Common fertilizer special for sesbania in medium and low-yield fields in Huang-Huai-Hai region

A special fertilizer and low-yield field technology, which is applied in the field of special fertilizer for common turmeric and its preparation and application, can solve the problems of low utilization rate of fertilizer nutrients in the current season, economic loss, environmental pollution, emphasis on quick-acting fertilizers, etc., and achieve rich organic matter content, Reduce the contact area and improve the effect of biological activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

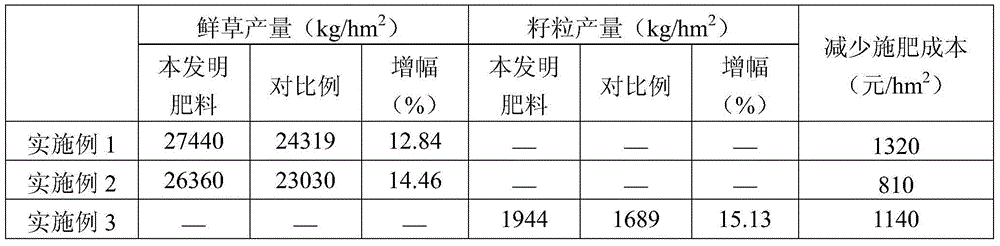

Examples

Embodiment 1

[0042] A kind of special fertilizer for ordinary celadon, with monoammonium phosphate, weathered coal, bentonite and trace element chelating agent as raw materials, the mass parts of each component are: 46 parts of monoammonium phosphate, 48 parts of weathered coal, 4 parts of bentonite, trace element Chelating agent 2 parts.

[0043] The preparation method is as follows:

[0044] (1) After the weathered coal is dried, it is crushed to a particle diameter of 0.1mm-0.3mm, mixed with 1.5wt% potassium hydroxide at a solid-to-liquid ratio of 1:20, stirred for 1 hour, left to stand for 24 hours, filtered or centrifuged to obtain Upper liquid A. According to the mass ratio, every 100 parts of liquid A add 2 parts of ferrous sulfate heptahydrate, 1 part of manganese sulfate and 2 parts of zinc sulfate heptahydrate, after stirring for 1 hour, let it stand for 24 hours, and obtain trace element chelating agent and manufacturing agent through filtration or centrifugation. Granular act...

Embodiment 2

[0048] A kind of special fertilizer for ordinary celadon, with urea, monoammonium phosphate, potassium sulfate, weathered coal, bentonite, trace element chelating agent as raw materials, the mass parts of each component are: 12 parts of urea, 32 parts of monoammonium phosphate, potassium sulfate 4 parts, 44 parts of weathered coal, 6 parts of bentonite, 2 parts of trace element chelating agent.

[0049] The preparation method is as follows:

[0050] Dry the weathered coal and crush it to a particle diameter of 0.1mm to 0.3mm, mix it with 2.5wt% potassium hydroxide at a solid-to-liquid ratio of 1:10, stir for 2 hours, then let it stand for 24 hours, then filter or centrifuge to get the upper layer liquid A . According to the mass ratio, every 100 parts of liquid A add 2 parts of ferrous sulfate heptahydrate, 1 part of manganese sulfate and 2 parts of zinc sulfate heptahydrate, after stirring for 2 hours, leave it for 24 hours, filter or centrifuge to obtain trace element chela...

Embodiment 3

[0054] A kind of special fertilizer for ordinary celadon, with urea, monoammonium phosphate, potassium sulfate, weathered coal, bentonite, trace element chelating agent as raw materials, the mass parts of each component are: 1 part of urea, 41 parts of monoammonium phosphate, chlorinated Potassium 4 parts, weathered coal 45 parts, bentonite 6 parts, trace element chelating agent 2 parts.

[0055] The preparation method is as follows:

[0056] Dry the weathered coal and crush it to a particle diameter of 0.1mm to 0.3mm, mix it with 2.5wt% potassium hydroxide at a solid-to-liquid ratio of 1:10, stir for 2 hours, then let it stand for 24 hours, then filter or centrifuge to get the upper layer liquid A . According to the mass ratio, every 100 parts of liquid A add 4 parts of ferrous sulfate heptahydrate, 2 parts of manganese sulfate and 4 parts of zinc sulfate heptahydrate, after stirring for 2 hours, leave it for 24 hours, filter or centrifuge to obtain trace element chelating a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com