Clean and environment-friendly biomass heating particle preparation equipment

A clean, environmentally friendly, biomass technology, used in die extrusion granulation, grain processing, chemical/physical processes, etc., it can solve the problems of large extrusion force, easy generation, easy blockage, etc., to ensure the crushing performance. , Improve the granulation ability and the effect of fast granulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

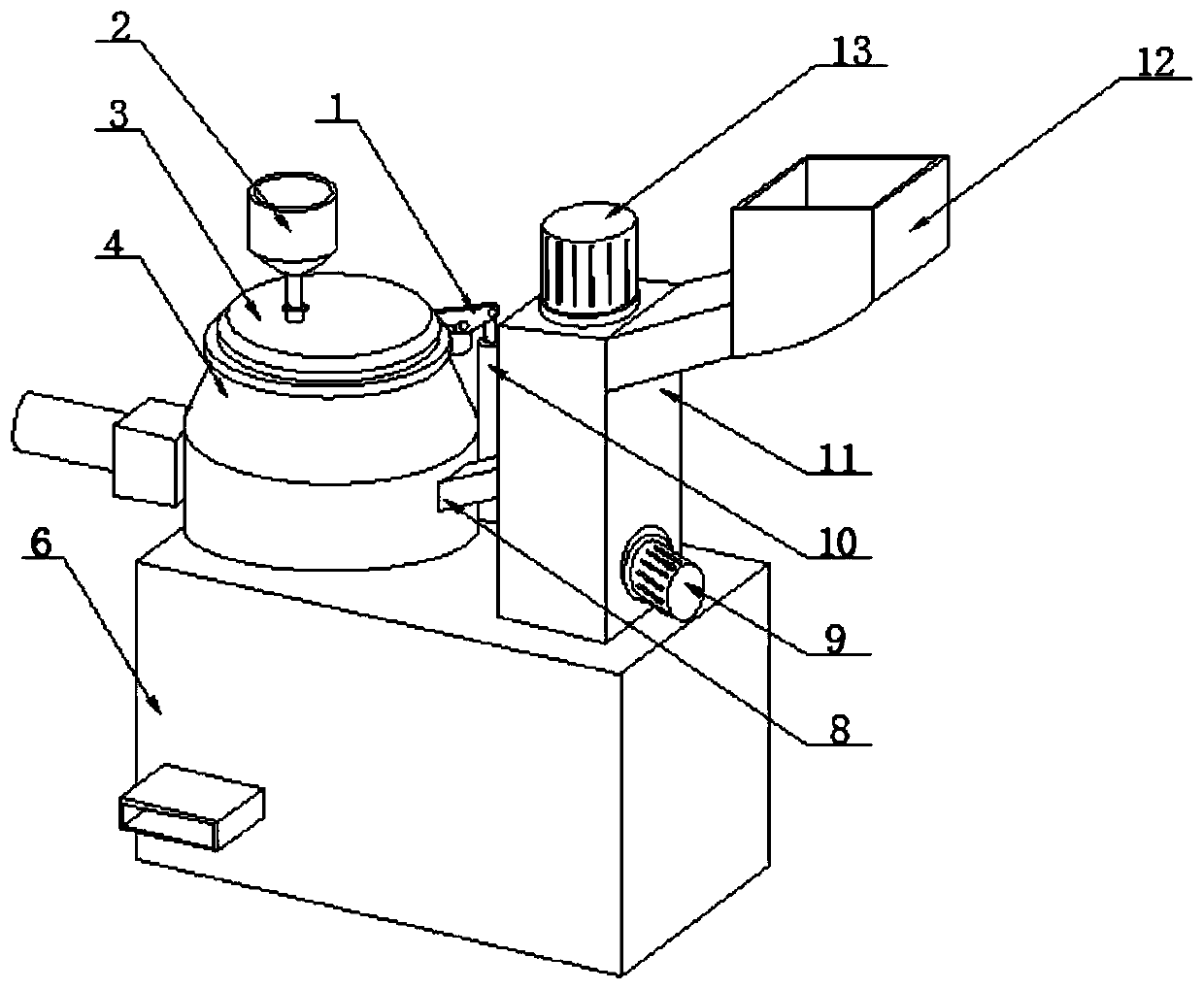

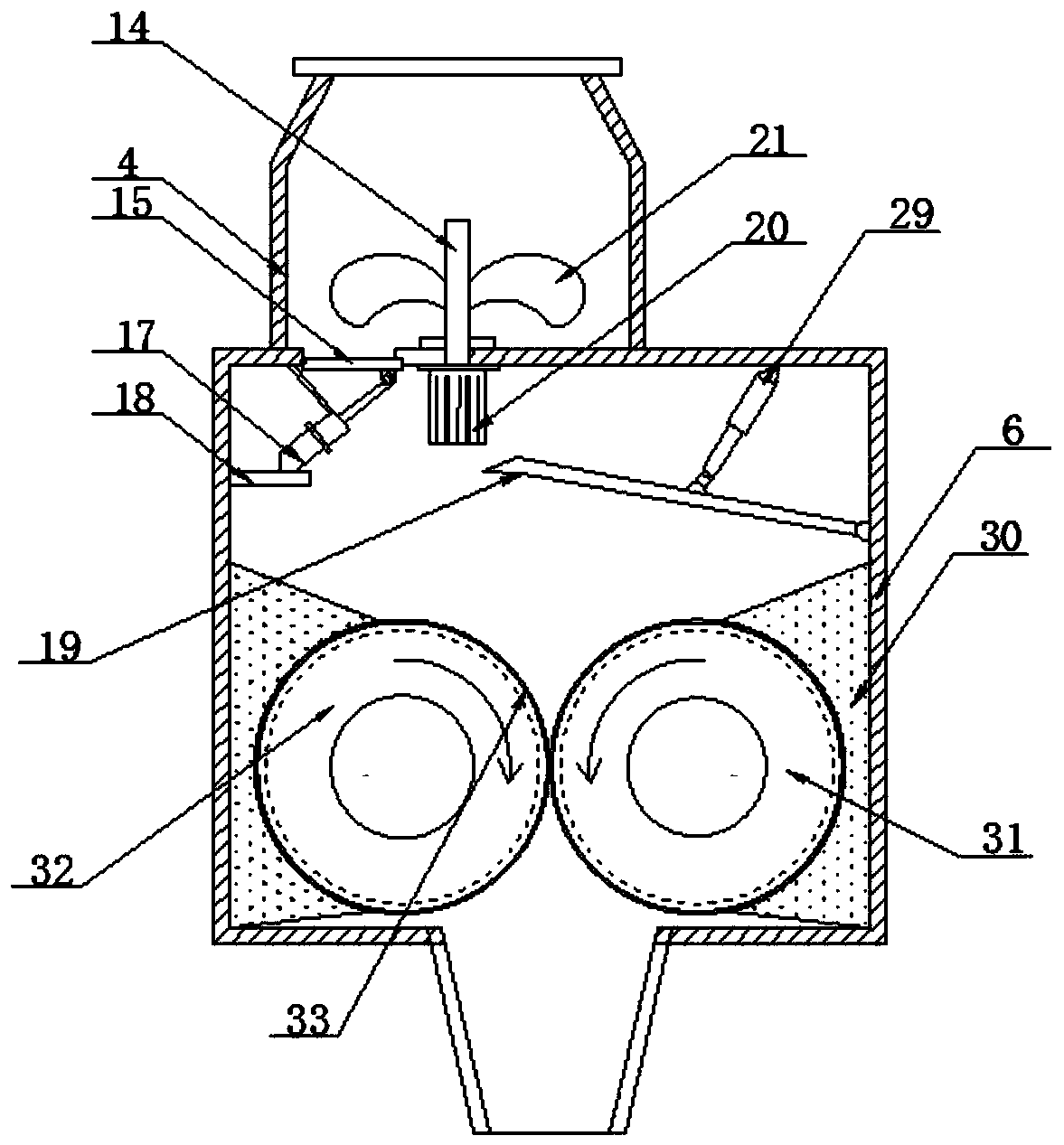

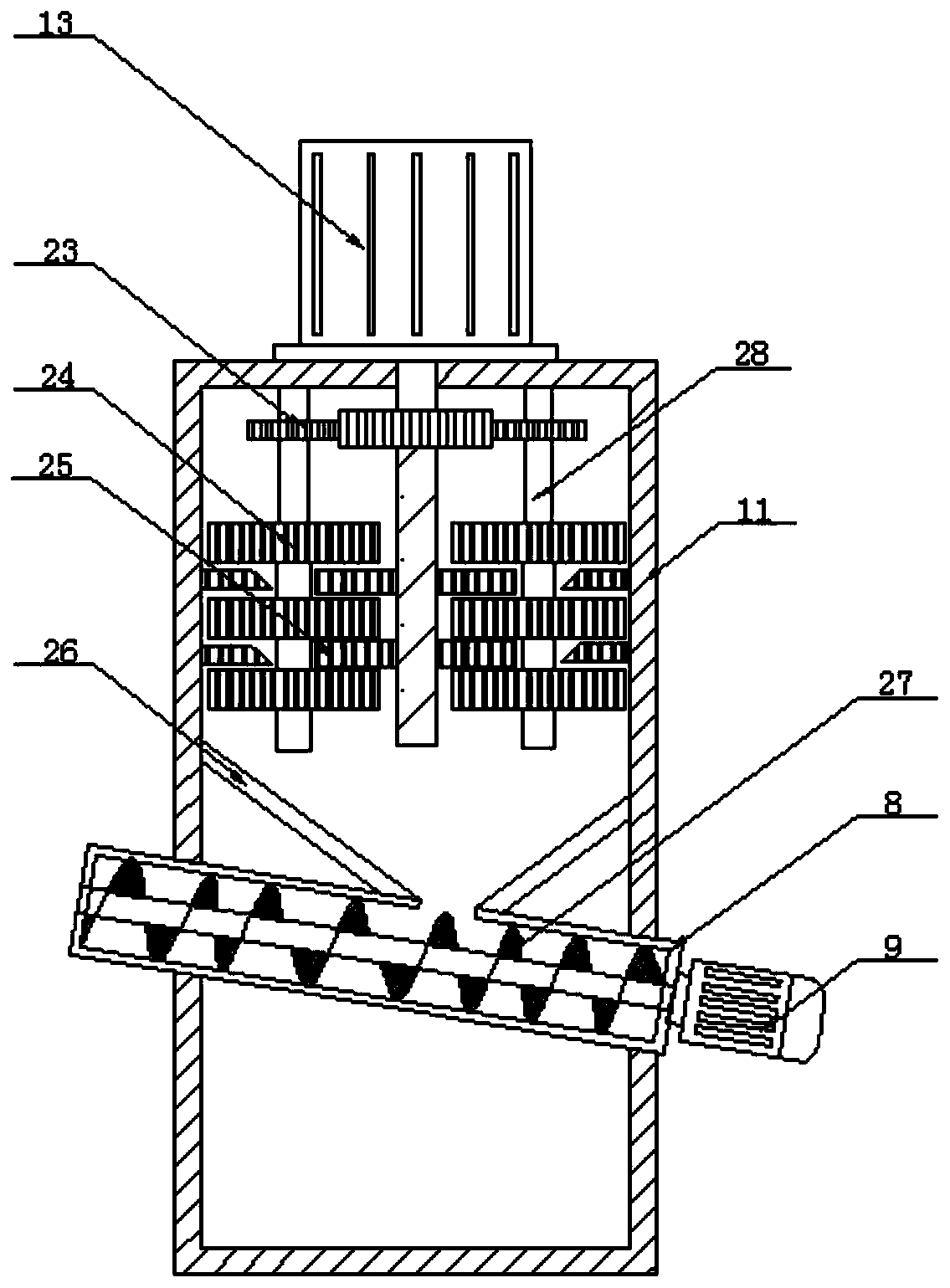

[0024] see Figure 1~4 , in the embodiment of the present invention: a clean and environmentally friendly biomass heating particle preparation equipment, including a crushing mechanism, a mixing mechanism and a granulation mechanism, wherein the granulation mechanism is arranged in the granulation box 6, and the granulation mechanism The material mixing and blending mechanism is arranged above one side of the granulation box, and the crushing mechanism is arranged above the other side of the granulation box, and the output end of the crushing mechanism is connected to the material mixing and blending mechanism, It is characterized in that the granulating mechanism includes a pressing mechanism, a granulating roller 1 31 and a granulating roller 2 32, wherein the pressing mechanism is arranged above the granulating roller 1 31 and the granulating roller 2 32 , the first granulation roller 31 and the second granulation roller 32 are arranged tangentially in the same horizontal d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com