A kind of strengthening agent for titanium concentrate granulation and a kind of granulation method of titanium concentrate

A technology of titanium concentrate and strengthening agent, which is applied in the granulation of titanium concentrate and the field of strengthening agent for titanium concentrate granulation. It can solve the problems of increased molding cost, high molding cost, and the inability to directly use wet ore, etc., to achieve optimization. Internal structure, the effect of improving the molding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Add titanium concentrate and strengthening agent according to the mass ratio of titanium concentrate dry basis to strengthening agent 100:1.8 and mix well to obtain a mixture. The final moisture content of the mixture is 12.5%. The strengthening agent is composed of polyvinyl alcohol: medium temperature Asphalt powder: plant adhesive = 20:5:75;

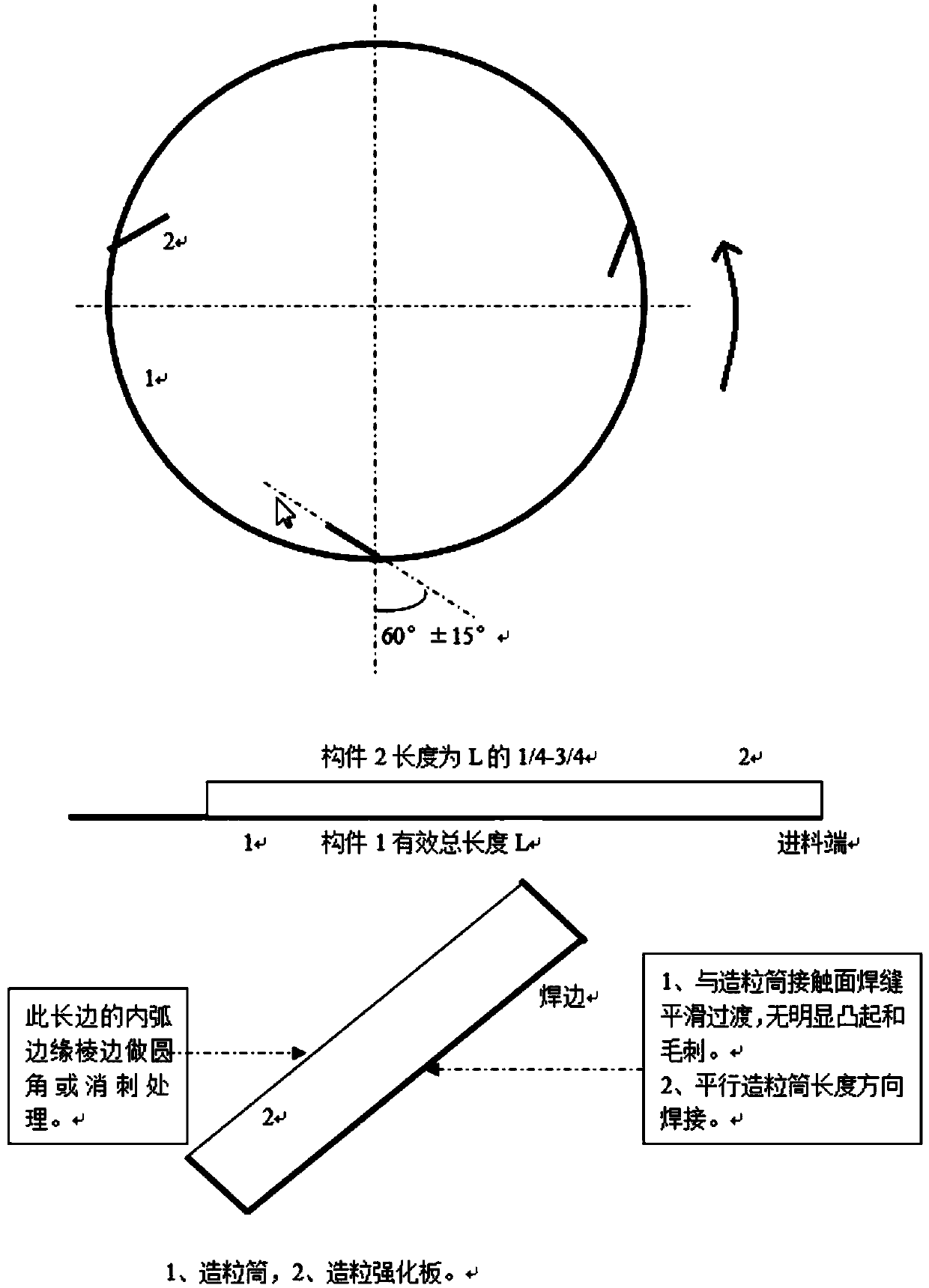

[0041] The above-mentioned mixture is granulated on a granulation equipment with a diameter of 700mm, a length of 2500mm, and an inclination angle of 4° to obtain wet granules formed from titanium concentrate; the rotational speed of the inner wall of the granulation equipment cylinder is 8cm / s, and The straight-line distance from the end of the granulation strengthening plate that is not in contact with the inner wall of the granulation device to the inner wall is 55mm, the length of the granulation strengthening plate in the axial direction of the cylinder is 1800mm, and the angle between the connecting line with the center of...

Embodiment 2

[0044] Add titanium concentrate and strengthening agent according to the ratio of titanium concentrate dry weight to strengthening agent mass ratio of 100:1.4 and mix well to obtain a mixture. The final moisture content of the mixture is 14.5%. The strengthening agent is composed of polyvinyl alcohol: medium temperature Asphalt powder: plant adhesive = 60:10:30;

[0045] The above-mentioned mixture is granulated on a granulation equipment with a diameter of 700mm, a length of 2500mm, and an inclination angle of 5.5° to obtain titanium concentrate shaped wet granules; the rotational speed of the inner wall of the granulation equipment cylinder is 25cm / s, and The straight-line distance from the end of the granulation strengthening plate that is not in contact with the inner wall of the granulation device to the inner wall is 40mm, the length of the granulation strengthening plate in the axial direction of the cylinder is 900mm, and the angle between the connecting line with the c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com