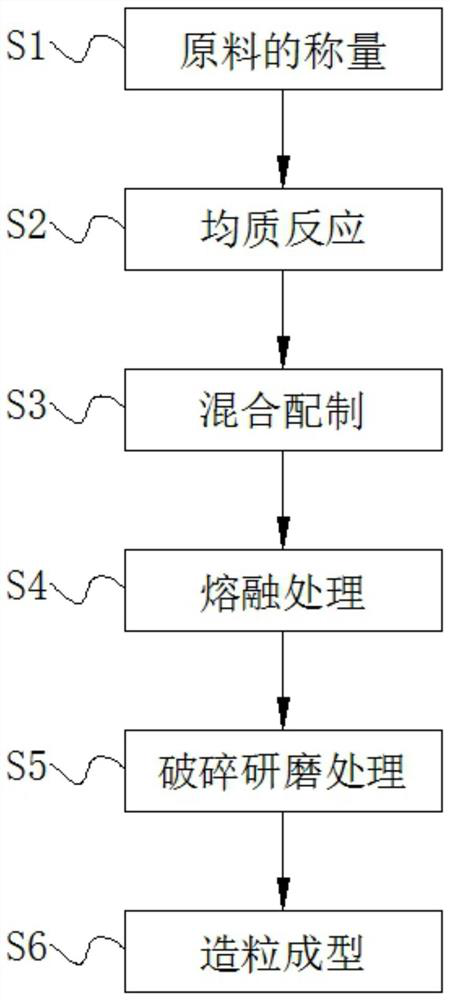

Granulation molding process of secondary element water-soluble fertilizer

A molding process, water-soluble technology, applied in the direction of organic fertilizers, inorganic fertilizers, calcareous fertilizers, etc., can solve the problems of inability to achieve, increase the workload of production personnel, and reduce production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] S1. Weighing of raw materials: First, 15 parts of calcium oxide, 15 parts of magnesium oxide, 15 parts of magnesium chloride, 170 parts of nitric acid solution, 7 parts of humic acid, 7 parts of seaweed and 250 part of additive composition, and store the measured components in the storage tank respectively for preservation. The additive composition is composed of potassium polyphosphate, urea, compound amino acid, tranexamic acid, slow-release capsules and ethylene glycol Alcohol mixed, humic acid is fulvic acid;

[0028] S2. Homogeneous reaction: Pour the calcium oxide, magnesium oxide, magnesium chloride and nitric acid solutions measured in step S1 into the reaction kettle in sequence, control the temperature at 63°C, start the stirring mechanism to stir and homogenize at a speed of 250r / min React for 35 minutes, thereby making calcium nitrate and magnesium nitrate water fertilizer raw materials;

[0029] S3. Mixing preparation: Pour the humic acid, seaweed and addi...

Embodiment 2

[0034] S1. Weighing of raw materials: First, 10 parts of calcium oxide, 10 parts of magnesium oxide, 10 parts of magnesium chloride, 150 parts of nitric acid solution, 5 parts of humic acid, 5 parts of seaweed and 200 part of additive composition, and store the measured components in the storage tank respectively for preservation. The additive composition is composed of potassium polyphosphate, urea, compound amino acid, tranexamic acid, slow-release capsules and ethylene glycol Alcohol mixed, humic acid is brown humic acid;

[0035] S2. Homogeneous reaction: Pour the calcium oxide, magnesium oxide, magnesium chloride and nitric acid solutions measured in step S1 into the reaction kettle in sequence, control the temperature at 60°C, start the stirring mechanism to stir and homogenize at a speed of 200r / min React for 30 minutes, thereby making calcium nitrate and magnesium nitrate water fertilizer raw materials;

[0036] S3. Mixing preparation: Pour the humic acid, seaweed and...

Embodiment 3

[0041] S1. Weighing of raw materials: First, 20 parts of calcium oxide, 20 parts of magnesium oxide, 20 parts of magnesium chloride, 200 parts of nitric acid solution, 10 parts of humic acid, 10 parts of seaweed and 300 parts part of additive composition, and store the measured components in the storage tank respectively for preservation. The additive composition is composed of potassium polyphosphate, urea, compound amino acid, tranexamic acid, slow-release capsules and ethylene glycol Alcohol mixed, humic acid is black humic acid;

[0042] S2. Homogeneous reaction: Pour the calcium oxide, magnesium oxide, magnesium chloride and nitric acid solutions measured in step S1 into the reaction kettle in sequence, control the temperature at 65°C, start the stirring mechanism to stir and homogenize at a speed of 300r / min React for 40 minutes, thereby making calcium nitrate and magnesium nitrate water fertilizer raw materials;

[0043] S3. Mixing preparation: Pour the humic acid, sea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com