Fertilizer granulation additive and preparation method thereof

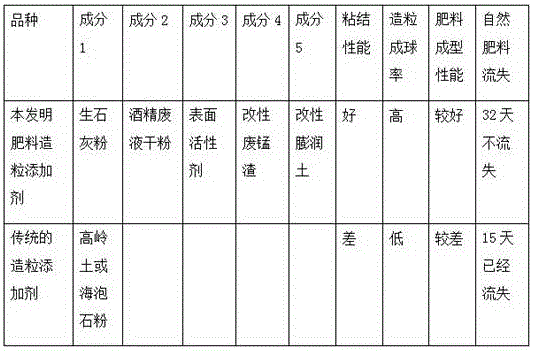

A technology for granulating additives and fertilizers, applied in the direction of organic fertilizers, inorganic fertilizers, calcium fertilizers, etc., which can solve the problems of easy breakage, uneven distribution, and increased contact surface, so as to improve the granulation rate and increase efficiency The effect is obvious and the effect of increasing the particle strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A kind of fertilizer granulation additive, by weight percentage, comprises quicklime powder 3%; Alcohol waste liquid dry powder 5%; Surfactant sodium dodecylbenzene sulfonate 0.2%; Modified waste manganese slag 1%; Modified bentonite 90.8%.

[0028] The above fertilizer granulation additive, the alcohol waste liquid dry powder is the dry powder obtained by concentrating and drying the molasses alcohol waste liquid; the modification method of the modified waste manganese slag is: take CITIC Dameng Daxin fraction The waste manganese slag obtained during filtration in the electrolytic manganese dioxide process of the company Daxin Manganese Industry Co., Ltd. is used as raw material, mixed with water at a mass ratio of waste manganese slag:water of 5:1, and then crushed into pulp, and then passed through a spiral classifier After classification, make the ore particles that have not passed the 100 mesh sieve be finely ground through a wet ball mill until passing the 100 mes...

Embodiment 2

[0033] A fertilizer granulation additive, in terms of weight percentage, including quicklime powder 4%; alcohol waste liquid dry powder 3%; surfactant sodium lauryl sulfate 0.3%; modified waste manganese slag 0.8%; modified bentonite 91.9% .

[0034] The above fertilizer granulation additive, the alcohol waste liquid dry powder is the dry powder obtained by concentrating and drying the molasses alcohol waste liquid; the modification method of the modified waste manganese slag is: taking the electrolytic manganese dioxide The waste manganese slag obtained during filtration is used as raw material, and mixed with water according to the mass ratio of waste manganese slag:water of 5:1, then pulverized into ore pulp, and then classified by a spiral classifier, so that the ore particles that have not passed the 100 mesh sieve are passed through Wet ball mill is finely ground until passing through a 100 mesh sieve to obtain a slurry, then press filter with a filter press, and dry the...

Embodiment 3

[0039] A fertilizer granulation additive, in terms of weight percentage, including quicklime powder 5%; alcohol waste liquid dry powder 4%; surfactant sodium dodecylbenzene sulfonate 0.4%; modified waste manganese slag 0.7%; modified bentonite 89.9%.

[0040] The above fertilizer granulation additive, the alcohol waste liquid dry powder is the dry powder obtained by concentrating and drying the molasses alcohol waste liquid; the modification method of the modified waste manganese slag is: take CITIC Dameng Daxin fraction The waste manganese slag obtained during filtration in the electrolytic manganese dioxide process of the company Daxin Manganese Industry Co., Ltd. is used as raw material, mixed with water at a mass ratio of waste manganese slag:water of 5:1, and then crushed into pulp, and then passed through a spiral classifier After classification, make the ore particles that have not passed the 100 mesh sieve be finely ground through a wet ball mill until passing the 100 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com