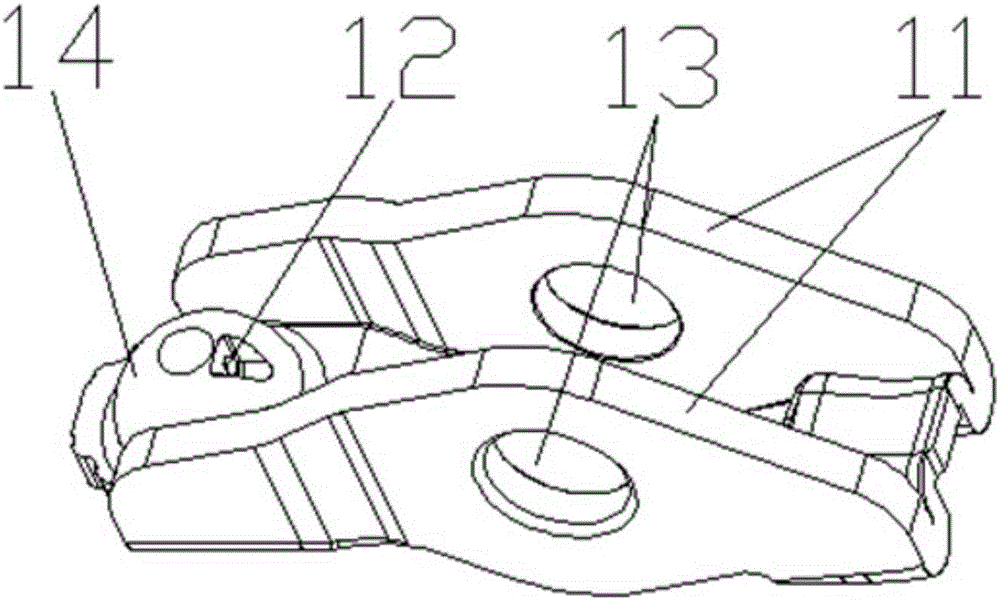

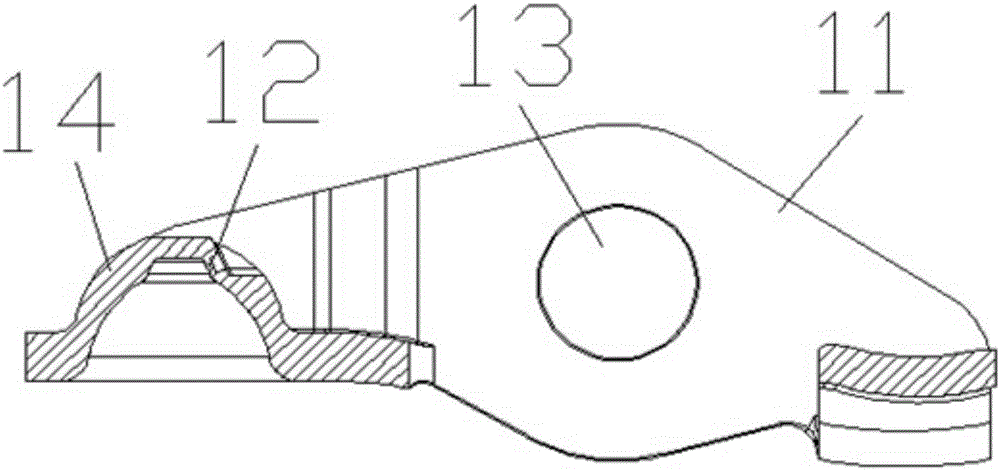

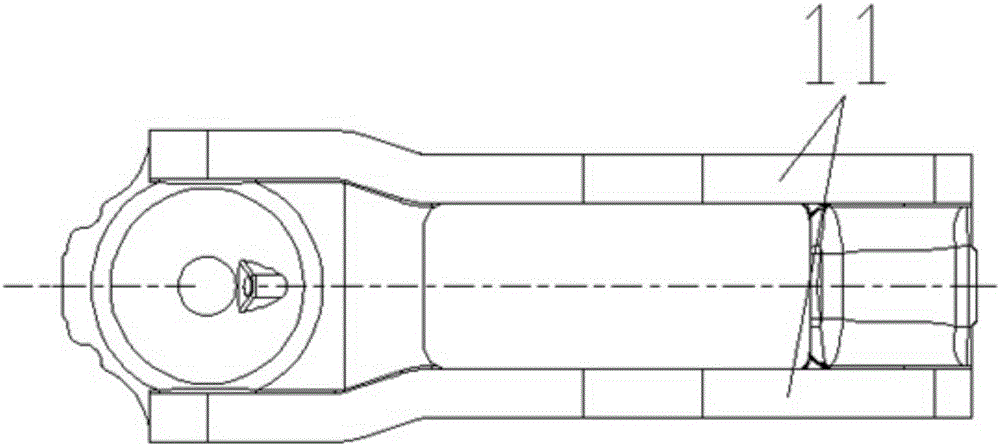

Side punching type progressive die for bending forming of rocker arm body

A technology of rocker body and progressive die, applied in the direction of forming tools, metal processing equipment, stripping devices, etc., can solve the problems of low production cost, high safety factor, high efficiency, etc., and achieve improved processing efficiency, good quality stability, The effect of ease of operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0025] Such as Figure 4 As shown, the side-punching progressive die for bending and forming the rocker body in this specific embodiment divides the entire processing process into 27 stations from g1 to g27 when processing the rocker body. Among them, station g1 is the station for punching guide holes and punching process holes; station g2 is the station for punching and chamfering corners; station g3 is the station for punching process cuts; station g4 is the empty station; station g5 is the station for punching The station for cutting shape process holes; station g6 is the chamfering station for punching all the process holes of the shape; station g7 is the empty station; station g8 is the station for bending and forming; station g9 is the station for empty; station g10 Stations are lateral forming and bending stations; stations g11 and g12 are empty stations; stations g13 and g14 are lateral punching stations; stations g15 are empty stations; stations g16 and g17 are side o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com