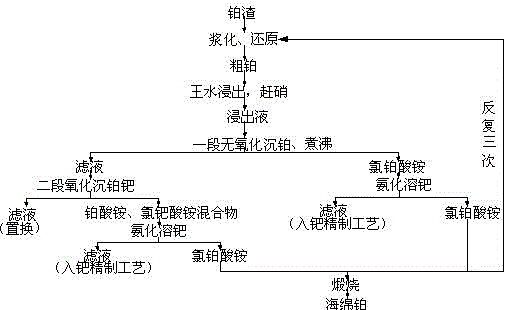

Platinum refining process based on two-stage sedimentation method

A deposition method and process technology, which is applied in the field of two-stage deposition process for refining platinum, can solve the problems of difficult operation, high equipment requirements, and large energy consumption, and achieve the effect of simple process and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Example 1: (1) Reduction of hydrazine hydrate: Add water to slurry the platinum concentrate, raise the temperature to 45°C, add hydrazine hydrate to reduce ammonium chloroplatinate to crude platinum, cool and filter after the reaction;

[0016] (2) Dissolving in aqua regia: Put the filtered crude platinum into an 80l white porcelain tank, add water to make a slurry, add aqua regia to dissolve, if the reaction does not proceed, suck out the solution and pour new aqua regia to continue dissolving until the platinum is completely dissolved Until then, let stand to filter, wash, and combine the filtrate and washing liquid to catch the nitrate;

[0017] (3), a stage of no-oxidation platinum precipitation-boiling palladium dissolution: control the solution containing platinum 50g / l, raise the temperature to 60°C, add NH4Cl to precipitate platinum, at this time a large amount of platinum and a small amount of palladium will be converted into ammonium chloroplatinate and palladi...

Embodiment 2

[0021] Example 2: (1) Reduction of hydrazine hydrate: Slurry the platinum concentrate with water, raise the temperature to 55°C, add hydrazine hydrate to reduce ammonium chloroplatinate to crude platinum, cool and filter after the reaction;

[0022] (2) Dissolving in aqua regia: put the filtered crude platinum into a glass, add water to slurry, add aqua regia to dissolve, if the reaction does not proceed, suck out the solution and pour new aqua regia to continue dissolving until the platinum is completely dissolved. Static filtration, washing, filtrate and washing liquid combined to catch nitrate;

[0023] (3), a stage of no-oxidation platinum precipitation-boiling palladium dissolution: control the solution containing platinum 50g / l, raise the temperature to 60°C, add NH4Cl to precipitate platinum, at this time a large amount of platinum and a small amount of palladium will be converted into ammonium chloroplatinate and palladium chloride The form of ammonium acid is deposite...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com