Method for separating and extracting platinum group metals

A platinum group metal, ammonium chloroplatinate technology, applied in the field of separation and extraction of platinum, can solve the problems of entrained organic phase, reduced extraction efficiency, pipeline blockage, etc., and achieves the effects of low cost, high direct yield and large production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

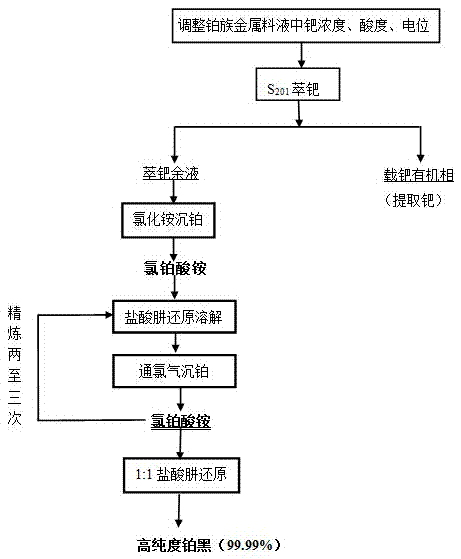

Method used

Image

Examples

Embodiment 1

[0019] It is 1.5g / L to control the palladium concentration in the platinum-group metal feed liquid, the platinum concentration is 10g / L, the volume is 1L, the potential is 850mv, and the acidity is 1mol / L. 201 Extraction and separation of palladium, palladium is extracted after organic reverse extraction of palladium; the concentration of platinum in the palladium residual solution is 9.4g / L, the concentration of palladium is 0.092g / L, and the volume is 1L, and the organic phase of palladium is extracted after back extraction; palladium is extracted After the remaining liquid is filtered, it is heated to boiling, and 25 g of ammonium chloride solids are added until no obvious precipitation is detected with a saturated ammonium chloride solution. After filtering, the obtained ammonium chloroplatinate is washed with ammonium chloride solution until the washing liquid is neutral, and the filtrate and Platinum was recovered from the lotion; 30 g of ammonium chloroplatinate obtained...

Embodiment 2

[0021] It is 5.5g / L to control the palladium concentration in the platinum group metal feed liquid, the platinum concentration is 20g / L, the volume is 1L, the potential is 950mv, and the acidity is 1.2mol / L. 201 Extraction and separation of palladium, palladium is extracted after organic reverse extraction of palladium; the concentration of platinum in the palladium residual solution is 19.8g / L, the concentration of palladium is 0.041g / L, and the volume is 1L, and the organic phase of palladium is extracted after back extraction; palladium is extracted After the remaining liquid is filtered, it is heated to boiling, and 40 g of ammonium chloride solid is added until no obvious precipitation is detected with a saturated ammonium chloride solution. After filtering, the obtained ammonium chloroplatinate is washed with ammonium chloride solution until the washing liquid is neutral, and the filtrate and Platinum was recovered from the lotion; 35g of ammonium chloroplatinate obtained...

Embodiment 3

[0023] It is 2.5g / L to control the palladium concentration in the platinum-group metal feed liquid, the platinum concentration is 15g / L, the volume is 1L, the potential is 900mv, and the acidity is 1.5mol / L. 201 Extraction and separation of palladium, palladium is extracted after organic reverse extraction of palladium; the concentration of platinum in the palladium residual solution is 14.1g / L, the concentration of palladium is 0.012g / L, and the volume is 1L, and the organic phase of palladium is extracted after back extraction; After the remaining liquid is filtered, it is warmed up to boiling, and 30 g of ammonium chloride solid is added until no obvious precipitation is detected with a saturated ammonium chloride solution. After filtering, the obtained ammonium chloroplatinate is washed with ammonium chloride solution until the washing liquid is neutral, and the filtrate and Platinum was recovered from the lotion; 30 g of ammonium chloroplatinate obtained by filtration was ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com