Preparation method for aerobic granular sludge

An aerobic granular sludge and granular technology, applied in the field of water treatment, can solve the problems of less industrialized application demonstration projects, etc., and achieve the effects of short cycle, saving floor space and stable system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

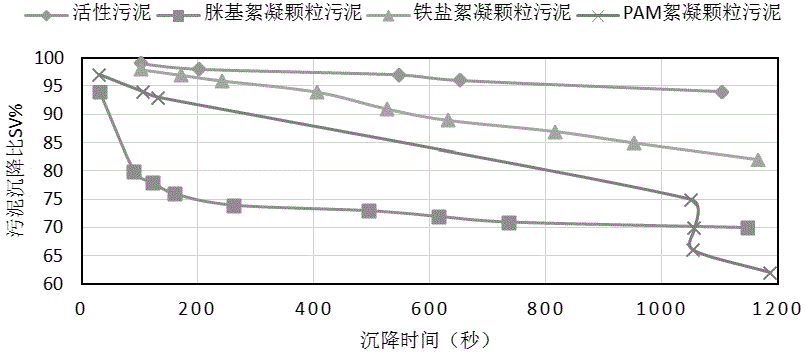

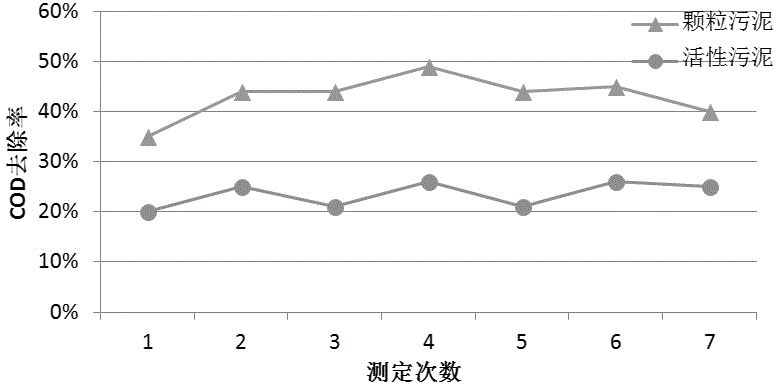

[0029] Take the sludge from the thickening tank of a sewage treatment plant, the water content is 98%, the concentration of polyvinylamidine is added to the sludge is 0.04g / L, and the sludge is made into granular sludge after stirring for 15 minutes. Taking domestic sewage from a sewage plant, its COD was measured to be 358 mg / L. After adding activated sludge and granular sludge of the same quality, they were aerated for 15 minutes to settle. The removal rates of COD in domestic sewage were 34% and 46%, respectively, and the adsorption effect of granular sludge on COD was better than that of activated sludge, and the granular sludge could settle within 5 minutes.

Embodiment 2

[0031]Mix and dissolve polyvinyl amidine with water to form a mixed solution with a concentration of 0.1% by mass, take sludge from a concentration tank of a sewage treatment plant, the water content is 98.5%, and add polyvinyl amidine to the sludge at a concentration of 0.03g / L , made into granular sludge after stirring for 15 minutes. Take the wastewater from a chemical plant, its CODcr is about 20400mg / L, add activated sludge and granular sludge of the same quality respectively, and prepare a mixed solution with an initial CODcr concentration of about 7220mg / L, and after aeration for 15 minutes, the measured The removal rates of COD by activated sludge and granular sludge are 23% and 47%, respectively. The adsorption effect of granular sludge on COD and TN is better than that of activated sludge, and granular sludge can settle within 5 minutes.

Embodiment 3

[0033] The COD of the biogas slurry wastewater from the breeding plant is about 1600mg / L, and the water sample with a COD of about 500-600mg / L is prepared according to a certain ratio with tap water and biogas slurry as the influent, and the activated sludge biochemical system is compared with the use of polyvinyl amidine The removal rate of organic matter by the biochemical system made of granular sludge with sludge with a water content of 98.5%. The quality of sludge in the two processes is basically the same. Under the condition of continuous water inflow and aeration for 8 hours, the removal rates of activated sludge and granular sludge for COD in biogas slurry were 25% and 46%, respectively, and aerobic granular sludge The removal rate of COD in sewage is greater than that of activated sludge, and the settling time is much shorter than that of aerobic activated sludge.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com