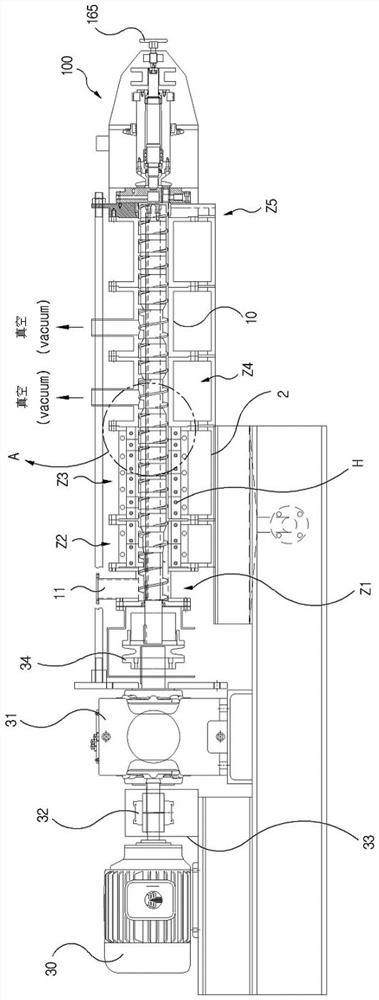

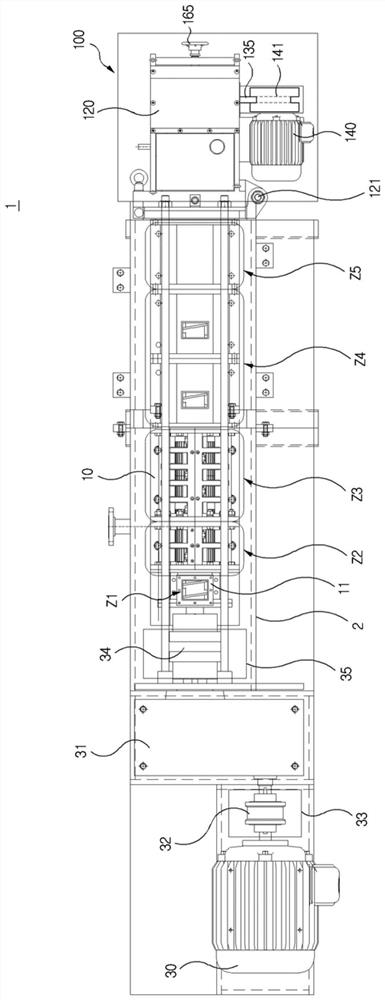

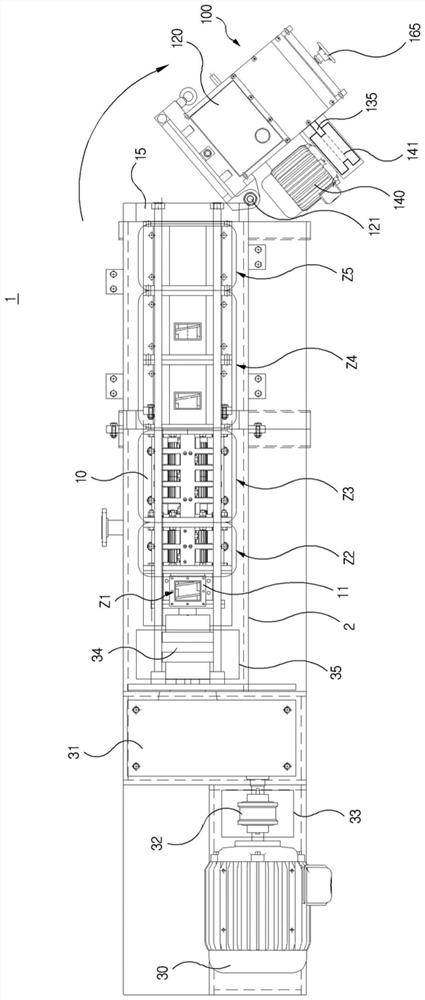

Dewatering screw extruder

An extruder and screw-type technology, applied in the field of screw-type dewatering extruders, can solve the problems of increased equipment and costs, inability to make materials into pellets, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] In order to allow those with ordinary knowledge in the technical field of the present invention to easily implement the present invention, preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0059]In describing the present embodiment, descriptions of technical contents that are widely known in the technical field to which the present invention pertains and are not directly related to the present invention will be omitted. This is to omit unnecessary explanations so that the gist of the present invention can be clearly expressed without being confused.

[0060] For the same reason, some elements in the drawings may be enlarged or schematically shown, or may be omitted.

[0061] Also, the size of each element does not utterly reflect its actual size. The same or corresponding elements in each figure use the same graphic symbol.

[0062] Furthermore, the present invention is directed to device ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com