Globular asphalt granulating device and granulating method

A spherical asphalt and granulation device technology, applied in the field of asphalt manufacturing, can solve the problems of high production cost, unsuitable for mass industrial production, complex process, etc., achieve low manufacturing cost and operating cost, adapt to mass production, The effect of simple equipment structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

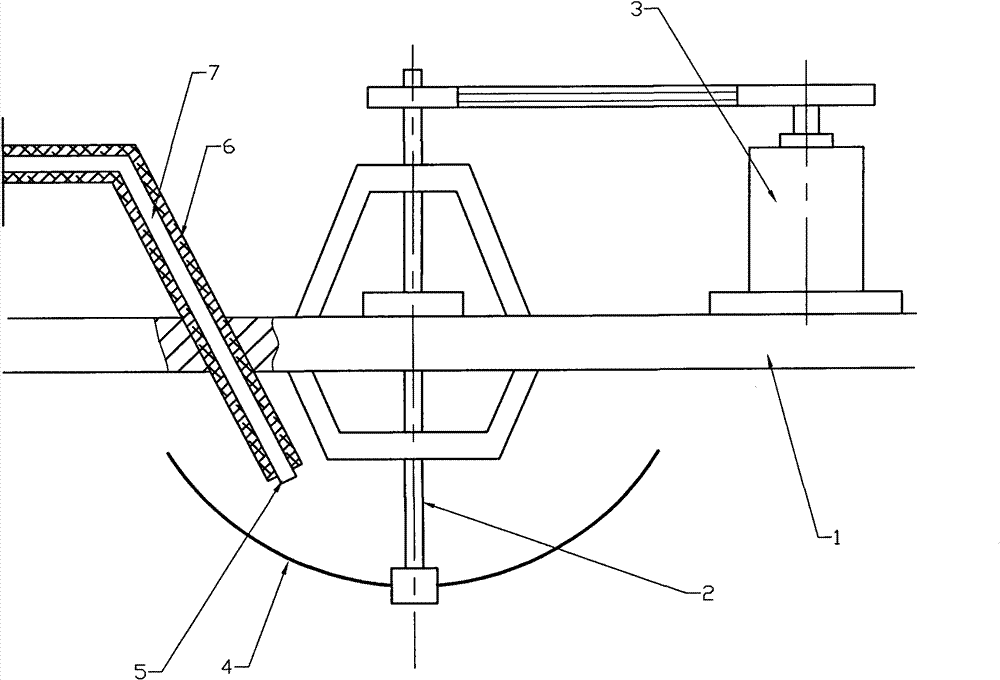

[0010] As shown in the figure, the spherical asphalt granulation device of the present invention includes a vertical rotating shaft 2 installed on the frame 1, the rotating shaft can be driven by a power device 3 to rotate, and the lower end of the rotating shaft is connected to a hemispherical inner cavity surface. The center of the centrifugal pot 4 can drive the centrifugal pot to rotate. There is an asphalt discharge port 5 on the upper side of the centrifugal pot. The asphalt discharge port passes through a section of thermal insulation discharge pipe 7 coated with thermal insulation material 6 and the asphalt storage for storing liquid asphalt. feeder connection.

[0011] Spherical asphalt granulation method Example 1: Spherical asphalt with a diameter of 0.2 mm to 1 mm is produced, and the raw material is coal tar pitch or petroleum pitch with a softening point of 120° C. to 130° C. The method is to complete the granulation process on the device of the present invention...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com