Method of extracting feldspar concentrate by using desert aeolian sand

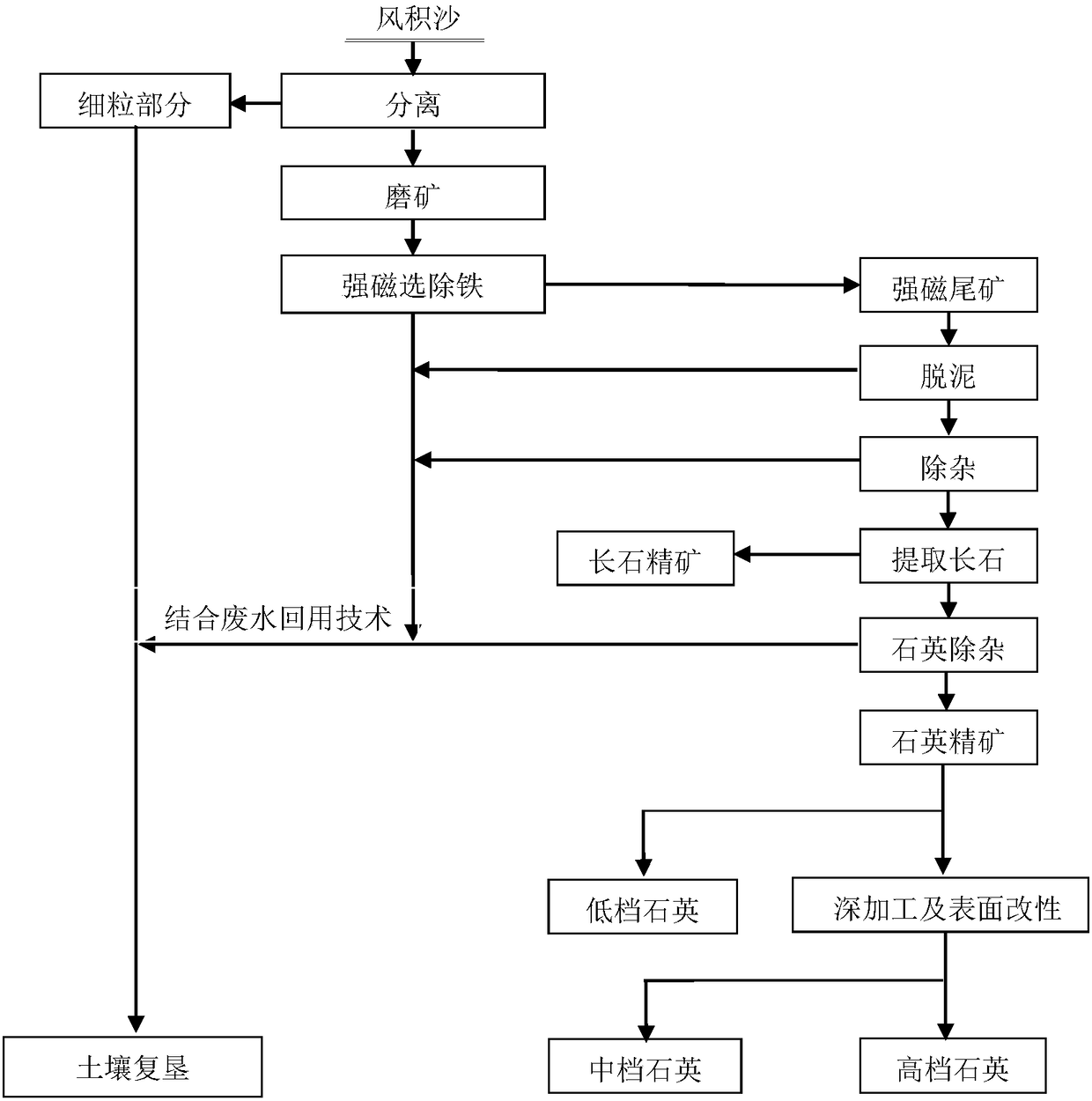

A technology of desert aeolian sand and aeolian sand, applied in the direction of silica, grain processing, silicon oxide, etc., can solve the problems of high cost, difficult practical operation, and difficult removal of insoluble substances, so as to reduce consumption and production cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

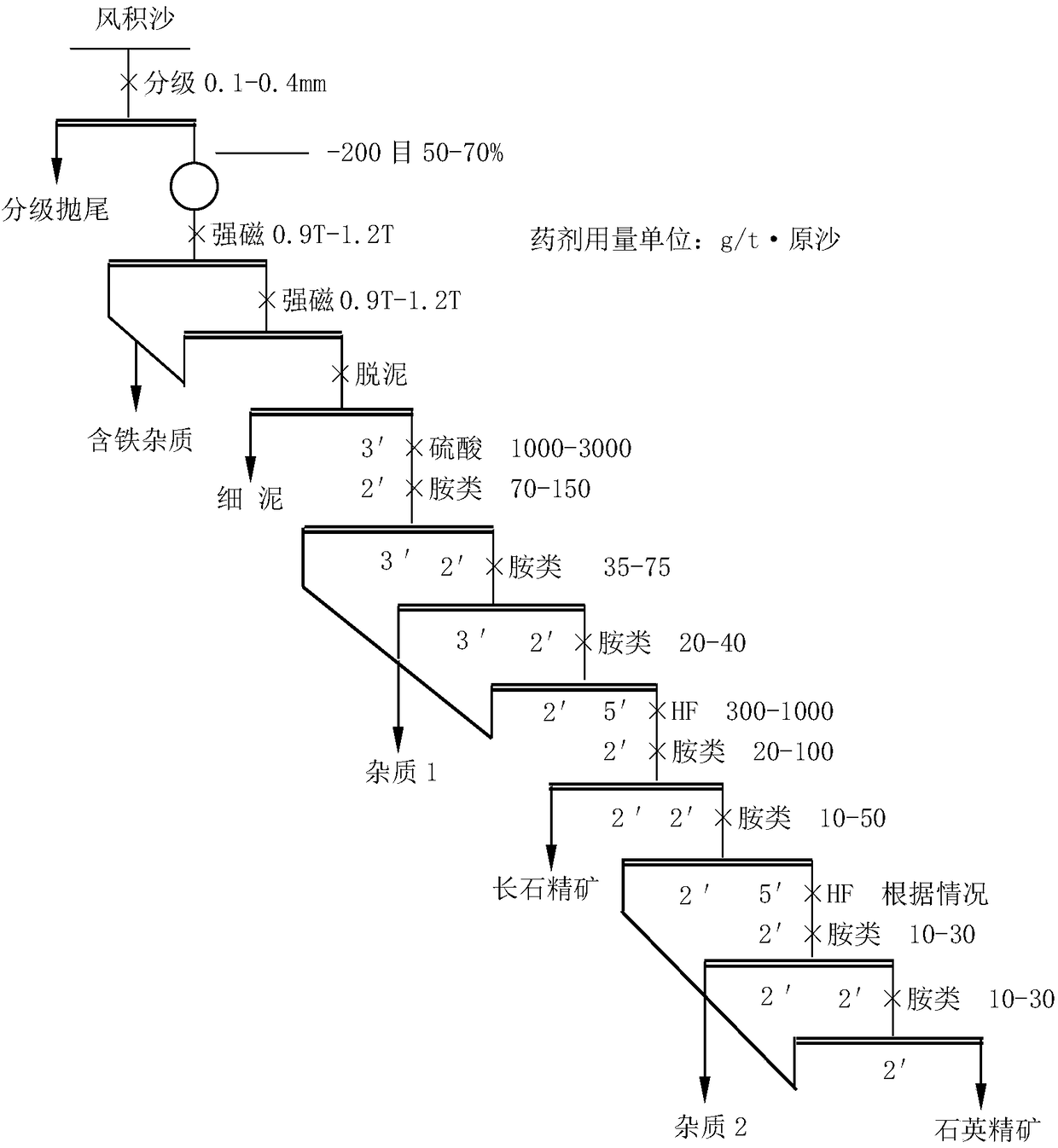

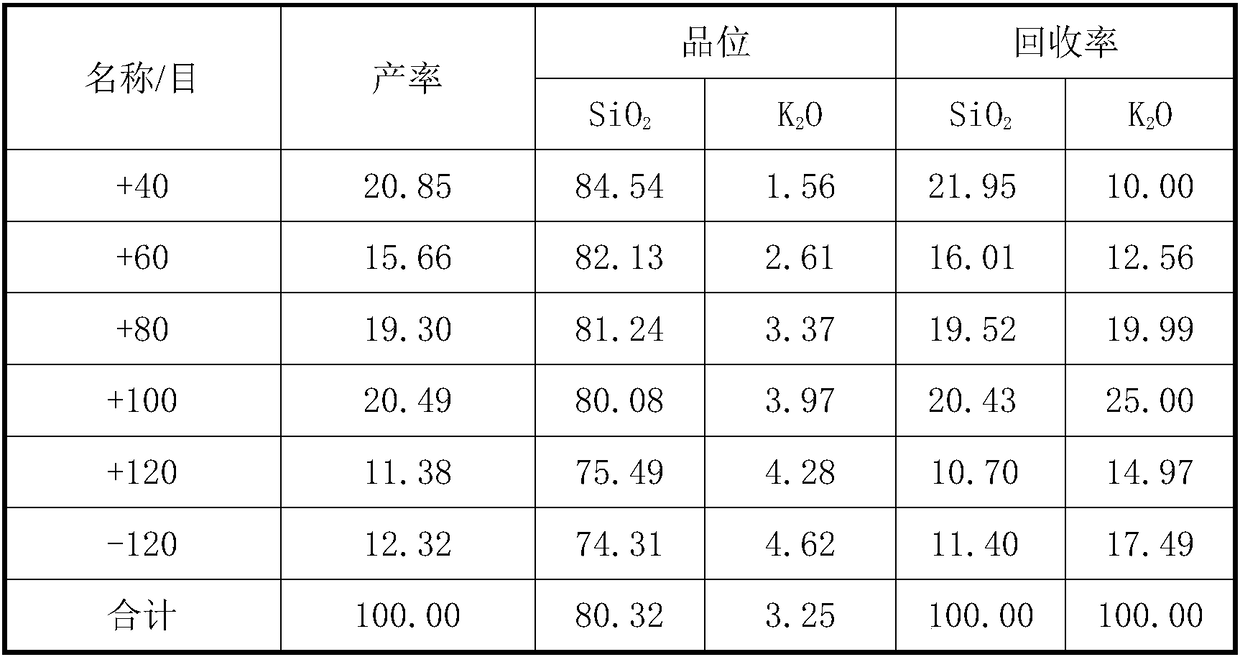

[0037] (1) Firstly, carry out screening analysis and microscopic examination on the aeolian sand, and determine that the sieving fineness is 0.1-0.4 mm, and pass the aeolian sand through a 0.5 mm sieve to remove impurities such as grass roots and leaves. Secondly, the under-sieve product enters the classification equipment, and most of the fine particle impurities of about 0.1mm are screened out. Impurities and fine particles of grass roots, leaves and leaves screened out are directly backfilled to the original sand position and reserved for soil reclamation.

[0038] (2) Feed the coarse grain part obtained above into a high-frequency fine sieve with a concentration of 15%, and screen out the remaining fine grain impurities of about 0.1 mm. Then the coarse particles on the grading screen are concentrated and fed into the shaping mill for grinding. The grinding concentration is 65%. The closed-circuit grinding system is composed of a long tube ball mill and a high-frequency fin...

Embodiment 2

[0044] (1) Firstly, carry out screening analysis and microscopic examination of the aeolian sand to determine the sieving fineness of 0.1-0.4mm, pass the aeolian sand through a 0.3mm sieve, and remove impurities such as grass roots and leaves. Secondly, the under-sieve product enters the classification equipment, and most of the fine particle impurities of about 0.1mm are screened out. Impurities and fine particles of grass roots, leaves and leaves screened out are directly backfilled to the original sand position and reserved for soil reclamation.

[0045] (2) Feed the coarse grain part obtained above into a high-frequency fine sieve with a concentration of 20%, and screen out the remaining fine grain impurities of about 0.1mm. Then the coarse particles on the grading screen are concentrated and fed into the shaping mill for grinding. The grinding concentration is 60%. The closed-circuit grinding system is composed of a long tube ball mill and a high-frequency fine screen, wh...

Embodiment 3

[0051] (1) First, carry out screening analysis and microscopic examination on the aeolian sand, and determine the sieving fineness to be 0.1-0.4mm, pass the aeolian sand through a 0.6mm sieve, and screen out impurities such as grass roots and leaves. Secondly, the under-sieve product enters the classification equipment, and most of the fine particle impurities of about 0.1mm are screened out. Impurities and fine particles of grass roots, leaves and leaves screened out are directly backfilled to the original sand position and reserved for soil reclamation.

[0052] (2) Feed the above-mentioned coarse-grained part into a high-frequency fine sieve with a concentration of 10%, and screen out the remaining fine-grained impurities of about 0.1 mm. Then the coarse particles on the grading sieve are concentrated and sent to the shaping mill for grinding. The grinding concentration is 70%. The closed-circuit grinding system is composed of a long tube ball mill and a high-frequency fine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com