Method for separating and purifying platinum by adopting holding potential

A purification method and potential technology, which can be applied to the improvement of process efficiency, photography technology, instruments, etc., can solve the problems of low selectivity, poor material adaptability, and unsatisfactory results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

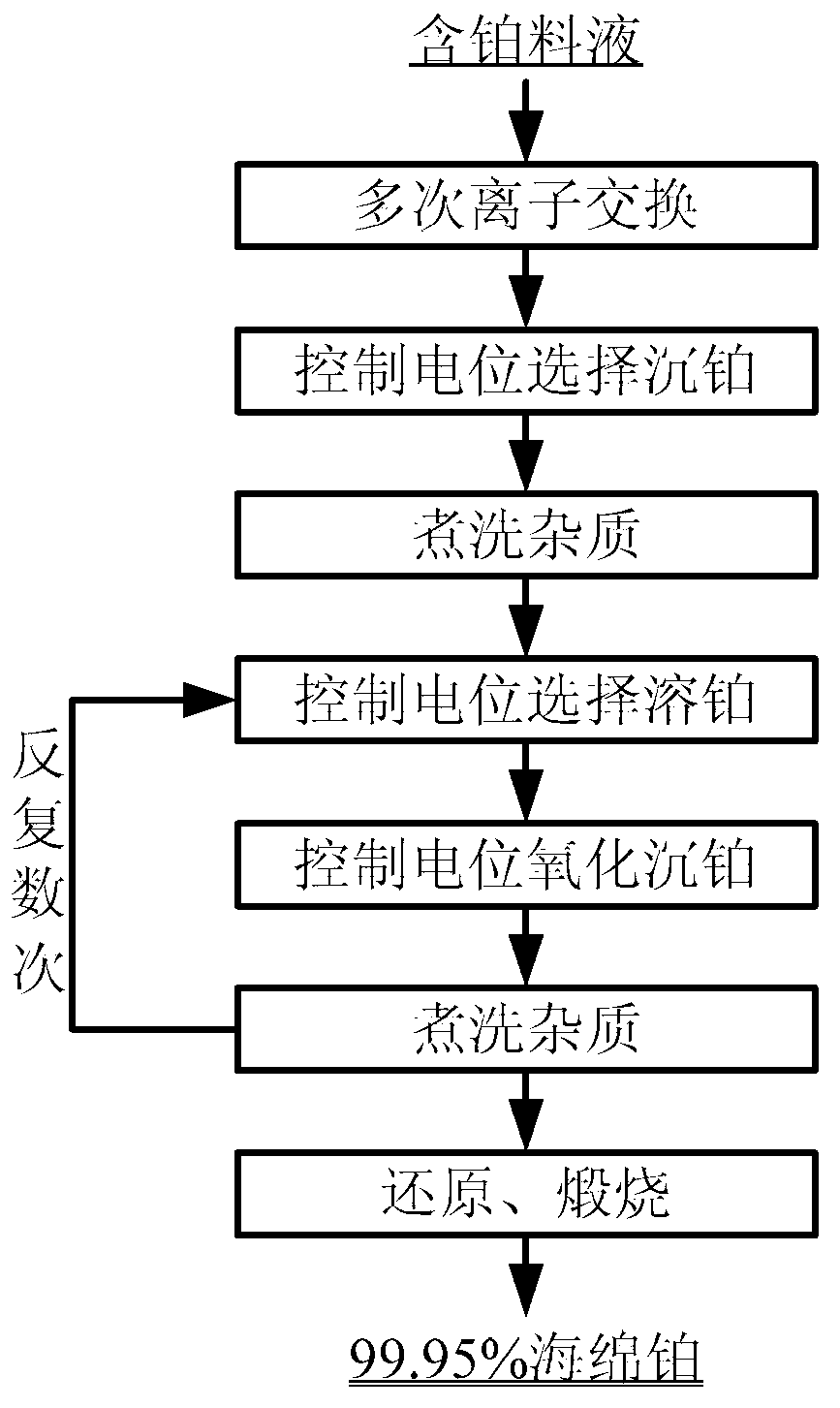

Method used

Image

Examples

Embodiment 1

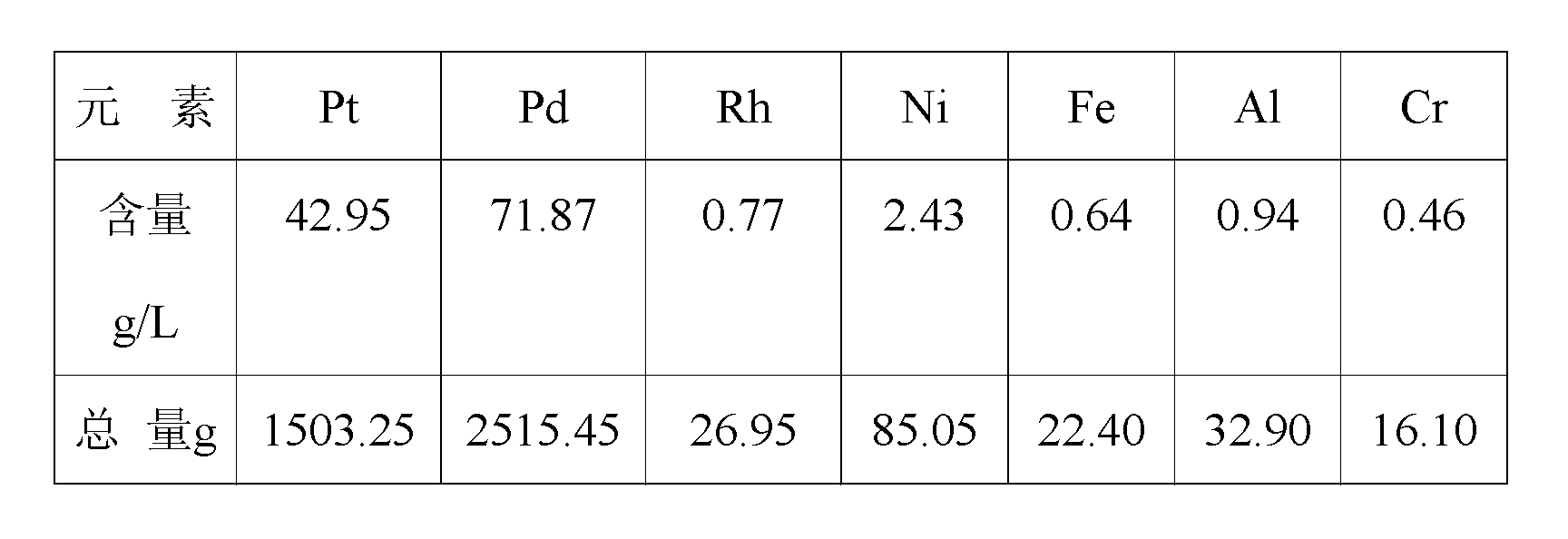

[0018] The raw material is an ammonia oxidation catalytic net for nitric acid industry, and after dissolving in aqua regia and removing nitric acid with hydrochloric acid, a solution of hydrochloric acid medium is obtained. The volume of feed liquid is 35.00L, and the composition analysis is shown in Table 1.

[0019] Table 1 Example 1 raw material composition table

[0020]

[0021] ①Adjust the acidity of the solution to a pH value of 1~1.5, exchange it twice with a cationic resin, and take samples for detection. The mass fraction of Ni, Fe, Al, Cr and other elements in the solution relative to Pt can reach GB 1419-2004 "Sponge Platinum The standard of 99.95% sponge platinum in the standard; ②add hydrochloric acid, adjust the pH value of the solution to 0.5~1, control the temperature above 90°C, add industrial hydrogen peroxide slowly under stirring, and monitor the solution in real time with a pHSJ-3F potentiometer When the solution potential is stable at about 700mV, s...

Embodiment 2

[0024] The raw material is the concentrated ore enriched by the waste catalyst of automobile exhaust, and the feed liquid is obtained after dissolving, hydrochloric acid medium, the volume of the solution is 27.30L, and the composition analysis is shown in Table 2.

[0025] Table 2 Example 2 raw material composition list

[0026] element

Pt

PD

Rh

Cu

Fe

Pb

Al

Zn

Contentg / L

45.80

31.26

7.78

0.42

1.30

0.31

0.75

1.21

Total amount g

1250.34

853.40

212.39

11.47

35.49

8.46

20.48

33.03

[0027] ①Adjust the acidity of the solution to a pH value of 1~1.5, and exchange it with cationic resin for 4 times; ②Add hydrochloric acid, adjust the pH value of the solution to 0.5~1, control the temperature above 90°C, slowly add industrial grade hydrogen peroxide while stirring, and at the same time Use a pHSJ-3F potentiometer to monitor the oxidation-reduction pote...

Embodiment 3

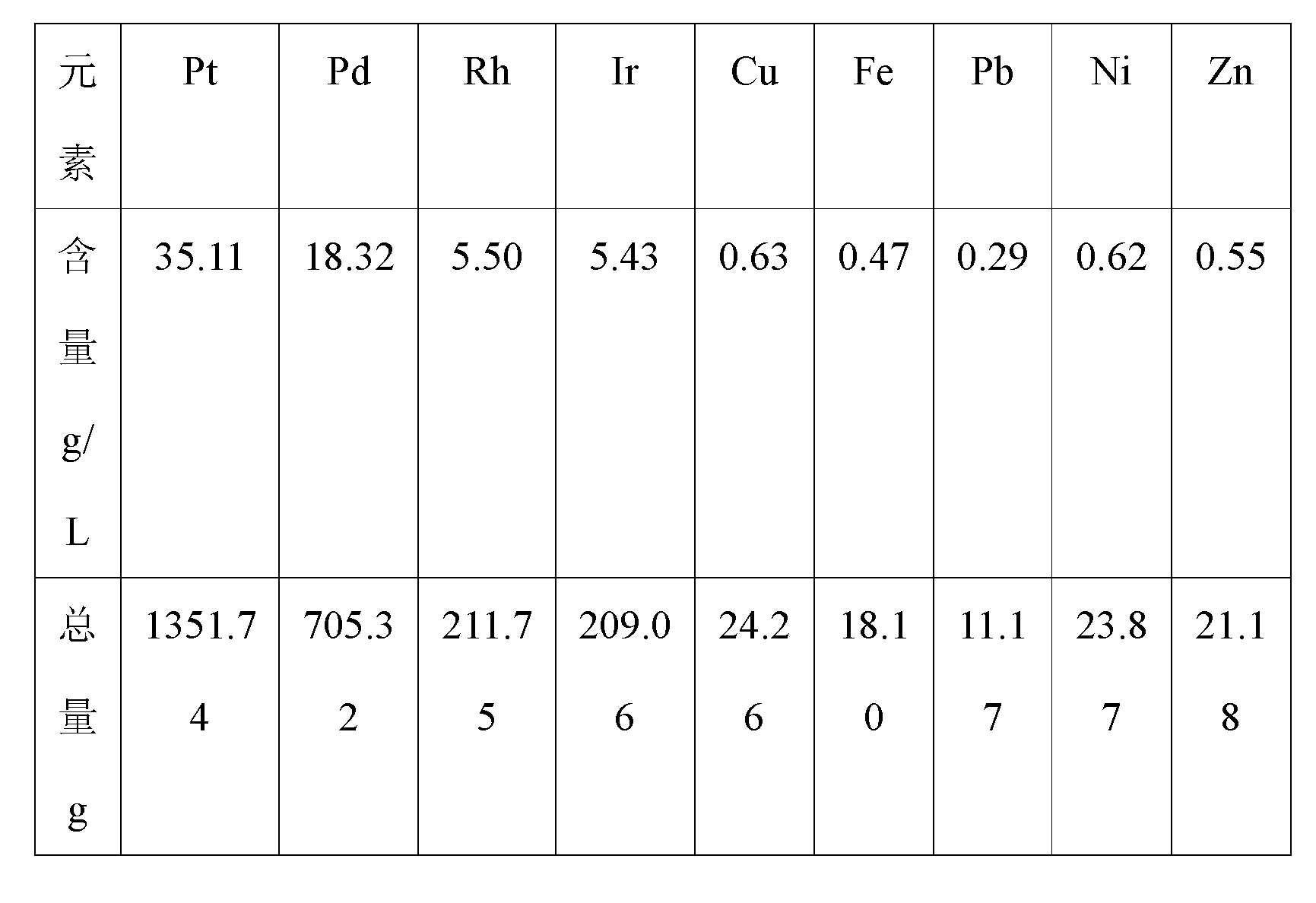

[0030] The raw material is a complex solution containing platinum, palladium, rhodium, and iridium obtained after the refining residue is dissolved. The medium is a hydrochloric acid system with a volume of 38.50 L. The composition analysis is shown in Table 3.

[0031] Table 3 Example 3 raw material composition list

[0032]

[0033]①Adjust the acidity of the solution to a pH value of 1~1.5, and exchange it with cationic resin for 3 times; ②Add hydrochloric acid, adjust the pH value of the solution to 0.5~1, control the temperature above 90°C, slowly add industrial grade hydrogen peroxide while stirring, and at the same time Use a pHSJ-3F potentiometer to monitor the oxidation-reduction potential of the solution in real time. When the potential of the solution reaches 650-700mV, stop adding hydrogen peroxide and keep it for more than 30 minutes; ③Add 1600g of reagent grade ammonium chloride, fully stir for 10 minutes, let stand, and cool overnight; ④ Filter out the yellow ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com