Method for deep hydrofinishing of lubricant base oil

A lubricating oil base oil, supplementary refining technology, applied in chemical instruments and methods, hydrocarbon oil treatment, petroleum industry, etc., can solve the problems of unqualified base oil light stability, achieve excellent light stability, high oxidation stability, Effect of Good Aromatic Saturation Performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Mix the modified γ-alumina carrier powder, additives and water according to the weight ratio of 1:0.15:1, extrude into a clover shape with a diameter of 1.5mm on an extruder, dry at 120°C for 4 hours, and roast at 480°C for 4 hours. A catalyst carrier is obtained. The impregnation solution was prepared according to the platinum content of the catalyst at 0.5 wt.%, and the impregnation method was used to uniformly infiltrate the catalyst carrier, dried at 120°C for 4 hours, and calcined at 480°C for 4 hours to obtain the catalyst. Catalyst properties are listed in Table 1.

[0018] The prepared catalyst is evaluated with real raw materials on the hydrogenation evaluation device. The catalyst needs to be pretreated before use. Pretreatment conditions: pressure 0.1~0.5MPa, temperature 450°C, residence time 4h, hydrogen flow rate 65ml / g min. Catalyst reaction conditions: reaction pressure 12.0MPa, reaction temperature 200°C, volume space velocity 2.0h -1 , The volume rati...

Embodiment 2

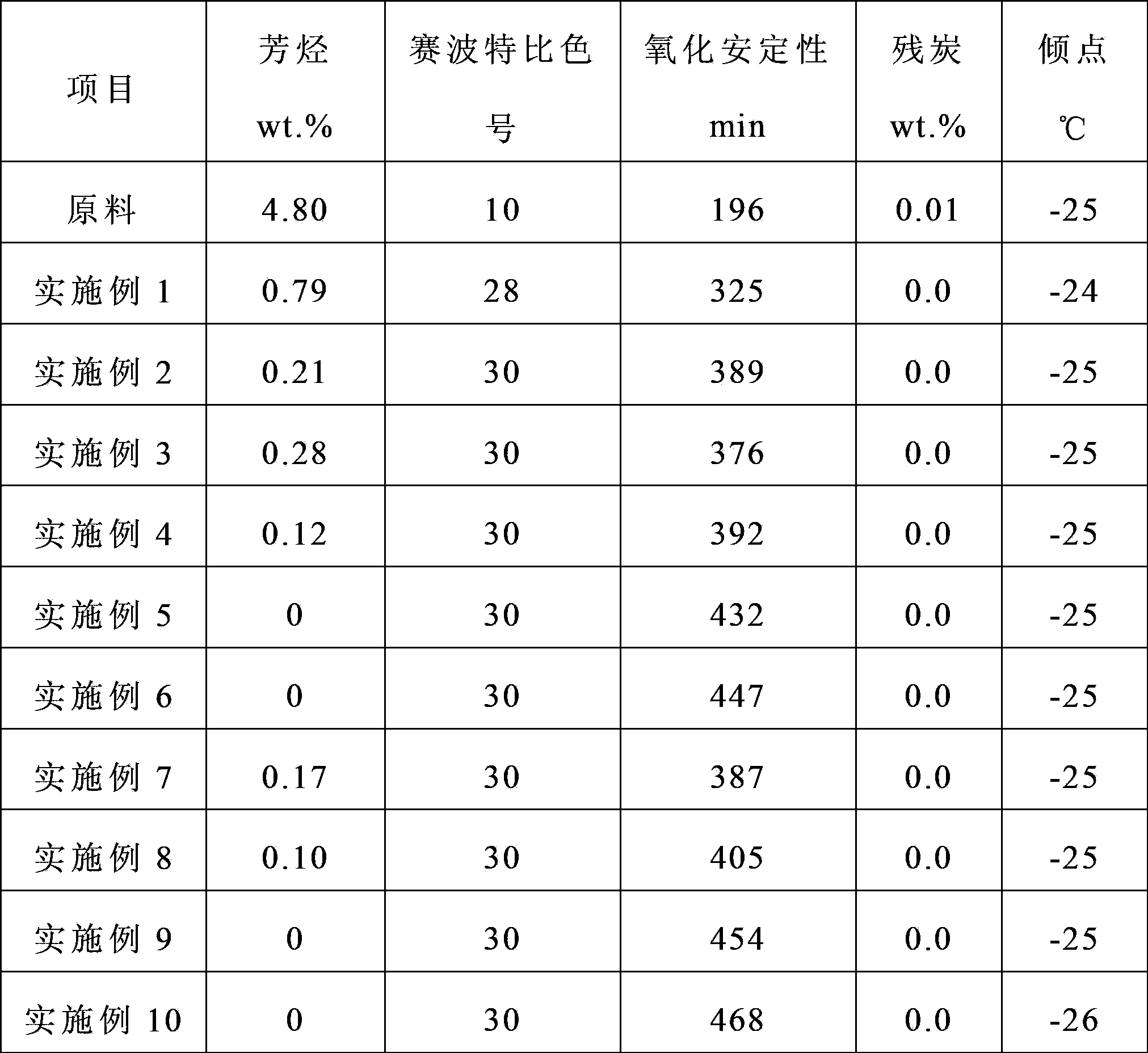

[0020] The modified γ-alumina carrier powder in Example 1 was replaced with a mixed powder of modified γ-alumina and modified amorphous silica-alumina with a weight ratio of alumina and silica of 1.8:1, and the others were the same as in the examples 1. The catalyst properties are shown in Table 1, and the evaluation results are shown in Table 2.

Embodiment 3

[0022] In embodiment 2, catalyst metal content is changed to platinum content 0.20wt.%, and palladium content 0.05wt.% prepares impregnation solution, and reaction temperature is changed into 220 ℃, and others are all the same as embodiment 2. The catalyst properties are shown in Table 1, and the evaluation results are shown in Table 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com