Side hole progressive die

A progressive die and side hole technology, applied in the direction of forming tools, stripping devices, manufacturing tools, etc., to achieve the effects of avoiding precision errors, good quality stability, and reducing labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

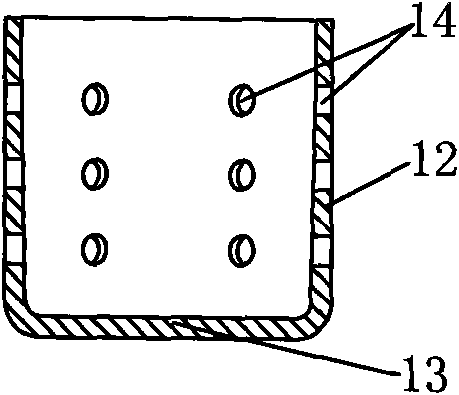

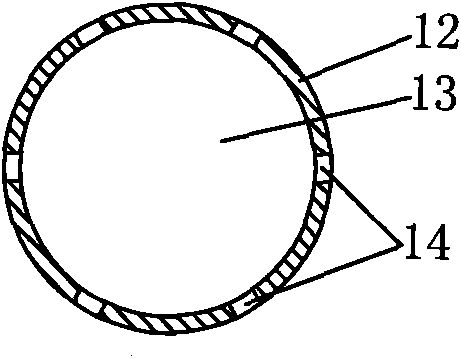

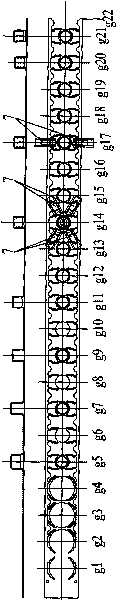

[0015] Such as image 3 As shown, the cup-type progressive die with side holes in this specific embodiment divides the entire process flow into 22 stations from g1 to g22 when processing the ignition tube. Among them, the g1 station is the punching hole and the process incision station; the g2 station is the punching process incision station; g3 and g4 are empty stations; the g5 station is the first step drawing station; the g6 station is the Empty station; g7 station is the second drawing station; g8 station is the empty station; g9 station is the first step shaping station; g10 station is the empty station; g11 station is the second step Shaping station; g12 and g13 stations are empty stations; g14 station is the first side punching station, punching out twelve symmetrical side holes; g15 and g16 stations are empty stations; g17 station is The second side punching station, punch out six side holes; g18, g19 stations are empty stations; g20 station is the third step shaping ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com