Method for short process preparation of superfine platinum powder

A technology of ultra-fine platinum powder and short process, which is applied in the field of short-process preparation of ultra-fine platinum powder to achieve the effect of simplifying the production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

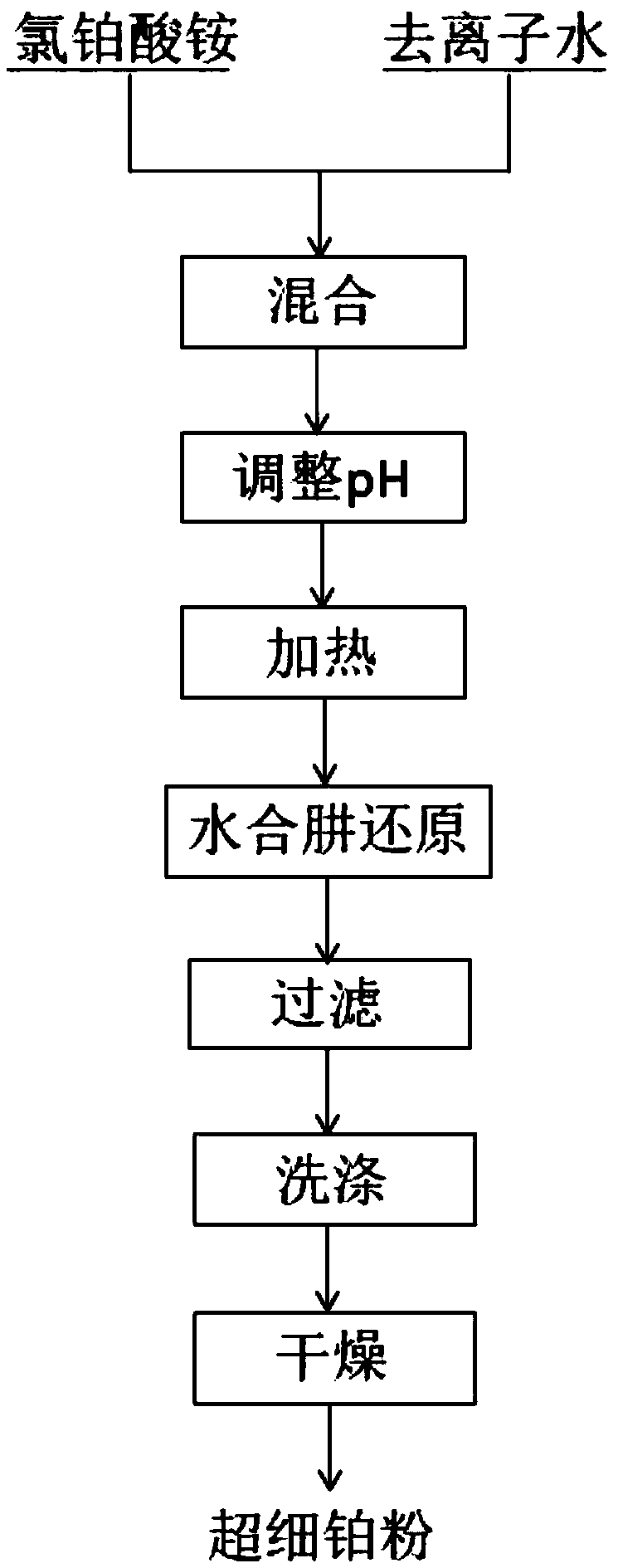

Method used

Image

Examples

Embodiment 1

[0026] A method for preparing superfine platinum powder in a short flow process, specifically comprising the following steps:

[0027] (1) Preparation of platinum-containing aqueous phase: Weigh 30 g of ammonium chloroplatinate solid in a beaker, add 300 ml of deionized water, and stir evenly;

[0028] (2) Adjustment of the pH value of the platinum-containing aqueous phase: adding dropwise a sodium hydroxide solution with a mass fraction of 5% in a stirred state to adjust the pH of the aqueous phase to 8;

[0029] (3) The preparation of reducing agent: take by weighing 33.8g mass fraction and be the hydrazine hydrate solution of 40%, add the deionized water of equal mass, it is diluted to mass fraction and be 20%, standby as reducing agent; The consumption of hydrazine hydrate is 4 times the theoretical amount of reduced platinum;

[0030] (4) Adjustment of the platinum-containing water phase temperature: heating in a water bath to maintain the system temperature at 50°C;

...

Embodiment 2

[0034] A method for preparing superfine platinum powder in a short flow process, specifically comprising the following steps:

[0035] (1) Preparation of platinum-containing aqueous phase: take 30 g of ammonium chloroplatinate solid in a beaker, add 450 ml of deionized water, and stir evenly;

[0036] (2) Adjustment of the pH value of the platinum-containing aqueous phase: adding dropwise a sodium hydroxide solution with a mass fraction of 5% in a stirred state to adjust the pH of the aqueous phase to 6;

[0037] (3) The preparation of reducing agent: take by weighing 25.4g mass fraction and be the hydrazine hydrate solution of 40%, add the deionized water of equal mass, it is diluted to mass fraction and be 20%, standby as reducing agent; The consumption of hydrazine hydrate is 3 times the theoretical amount of reduced platinum;

[0038] (4) Adjustment of the platinum-containing water phase temperature: heating in a water bath to maintain the system temperature at 50°C;

[...

Embodiment 3

[0042] A method for preparing superfine platinum powder in a short flow process, specifically comprising the following steps:

[0043] (1) Preparation of platinum-containing aqueous phase: take 30 g of ammonium chloroplatinate solid in a beaker, add 600 ml of deionized water, and stir evenly;

[0044] (2) Adjustment of the pH value of the platinum-containing aqueous phase: drip an ammonia solution with a mass fraction of 25% under stirring, and adjust the pH of the aqueous phase to 4;

[0045] (3) The preparation of reducing agent: take by weighing 16.9g mass fraction and be the hydrazine hydrate solution of 40%, add the deionized water of equal mass, it is diluted to mass fraction and be 20%, standby as reducing agent; The consumption of hydrazine hydrate is 2 times the theoretical amount of reduced platinum;

[0046] (4) Adjustment of the temperature of the platinum-containing aqueous phase: heating in a water bath to maintain the system temperature at 40°C;

[0047] (5) P...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com