Vertical electric numerical control knife rest

An electric and tool holder technology, applied in metal processing equipment and other directions, can solve the problems of loss of motor transmission efficiency, poor waterproof performance of the tool holder, insufficient locking force of the movable tooth plate, etc., to improve the transmission efficiency of the worm gear and the reliable bearing Tightening method to ensure the effect of the initial positioning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

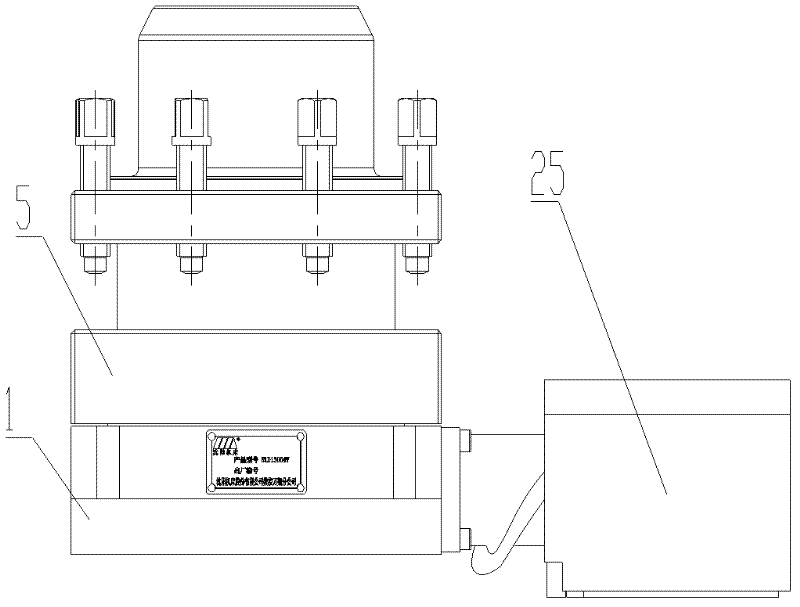

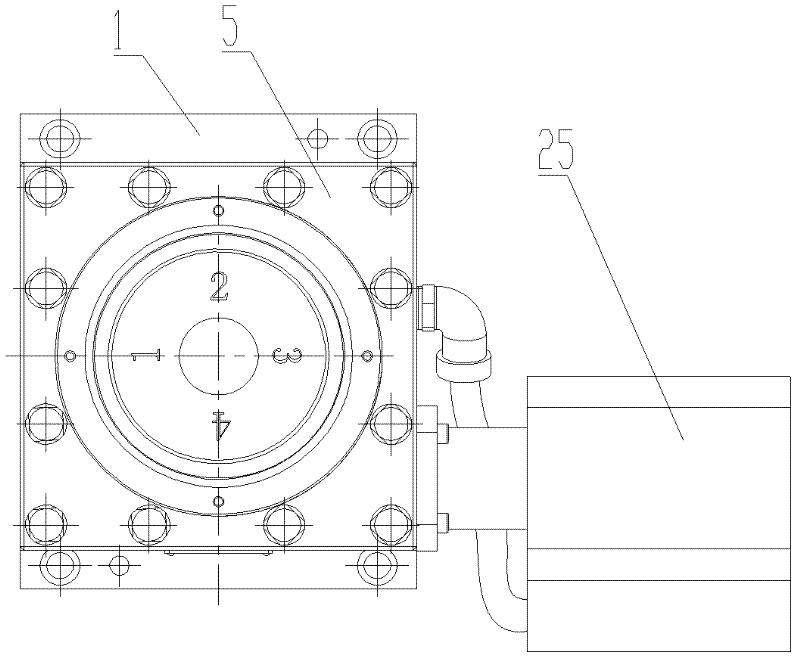

[0038] Fig. 1 (a)-(b) Appearance view of the four-station vertical electric CNC tool post of the present invention, which is a high-performance vertical electric CNC tool post developed for economical horizontal CNC lathes according to market conditions.

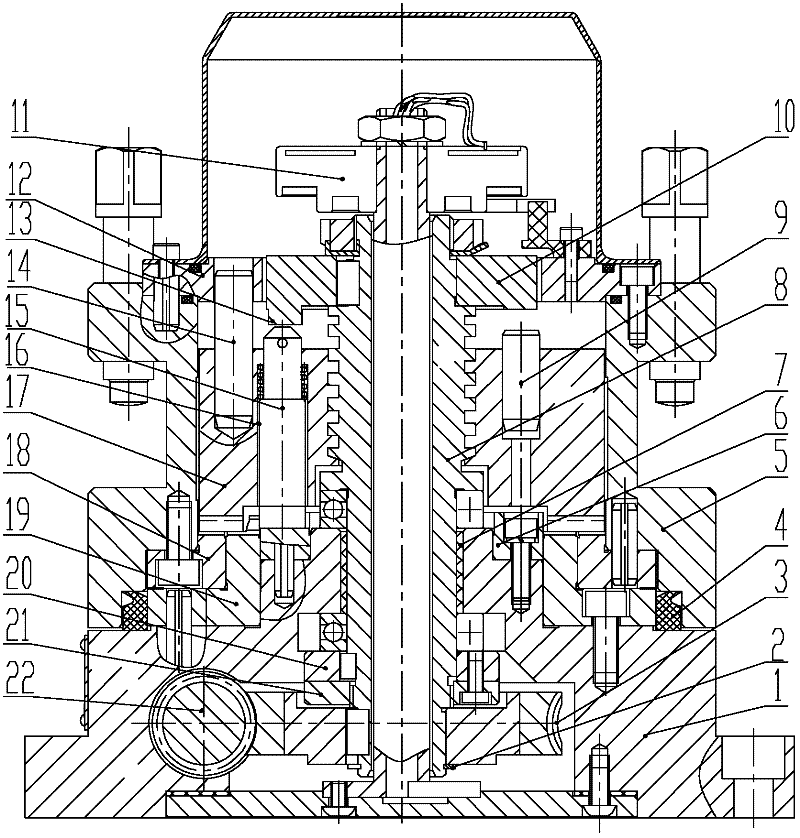

[0039] As shown in Fig. 1 (a)-(b) and Fig. 2 (a)-(b), the vertical electric numerical control tool post of the present invention can be divided into the following mechanisms: power transmission mechanism (transmission mechanism), initial positioning mechanism, precision Positioning mechanism, locking mechanism. The locking mechanism and the transmission mechanism are independent, which ensures the maximum power transmission of the tool post and the maximum rigidity of the tool post during locking. The transmission disk links in the transmission mechanism are completely interchangeable, which provides...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com