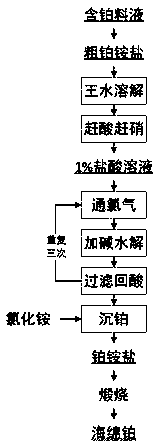

A platinum refining process

A technology of process and process steps, applied in the field of platinum refining process, to achieve the effects of reducing negative impact, improving direct yield and shortening production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] For platinum-containing concentrates with a grade greater than 80%, the primary solution of aqua regia is filtered with a hydrochloric acid solution with a mass fraction of 1% after acid removal and nitration; The filtrate control chlorine flow of volume 900L is 20L / min. Control the temperature at 85°C, measure the potential at 1050mV, the color of the feed liquid becomes darker, stop the chlorine gas flow; adjust the pH value of the feed liquid to 8 with liquid caustic soda, control the temperature during the entire hydrolysis process at 85°C, and the stirring intensity during the addition of alkali is 80r / min , after the pH = 8 is stable for 5 minutes, cool and filter directly, the filtrate is orange red; back to acid to pH = 1, repeat the above steps 2 and 3 three times. Return the obtained liquid after three times of hydrolysis to acid, control the acidity pH=1, add saturated ammonium chloride solution with a volume ratio of 1:1 to precipitate platinum after boiling...

Embodiment 2

[0020] For platinum-containing concentrates with a grade greater than 80%, the primary solution of aqua regia is filtered with a hydrochloric acid solution with a mass fraction of 1% after acid removal and nitration; The filtrate control chlorine flow of volume 800L is 10L / min. Control the temperature at 75°C, measure the potential at 1000mV, the color of the feed liquid becomes darker, stop the chlorine gas flow; adjust the pH value of the feed liquid to 9 with liquid caustic soda, control the temperature of the entire hydrolysis process at 75°C, stir during the addition of alkali, and the stirring rate is 120r / min, after the pH = 9 is stable for 7 minutes, quickly cool and filter, the filtrate is orange red; back to acid to pH = 1.5, repeat the above steps 2 and 3 three times. Return the obtained three-time hydrolyzed solution to acid, control the acidity pH=0.5, add saturated ammonium chloride solution with a volume ratio of 1:1 to precipitate platinum after boiling, cool a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com