Device for rapidly granulating aerobic sludge and method thereof

An aerobic sludge and granulation technology, which is applied in chemical instruments and methods, biological treatment devices, water/sludge/sewage treatment, etc., can solve the problem of long granulation cycle, easy instability of granules, and restrictions on the wide application of modified processes and other problems, to achieve the effect of compact particle structure, speed up the process of sludge cultivation and enrichment, and overcome the long time of sludge granulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

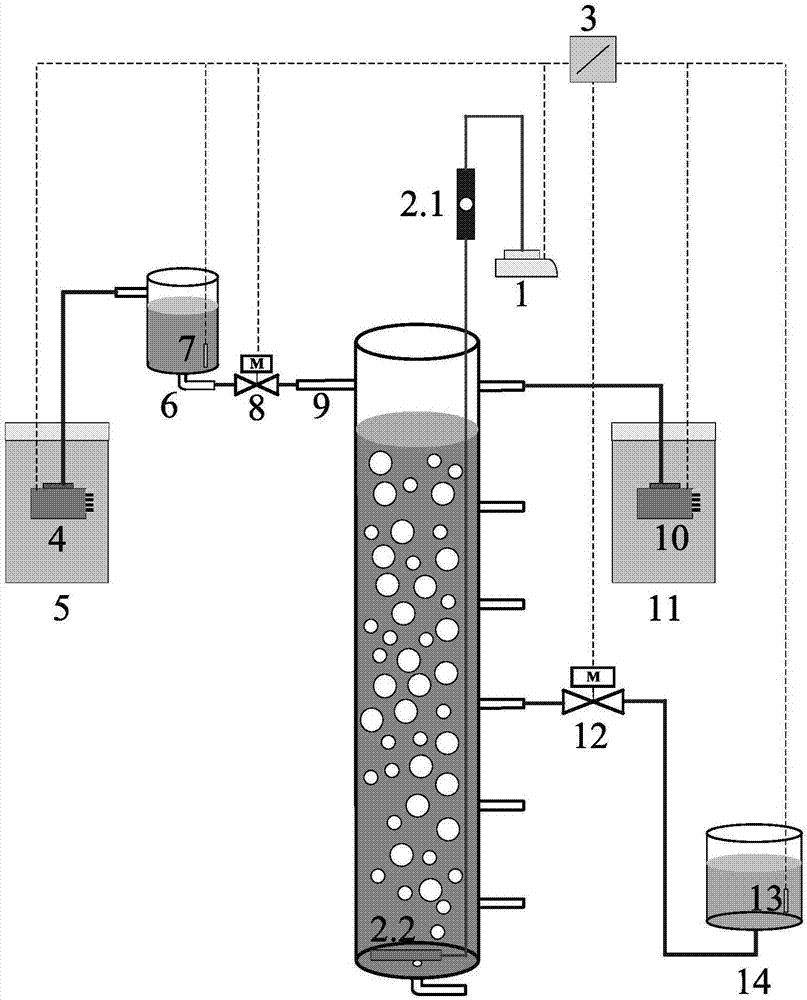

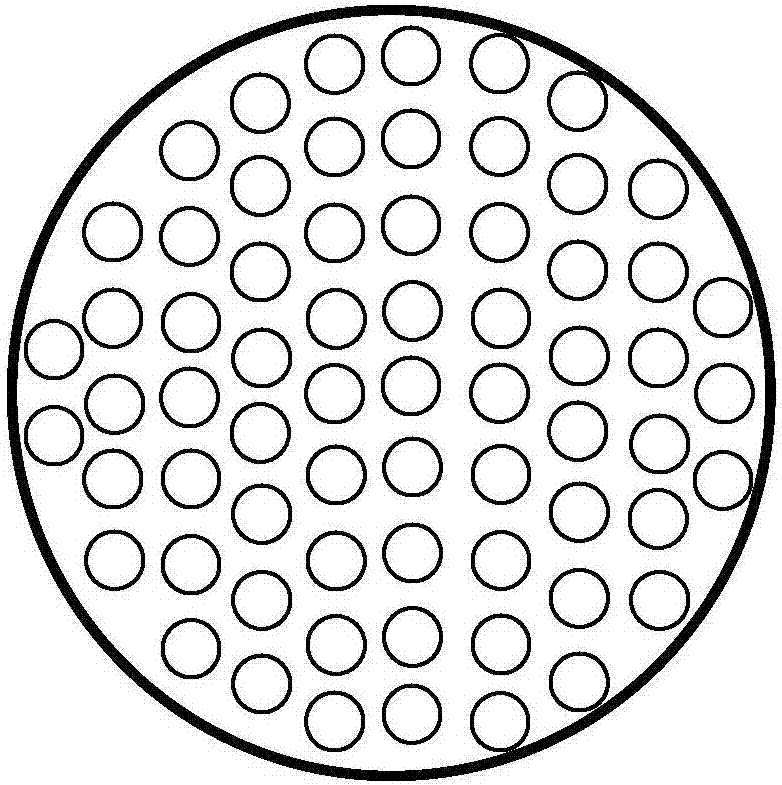

[0035] In this example, a cylindrical sequencing batch reactor (SBR) with an effective volume of 3.5 L is used in the aerobic granular sludge process for treating urban sewage. The main body of the reactor is a cylindrical plexiglass cylinder with a height of 55 cm and an inner diameter of 9 cm. Its structure is as figure 1 and 2 As shown in the foregoing description, no further details are given.

[0036] In this example, the inoculated sludge was taken from the aeration tank of the municipal sewage treatment plant, and the Shannon index was 4.79, which means that there is a relatively high abundance of flora in the particles. The analysis of the flora structure at the phylum level found that Proteobacteria and Bacteroides Gates accounted for more than 65%, and these bacteria are important flora in aerobic granular sludge, which can help the device to achieve rapid granulation of aerobic granular sludge. The influent matrix is urban domestic sewage.

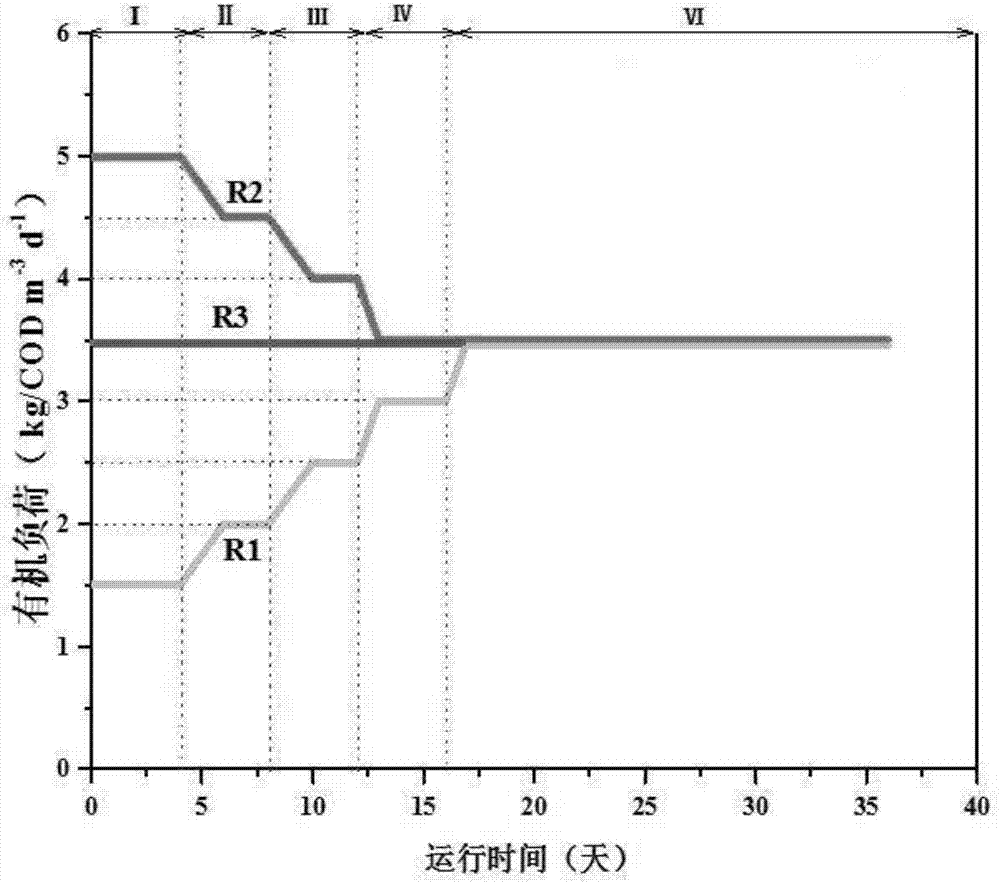

[0037] The operati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com