Recycling method of ammonium chloroplatinate reduction waste liquid

An ammonium chloroplatinate and waste liquid recycling technology, applied in the direction of improving process efficiency, can solve the problems of difficult recovery, high treatment cost, low precious metal recovery rate, etc., and achieve the effect of saving wastewater treatment cost and reducing cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

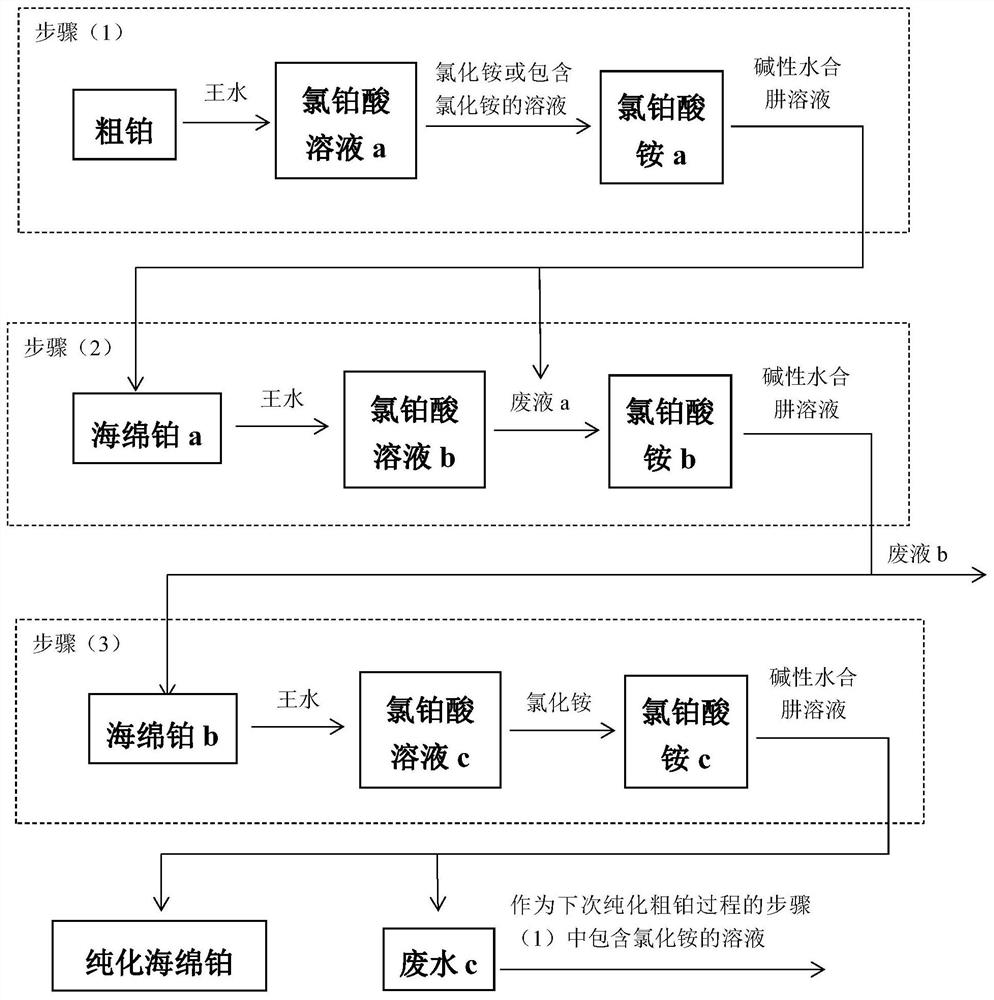

[0037]According to the ammonium chloroplatinate reduction waste liquid recycling method of the present application, the method comprises the following steps in sequence:

[0038] (1) Add 100g of crude platinum (purity 95.2%) into 400mL of aqua regia, dissolve at 80°C, then raise the temperature of the system to 110°C, add concentrated hydrochloric acid in batches under stirring until there is no reddish-brown gas in the system Escape, obtain chloroplatinic acid solution a, the chloroplatinic acid solution a is heated to boiling, add the ammonium chloride of 42g under agitation to precipitation completely, filter, filter cake is that the weight concentration is 10% ammonium chloride aqueous solution Wash to obtain 217.92g of ammonium chloroplatinate a, after which the ammonium chloroplatinate a is mixed with 110g of basic hydrazine hydrate solution (comprising 20wt% NaOH and 50wt% hydrazine hydrate), stirred and heated at 90°C Heat and reduce for 3.0 hours, filter to obtain 95....

Embodiment 2

[0044] According to the ammonium chloroplatinate reduction waste liquid recycling method of the present application, the method comprises the following steps in sequence:

[0045] (1) Add 100g of crude platinum (purity 98.1%) into 400mL of aqua regia, dissolve at 75°C, then raise the temperature of the system to 115°C, add concentrated hydrochloric acid in batches under stirring until there is no reddish-brown gas in the system Escape, obtain chloroplatinic acid solution a, the chloroplatinic acid solution a is heated to boiling, add the waste water c of embodiment 1 step (3) gained under stirring (adding ammonium chloride to its ammonium chloride total amount 41g) to precipitate completely, filter, and the filter cake is washed with the ammonium chloride aqueous solution of 7% with weight concentration, obtains the ammonium chloroplatinate a of 223.98g, then the basic hydrazine hydrate of described ammonium chloroplatinate a and 100g The solution (comprising 18wt% of NaOH and...

Embodiment 3

[0051] According to the ammonium chloroplatinate reduction waste liquid recycling method of the present application, the method comprises the following steps in sequence:

[0052] (1) Add 100g of crude platinum (purity 98.9%) into 390mL of aqua regia, dissolve at 80°C, then raise the temperature of the system to 115°C, add concentrated hydrochloric acid in batches under stirring until the system has no reddish-brown gas Escape, obtain chloroplatinic acid solution a, the chloroplatinic acid solution a is heated to boiling, add the waste water c of embodiment 2 step (3) gained under stirring (add ammonium chloride to its ammonium chloride total amount 42g) to precipitate completely, filter, and the filter cake is washed with the ammonium chloride aqueous solution of 5% with weight concentration, obtains the ammonium chloroplatinate a of 225.63g, then the basic hydrazine hydrate of described ammonium chloroplatinate a and 130g The solution (comprising 22wt% of NaOH and 45wt% of h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com