Preparation method of micron-grade spherical Pt-Ru alloy powder

A technology of micron-scale, alloy powder is applied in the field of preparation of micron-scale spherical Pt-Ru alloy powder, which can solve the problems of unfavorable industrial production and complicated operation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

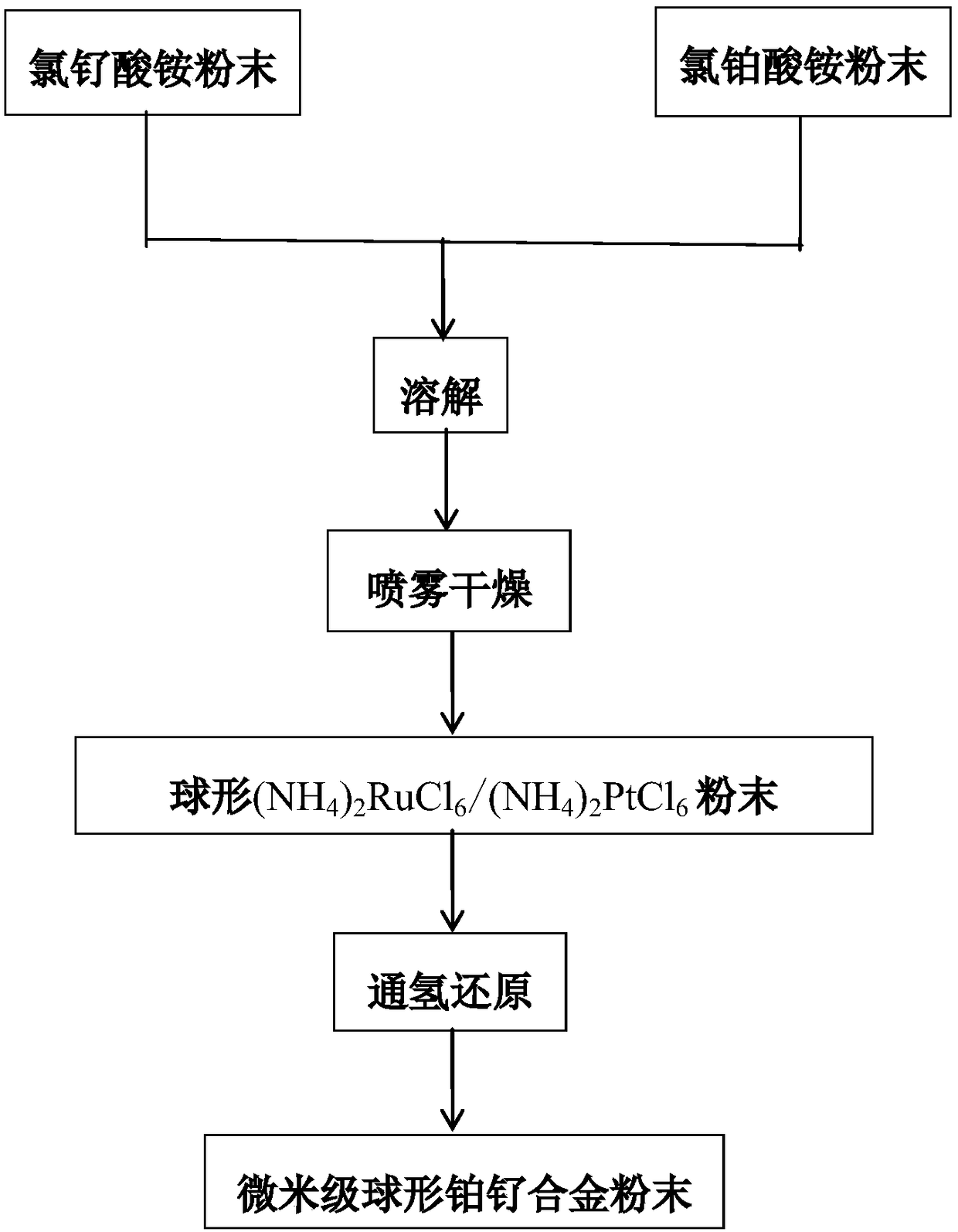

[0020] The preparation steps of the micron-scale spherical Pt-Ru alloy powder of the present invention are as follows:

[0021] 1. Spray drying: with (NH 4 ) 2 RuCl 6 and (NH 4 ) 2 PtCl 6 As a raw material, under the premise that the atomic ratio of platinum atoms and ruthenium atoms is 1:1, weigh the corresponding weight, configure it into a solution, and adopt the method of spray drying, control the liquid flow rate to 5.0ml / min, and the atomization pressure to 0.7 MPa, the inlet temperature is 180°C, and the flow rate of hot air is 10.0L / min, and the homogeneously mixed (NH 4 ) 2 RuCl 6 and (NH 4 ) 2 PtCl 6 Powder, the particle size is 1-4μm, its microscopic appearance is as image 3 shown.

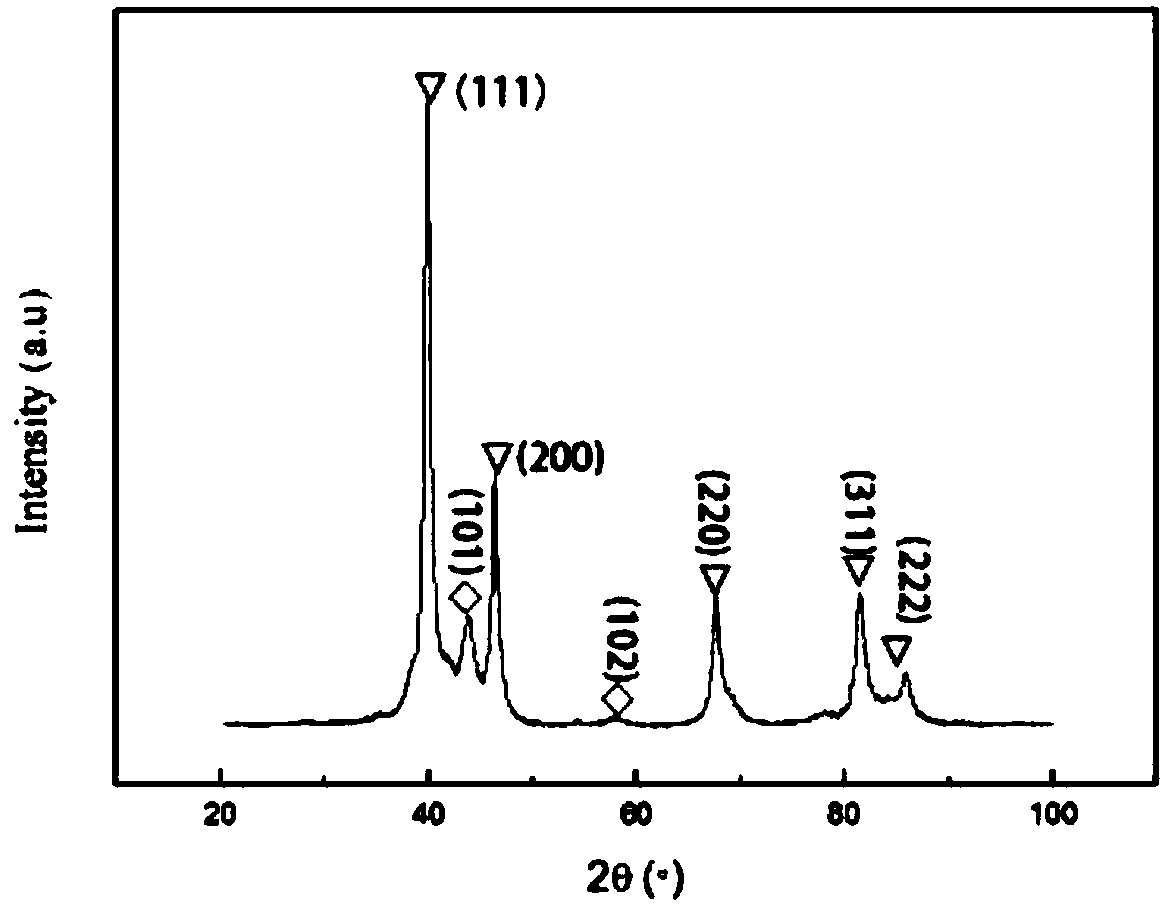

[0022] 2. Hydrogen reduction: the uniform spherical precursor powder is calcined in a tube furnace under a hydrogen atmosphere, the temperature is controlled at 650°C, the holding time is 180min, and it is cooled under nitrogen. The particle size range At 1-4μm, the specif...

Embodiment 2

[0024] Compared with Example 1, the process parameters for manufacturing the precursor are the same, the difference is that the calcination temperature is 550 ° C, the holding time of the powder is 150 min, the size of the particles is in the range of 1-4 μm, and its microstructure is as follows: Figure 4b shown.

Embodiment 3

[0026] Compared with Example 1, the process parameters for manufacturing the precursor mixed powder are the same, the difference is that the calcination temperature is 450°C, the holding time of the powder is 120min, the size of the particles is in the range of 1-4μm, and its microstructure is as follows: Figure 4c shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Average size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com