported Pt catalyst, preparation method and application

A zeolite molecular sieve and catalyst technology, which is applied to molecular sieve catalysts, including molecular sieve catalysts, catalysts and other directions, can solve the problems of poor aromatics selectivity, easy formation of carbon deposits, poor catalyst sulfur resistance, etc., and achieves good aromatics selectivity and less cracked dry gas. , The effect of strong sulfur resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

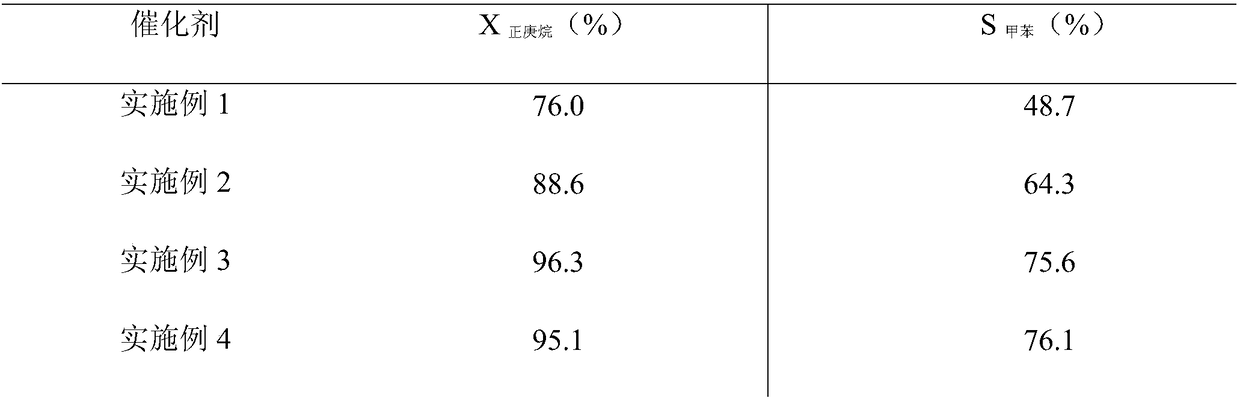

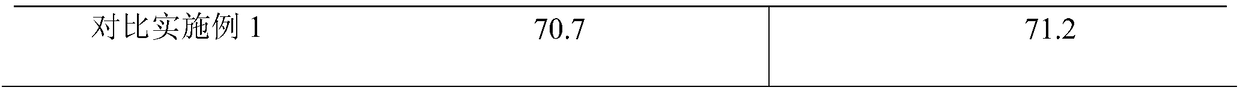

Examples

Embodiment 1

[0046] Preparation of Pt 0.1 -ZnO 1.0 / Silicalite-1 paraffin reforming catalyst (ZnO / Silicalite-1 carrier, ZnO loading is 1.0wt%; Pt-ZnO / Silicalite-1 paraffin reforming catalyst, Pt loading is 0.1wt%)

[0047] (1) Preparation of Synthetic Silicalite-1 Zeolite Molecular Sieve:

[0048] Reference is made to the publication Chin. J. Catal., 2001, 22, 513-514. Tetraethyl orthosilicate (TEOS) and tetrapropylammonium hydroxide (TPAOH) and deionized water in the following molar ratio SiO 2 :0.3TPAOH:30H 2 O mixed, stirred at 60°C for 3h; then placed in a stainless steel hydrothermal kettle for crystallization at 170°C for 24h to obtain the all-silicon S-1 zeolite precursor; further filtered, washed, and then dried in air at 110°C for 12h, 550°C Calcined in air atmosphere for 6h to obtain Silicalite-1 zeolite molecular sieve.

[0049] (2) Preparation of ZnO 1.0 / Silicalite-1 carrier

[0050] First prepare 0.0123mol / L zinc nitrate aqueous solution; then take the dried and roaste...

Embodiment 2

[0054] Preparation of Pt 0.1 -ZnO 3.0 / Silicalite-1 paraffin reforming catalyst (ZnO / Silicalite-1 carrier, ZnO loading is 3.0wt%; Pt-ZnO / Silicalite-1 paraffin reforming catalyst, Pt loading is 0.1wt%)

[0055] Repeat Example 1, but in step (2), zinc nitrate concentration is configured as 0.0369mol / L, obtains the Pt that ZnO content is 3.0Wt%. 0.1 -ZnO 3.0 / Silicalite.

Embodiment 3

[0057] Preparation of Pt 0.1 -ZnO 6.0Silicalite-1 paraffin reforming catalyst (ZnO / Silicalite-1 carrier, ZnO loading is 6.0wt%; Pt-ZnO / Silicalite-1 paraffin reforming catalyst, Pt loading is 0.1wt%)

[0058] Repeat Example 1, but in step (2), zinc nitrate concentration is configured as 0.0738mol / L in the zinc nitrate aqueous solution, obtains the Pt that ZnO content is 6.0Wt%. 0.1 -ZnO 6.0 / Silicalite-1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com