Method for purifying platinum through reduction

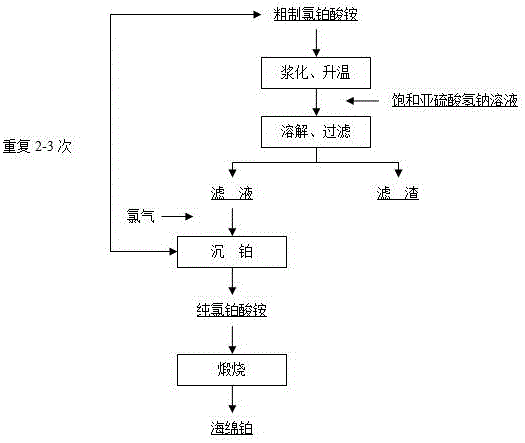

A new method, the technology of ammonium chloroplatinate, is applied in the direction of improving process efficiency, which can solve the problems of long process flow, low platinum direct recovery rate, and heavy labor, and achieve simple operation, improved yield and quality, and easy operation. good elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

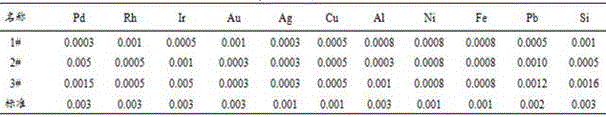

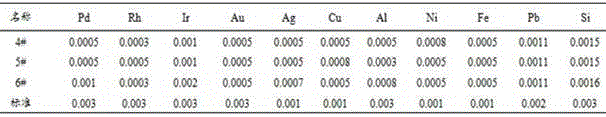

Embodiment 1

[0023] A new method for reducing and purifying platinum. The process steps are: extract 1000g of crude platinum ammonium salt obtained by extracting mineral platinum group concentrate, add 8L of pure water at a solid-to-liquid ratio of 1:8 for slurrying, and heat up to 90°C. Add 1.5 L of sodium bisulfite solution with a mass fraction of 35% to the slurry at 90°C within 5 minutes at a rate of 30 L / h, and react at a constant temperature for 40 minutes. After the reaction was completed, the temperature was rapidly lowered and filtered, and the filter residue weighed 13.526g. The temperature of the filtrate was raised to 85° C., and chlorine gas was introduced into the filtrate until the filtrate continued to be fed with chlorine gas, and there was almost no precipitation. The mixture was heated and boiled for 30 minutes, and then rapidly cooled and filtered. The filter residue was washed with ammonium chloride water with a mass fraction of 17%, and the washing liquid was incorpor...

Embodiment 2

[0027] A new method for reducing and purifying platinum. The process steps are: add 1000g of crude platinum ammonium salt obtained by enrichment and preliminary extraction of exhausted petrochemical catalysts into 6L of pure water at a solid-to-liquid ratio of 1:6 for slurrying, and heat up to 85°C . Add 1.8 L of sodium bisulfite solution with a mass fraction of 30% to the slurry at 85°C within 5 minutes at a rate of 25 L / h, and react at a constant temperature for 30 minutes. After the reaction was completed, the temperature was rapidly lowered and filtered, and the filter residue weighed 14.673g. The temperature of the filtrate was raised to 80° C., and chlorine gas was passed therein until the filtrate continued to be fed with chlorine gas and almost no precipitation occurred, then the mixture was heated and boiled for 20 minutes, and then rapidly cooled and cooled to filter. The filter residue was washed with ammonium chloride water with a mass fraction of 17%, and the was...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bronsted acidity | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com